Cellular Factories

Emerging Technologies for Fabrication of Nanomedicines?

V. Ramos

1

, X. Turon

2

and S. Borros

1

1

Grup d’Enginyeria de Materials, Institut Quimic de Sarria, Universitat Ramon Llull, Barcelona, Spain

2

Department of Bioengineering, Institut Quimic de Sarria, Universitat Ramon Llull

Via Augusta 390, 080017 Barcelona, Spain

Keywords: Bioprocessing, Nanomedicine, Drug Delivery, Metabolomics, Recombinant Dna, Microbial Factories,

Protein Nanocages.

Abstract: The development of innovative nanomedicines requires the implementation of new biocompatible materials

and their efficient assembly into defined nanostructures. Complex and costly synthesis of these materials

can be coped with biological fabrication using microorganism factories, recombinant DNA and metabolic

engineering. Modern bioprocess technologies may have the key for the implementation of tomorrow’s

nanomedicines. This paper specifically focuses on the current state of the art of nanopharmaceuticals and

their future perspectives.

1 INTRODUCTION TO DRUG

DELIVERY

The majority of clinically approved drugs are low

molecular weight molecules (below 10

3

g/mol),

which are often membrane permeable and generally

spread throughout the whole body. As a

consequence drugs reach healthy tissues as well as

disease targets, which may result in unwanted side

effects and/or rapid clearance and elimination. Non-

specific biodistribution also results in a decreased

therapeutic effect due to lowered accumulation at the

target site. An effective approach to decrease side

effects and enhance drug potency makes use of

sophisticated delivery systems, several of which

have crystalized in new approved therapies (Duncan

2003). Over the last years, multidisciplinar

collaboration in biomedical research together with

converging scientific technologies, such as

nanotechnology and biotechnology have led to the

development of modern nanomedicine (Duncan and

Gaspar, 2011).

2 CURRENT STATE OF

NANOMEDICINE

Nanomedicine is an overall term that has been

defined by the European Science Foundation´s

Forward Look Nanomedicine in the following

manner: “Nanomedicine uses nano-sized tools for

the diagnosis, prevention and treatment of disease

and to gain increased understanding of the complex

underlying pathophysiology of disease. The ultimate

goal is improve quality-of-life”.

Modern nanomedicines fit into three groups. The

first group consists of first generation

nanomedicines that have already entered routine

clinical use and they include blockbuster products

and certain products that are of such an age that they

will soon begin to appear as generics. This group is

mainly formed by technologies developed during the

second half of the 20

th

century, such as liposomes

(e.g: liposomal amphotericin B Ambisome (Lopez-

Berestein, 1986) or liposomal doxorubicin Myocet

(Mross et al., 2004)), polymer-protein conjugates

(e.g.: styrene maleic anhydride-neocarcinostatin

Zinostatin Stimaler (Maeda, 2001) or pegylated

adenosine deaminase Adagen (Gaspar et al., 2009))

and polymeric drugs (e.g.: Glu-Ala-Tyr copolymer

Copaxone (Johnson et al. 1995)).

The second group is made of an increasing

209

Ramos V., Turon X. and Borros S..

Cellular Factories - Emerging Technologies for Fabrication of Nanomedicines?.

DOI: 10.5220/0004329202090215

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2013), pages 209-215

ISBN: 978-989-8565-34-1

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

number of nanomedicines in clinical development. It

seems certain that a significant number of

nanomedicines based on already approved delivery

systems, such as liposomes and polymer-protein

conjugates, encompassing new bioactives will

continue to reach market approval. In addition, it is

likely that other technologies, such as polymer- or

antibody-drug conjugates (LoRusso et al., 2011),

block co-polymer micelles (Hamaguchi et al., 2005)

and/or nanoparticles (Wohlfart et al., 2011) will

have their first regulatory approval and commercial

success over the next decade, increasing the

confidence of new technology approval.

Finally, the third group comprises innovative

nanotechnologies, mostly still in pre-clinical or even

proof-of-concept stages that may have the potential

to enter clinical development. Many

nanotechnologies are being continuously proposed

for use as nanomedicines, such as carbon nanotubes

(Wu et al., 2009), inorganic nanosized particles

(Goel et al., 2009) or PRINT (particle replication in

non-wetting templates) particles (Canelas et al.,

2009). Significant progress in nanomedicine design

together with the maturing of regulatory aspects

experienced during the last decades are expected to

fertilize the route towards a new paradigm to

diagnosis and therapy.

Although it is difficult to predict the future in

nanomedicine development, the lessons learned

from first generation nanomedicines permits some

speculation about preferred features and avoidable

aspects of tomorrow’s nanomedicines. Hence, it is

important to emphasize that well-defined materials

must be used for future developments, since many

current nanomaterials are inherently heterogeneous.

In addition, nanomedicines should preferably arise

from rational design rather than a let’s try attitude.

For safety reasons, nanomedicines should be

biodegradable to known and non-toxic metabolites

or alternatively be engineered for efficient

elimination via renal and/or hepatobiliary routes in

order to avoid lysosomal storage disorders (Garnett

and Kallinteri, 2006). Another important challenge

is that emerging nanomedicines must be

technologically feasible for large-scale

manufacturing and processing to translate in cost

effective novel therapies. However, fabrication of

nanomedicines via synthetic approaches tends to be

costly and technically difficult due to the large

number of processing and purification steps. The

purpose of this paper is to ponder whether

nanomedicines of the future might be synthesized by

biological means (bioprocessing). Such

biofabrication platforms would represent direct and

cost-effective systems for the production of complex

nanomedicines.

3 FUTURE OF NANOMEDICINE

Evolution has furnished biological processes with an

enviable level of control and specificity, which

translates into exquisitely controlled hierarchical

architectures at the molecular and supramolecular

scale. These elegant structures and precise functions

of biomacromolecules have inspired and continue to

inspire strategies for nanomedicine development.

However, it is likely that the next revolution in

nanomedicine research will be fuelled by

convergence of molecular and cellular biology with

genomics, engineering and physical sciences to

biofabricate nanomedicines (Sharp et al., 2011)

rather than by construction of (bio)inspired

macromolecular synthetic mimics or biological-

synthetic hybrid structures (Pasparakis et al., 2010).

The possibility to use the cellular machinery to

entirely biosynthesize nanomedicines, would open

the way to the development of innovative

nanomedicines from new biocompatible materials

produced by cost-effective fabrication methods, in

contrast to difficult entirely synthetic methods. The

biological fabrication of materials, mostly carried

out by microorganisms, has historically provided

biomacromolecules with wide-spectrum biomedical

applications, including drugs (Engels et al., 2008),

polymers (Liu et al., 2011), proteins (Ferrer-Miralles

et al., 2009) and nucleic acids. Although

microorganisms might be simply seen as reaction

vessels for bioproduction, development of genetic

and metabolic engineering is likely to render

efficient platforms capable of producing complex

nanomedicines, such as polymer-drug conjugates,

protein nanoparticles or other nanoscale entities. The

tremendous therapeutic potential of such organized

and functional materials in nanomedicine prompts

serious consideration of further exploitation of cell

factories and recombinant DNA technologies as

powerful alternatives to chemical synthesis. For this

purpose, heterologous biosynthesis in engineering-

and process-friendly hosts, such as Escherichia coli

or Saccharomyces cerevisiae, of components and

their subsequent assembly into finished functional

nanomedicines, emerges as a promising technically

feasible and cost-effective platform.

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

210

4 THE QUESTION IS: CAN

THESE NEW BIOPROCESSED

NANOMEDICINES BE MADE?

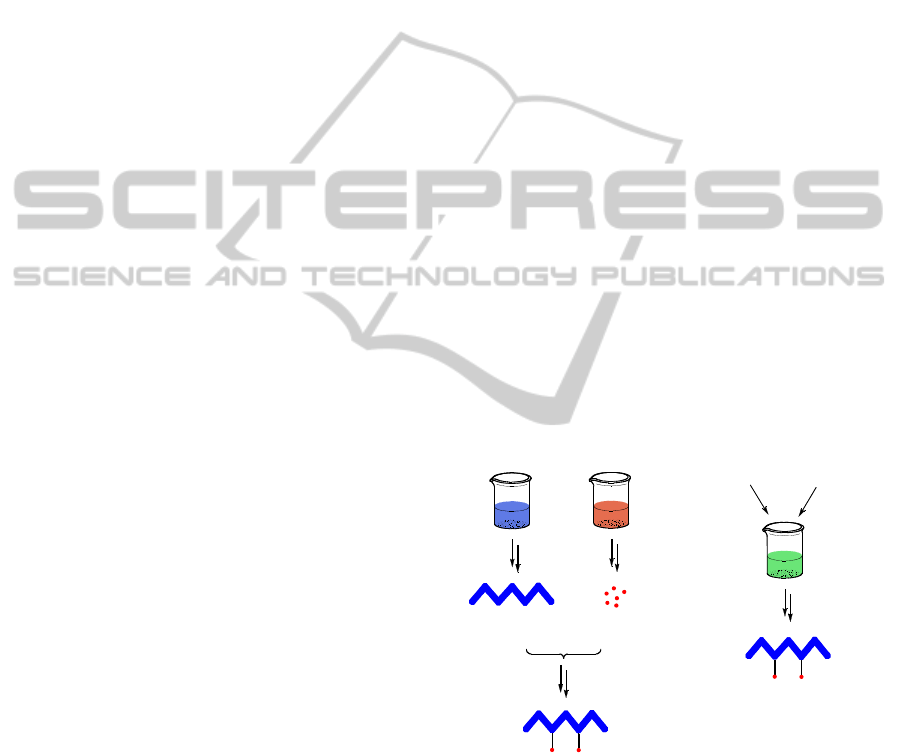

4.1 Polymer-Drug Conjugates

Microorganism-produced polymers are known

interesting alternatives to synthetic polymers, as they

are non-toxic, biocompatible and biodegradable

materials. According to their chemical structure,

biopolymers can be distinguished between

polysaccharides, such as hyaluronic acid (Leonelli et

al., 2008), polyamides, such as poly(γ-glutamic acid)

(Choi et al., 2004), and polyesters, such as

polyhydroxyalkanoates (Kim et al., 2009). Most of

these polymers contain amenable sites for chemical

modification – i.e. ligand conjugation or

functionality introduction – that can render

appropriate polymer tailoring for biomedical

applications. Chemical conjugation of drugs to such

polymers has been widely explored to produce

polymer-drug conjugates that have been evaluated as

potential therapies for cancer (Leonelli et al., 2008)

and inflammatory (Yang et al., 2008) diseases. Some

of these conjugates have had or are experiencing

notable success, such as poly(glutamic acid)-

paclitaxel conjugate (Opaxio), which is currently

under phase III clinical evaluation (Galic et al.,

2011). However, the production of such

macromolecular constructs is often characterized by

difficulties in their manufacture and processing. The

reason for such costly development is the

requirement of reproducible and specific procedures

for chemical conjugation of the drug, followed by

efficient purification of unreacted materials and by-

products. Since a great number of drugs are obtained

or can be obtained by microbial production, such as

anti-cancer blockbusters doxorubicin and Colombo,

1999) and paclitaxel (Engels et al., 2008), it is not

difficult to envisage that some of these polymer-drug

conjugates could be obtained directly in bioprocess

factories as a single final product. The development

of a microorganism-based platforms capable of

simultaneous production of both precursors – i.e. the

drug and the polymer – followed by appropriate

biotransformation mechanisms for successful

conjugation of these precursors into organized

nanostructures emerges as a promising system for

the production of polymer-drug conjugates in a fast,

technically feasible and cost effective manner

(figure 1).

Notably, the main current limitation is the

introduction of cellular mechanisms capable of

conjugating the drug to the polymer chains inside

modified microorganisms. Such systems would

probably require the introduction of sets of enzymes

capable of chemically linking the drug to the

polymer in a site-specific, robust and reproducible

manner. To the best of our knowledge, there are no

references in the literature about known enzymes

that mediate drug conjugation to polymers.

However, research in this area is likely to identify

enzymes capable of mediating specific polymer-drug

conjugation. This is supported by the fact that a few

enzyme-based approaches for peptide ligation have

been already described. For example, sortase is an

extensively studied transpeptidase found in the cell

envelope of many Gram-positive bacteria that

mediates transpeptidation by recognition of specific

terminal aminoacid motifs at the C- and N-terminal

of its substrates and ligands, respectively (Mao et al.,

2004). Since sortase has shown transpeptidase

activity in other non-amino acid primary amine-

containing substrates, it is likely that the chemical

structure of polymer and drug molecules may be

engineered to make use of such enzyme-based

coupling strategies (Ta et al., 2012). Another

promising family of enzymes to be considered for

enzymatic-based coupling of polymers and drugs are

glycosyltransferases (Boltje et al., 2009); (Wagner

and Pesnot, 2010).

Figure 1: Synthesis of polymer-drug conjugates: synthetic

vs. bioprocess approach.

4.2 Polymer-Protein Conjugates

Deficiency of specific proteins or non-functional

versions of biologically relevant proteins may derive

in diverse pathologies. Such disorders can be

addressed clinically by administration of the missing

protein to reach adequate physiological concentra-

tions. However, in many cases therapeutic proteins

Engineered

microorganisms

Appropriate

feedstock

Polymer

Synthesis

D

r

ug

Synthesis

Chemical

Conjugation

drug

polymer

Polymer-Drug Conjugate

CellularFactories-EmergingTechnologiesforFabricationofNanomedicines?

211

are very difficult to obtain from their natural sources

and therefore bioprocess platforms using

recombinant DNA technologies have been

developed. Potent and relatively cost-effective

production procedures can be achieved by

cultivation of conveniently modified microbial cells,

such as bacteria and yeast (Ferrer-Miralles et al.,

2009).

Although there is an increasing number of

approved recombinant proteins to be used as

biopharmaceuticals, many of these therapeutic

proteins face some limitations, which include short

circulating half-life, immunogenicity, low solubility

and proteolytic degradation (Duncan, 2003). A few

strategies have been developed in order to improve

their pharmacological properties for safer and more

efficient use. Such strategies include changes in their

amino acid sequence to reduce immunogenicity and

proteolytic cleavage, conjugation to other proteins,

such as albumin (Kurtzhals et al., 1995), or

conjugation to natural or synthetic polymers

(Roberts et al., 2012). The most efficient and

versatile strategy so far consists on the chemical

coupling of poly(ethylene glycol) (PEG). PEG

conjugation can protect therapeutic proteins from

premature clearance, proteolytic enzyme degradation

and immunogenicity. In addition, PEGylation

increases the apparent size of proteins, thus reducing

renal filtration, which results in extended circulating

half-life (Veronese and Pasut, 2005). Undoubtedly,

PEGylation has made possible the clinical use of

certain therapeutic proteins, whose administration

compliance would otherwise be unfeasible. Despite

clinical success, PEGylation of biologically active

proteins may present drawbacks with respect to

biopharmaceutical development and production,

since additional in vitro processing and purification

steps are required. Furthermore, the biological

function of the therapeutic protein may be impaired,

if chemical coupling takes place in the vicinity of its

bioactive site. In addition, PEG is not biodegradable

and may cause severe side effects, such as

vacuolation of organs upon chronic administration.

A wide arsenal of both synthetic and natural

polymers, such as poly[N-(2-hydroxypropyl)-

methacrylamide] (Johnson et al., 2012) and

polyvinylpyrrolidone (Shibata et al., 2005) or

polysialic acid (Pisal et al., 2010) or hyaluronic acid

(Ferguson et al., 2010), have been explored as

alternatives to PEG, however these systems do not

avoid the need for additional processing and

purification steps in order to obtain the final

polymer-protein conjugates, and finally they have

not shown superior performance than PEG.

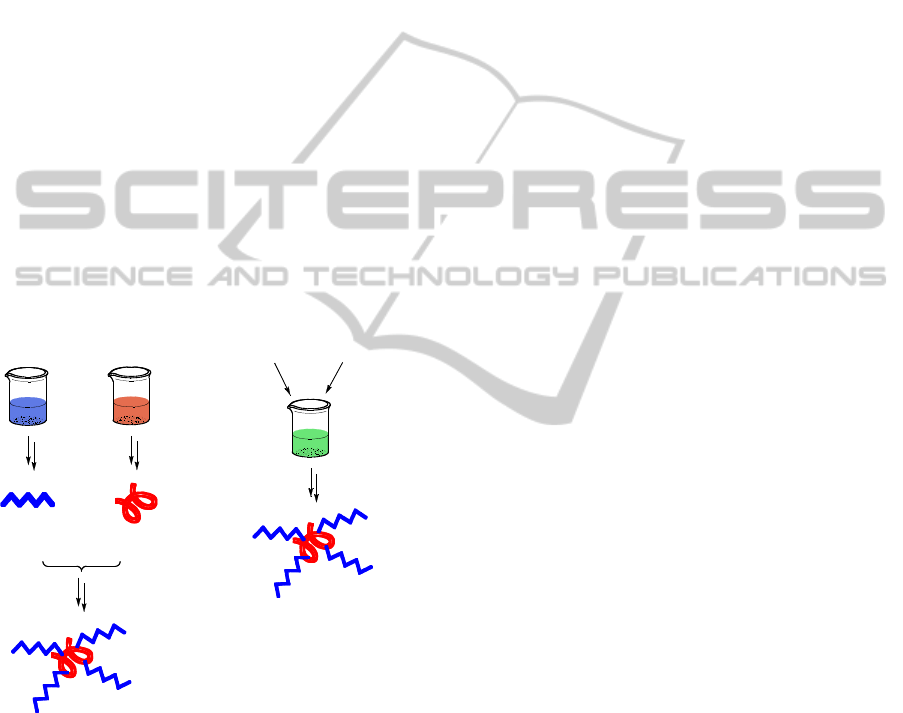

Similarly as discussed earlier for polymer-drug

conjugates, the development of bioprocess platforms

capable of producing polymer-protein conjugates,

either during protein synthesis (co-translational

modification) or on finished proteins (post-

translational modification), emerges as a promising

alternative to polymer modification via chemical-

based coupling strategies (figure 2). In this case,

protein processing may also provide appropriate

targeting signals to traffic the therapeutic protein to

specific target sites.

A few alternative strategies to avoid synthetic

post-modification strategies have been already

proposed during the recent years, including

glycosylation (Flintegaard et al., 2010) and genetic

fusion of carrier proteins and polypetides (Cleland

and Geething 2012). Modification of therapeutic

proteins with glycans to prolong their in vivo half-

life can be achieved by introducing mutations in

their amino acid sequence in order to establish

glycosylation sites. Glycosylation at these sites

occurs via glycosyltransferase enzymes in protein

processing events, either at the rough endoplasmic

reticulum or the golgi apparatus. For success, the

host platform requires to be suitably

glycoengineered in order to correctly biosynthesize

the therapeutic glycoprotein. Following this strategy,

a first successful pharmaceutical product, Aranesp

(glycoengineered erythropoietin), received market

approval in 2001 and it is expected that others will

follow. Although specific glycosylation might be

useful for prolonging half-life, it may result in

unwanted retargeting or increased immunogenicity.

An emerging alternative to PEGylation and

glycosylation of proteins is the post-translational

enzymatic-conjugation of natural polysaccharides

found in the human body, such as polysialic acid or

hyaluronic acid. The hypothesis behind this strategy

is that glycoengineered microorganisms could be

used to produce PSA- or HyA-conjugated proteins in

a single fermentation without the need for in vitro

chemical modification.

Genetic fusion of either natural proteins, such as

albumin (Sheffield et al., 2004), or unstructured

polypeptide sequences of hydrophilic amino acids to

either C,N-terminus or both termini of a

recombinant protein provides a simple way to

prolong plasma half-life and to diminish

immunogenicity and proteolytic cleavage of

biopharmaceuticals. Genetic fusion strategy allows

biotechnological production of polymer-conjugated

therapeutic proteins as one single product without

the need of additional processing and purification

steps. In addition, this system can be easily adjusted

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

212

to match the pharmacological needs by varying the

polypeptide length and composition. Alternatively,

targeting signals can be generated at C- or N-

terminus to enable protein trafficking towards target

tissues or cells. An interesting advantage of this

technology is that in contrast to PEGylation genetic

fusion of polypeptides renders a homogenous,

monodisperse product with a defined chemical

composition.

PASylation and XTEN technologies are two

proprietary genetic fusion technologies that consist

of disordered polypeptide sequences of Pro, Ala and

Ser, and unstructured polypeptide containing Ala,

Glu, Gly, Pro, Ser and Thr, respectively. It has been

claimed that these technologies may reduce the cost

of goods by up to 10-fold relative to PEGylation

technologies.

A parallel alternative to genetic fusion is the

polyglutamation and polyglycilation of therapeutic

proteins, which consists of post-translational

enzymatic-conjugation at the C-terminus of

polymeric Glu and Gly, respectively (Janke et al.,

2008).

Figure 2: Synthesis of polymer-protein conjugates:

synthetic vs. bioprocess approach.

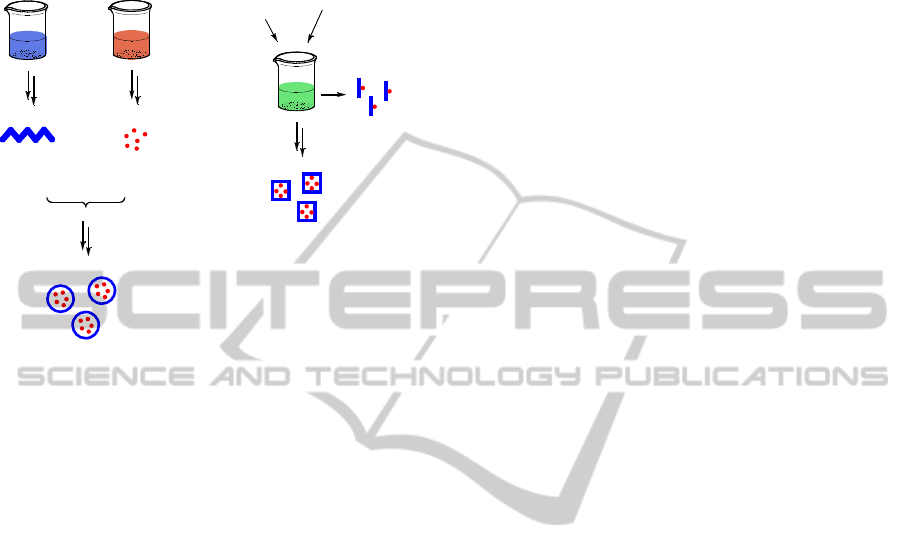

4.3 Protein Cages and Nanoparticle

Drug Encapsulation

Drug delivery systems based on drug encapsulation

have been largely explored as potential therapeutic

agents. In general, drug encapsulation enhances drug

efficacy and reduces unwanted effects of free drug

during trafficking to the target site. Lipid (mainly

liposomes) and polymeric nanoparticles (i.e. PLA

(Krause et al., 1985) or Abraxane (Zhao and Astruc,

2012)) have been under continuous development

during the last decades and some products have

already received market approval. These

nanomedicines present some advantages, when

compared to polymer-drug conjugation, including

the protection of premature drug degradation and

restricted interaction with the biological

environment, preferential absorption into a selected

tissue due to their nanoparticulate nature,

bioavailability and retention time. Molecular

organization, shape and size dispersion and drug

encapsulation efficiency of these constructs is

achieved by mechanical and chemical approaches.

However, these constructs are obtained as rather

heterogeneous mixtures. In addition, most of these

particles require surface functionalization to enhance

their pharmacological properties, mainly their half-

life, and to present targeting motifs for specific and

efficient trafficking to diseased tissues or cells.

Inspired by the monodisperse nature of viral

particles and intracellular nanocompartments, it has

been hypothesized that if properly adapted, these

nanostructures could be turned into potent

nanomedicine platforms. Additionally, due to

evolution, viral particles posses specific targeting

and cell-entry machinery, which are highly sought

features in nanomedicine systems. Adaptation of

viral particles as nanomedicine constructs via

conventional chemical techniques would require

casting of the genetic material and maintenance of

the structural capsid for subsequent drug loading or

conjugation and modification. However, one of the

main limitations for using these constructs is the

difficulty to have access to sufficient material of

empty viral capsids, since viruses are obtained by

culturing of host cells. Even if large amounts of viral

capsids were available, chemical conjugation

processes would be complex and expensive and

would probably result in random attachment patterns

and undesirable heterogeneity. For these reasons, a

versatile bioprocess platform for the production of

virus-like capsids or any other supramolecular

structure suitable for accommodating drugs, small

proteins or even nucleic acids in a cost-effective

manner would be highly appealing (figure 3).

In this scenario, the development of bioprocess

platforms capable of producing capsid proteins

followed by macromolecular self-assembly could be

exploited to engineer materials for encapsulation of

active principles. Protein-based capsids are

interesting vehicles for delivery applications, since

they are biocompatible and their versatility of design

would allow protein engineering to enhance vital

Engineered

microorganisms

Appropriate

feedstock

Polymer

Synthesis

Protein

Synthesis

Chemical

Conjugation

protein

polymer

Polymer-Drug Conjugate

CellularFactories-EmergingTechnologiesforFabricationofNanomedicines?

213

pharmacokinetic properties, such as prolonged half-

life, enhanced proteolytic resistance and reduced

immunogenicity.

Figure 3: Synthesis of drug-nanoparticles: synthetic vs.

bioprocess approach.

Mechanisms directing drug encapsulation within

capsids, similar to the ones discussed for enzymatic

polymer-drug or polymer-protein conjugation should

be designed to direct drug conjugation to the inner

surface of the capsid. A few early proof of concept

works have demonstrated that it is feasible to

encapsulate small enzymes in the interior of protein-

based bacterial organelles both by specific

enzymatic-based conjugation strategies at the inner

side of the capsid proteins and by gene fusion of

capsid and enzyme proteins (Fan et al., 2010). Upon

macromolecular self-assembly, successful enzyme

encapsulation inside the capsid was observed.

It is likely that the development of enzymatic-

based conjugation strategies and gene fusion

techniques to create specific docking sites in the

interior of protein nanocages will not only allow the

encapsulation of a wide range of therapeutic

molecules, such as small drugs, therapeutic proteins,

nucleic acids and imaging agents, but also the

introduction of cell- or tissue-specific targeting

motifs on the exterior and particle disassembly

mechanisms for efficient release of the therapeutic

load at the target site.

5 CONCLUDING REMARKS

Innovative nanoengineering together with increased

knowledge arising from genomics, proteomics and

metabolomics research brings exciting novel

opportunities for nanomedicine development. There

is a real chance to spur on modern nanomedicine

development, as too many new nanomedicines still

use old strategies and old drugs as the bioactive.

Bioprocessing in the broadest conception of this

term, including fermentation, biotransformation and

downstream separation techniques in favour of new

nanomedicine engineering may open the future to

obtain more specific, defined and potent

nanomedicine systems to improve patient therapy.

REFERENCES

Boltje, T. J., Buskas, T., Boons, G.-J., 2009. Opportunities

and challenges in synthetic oligosaccharide and

glycoconjugate research. Nat Chem, 1(8), pp.611-622.

Canelas, D. A., Herlihy, K. P., DeSimone, J. M., 2009.

Top-down particle fabrication: control of size and

shape for diagnostic imaging and drug delivery. Wiley

Interdisciplinary Reviews: Nanomedicine and

Nanobiotechnology, 1(4), pp.391-404.

Choi, S.-hyun et al., 2004. Production of Microbial

Biopolymer , Poly ( γ-glutamic acid ) by Bacillus

subtilis BS 62. Agricultural Chemistry &

Biotechnology, 47(2), pp.60-64.

Cleland, J., Geething, N., 2012. A Novel Long-Acting

Human Growth Hormone Fusion Protein ( VRS-317 ):

Enhanced In Vivo Potency and Half-Life. Journal of

Pharmaceutical Sciences, 101(8), pp.2744-2754.

Duncan, R., 2003. The dawning era of polymer

therapeutics. Nature reviews. Drug discovery, 2(5),

pp.347-60.

Duncan, R., Gaspar, R., 2011. Nanomedicine(s) under the

Microscope. Molecular Pharmaceutics, 8, pp.2101 -

2141.

Engels, B., Dahm, P., Jennewein, S., 2008. Metabolic

engineering of taxadiene biosynthesis in yeast as a first

step towards Taxol (Paclitaxel) production. Metabolic

engineering, 10(3-4), pp.201-6.

Fan, C. et al., 2010. Short N-terminal sequences package

proteins into bacterial microcompartments.

Proceedings of the National Academy of Sciences of

the United States of America, 107(16), pp.7509-14.

Ferguson, E. L., Alshame, A.M.J., Thomas, D. W., 2010.

Evaluation of hyaluronic acid–protein conjugates for

polymer masked–unmasked protein therapy.

International Journal of Pharmaceutics, 402(1–2),

pp.95-102.

Ferrer-Miralles, N. et al., 2009. Microbial factories for

recombinant pharmaceuticals. Microbial cell factories,

8, p.17.

Flintegaard, T. V. et al., 2010. N-glycosylation increases

the circulatory half-life of human growth hormone.

Endocrinology, 151(11), pp.5326-36.

Galic, V. L. et al., 2011. Paclitaxel poliglumex for ovarian

Engineered

microorganisms

Appropriate

feedstock

Carrier

Synthesis

Drug

Synthesis

Chemical Conjugation

Drug Encapsulation

Surface Modification

...

carrier system

Drug-Nanoparticle

drug

drug-macromolecule

monomer

Drug-Nanoparticle

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

214

cancer. Expert Opinion on Investigational Drugs,

20(6), pp.813-821.

Garnett, M. C., Kallinteri, P., 2006. Nanomedicines and

nanotoxicology: some physiological principles.

Occupational medicine, 56(5), pp.307-11.

Gaspar, H. B. et al., 2009. How I treat ADA deficiency.

Blood, 114(17), pp.3524-3532.

Goel, R. et al., 2009. Biodistribution of TNF-α-coated

gold nanoparticles in an in vivo model system.

Nanomedicine, 4(4), pp.401-410.

Hamaguchi, T. et al., 2005. NK105, a paclitaxel-

incorporating micellar nanoparticle formulation, can

extend in vivo antitumour activity and reduce the

neurotoxicity of paclitaxel. Br J Cancer, 92(7),

pp.1240-1246.

Hutchinson, C. R., Colombo, A. L., 1999. Genetic

engineering of doxorubicin production in

Streptomyces peucetius: a review. Journal of

Industrial Microbiology & Biotechnology, 23(1),

pp.647-652.

Janke, C., Rogowski, K., van Dijk, J., 2008.

Polyglutamylation: a fine-regulator of protein

function? EMBO Rep, 9(7), pp.636-641.

Johnson, K. P. et al., 1995. Copolymer 1 reduces relapse

rate and improves disability in relapsingremitting

multiple sclerosis: Results of a phase III multicenter,

doubleblind, placebocontrolled trial. Neurology,

45(7), pp.1268-1276.

Johnson, R. N., Kopečková, P., Kopeček, J., 2012.

Biological activity of anti-CD20 multivalent HPMA

copolymer-Fab’ conjugates. Biomacromolecules,

13(3), pp.727-35.

Kim, H.-N. et al., 2009. Enzymatic synthesis of a drug

delivery system based on polyhydroxyalkanoate-

protein block copolymers. Chemical communications,

7345(46), pp.7104-6.

Krause, H.-J., Schwarz, A., Rohdewald, P., 1985.

Polylactic acid nanoparticles, a colloidal drug delivery

system for lipophilic drugs. International Journal of

Pharmaceutics, 27(2–3), pp.145-155.

Kurtzhals, P. et al., 1995. Albumin binding of insulins

acylated. , 731, pp.725-731.

Leonelli, F. et al., 2008. Design, synthesis and applications

of hyaluronic acid-paclitaxel bioconjugates.

Molecules, 13(2), pp.360-78.

Liu, L. et al., 2011. Microbial production of hyaluronic

acid: current state, challenges, and perspectives.

Microbial cell factories, 10, p.99.

LoRusso, P. M. et al., 2011. Trastuzumab Emtansine: A

Unique Antibody-Drug Conjugate in Development for

Human Epidermal Growth Factor Receptor 2–Positive

Cancer. Clinical Cancer Research, 17(20), pp.6437-

6447.

Lopez-Berestein, G., 1986. Liposomal Amphotericin B in

the Treatment of Fungal Infections. Annals of Internal

Medicine, 105(1), pp.130-131.

Maeda, H., 2001. SMANCS and polymer-conjugated

macromolecular drugs: advantages in cancer

chemotherapy. Advanced Drug Delivery Reviews,

46(1–3), pp.169-185.

Mao, H. et al., 2004. Sortase-mediated protein ligation: a

new method for protein engineering. Journal of the

American Chemical Society, 126(9), pp.2670-1.

Mross, K. et al., 2004. Pharmacokinetics of liposomal

doxorubicin (TLC-D99; Myocet) in patients with solid

tumors: an open-label, single-dose study. Cancer

Chemotherapy and Pharmacology, 54(6), pp.514-524.

Pasparakis, G. et al., 2010. Controlled polymer synthesis--

from biomimicry towards synthetic biology. Chemical

Society reviews, 39(1), pp.286-300.

Pisal, D. S., Kosloski, M. P., Balu-Iyer, S. V., 2010.

Delivery of therapeutic proteins. Journal of

Pharmaceutical Sciences, 99(6), pp.2557-2575.

Roberts, M. J., Bentley, M. D., Harris, J. M., 2012.

Chemistry for peptide and protein PEGylation.

Advanced drug delivery reviews, 54, pp.459-476.

Sharp, P. A. et al., 2011. The Third Revolution: The

Convergence of the Life Sciences , Physical Sciences

and Engineering.

Sheffield, W. P. et al., 2004. Effects of genetic fusion of

factor IX to albumin on in vivo clearance in mice and

rabbits. British Journal of Haematology, 126(4),

pp.565-573.

Shibata, H., Nakagawa, S., Tsutsumi, Y., 2005.

Optimization of protein therapies by polymer-

conjugation as an effective DDS. Molecules, 10(1),

pp.162-80.

Ta, H. T., Peter, K., Hagemeyer, C. E., 2012. Enzymatic

antibody tagging: toward a universal biocompatible

targeting tool. Trends in cardiovascular medicine,

22(4), pp.105-11.

Veronese, F., Pasut, G., 2005. PEGylation, successful

approach to drug delivery. Drug discovery today,

10(21), pp.1451-8.

Wagner, G. K., Pesnot, T., 2010. Glycosyltransferases and

their Assays. ChemBioChem, 11(14), pp.1939-1949.

Wohlfart, S. et al., 2011. Efficient Chemotherapy of Rat

Glioblastoma Using Doxorubicin-Loaded PLGA

Nanoparticles with Different Stabilizers. PLoS ONE,

6(5), p.e19121.

Wu, W. et al., 2009. Covalently combining carbon

nanotubes with anticancer agent: preparation and

antitumor activity. ACS nano, 3(9), pp.2740-50.

Yang, S. C. et al., 2008. Polyketal copolymers: a new

acid-sensitive delivery vehicle for treating acute

inflammatory diseases. Bioconjugate chemistry, 19(6),

pp.1164-9.

Zhao, P., Astruc, D., 2012. Docetaxel Nanotechnology in

Anticancer Therapy. ChemMedChem, 7(6), pp.952-

972.

CellularFactories-EmergingTechnologiesforFabricationofNanomedicines?

215