Equivalence between Two Flowshop Problems

MaxPlus Approach

Nhat Vinh Vo and Christophe Lent

´

e

Universit

´

e Franc¸ois Rabelais Tours, Laboratoire d’Informatique (EA 6300),

´

Equipe Ordonnancement et Conduite (ERL CNRS 6305), Tours, France

Keywords:

Flowshop, MaxPlus Algebra, Modeling.

Abstract:

In this paper, a flowshop problem with minimal and maximal delays, setup and removal times is tackled. It

is shown that this problem is equivalent to another flowshop problem with only minimal and maximal delays,

which can be seen as a central problem. The proof is done using an algebraic way which allows to identify the

role of each constraint, once the modeling is performed.

1 INTRODUCTION

In this paper, a flowshop problem with a large set of

constraints is tackled, the objective is to minimize the

makespan. It is shown that this problem can be mod-

eled in an algebraic way and that, as a consequence, a

kind of central problem can be highlighted.

The proposed model is based on MaxPlus alge-

bra. This algebra is sometimes used in control sys-

tem, particularly in relation with Petri Nets, but very

few in scheduling theory. Nevertheless, one can cite

some articles like (Giffler, 1963) on project schedul-

ing, (Hanen and Munier, 1995) on cyclic parallel ma-

chine problems, (Cohen et al., 1985), (Gaubert, 1992)

on cyclic flowshop scheduling problem and (Gaubert

and Mairesse, 1999) on cyclic job-shop scheduling

problems. The MaxPlus approach was applied in

modeling and scheduling flowshop problem with min-

imal delays, setup and removal times in (Lent

´

e, 2001),

(Bouquard et al., 2006) and flowshop problems with

minimal and maximal delays in (Bouquard and Lent

´

e,

2006) for two machines flowshop problems and in

(Augusto et al., 2006) for any number of machines.

In each case, a square matrix was associated to each

job and a similar matrix could be associated to each

sequence of jobs. In the two last articles, it is shown

how to derive lower bounds by constructing a no-wait

instance from the job-matrices that can be solved by

an efficient procedure designed for the traveling sales-

man problem (Carpaneto et al., 1995).

This paper presents a synthesis and a generaliza-

tion of these studies, by considering simultaneously

minimal and maximal delays and setup and removal

times. The objective of this paper is to bring out

equivalence between this general flowshop problem

and the flowshop problem with only minimal and

maximal delays. This equivalence will be put in evi-

dence through a MaxPlus modeling.

Following this introduction, this general flowshop

problem with associated constraints and also nota-

tions used in this paper will be described. The third

part describes the algebraic approach, using MaxPlus

algebra. The fourth one presents how to model the so

called general problem and to calculate in detail job

associated matrix in MaxPlus. The next part indicates

how to transform a Job-matrix of this problem into

a Job-matrix of a minimal - maximal delay flowshop

problem that therefore will be highlighted as a central

problem.

2 FLOWSHOP WITH

MINIMAL - MAXIMAL

DELAYS, SETUP AND

REMOVAL TIME

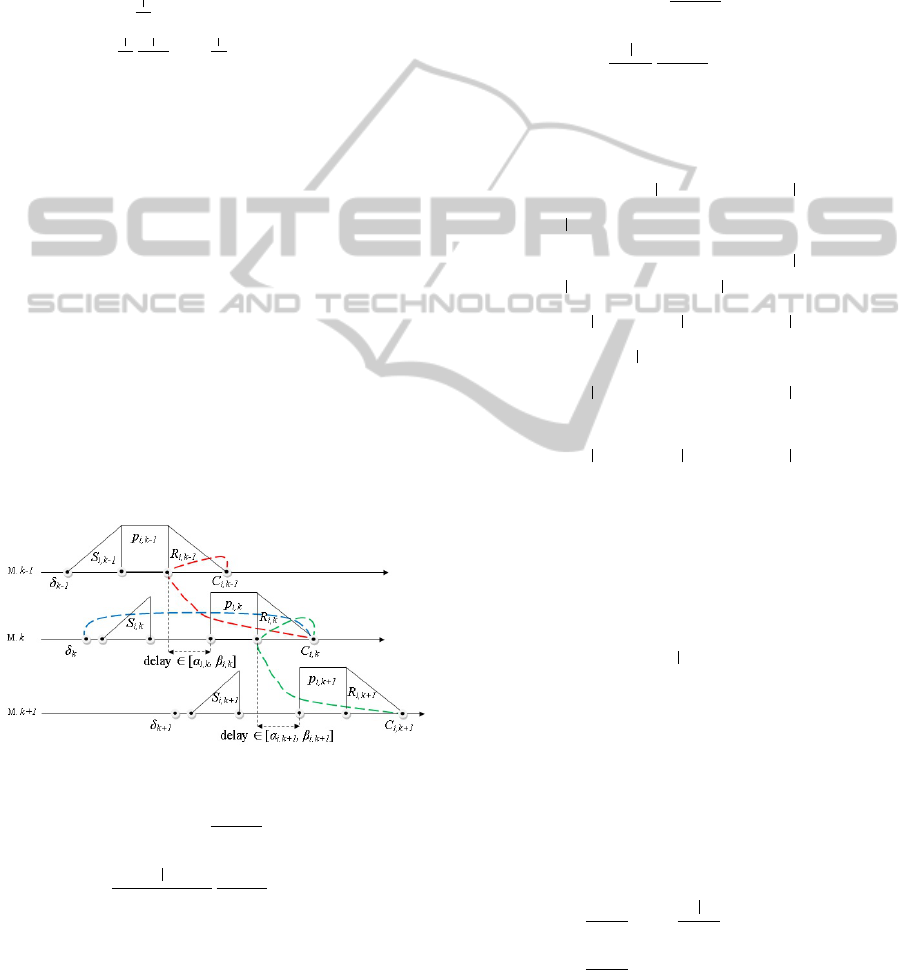

Figure 1 illustrates the constraints that are applied to

a job. The considered flowshop problem is composed

of m machines numbered from M

1

to M

m

and a set

of n jobs. A job J

i

is then composed of m operations

with duration p

i1

, p

i2

, . .., p

im

: the k

th

operation has

to be executed on the k

th

machine and it can be done

only when the (k − 1)

th

operation of the same job has

been completed on machine M

k−1

. Before and after

its execution, an operation requires a setup and a re-

174

Vo N. and Lenté C..

Equivalence between Two Flowshop Problems - MaxPlus Approach.

DOI: 10.5220/0004278903220325

In Proceedings of the 2nd International Conference on Operations Research and Enterprise Systems (ICORES-2013), pages 322-325

ISBN: 978-989-8565-40-2

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

Figure 1: Schema of the system.

moval time, noted S

ik

and R

ik

. During these times the

machine is considered as occupied. At any moment,

each machine can handle at most one task.

Moreover, a waiting time between the execution

of two consecutive operations of the same job must

respect both a minimal and maximal delays that are

noted α

ik

and β

ik

(2 ≤ k ≤ m).

The preemption is not allowed but only permuta-

tion schedules are considered, which means that all

jobs are executed in the same order by all machines.

For a given sequence, the end date C

ik

of the opera-

tion k of the job J

i

is measured by the end of its asso-

ciated removal time. The makespan of a schedule is

then defined by the maximum of dates C

im

for all jobs

J

i

(C

max

= max

1≤i≤n

C

im

). This problem can be denoted

by F

m

—S

nsd

, R

nsd

, min −max delay, perm—C

max

ac-

cording to notation of Graham (Graham et al., 1979).

3 ALGEBRAIC APPROACH

3.1 MaxPlus Algebra

As a short introduction of MaxPlus algebra, let’s say

that in this algebra we denote the maximum by ⊕ and

the addition by ⊗. The first operator, ⊕, is idempo-

tent, commutative, associative and has a neutral ele-

ment (−∞) denoted by 0. The second operator, ⊗,

is associative, distributive on ⊕ and has a neutral ele-

ment (0), denoted by 1. The element 0 is an absorbing

element for the operator ⊗. These properties can be

summarized by saying that R

max

= (R ∪ {−∞}, ⊕, ⊗)

is a dioid. It is important to note that in MaxPlus al-

gebra and more generally in dioids, the first operator

does not allow simplification: a ⊕ b = a ⊕ c 6⇒ b = c.

Furthermore, in R

max

, the second operator ⊗ is com-

mutative, and except for 0 , every element is invert-

ible: the inverse of a is denoted by a

−1

or

1

a

. For

more convenience we denote the ordinary subtraction

by

a

b

instead of a ⊗ b

−1

and by ab the product a ⊗ b.

Moreover, it is possible to extend these two opera-

tors to m × m matrices of elements of R

max

. Let A and

B be two matrices of size m × m and let [.]

i, j

be the

element at row i and column j of a matrix, operators

⊕ and ⊗ are defined by:

∀(i, j) ∈ {1, . . . , m}

2

,[A ⊕ B]

i, j

= [A]

i, j

⊕ [B]

i, j

∀(i, j) ∈ {1, . . . , m}

2

,[A ⊗ B]

i, j

=

m

O

k=1

[A]

i,k

⊗ [B]

k, j

The set of m × m matrices in R

max

endowed with

these two operators is also a dioid. But the operator ⊕

is not commutative and matrices are generally not in-

vertible. For more details, please see (Gaubert, 1992;

Baccelli et al., 1992; Gunawardena, 1998).

3.2 Generalities about MaxPlus

Modeling of Flowshop Problems

The MaxPlus modeling of a flowshop problem al-

ways follows the same principles, whatever the con-

straints are. A matrix T

i

is associated to each job

J

i

. This matrix is computed from data linked to the

job and defines entirely this job. This matrix allows

also to compute the completion times

~

C

i

of the op-

erations of the job knowing the dates of availabil-

ity

~

δ of all the machines

~

C

i

=

~

δ ⊗ T

i

. As a conse-

quence, considering a sequence σ of ν jobs, if ma-

chines are available at dates

~

δ, the dates of liberation

~

C

σ

of the machines by the sequence are given by for-

mula

~

C

σ

=

~

δ ⊗

ν

O

i=1

T

σ(i)

. So it is possible to associate

to a sequence σ the matrix T

σ

=

ν

O

i=1

T

σ(i)

. Then lower

bounds can be derived from the algebraic modeling

by extracting sub-matrices from matrices T

i

(Lent

´

e,

2001; Augusto et al., 2006). MaxPlus provides a for-

mal framework for the study of flowshop problems.

It allows to extend or adapt easily results from some

kinds of flowshop problems to others.

3.3 Application to Flowshop with

Minimal - Maximal Delays

In (Augusto et al., 2006), the authors have studied and

solved a flowshop with minimual and maximal de-

lays. The flowshop problem is the same that the one

described in section 2 except that there is no setup

nor removal time. They established the form of the

matrix T

i

associated to a job J

i

(Equation (1) shows

an example for three machines). Then they defined

a lower bound following this way: from a matrix T

i

,

EquivalencebetweenTwoFlowshopProblems-MaxPlusApproach

175

they built a lower matrix T

NW

i

(T

NW

i

≤ T

i

) character-

istic of a nowait flowshop job. The resolution of the

corresponding nowait flowshop problem, which can

be done using a fast TSP resolution procedure, gives

a lower bound of the initial flowshop problem. Fi-

nally, they designed a Branch and Bound procedure

to solve the F

m

|min − max delay, perm|C

max

.

T

i

=

p

i1

p

i1

p

i2

α

i2

p

i1

p

i2

α

i2

p

i3

α

i3

1

β

i2

p

i2

p

i2

p

i3

α

i3

1

β

i3

1

p

i2

β

i2

1

β

i3

p

i3

(1)

4 F

M

|S

NSD

,R

NSD

,MIN −

MAX DELAY S, PERM|C

MAX

4.1 Modeling

The description from section 2 leads to the sets of in-

equations (2), (3) and (4), written in MaxPlus nota-

tions. They summarize all the constraints applied to

the k

th

operation of a job J

i

. The term δ

k

represents

the date of availability of machine M

k

to perform the

setup operation. Typically, in a schedule, δ

k

could be

the completion time of operation k of the job preced-

ing J

i

. These inequations are illustrated in figure 2,

they will serve to determine a linear relation between

the dates of availability δ

k

of the machines and the

end dates C

ik

of job J

i

.

Figure 2: Model for calculation.

C

ik

≥ C

i(k−1)

α

ik

p

ik

R

ik

R

i(k−1)

(2 ≤ k ≤ m) (2)

C

ik

≥ C

i(k+1)

1

p

i(k+1)

β

i(k+1)

R

ik

R

i(k+1)

(1 ≤ k ≤ m − 1) (3)

C

ik

≥ δ

k

S

ik

p

ik

R

ik

(1 ≤ k ≤ m) (4)

4.2 Job Associated Matrix

Remembering section 3.2, an expected relation is of

the form:

~

C

i

=

~

δT

i

(5)

where T

i

is the matrix associated to the job J

i

. Let in-

troduce some new notations before pursuing calculus:

a

ik

= α

i(k+1)

p

i(k+1)

R

i(k+1)

R

ik

(1 ≤ k ≤ m − 1) (6)

b

ik

=

1

β

ik

p

ik

R

i(k−1)

R

ik

(2 ≤ k ≤ m) (7)

~

C

i

= (C

i1

, C

i2

,..., C

im

) (8)

~

δ = (δ

1

, δ

2

,..., δ

m

) (9)

P

i

=

S

i1

p

i1

R

i1

0 ... 0

0 S

i2

p

i2

R

i2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

0

0 ... 0 S

im

p

im

R

im

(10)

A

i

=

0 a

i1

0 ... 0

b

i2

0 a

i2

.

.

.

.

.

.

0 b

i3

.

.

.

.

.

.

0

.

.

.

.

.

.

.

.

.

.

.

.

a

i(m−1)

0 ... 0 b

im

0

(11)

Basically, vector

~

C

i

represents end dates of operations

of job J

i

, matrix P

i

regroups data defining an operation

and matrix A

i

the data linking two successive opera-

tions of job J

i

, it can be seen as a ”delay matrix”.

According to this system of inequations (2), (3) and

(4), it can be inferred that:

~

C

i

≥

~

δP

i

⊕

~

C

i

A

i

. The small-

est solution of this system is found using Kleene star:

~

C

i

=

~

δP

i

A

i

∗

where A

∗

i

= (1 ⊕ A

i

⊕A

2

i

⊕. . . ⊕A

q

i

⊕. . .).

Therefore, to meet relation (5) we must define

T

i

= P

i

A

i

∗

(12)

T

i

is the matrix associated to job J

i

. Note that this ma-

trix is totally independent of position of the associated

job in the sequence. The general form of matrix T

i

is:

[T

i

]

`,c

=

S

i`

p

i`

R

ic

c

O

k=`+1

p

ik

α

ik

if ` < c

S

i`

p

i`

R

ic

if ` = c

S

i`

R

ic

β

i`

`−1

O

k=c+1

1

p

ik

β

ik

if c < ` − 1

S

i`

R

ic

β

i`

if c = ` − 1

(13)

As an example, in case of 3 machines, the matrix

associated to the job J

i

is:

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

176

T

i

=

S

i1

p

i1

R

i1

S

i1

p

i1

R

i2

p

i2

α

i2

S

i1

p

i1

R

i3

p

i2

α

i2

p

i3

α

i3

S

i2

R

i1

β

i2

S

i2

p

i2

R

i2

S

i2

p

i2

R

i3

p

i3

α

i3

S

i3

R

i1

β

i3

1

p

i2

β

i2

S

i3

R

i2

β

i3

S

i3

p

i3

R

i3

(14)

It must be noted that this model can be generalized

to additional constraints such as release dates (r

i

), la-

tency duration (q

i

) or some batch constraints.

5 CENTRAL PROBLEM

In (Augusto et al., 2006) or (Fondrevelle et al., 2006),

authors proposed a way to calculate lower bounds

and optimal schedules for problem Fm—min − max

delays; perm—C

max

. This section represents now

how to transform our studied problem into flowshop

with only minimal and maximal delays. To do that,

terms relating to setup and removal times must be in-

tegrated to the definition of new processing times and

minimal and maximal delays. It will define a new

flowshop problem whose characteristics are described

below. In this new formulation, a job J

i

is only defined

by operations’ processing times p

ik

and minimal and

maximal delays α

ik

and β

ik

. But its associated matrix

T

i

remains unchanged.

p

ik

= S

ik

p

ik

R

ik

(1 ≤ k ≤ m)

β

ik

=

β

ik

S

ik

R

i(k−1)

(2 ≤ k ≤ m)

α

ik

=

α

ik

S

ik

R

i(k−1)

(2 ≤ k ≤ m)

(15)

For example, in case of three machines, the matrix

associated to job J

i

becomes

T

i

=

p

i1

p

i1

α

i2

p

i2

p

i1

α

i2

p

i2

α

i3

p

i3

1

β

i2

p

i2

p

i2

α

i3

p

i3

1

β

i2

p

i2

β

i3

1

β

i3

p

i3

(16)

6 CONCLUSIONS

Thanks to MaxPlus approach, it is possible to trans-

form a flowshop scheduling problem into a matrix

problem. Some manipulations over these matrices al-

low us to exhibit a sort of central problem. Permu-

tation flowshop with several classical constraints are

equivalent to some permutation flowshop with min-

imal and maximal delays. Calculus have been pre-

sented with non sequence dependent setup and re-

moval times, but the equivalence can also be stated for

release dates or groups of jobs for example. This re-

sult means that one can focus our efforts to solve this

central problem. It also means that it must be possible

to adapt automatically a method developed for a type

of constraints to another type of constraints.

Further research will concern modeling a greater

set of constraints, like limited stocks between ma-

chines or blocking constraints and, if possible and

if necessary, the definition of an other central prob-

lem. They will also concern improvements of solving

methods presented in (Augusto et al., 2006).

REFERENCES

Augusto, V., Lente, C., and Bouquard, J. L. (2006).

R

´

esolution d’un flowshop avec delais minimaux et

maximaux. In MOSIM.

Baccelli, F., Cohen, G., Olsder, G., and Quadrat, J. (1992).

Synchronisation and Linearity: An Algebra for Dis-

crete Event Systems. John Wiley and Sons, New York.

Bouquard, J. and Lent

´

e, C. (2006). Two-machine flow shop

scheduling problems with minimal and maximal de-

lays. 4’OR, 4(1):15–28.

Bouquard, J., Lente, C., and Billaut, J. (2006). Applica-

tion of an optimization problem in Max-Plus algebra

to scheduling problems. Discrete Applied Mathemat-

ics, 154(15):2064–2079.

Carpaneto, G., Dell’amico, M., and Toth, P. (1995).

Carpaneto, Dell’amico, Toth - 1995 - Exact solu-

tion of large asymmetric traveling salesman prob-

lems.pdf. ACM Transactions on Methematical Soft-

ware, 21(4):394–409.

Cohen, G., Dubois, D., Quadrat, J., and Viot, M. (1985).

A linear system-theoretic view of discret-event pro-

cesses and its use for performance evaluation in man-

ufacturing. IEEE Trans. Automatic Control, 30:210–

220.

Fondrevelle, J., Oulamara, A., and Portmann, M.-C. (2006).

Permutation flowshop scheduling problems with max-

imal and minimal time lags. Computers & Operations

Research, 33:1540–1556.

Gaubert, S. (1992). Th

´

eorie des syst

`

emes lin

´

eaires dans les

dio

¨

ıdes. PhD thesis.

Gaubert, S. and Mairesse, J. (1999). Modeling and analysis

of timed petri nets using heaps of pieces. IEEE Trans.

Automatic Control, 44(4):683–698.

Giffler, B. (1963). Schedule algebras and their use in

formulating general systems simulations,. in ”Indus-

trial scheduling”, Muth and Thompson (eds.),Prentice

Hall, New Jersey (U.S.A.).

Graham, R. L., Lawler, E. L., Lenstra, J. K., and Rinnooy

Kan, A. H. (1979). Optimization and approximation

in deterministic sequencing and scheduling: A survey.

Annals of Discrete Mathematics, 5(2):287–326.

Gunawardena, J. (1998). Idempotency. Publications of the

Newton Institute, Cambridge University Press.

Hanen, C. and Munier, A. (1995). Cyclic scheduling on

parallel processors: an overview. In Chretienne, P.,

Coffman, E., Lenstra, J., and Liu, Z., editors, Schedul-

ing Theory and its Applications, pages 193–226. John

Wiley.

Lent

´

e, C. (Nov. 2001). Analyse Max-Plus de probl

`

emes

d’ordonnancement de type Flowshop. Th

`

ese de doc-

torat, Universit

´

e Frano¸is Rabelais de Tours.

EquivalencebetweenTwoFlowshopProblems-MaxPlusApproach

177