A Maintenance-optimal Swapping Policy

For a Fleet of Electric or Hybrid-electric Vehicles

Ahmad Almuhtady

1

, Seungchul Lee

1

, Edwin Romeijn

2

and Jun Ni

1

1

Deapartment of Mechaincal Engineering, University of Michigan, Ann Arbor, U.S.A.

2

Department of Industrial and Operations Engineering, University of Michigan, Ann Arbor, U.S.A.

Keywords: Resource Allocation Policy, Swapping Policy, Branch and Bound, Intelligent Maintenance.

Abstract: Motivated by high oil prices, several large fleet companies initiated future plans to hybridize their fleets to

establish immunity for their optimized business models against severe oil price fluctuations, and adhere to

increasing awareness of environmentally-friendly solutions. The hybridization projects increased

maintenance costs especially for highly costly and degradable components such as Li-ion batteries. This

paper introduces a degradation-based resource allocation policy to optimally utilize batteries on fleet level.

The policy, denoted as Degradation-based Optimal Swapping Policy, incorporates optimal implementation

of swapping and substitution actions throughout a plan of finite time horizon to minimize projected

maintenance costs. The swapping action refers to the inter-change in the placement of two batteries within a

fleet. The substitution action refers to the replacement of degraded batteries with new ones. The policy takes

advantage of the different degradation rates in the batteries health states; due to different loading conditions;

achieving optimal placement at different time intervals throughout the plan horizon. A mathematical model

for the policy is provided. The optimization of the generated model is studied through several algorithms.

Numerical results for sample problems are shown to illustrate the capability of the proposed policy in

establishing substantial savings in the projected maintenance costs compared to other policies.

1 INTRODUCTION

While Oil prices throughout the last decades have

undergone significant increases, transportation still

in general relies on it for 97% of its energy. It

becomes significantly harder for companies and

corporations with large fleets to maintain their

preferred higher profit margins. Therefore, many of

these fleet companies were highly motivated to

reduce their annual fuel consumption which reflects

on millions of dollars in savings. Additionally,

environmentally friendly technologies have attracted

large companies and corporations who benefit from

both commercial advertisement of endorsing such

technologies and established savings. For example,

Wal-Mart has set a goal of doubling the fleet

efficiency by 2015 from a 2005 baseline. One aspect

of these plans has included the consideration of

hybridizing fleets to enhance the fuel economy. Both

FedEx and UPS have as well endorsed hybridizing

parts of their fleets. Environmentally conscious

cities, schools and universities (e.g. University of

Michigan) have as well introduced hybrid-electric

buses into their fleets.

In a hybrid system, batteries have the most

significant share of the total cost of the hybrid

system. These components degrade to a point where

substitution with new ones becomes inevitable. The

substitution action here is defined as the replacement

of the degraded battery with a new one. The limited

battery useful life motivates the consideration of

maintenance plans which can incorporate a

predictive scheme of batteries health states. This

plan will reduce the projected battery maintenance

costs and ensure less abruptly interrupted daily task

assignment to these hybrid vehicles. Fair prediction

of the battery degradation within commercial fleets

is attainable due to the consistency in the expected

work load. For example, in a fleet of delivery trucks,

the batteries in hybrid vehicles assigned to

Downtown area routes are most likely subjected to

larger frequencies of micro charging and discharging

cycles in comparison to those within vehicles

assigned to the suburbs. This reflects significantly

on the degradation rate of these batteries. This

consistency can help a predictive maintenance

policy to optimally utilize all the batteries on fleet

35

Almuhtady A., Lee S., Romeijn E. and Ni J..

A Maintenance-optimal Swapping Policy - For a Fleet of Electric or Hybrid-electric Vehicles.

DOI: 10.5220/0004270601830192

In Proceedings of the 2nd International Conference on Operations Research and Enterprise Systems (ICORES-2013), pages 183-192

ISBN: 978-989-8565-40-2

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

level. To achieve this, a uniquely formulated policy,

designated as Degradation-based Optimal Swapping

(DBOS) policy, is proposed in this paper.

In most current companies which run hybrid

vehicles in their fleets, batteries are used until they

reach retirement. However, swapping batteries

within their fleet can achieve a reduction in the

projected cost of the maintenance plans. The

swapping action here is defined as the inter-change

in the placement of two batteries from two different

loading (degradation) profiles. This swapping policy

relies on the prediction of the different degradation

rates which is attributed mainly to the loading and

usage conditions. The prediction of such degradation

level introduces a potential to conduct swapping

actions among batteries and to control the timing of

the end of life for these batteries, where substitution

becomes inevitable. One direct impact of this is

providing substantial savings in projected

maintenance costs as a result of the application of

such policy. Additionally, this policy has the

potential to provide an integration between

maintenance actions and the company's daily

operations (integration of maintenance and

logistics). This enables a sustainable management of

the costly hybrid fleet asset. Additionally, the

information obtained throughout the policy can be

invested to build up a database of retired batteries in

terms of their conditions and predicted date of

retirement. This database can significantly improve

the success of the retired batteries remanufacturing

schemes, already implemented in several OEMs.

The remanufacturing helps both reduce the

environmental impact resulting from the disposal of

such batteries and promotes the use of cheap second-

hand hybrid technologies.

The research in this paper includes the

development of the model to describe the policy in

its general form and the investigation of suitable

approaches to achieve the optimum solution. The

remainder of this paper is organized as follows.

Section 2 will review relevant research work.

Section 3 will focus on modeling the policy in a

comprehensive mathematical model which accounts

for all the decision variables necessary to apply the

policy. The solution to the generated model

including the development of a policy-specific

optimization algorithm will be the focus of Section

4.

2 LITERATURE REVIEW

This problem can be categorized under the planning

and scheduling optimization, as the generated output

could be in the form of a schedule of different

placements for the batteries within the fleet. Both

planning and scheduling deal with the allocation of

available resources over time to perform a collection

of tasks. The difference between planning and

scheduling is not always clear cut (Grossmann et al.,

2002). However, in general planning deals with

longer time horizons (e.g. weeks, few months) and it

deals with high level decisions such as investment in

new facilities and production levels. Scheduling on

the other hand is concerned with shorter time

horizons (e.g. days, few weeks) with the emphasis

often being on the lower level decisions such as

sequencing of operations. Although the expected

outcome decisions from the DBOS policy are low

level decisions such as the change of the placement

of a battery, DBOS is intended to be part of a long

maintenance plan horizon. Therefore the policy can

be classified under either scheduling or planning.

DBOS model is expected to partially share the

form of one of the most famous scheduling problems

which is globally known as the fleet assignment

problem in transportation science. Given a flight

schedule and a set of aircraft of different types, the

fleet assignment problem faced by an airline is to

determine which type of aircraft should fly each

flight segment on the airline’s daily (or weekly)

schedule (Bertsimas and Tsitsiklis, 1997). The

similarity between these two problems mainly arises

in the placement decision variable; chosen to be

binary in many cases; this variable holds the key to

optimize the objective function. In the fleet

assignment problem, there are several factors

considered in assigning a fleet to a flight leg. These

factors include passenger demand, revenue, seating

capacity, fuel costs, crew size, availability of

maintenance at arrival and departure stations, gate

availability, and aircraft noise. Many of these factors

are captured in the objective coefficient of the

decision variable; others are captured by constraints

(Hane et al., 1995). On a similar basis, modelling the

problem for the DBOS policy is intended to take into

account several factors, such as degradation profiles,

demand, health states tracking, maintenance

capabilities and costs associated with the swapping

and substitution actions. However, there are several

important differences between the two problems

such as the substitution variables (reset variables)

needed for DBOS to function properly. The

substitution variables interaction with the placement

variables and their major contribution in the

objective function uniquely characterizes DBOS.

The fleet assignment problem has been studied

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

36

by numerous researchers. The daily scheduling of

the fleet assignment problem formulation impose

large number of integer variables and severely

degenerate model which leads to poor performance

of standard linear programming techniques. Methods

to address this problem include an interior-point

algorithm, dual steepest edge simplex, cost

perturbation, model aggregation, branching on set-

partitioning constraints, and prioritizing the order of

branching (Hane et al., 1995). In (Talluri, 1996), a

model and an algorithm for swapping applications in

a daily airline fleet assignment have been developed.

Given a daily fleet assignment, the problem of

changing the assignment of a specified flight leg to a

different equipment type while still satisfying all the

constraints have been considered. As airline

planning process evolves through several decision

making phases including schedule construction and

fleet planning that are succeeded by aircraft

maintenance routing and crew scheduling, the need

for integrated planning and robust planning were

realized. Integrated planning is intended to integrate

the functional phases at the planning stage, and

robust planning is intended to make decisions at the

planning stage that are beneficial to the operations

(Gao et al., 2009). Integrating schedule design and

fleet assignment was implemented in (Rexing et al.,

2000); (Lohatepanont and Barnhart, 2004).

Examples of research on robust planning include

robust fleet assignment as in (Rosenberger et al.,

2004); (Smith and Johnson, 2006).

Planning and scheduling problems generally

incorporate discrete/continuous optimization

problems. The mixed integer nonlinear program

(MINLP), inherently require special treatment as

complexities arise due to nonlinearity and integer

choices. The most common MINLPs encountered in

planning are 0-1 integer nonlinear programming

(ZOINLP) problems where none of the continuous

variables exist and all the decision variables are

binary. As section 3 of this paper details the

modelling of the DBOS policy, it will become

apparent that the generated model falls under

(ZOINLP) problems category.

The basis of tackling integer programming

problems (whether linear or nonlinear) in many

algorithms rely on relaxing the problem into

continuous sub-problems. The algorithm in this case

works on a higher level establishing control on the

sub-solvers and using the information from the sub-

problems solutions to arrive to the integer solution.

The sub-problems are solved by some well-

performing continuous variable programming

problem solver (such as Simplex for linear

programming (LP) problems (Chvátal, 1983) and

Sequential Quadratic Programming (SQP) with

reduced gradient method (Schittkowski, 1982) for

nonlinear programming (NLP) problems). Branch

and Bound (B&B) algorithm (Gupta and Ravindran,

1985) falls under this category of integer

programming problem solvers. B&B consists of a

tree enumeration in which LP or NLP sub-problems

are solved at each node, and eliminated based on

bounding properties. B&B’s success and speed in

finding the solution inherently depends on the

relaxed problem sub-solver.

Other algorithms for solving MINLP include

Generalized Benders Decomposition (GBD)

(Benders, 1962); (Geoffrion, 1972), Outer-

Approximation (OA) (Duran and Grossmann, 1987);

(Fletcher and Leyffer, 1994), and Extended Cutting

Plane Method (ECP) (Westerlund and Pettersson,

1995). The literature also provides some non-

rigorous methods for handling non-convexities such

as the equality relaxation algorithm (Kocis and

Grossmann, 1987) and the augmented penalty

version of it by (Viswanathan and Grossmann,

1990). Modifications on standard Stochastic

methods such as Genetic Algorithm (GA) originally

developed by (Holland, 1975) and Simulated

Annealing (SA) originally developed by (Metropolis

et al., 1953) have promoted their use to solve

MINLPs. These algorithms impose no limitation

(such as continuity and differentiability) on the

search space of the optimization problem.

Additionally, some of these algorithms could benefit

from parallel processing which in turn accelerates

convergence. Hybrid algorithms as in (Adler, 1993);

(Robinson et al., 2002); (Xia and Wu, 2005) are as

well widely found in Literature. Such algorithms

intend to take advantage of the merits of two or

more of the standard algorithms to achieve better

solutions (in terms of convergence, global optima,

etc.).

3 MATHEMATICAL

MODELLING OF DBOS

POLICY

The key to apply the DBOS policy is a concise and

representative model which accounts for swapping

and substitution actions. The objective of the policy

aims towards optimal battery utilization over a finite

plan horizon in a way that minimizes total

maintenance plan projected costs.

Typical constraints are formulated for demand

AMaintenance-optimalSwappingPolicy-ForaFleetofElectricorHybrid-electricVehicles

37

(number of vehicles operating in each degradation

profile), batteries health state degradation tracking

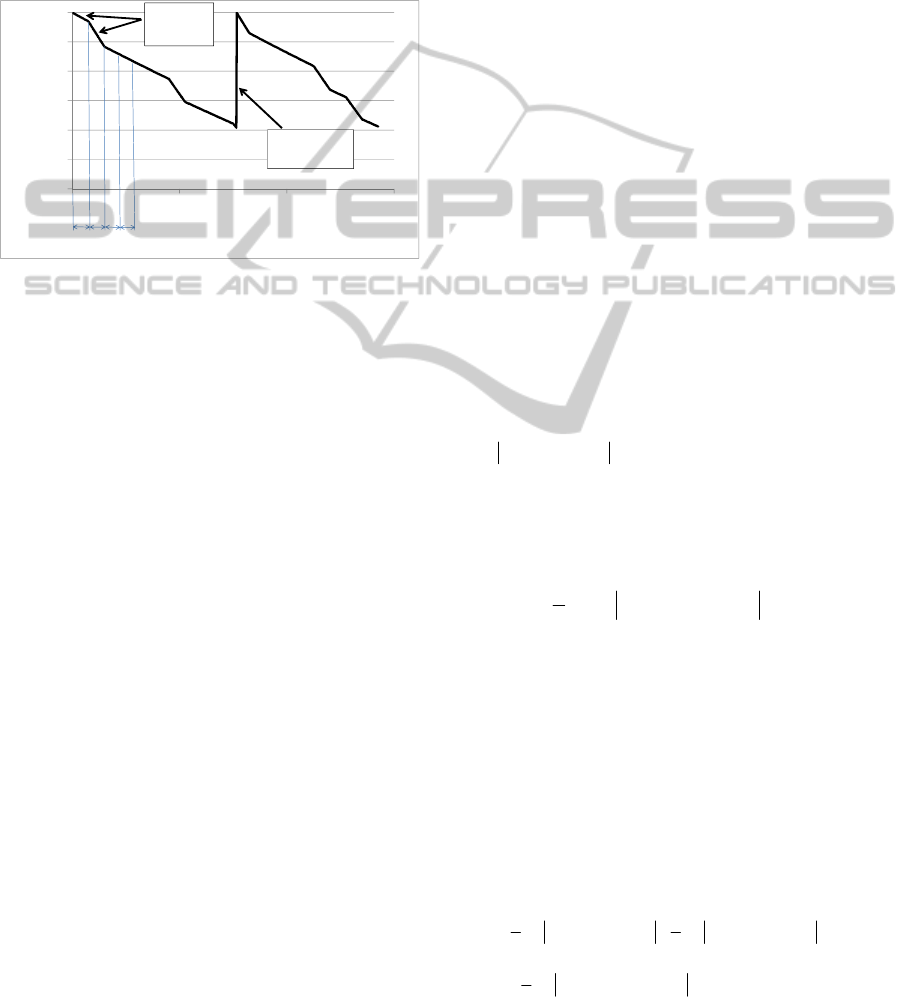

(swapping and substitution effects, threshold, etc.)

(See Figure 1). Other constraints are relevant to the

company’s logistics such as maintenance crew

availability, business requirements, etc. The model

includes two types of decision variables: placement

variables and substitution variables (or reset

variables).

Figure 1: Health State Changes with Swapping and

Substitution Actions.

3.1 Placement Decision Variables

The model is formulated to follow the placement of

batteries in terms of location and time. The location

here refers to the loading profile in which the battery

is placed, and for which predicted degradation rate

of the health state is assumed to be known. The

variable is studied at predefined constant discrete

intervals of time (Δ), which are chosen upon the

company’s preference and capability to achieve

regular workflow. This interval should be inspired

by the company’s prescheduled checkups cycles. For

example if the company’s vehicles are usually

maintained or checked up monthly, then choosing Δ

to be equal to 1 month is reasonable. Δ relates the

frequency of the discrete time points at which the

scheduler has the option to perform a swapping

action. Theoretically as ∆ gets smaller, more

swapping options are present and we expect the total

maintenance cost to decrease to a certain limit. This

limit is where introducing further swapping actions

will not improve the cost function and the optimizer

opts for no additional swapping actions upon correct

implementation of the policy (accurate

optimization). The validation of such behaviour is

shown in Section 4.3.

In this formulation, the placement decision

variable,

() 0,1

ij

Xk

in the model is chosen to be

binary, where its indices stand for

1,2, , battery index in the fleet

1, 2, , degradation/loading profile

1,2, , discrete time, where:

plan horizon

in

jm

kK

KT

(1)

For example, if Δ = 1 month, and X

31

(7) = 1 means

that the 3

rd

battery is placed in the first degradation

profile at the 7

th

month.

There are several constraints which are related

directly to the placement decision variable. Some of

these constraints arise from physical sense, others

from demands and capabilities. The first constraint

relates to the physical sense that a specific battery

can be only assigned to one degradation profile for a

specific interval. Additionally, the demand

j

d

drives the number of batteries assigned to the jth

degradation profile per interval. In formulation,

these two constraints; respectively; translate to:

1

1

( ) 1, 1, , ; 1, ,

() , 1, , ; 1, ,

m

ij

j

n

ij j

i

X

kinkK

X

kd j m k K

(2)

The placement variable is the indirect indicator for

whether a swapping action has taken place or not.

This can be formulated through:

if the th battery is

1 swapped at time to/from

() ( 1)

the th degradation profile

0 otherwise

ij ij

i

k

Xk Xk

j

(3)

The total number of swapping actions which take

place at time k can be given by:

11

1

() ( 1)

2

nm

ij ij

ij

Xk Xk

(4)

Equation (4) enables us to formulate the constraints

related to the company’s preferential rules for

swapping. Examples of these rules include an

enforced minimum span between subsequent

swapping actions for the same battery, and

maximum number of allowable swapping actions

within the fleet per interval. For the first one, if Δ is

assumed to be equal to 1 month (for example), and a

minimum of 3 months of enforced span between

subsequent swapping actions for the same battery,

then it translates to:

11

1

11

() ( 1) ( 1) ()

22

1

(2) (1)1,

2

1, , ; 2, ,

mm

ij ij ij ij

jj

m

ij ij

j

X

kXk Xk Xk

Xk Xk

ink K

(5)

0.7

0.75

0.8

0.85

0.9

0.95

1

0 2000 4000 6000

DegradationIndicator

Time

∆ ∆ ∆∆

Swapping

effect

Substitution

effect

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

38

Or it can be abbreviated as:

2

01

1

() ( 1)1,

2

1, , ; 2, ,

m

ij ij

hj

Xkh Xkh

ink K

(6)

In the general form, the constraint can be

represented as (for a minimum span of

H

between swapping actions for the same battery):

1

01

1

() ( 1)1,

2

1, , ; 2, ,

Hm

ij ij

hj

Xkh Xkh

ink K

(7)

Maximum number (

) of swapping actions per

interval can be easily modelled as:

11

1

() ( 1) , 2, ,

2

nm

ij ij

ij

X

kXk k K

(8)

3.2 Substitution Decision Variables

A substitution decision variable,

()

i

Z

k

to represent

any substitution action is included in the modelling.

if the th battery is substituted

1

at the begining of epoch

()

no substitution at the

0

begining of epoch

i

i

k

Zk

k

(9)

The substitution variable has only two indices as it

relates only to battery i being substituted and time k

at which substitution takes place.

The decision whether to initiate a substitution

action or not, is merely dependent on the state of the

battery health. This indicates the need to track the

battery’s health state degradation throughout its

deployment in the field. In modelling DPSO with

deterministic states, it is assumed that the degradable

health states are predictable. The prediction is

dependent on both the battery state at the beginning

of the current interval and the degradation profile at

which the battery is placed.

To track the degradation of the batteries health

states, an accumulative degradation dependent

quantity

()

i

yk

is defined. The accumulative

degradation is a monotonically increasing dependent

variable which is calculated in the model based on

the decision variables (placement and substitution

variables). In this formulation, when a new battery is

brought in, the accumulative degradation is set to

zero. Based on the assumption of linear degradation

the accumulative degradation can be found by:

1

1

1

(0) 0 1, ,

() 1 () ( 1) ()

() ()

1(1) (),

1, , ; 1, ,

i

m

iii jij

j

m

ijij

j

m

ik i j ij

j

yin

yk Zk yk rX k

Zk rX k

Zyk rXk

kKin

(10)

where

j

r

is the degradation rate when the battery is

assigned to jth degradation profile.

Additional constraints arise from the bounds on

the accumulative degradation variable:

0(),

1, , ; 1, ,

i

yk

kKin

(11)

where

is the threshold at which substitution

becomes inevitable.

3.3 Objective Function

There are several objectives that could be used

towards an optimum policy. The policy can aim for

minimized maintenance costs, maximized utilization,

or a combination of both. One direct and simplified

objective that can be chosen is to minimize the

projected maintenance costs over a finite plan

horizon. With the satisfaction of the constraints

described above, the minimization of the projected

costs which are attributed to the batteries

substitution and swapping actions can achieve an

optimum scheduling policy. Based on the discussion

previously, the cost can be found by:

1

211

2

11

1

() () ( 1)

2

() ()

Knm

ij ij

kij

nK

i

ik

JckXkXk

ckZk

(12)

where c

1

(k) is time dependent swapping cost

coefficient, which includes penalties and potential of

loss due to swapping, and c

2

(k) is time dependent

substitution cost coefficient. The choice to make

both cost coefficients as time dependent increases

the flexibility of the model.

AMaintenance-optimalSwappingPolicy-ForaFleetofElectricorHybrid-electricVehicles

39

4 OPTIMIZATION IN DBOS

POLICY

The mathematical model of DBOS policy with

deterministic states has been introduced in Section 3.

This section is dedicated to the solution of the

DBOS policy model.

4.1 DBOS-Policy-specific

Branch-and-Bound-based

Algorithm

Although the generated model successfully captures

the intended functionality of the policy, the DBOS

policy model is a Zero-One Integer Nonlinear

programming (ZOINLP) problem. In similar work

(Almuhtady et al., 2012), typical stochastic

algorithms such as Genetic Algorithm (GA) and

Simulated Annealing (SA) Algorithm have been

shown to be capable of solving small size problems

of this type. However, repeatability in results and

robustness for large scale problems were absent in

the implementation. Additionally, the

implementation of a direct Branch and Bound (B&B)

scheme with variant NLP sub-solvers has not been

successful due to the growing nonlinearity in health

state updates in Equation (10).

In this paper, we introduce a DBOS-policy-

specific Branch-and-Bound-based algorithm that

successfully generates repeatable answers as well as

provide robustness over all problem sizes. The

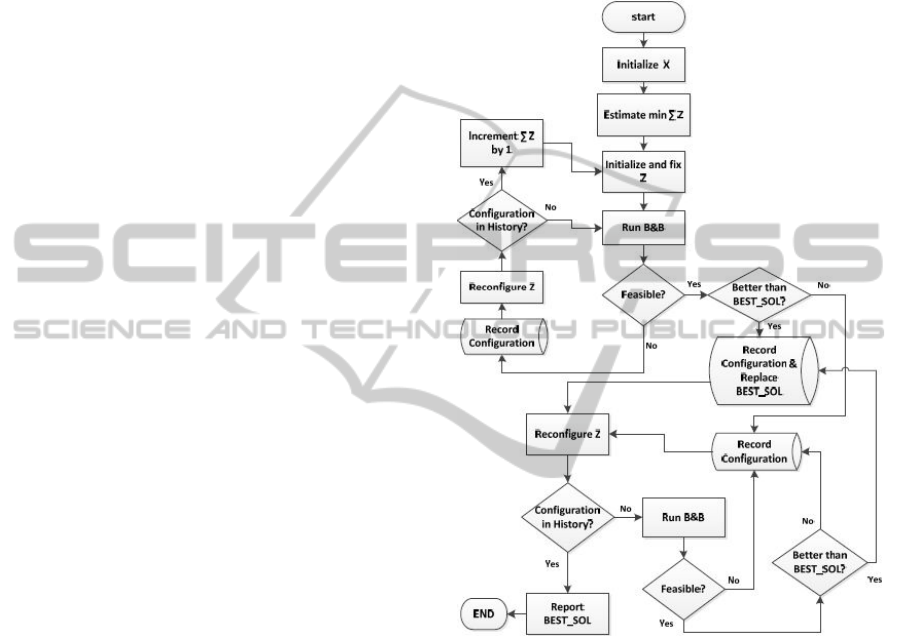

algorithm is illustrated in Figure (2).

The algorithm reduces the complexity of the

model by providing incremented estimates of the

total number of required substitutions (Z

i

(k)). The

estimates are generated from expected loads and

logic-based rules. Total demand over horizon (when

averaged per battery) dictates whether this estimate

is started at zero or not. For example, if the average

demand per battery exceeds threshold value (),

starting with estimate (Z

i

(k)=0) becomes trivial.

For each estimate, all satisfying (non-repeated)

configurations are investigated. The reconfiguration

is done systematically that it will generate each time

a new configuration until all possible unrepeated

configurations for that estimate have been tested.

We note here that repeated configurations include

any new Z

i

(k) array that is generated from swapping

rows in an old Z

i

(k) array as this action provides no

new configurations. The first estimates are chosen to

be very conservative (low number of substitutions).

This probably leads to infeasibility for all or most

reconfigurations of Z

i

(k) for the first iteration.

Nevertheless, the conservativeness provides

assurance for minimum objective value function as

the major part of the cost is attributed to the

substitution. We note here that the infeasibility is

identified quickly and therefore the performance of

the algorithm in general is not hindered by the

conservativeness.

Figure 2: DBOS-Policy-Specific Branch-and-Bound-based

Algorithm.

With this implementation, at each instant the

nonlinearity in the model (Equation 10) ceases to

exist and the problem is reduced to a Zero-One

Integer Linear Programming (ZOILP) problem. This

promotes the utilization of a Branch and Bound

(B&B) scheme with a (LP) sub-solver. The later

only applies if the absolute value in the objective

function is formatted in the standard LP form as well.

This is easily implemented through a number of

well-known mathematical tricks. It should be noted

that the formatting of the absolute value into the

standard LP form incorporates an increase in the

decision variables which may adversely affect the

algorithm’s performance for significantly large

problems.

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

40

4.2 Case Study I

In this section, we report numerical results of a 5-

vehicle fleet case study. The problem parameters are

available in Table (1).

Table 1: Case Study I Parameters.

Parameter symbol value

N

umber of vehicles N 5

N

umber of loading profiles M 4

Plan Horizon (months) K

4

vehicles allocated per loading profile

J

N

[1, 1, 1, 2]

Degradation rates (per month)

j

r

[0.11, 0.08, 0.04,

0.02]

Swapping Cost Coefficient

1

()ck

400

Substitution Cost Coefficient

2

()ck

11600

Threshold β 0.2

Discretization Interval (month) ∆ 1

The cost coefficients are inspired by real

applications. The degradation coefficients have been

modified to reflect shorter chosen plan horizon for

the numerical case study as a sample problem. The

modification in the coefficients is intended to

simulate the real scenario where longer horizons are

chosen, and thus substitutions are inevitable.

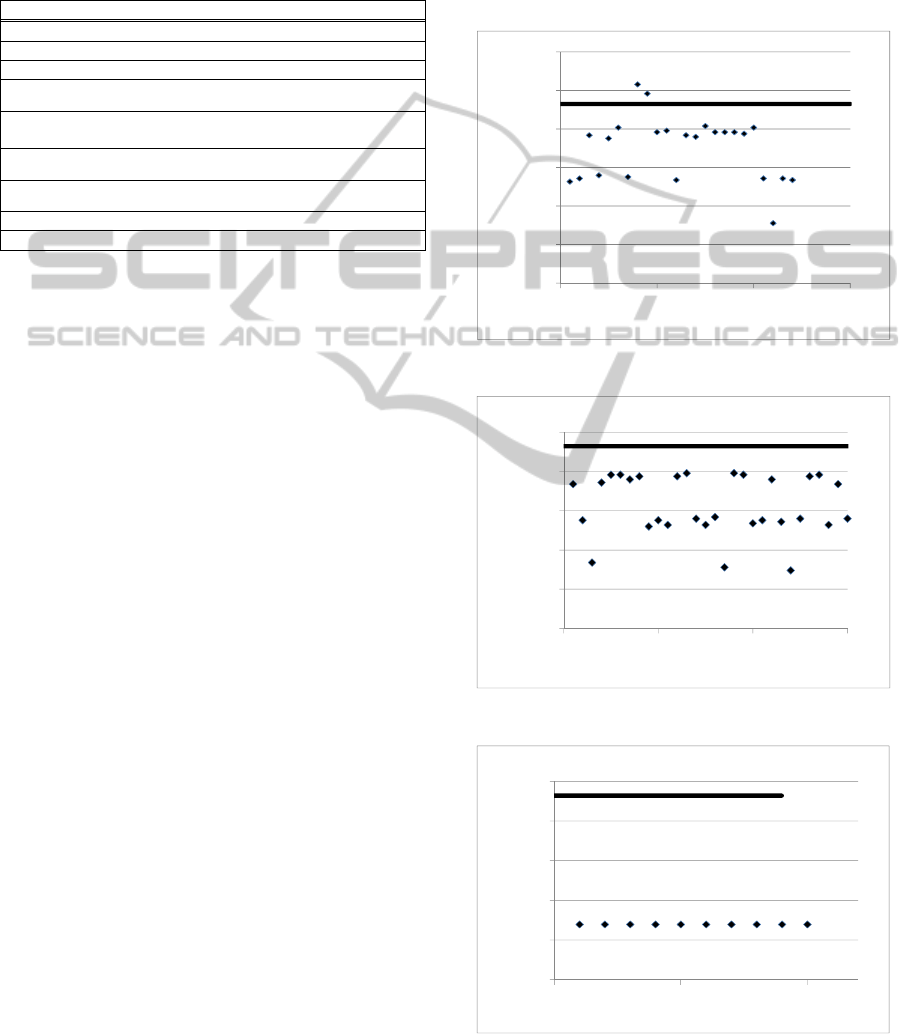

The solutions generated by GA and SA are

shown in Figures (3) and (4). The horizontal line

indicates the cost upon the application of no

swapping policy for the case study. Though SA

outperforms GA in this case, repeatability in results

and lack of runs achieving the global minima are

shortcomings of both algorithms. The runtimes for

GA and SA algorithms were 19 minutes and 45

seconds; respectively.

The solutions generated by DBOS-policy-

specific B&B-based algorithm are shown in Figure

(5). It is clear that the repeatability has been attained

only in the DBOS-policy-specific B&B-based

algorithm where global optima have been achieved

at every single run. The runtime was found to be 41

minutes.

Though repeatability might not represent great

significance in this small size problem as SA can be

run cheaply several times, there are two main

advantages of using DBOS-policy-specific B&B-

based algorithm. The first is that the total cost

associated by the swapping and substitution actions

is $14000 with the DBOS-policy-specific algorithm

in comparison to the best run of SA with cost equal

to $14800. That means SA best run has generated a

suboptimal solution with 5.4% difference. The

guarantee of achieving the global minima with the

proposed algorithm is a key for its outperformance.

That is, for this small problem, the difference in cost

between SA best run and the proposed algorithm

solutions are 5.4%. This can be higher for a different

problem. The second advantage will be present in

the scalability as Case Study II will show.

Specifically, the case study will demonstrate what

the outcomes are when larger numbers of decision

variables are involved.

Figure 3: GA Different Runs.

Figure 4: SA Different Runs.

Figure 5: DBOS-Policy-specific B&B-based Algorithm

Different Runs.

0

10000

20000

30000

40000

50000

60000

0 102030

Cost

run

noswapping

cost

0

10000

20000

30000

40000

50000

0 102030

Cost

run

noswapping cost

0

10000

20000

30000

40000

50000

0510

Cost

run

noswapping cost

AMaintenance-optimalSwappingPolicy-ForaFleetofElectricorHybrid-electricVehicles

41

The optimum schedule per DBOS policy for Case

Study I is shown in Table (2).

Table 2: Schedule of Batteries Placement from the DBOS-

Policy-specific B&B-based Algorithm.

Battery 1st month 2nd month 3rd month 4th month

A 4 4 4 1

B 2 1 1* 2

C 4 2 2 4

D 3 3 3 3

E 1 4 4 4

(*) means a substitution action has taken place

Finally for case study I, we benchmark the

performance of the DBOS policy, several

management policies have been applied (see Figure

6).

The maintenance plan cost has been evaluated

for each of the four shown policies. In the “No-

swapping” policy, the batteries in the fleet are

dedicated to one degradation profile throughout the

plan horizon, where no swapping is allowed. The

rotational fixed swapping policy refers to the policy

where swapping actions are conducted on a timely,

fixed and cyclic manner. An example of that is the

rotational swapping of tires in automobiles to even

out the degradation (front wheel driving or rear

wheel driving). The third policy (Intelligent fixed

swapping) refers to the case when swapping actions

are conducted between the most and the least

degraded batteries at each cycle (The intelligence

refers to basing decision on being informed about

the health state of the battery). Though the later

performs better than the No-swapping and

Rotational Fixed Swapping policies, the DBOS

policy clearly outperforms all of them.

Figure 6: Benchmarking DBOS policy.

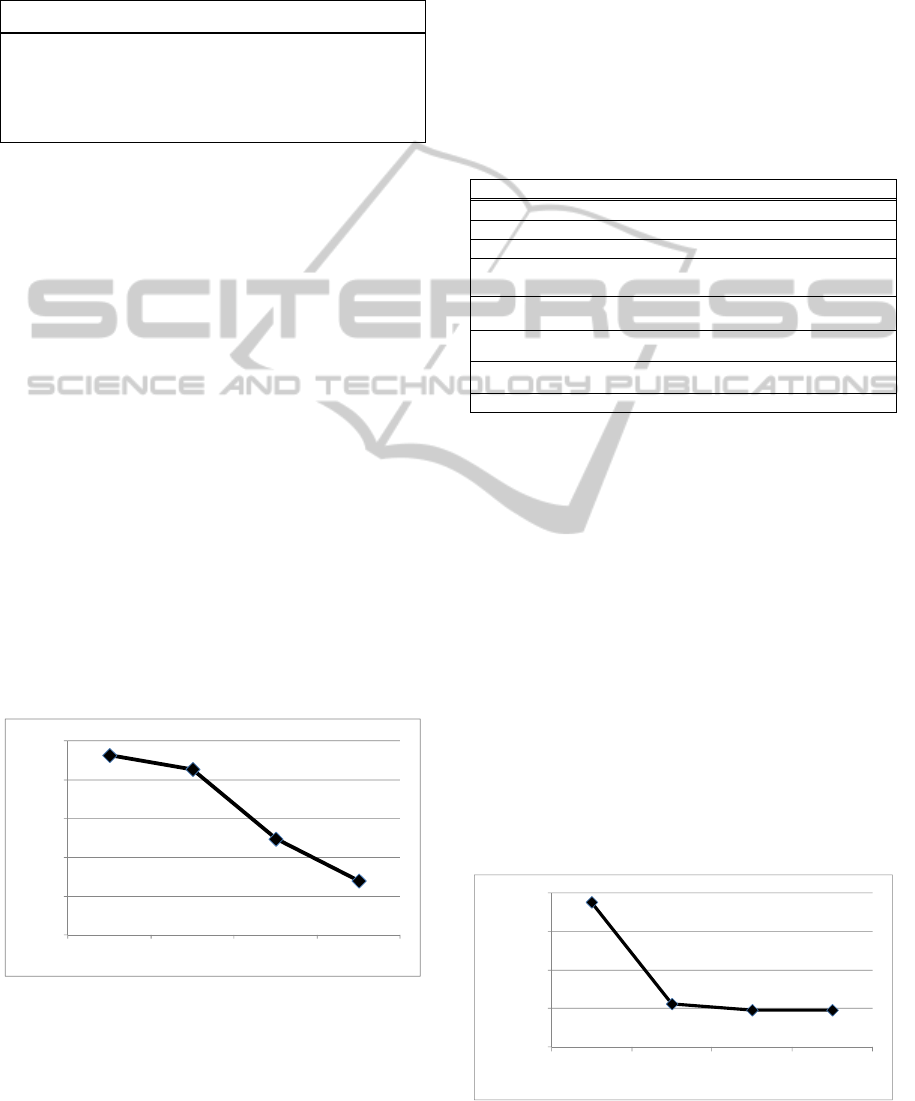

4.3 Case Study Ii (∆ Variation)

In this section, we verify the claim we made in

Section 3.1 about the role of ∆. The DBOS-policy-

specific branch-and-bound-based algorithm is

implemented on a second case study (see Table 3)

where ∆ is varied from 1 week to 1 month. The case

study will serve as well to illustrate the scalability of

the proposed algorithm when larger numbers of

decision variables are involved. That is, decreasing

∆ increases the size of the problem significantly due

to the increase in the placement and substitution

variables under investigation. The outcome of this

increase on the performance of SA and the proposed

policy is investigated.

Table 3: Case Study II Parameters.

Parameter symbol value

Number of vehicles N 3

Number of loading profiles M 2

Plan Horizon (months) K

4

vehicles allocated per loading

profile

J

N

[1, 2]

Degradation rates (per month)

j

r

[0.11, 0.04]

Swapping Cost Coefficient

1

()ck

400

Substitution Cost Coefficient

2

()ck

11600

Threshold β 0.2

Figure (7) shows the results when SA was used.

It can be seen that SA algorithm is unable to capture

the intended behaviour of the DBOS policy. The

policy aims to opt for swapping when swapping

achieves decreased objective values. In this case, as

the problem size grows the optimizer fails to

recognize the unnecessary swapping actions and

therefore the total cost increases. On the other hand,

Figure (8) shows the results of the DBOS-policy-

specific B&B-based algorithm when ∆ is varied. The

anticipated behaviour appears clearly. The cost

decreases when ∆ is varied from 1 month, to 20 days

and finally to half month. After that, there is no

improvement in the objective value when ∆ is

shortened from 15 days to 1 week. The optimizer in

this case opts for no more swapping actions than

what has been chosen for the 15 days discretization

interval, and therefore the policy is correctly

captured.

Figure 7: SA algorithm best run result when ∆ is varied.

0

100

200

300

400

500

Noswapping RotationalFixed

Swapping

IntelligentFixed

Swapping

DBOS

Cost

x10

2

20000

25000

30000

35000

40000

1week 15days 20days 1month

Cost

∆

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

42

Figure 8: DBOS-policy-specific B&B-based algorithm

result when ∆ is varied.

5 CONCLUSIONS

Plans for electrification and hybridization of fleets

are already in progress to minimize the overall cost

of operation and fuel consumption and adhere to

environmentally friendly awareness. The

hybridization projects increased maintenance costs

especially for highly costly and degradable

components such as Li-ion batteries. This paper

presented a uniquely formulated resource allocation

policy based on the degradation of the health states

of the batteries, to be part of the maintenance

planning for the fleet. The policy, denoted as

Degradation-based Optimal Swapping (DBOS),

utilizes batteries on fleet level through a series of

optimally chosen swapping and substitution actions.

The policy takes advantage of the different

degradation rates of the batteries within the fleet,

based on loading conditions, to choose optimal

placements of these batteries. A representative

mathematical model with deterministic health states

have been presented in this paper as well. The

optimization of the generated model of DBOS policy

has been investigated as well. A DBOS-policy-

specific algorithm has been developed and

successfully implemented. Numerical results showed

the outperformance of the algorithm in comparison

to standard optimization techniques. Numerical

results as well validated the role of the discretization

interval in the DBOS policy, allowing but not

necessary choosing the option to perform additional

swapping actions minimizing the costly substitution

ones.

ACKNOWLEDGEMENTS

This material is based upon work supported by the

National Science Foundation under Grant No.

0639468 (the Industry/University Cooperative

Research for Intelligent Maintenance Systems).

REFERENCES

Adler, D. Genetic Algorithms And Simulated Annealing:

A Marriage Proposal. Neural Networks, 1993., IEEE

International Conference, 1993 1993. 1104-1109

Vol.2.

Almuhtady, A., Lee, S. & Ni, J. 2012. Degradation-Based

Swapping Polcy With Application To System-Level

Manufacturing Utilization. ASME 2012 International

Manufacturing Science And Engineering Conference -

MSEC2012. Notre Dame, IN.

Benders, J. F. 1962. Partitioning Procedures For Solving

Mixed-Variables Programming Problems. Numerische

Mathematik, 4, 238-252.

Bertsimas, D. & Tsitsiklis, J. N. 1997. Introduction To

Linear Optimization, Athena Scientific.

Chvátal, V. 1983. Linear Programming, New York, W. H.

Freeman.

Duran, M. & Grossmann, I. 1987. An Outer-

Approximation Algorithm For A Class Of Mixed-

Integer Nonlinear Programs. Mathematical

Programming, 39, 337-337.

Fletcher, R. & Leyffer, S. 1994. Solving Mixed Integer

Nonlinear Programs By Outer Approximation.

Mathematical Programming, 66, 327-349.

Gao, C., Johnson, E. & Smith, B. 2009. Integrated Airline

Fleet And Crew Robust Planning. Transportation

Science, 43, 2-16.

Geoffrion, A. M. 1972. Generalized Benders

Decomposition. Journal Of Optimization Theory And

Applications, 10, 237-260.

Grossmann, I. E., S. A. Van Den Heever And I.

Harjunkoski, 2002. Discrete Optimization Methods

And Their Role In The Integration Of Planning And

Scheduling. AICHE Sympsium Series, 98, 150-168.

Gupta, O. K. & Ravindran, A. 1985. Branch And Bound

Experiments In Convex Nonlinear Integer

Programming. Management Science, 31, 1533-1546.

Hane, C. A., Barnhart, C., Johnson, E. L., Marsten, R. E.,

Nemhauser, G. L. & Sigismondi, G. 1995. The Fleet

Assignment Problem: Solving A Large-Scale Integer

Program. Mathematical Programming, 70, 211-232.

Holland, J. H. 1975. Adaptation In Natural And Artificial

Systems: An Introductory Analysis With Applications

To Biology, Control, And Artificial Intelligence,

Oxford, England: U Michigan Press.

Kocis, G. R. & Grossmann, I. E. 1987. Relaxation

Strategy For The Structural Optimization Of Process

Flow Sheets. Industrial & Engineering Chemistry

Research, 26, 1869-1880.

Lohatepanont, M. & Barnhart, C. 2004. Airline Schedule

Planning: Integrated Models And Algorithms For

Schedule Design And Fleet Assignment.

Transportation Science, 38, 19-32.

10000

15000

20000

25000

30000

1week 15days 20days 1month

Cost

∆

AMaintenance-optimalSwappingPolicy-ForaFleetofElectricorHybrid-electricVehicles

43

Metropolis, N., Rosenbluth, A., Rosenbluth, M., Teller, A.

& Teller, E. 1953. {E}Quation Of State Calculations

By Fast Computing Machines. Journal Of Chemical

Physics, 21.

Rexing, B., Barnhart, C., Kniker, T., Jarrah, A. &

Krishnamurthy, N. 2000. Airline Fleet Assignment

With Time Windows. Transportation Science, 34, 1-

20.

Robinson, J., Sinton, S. & Rahmat-Samii, Y. Particle

Swarm, Genetic Algorithm, And Their Hybrids:

Optimization Of A Profiled Corrugated Horn Antenna.

Antennas And Propagation Society International

Symposium, 2002. IEEE, 2002 2002. 314-317 Vol.1.

Rosenberger, J. M., Johnson, E. L. & Nemhauser, G. L.

2004. A Robust Fleet-Assignment Model With Hub

Isolation And Short Cycles. Transportation Science,

38, 357-368.

Schittkowski, K. 1982. The Nonlinear Programming

Method Of Wilson, Han, And Powell With An

Augmented Lagrangian Type Line Search Function.

Numerische Mathematik, 38, 115-127.

Smith, B. C. & Johnson, E. L. 2006. Robust Airline Fleet

Assignment: Imposing Station Purity Using Station

Decomposition. Transportation Science, 40, 497-516.

Talluri, K. T. 1996. Swapping Applications In A Daily

Airline Fleet Assignment. Transportation Science, 30,

237-248.

Viswanathan, J. & Grossmann, I. E. 1990. A Combined

Penalty Function And Outer-Approximation Method

For MINLP Optimization. Computers & Chemical

Engineering, 14, 769-782.

Westerlund, T. & Pettersson, F. 1995. An Extended

Cutting Plane Method For Solving Convex MINLP

Problems. Computers & Chemical Engineering, 19,

Supplement 1, 131-136.

Xia, W. & Wu, Z. 2005. An Effective Hybrid

Optimization Approach For Multi-Objective Flexible

Job-Shop Scheduling Problems. Computers &

Industrial Engineering, 48, 409-425.

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

44