Far-field Scatter Measurements of Planar Optical Waveguides using

a Variable Launch System

Robert Ferguson, Irshaad Fatadin, Subrena Harris and James Allerton

National Physical Laboratory, Teddington, Middlesex, TW11 0LW, U.K.

Keywords:

OPCB, Waveguides, Far-field.

Abstract:

Polymer planar optical waveguides fabricated onto electrical printed circuit boards are an emerging technology

to provide high-speed communications on computer backplanes. Along with the key parameters of attenuation

and isolation, the variable launch system developed at NPL can now be used to measure the transmitted scatter

profile of optical printed circuit boards (OPCBs) in order to explore the relationship between launch condition,

waveguide and end-face quality. In this paper we describe the modifications to the existing NPL system and

measurements of the far-field intensity profiles of a group of reference waveguides using a variety of spot sizes

and numerical apertures.

1 INTRODUCTION

Polymer planar optical waveguides fabricated onto

electrical printed circuit boards and incorporated onto

computer backplanes are an emerging cost effective

technology to facilitate high-speed data transfer in

modern high speed computing and data storage sys-

tems. The integrated manufacture of these OPCBs has

been investigated (Selviah, 2008, Bamiedakis, 2012)

and is being further refined with demonstrators cur-

rently operating >10 Gb/s. Their bandwidth capac-

ity, size and lower energy demands ensure continuing

interest among the leading international communica-

tions companies. Along with the technical demands

of fabricating the boards or backplanes, a need to

characterise the actual guides themselves is also es-

sential. The optical performance of the waveguides

is an important aspect to refining the manufacturing

process (Kai Su, 2005). Currently these waveguides

are multimoded, operating at 850 nm and intended for

very high data rates. In addition to the fundamen-

tal parameters of attenuation and isolation, there is

a need to understand the losses associated with the

end-face surfaces and waveguide quality. An estab-

lished system at NPL already measures the attenua-

tion and isolation from the transmitted power and has

the ability to vary the launch spot size and numerical

aperture to fully explore the capability of these multi-

mode waveguides (Ferguson, 2012). This system has

now been modified to enable measurement scans of

far-field intensity profiles across a range of different

launch conditions.

2 THE MODIFIED

MEASUREMENT SYSTEM

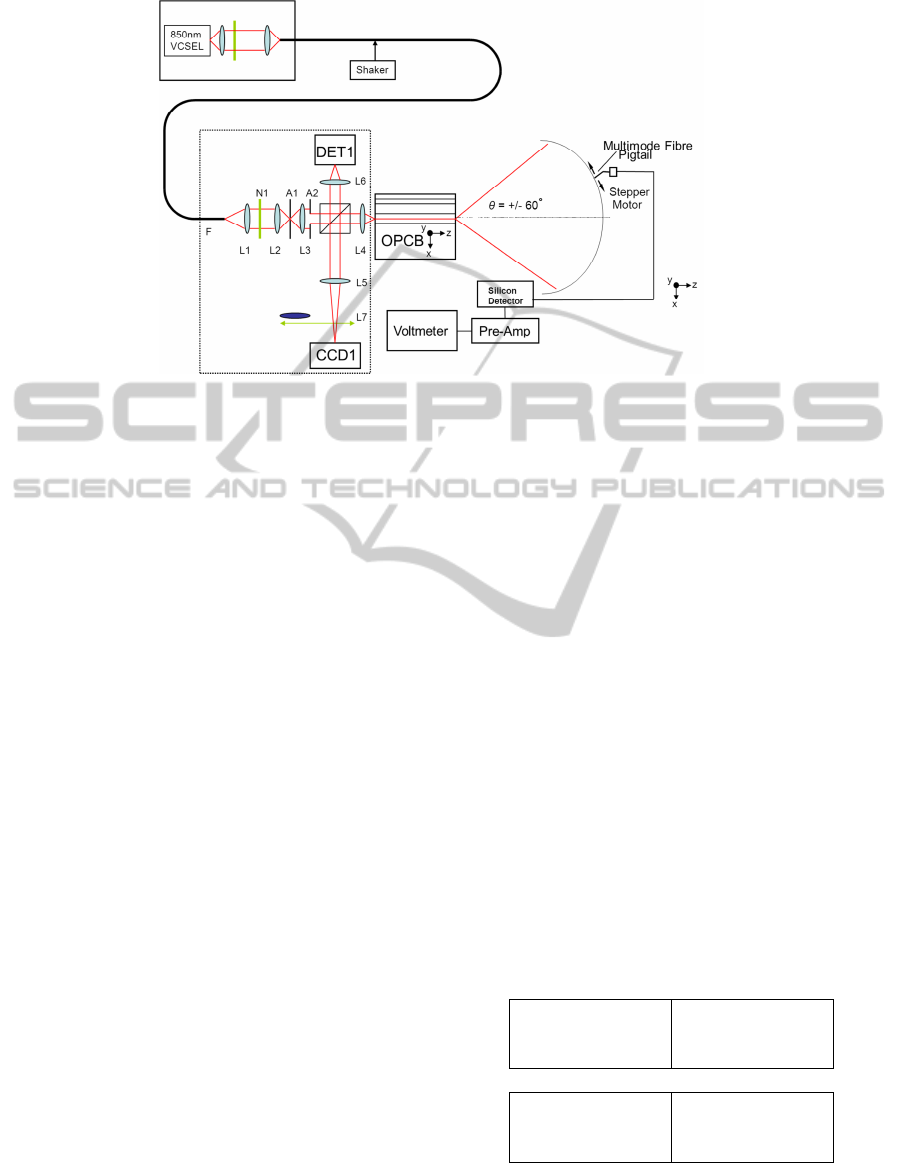

The modified variable launch system is shown in Fig-

ure 1 and builds on previous work carried out at NPL

(Ives, 2011, Ferguson, 2007). Light from an 850 nm

VCSEL laser is launched into a step-index fibre with

a 365 µm core and a numerical aperture (NA) of 0.22.

The fibre is shaken at a few Hertz with an amplitude

of a few millimetres to slowly scramble the speckle.

The fibre provides the input illumination to the vari-

able launch board. This allows the variation of the

launch spot size, which is defined by a range of in-

terchangeable pin-holes ranging from 5 to 100 µm

and the NA which is controlled by a variable aper-

ture giving numerical apertures in the range 0.02 to

0.28. The launch board also includes a reference de-

tector to monitor the launch power and a CCD with

imaging optics to allow the alignment of the launch

spot with the waveguide under test. The OPCB under

test and the receive optics were mounted on movable

stages. For attenuation measurements the output from

the waveguide under test is imaged onto a CCD array

to measure the total transmitted power. However, in

order to measure the far-field intensity of the trans-

mitted power P(θ) a detector is scanned around an arc

centred on the end of the waveguide under test. The

96

Ferguson R., Fatadin I., Harris S. and Allerton J..

Far-field Scatter Measurements of Planar Optical Waveguides using a Variable Launch System.

DOI: 10.5220/0004334200960100

In Proceedings of the International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2013), pages 96-100

ISBN: 978-989-8565-44-0

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

Figure 1: Measurement system optical layout. F = 365 µm 0.22 NA step index fibre; L1 = 50 mm focal length lens; L2, L3

and L4 = 16 mm focal length 0.4 NA objective; L5 = 150 mm focal length lens; L6 = 30 mm focal length lens; L7 = 60 mm

focal length lens; N1 = neutral density filter; A1 = interchangeable pin-hole to set the launch spot size, A2 = variable aperture

to control the launch spot NA. The CCD arrays image the near field surface of the waveguide, and with the addition of L7 can

image the far field distribution.

detector comprises of a 100 µm core diameter cleaved

fibre pigtail mounted at the centre of a frustrum cone

which is mounted on a rotation stage and scanned in

angular steps of 1

o

. The fibre is connected to a sili-

con detector, pre-amplifier and voltmeter to measure

the far-field intensity profiles. To ensure that the de-

tector is in the far-field, the separation between the

waveguide and the detector only needs to be greater

than a few mm. However, to ensure good angular res-

olution the detector was located at 10 mm from the

end of the waveguide. The size of the detector is an-

other factor which determines the angular resolution,

the fibre pigtail of a photodiode can provide a small

area detector allowing the fibre-detector distance to

be reduced without degrading the angular resolution.

Reference measurements were made on the modified

system using a characterised multimode fibre with an

established value of 0.195 ± 0.005 NA. The measured

values ranged from 0.191 to 0.208 ±0.01 NA. The

worst case Type A standard uncertainty (at ∼ ±35

o

)

is ±1.0 dB. The uncertainties include the contribu-

tions associated with launch condition, the waveguide

condition, the power measurements and the measure-

ment repeatability and reproducibility. The uncertain-

ties associated with the power measurement include

the linearity of the reference detector. Uncertainties

associated with the waveguide condition include the

quality of the end faces and the alignment of the end

face. All of these sources of uncertainty require fur-

ther study.

3 END FACE QUALITY

To study the impact of surface roughness associated

with the waveguides for the far-field measurements, a

technique was developed to polish the end faces based

on traditional optical glassworking methods. Surfaces

were measured using a Taylor Hobson Form Taly-

surf PGI 1000. The mean values as well as a typ-

ical surface scan are summarised below for the sur-

face roughness measurements where Rv is the largest

profile valley depth within the sampling length and

Ra is the arithmetic mean of the absolute ordinate

values within the sampling length (Leach, 2001). It

can be seen that the polishing process significantly re-

duces the surface damage and produces surface quali-

ties comparable to optically polished commercial op-

tics. The resolution of the measuring instrument was

∼12 nm in the z-axis.

Wafer Sawn:

End A:

Rv = 3.55 µm +/- 0.30 µm

Ra = 0.50 µm +/- 0.07 µm

End B:

Rv = 2.83 µm +/- 0.46 µm

Ra = 0.33 µm +/- 0.10 µm

Optically Polished:

End A:

Rv = 0.20 µm +/- 0.05 µm

Ra = 0.06 µm +/- 0.03 µm

End B:

Rv = 0.32 µm +/- 0.03 µm

Ra = 0.13 µm +/- 0.03 µm

Figure 2: Scan length was ∼3 mm with 5 parallel runs car-

ried out on each end of the board. Note that standard uncer-

tainties are quoted.

Far-fieldScatterMeasurementsofPlanarOpticalWaveguidesusingaVariableLaunchSystem

97

Figure 3: Typical surface roughness scan using the Talysurf

PGI 1000 made on one of the polished ends of the sample.

4 FAR-FIELD MEASUREMENTS

OF TRANSMITTED POWER

Measurements were made on a sample group of 30

x 30 µm siloxane (Kai Su, 2005) waveguides, ∼ 125

mm in length on an FR4 board produced using pho-

tolithography. The group was measured with both

wafer sawn and polished end faces. Using the system

described in Section 2, the transmitted power P(θ)

was measured over an angular scan range of ±60

o

in

1

o

steps. At each angular measurement an average of

100 frames was taken to improve the signal-to-noise

ratio and average the speckle. The entire measure-

ment scan was repeated three times to monitor the

stability of the launch. The measured power was nor-

malised to the reference power and measured using

the pick-off detector on the launch board, DET1. The

camera CCD1 is only used to allow alignment and fo-

cussing of the launch spot onto the input surface of

the waveguide under test. The launch NA was ini-

tially varied to investigate the subsequent changes in

the scatter profile for the different surfaces using a

spot size of 20 µm. More comprehensive measure-

ments were then carried out on the sample waveguide

group with the launch condition set to 0.16 NA and

an under-filled spot of 20 µm in order to emulate typ-

ical integrated VCSEL sources. The NA was calcu-

lated using the sine of the half angle at which the far

field intensity dropped to 5% of the peak value (IEC

60793-1-43 Ed. 1.0, 2001-07).

Figure 4: Sample OPCB containing groups of planar silox-

ane waveguides.

5 LAUNCH NUMERICAL

APERTURE COMPARISON

Changes were made to the launch condition by in-

creasing the numerical aperture from between 0.02,

0.16 and 0.28 NA. Far-field scans were carried out

with the end surfaces wafer sawn and with the ends

optically polished. As expected, the profiles reveal a

change in the exit NA with respect to the set launch

condition NA as more modes are excited within the

waveguide. However, the increase in the exit NA is

minimal once the launch NA increases beyond 0.16 to

0.28. The greater scatter associated with wafer sawn

surfaces shows a slight increase for each of the calcu-

lated NAs.

Figure 5: Far-field intensity scans of selected waveguides.

The graph shows normalised signal against angle on sam-

ple with wafer sawn end faces with a launch at End A.

Also shown are the calculated numerical apertures of each

waveguide.

Figure 6: Far-field intensity scans of selected waveguides.

The graph shows normalised signal against angle on sample

with optically polished end faces with a launch at End A.

Also shown are the calculated numerical apertures of each

waveguide.

PHOTOPTICS2013-InternationalConferenceonPhotonics,OpticsandLaserTechnology

98

6 RESULTS

AND UNCERTAINTIES

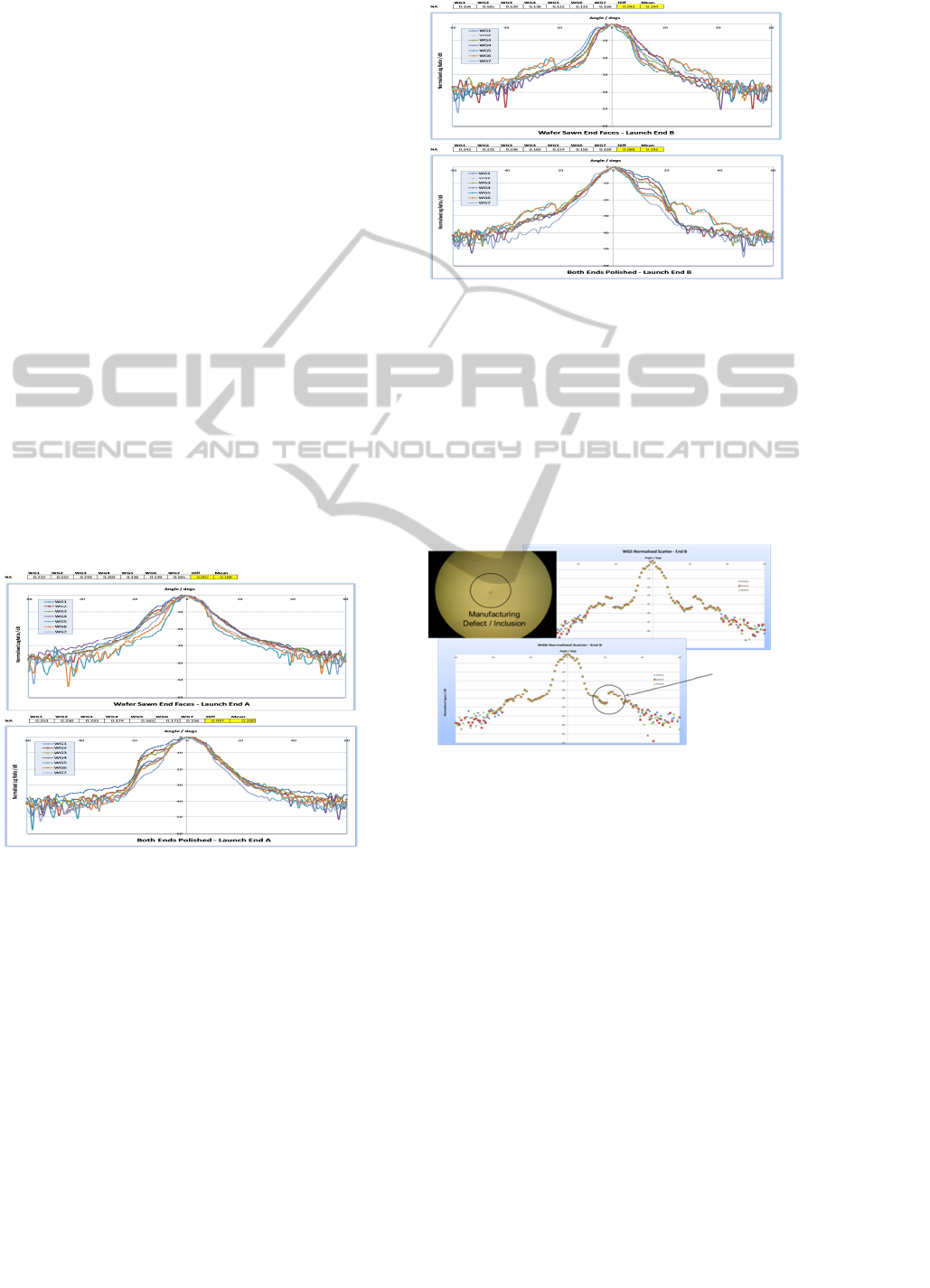

Figures 7 and 8 show the far-field scans for the se-

lected group of waveguides with two different end-

face surface treatments (with launches at ends des-

ignated A and B). For comparison measurements

launched into end A are shown first. The greater scat-

ter associated with the rougher surface of the wafer

sawn end faces tends to obscure the asymmetry as-

sociated with the waveguides and their performance.

The asymmetry of the scans is likely to be due to

corresponding material asymmetries in the waveg-

uide cross-section ie: a non-uniform refractive index

profile across the waveguides and along their length.

When looking at the waveguide group as launched

from end B the plots compare well between the two

different surface conditions. They also compare with

the scan profiles when launched at end A, especially

with the polished end faces. However, there is a clear

difference for the waveguides number 5 and 6 where

the scans exhibit a profile suggesting the presence of

cladding modes. As the scan has not been mathemat-

ically corrected for any electrical field inversion they

must be due to the presence of irregularities or defects

affecting these particular waveguides.

Figure 7: Far-field intensity scans of waveguide group con-

taining 7 individual waveguides. Graph shows normalised

signal against angle on sample with wafer sawn and pol-

ished end faces with a launch at End A. Also shown are the

calculated numerical apertures of each waveguide.

7 FAR-FIELD DISCONTINUITIES

Further investigation of waveguides 5 and 6 showed

how the far-field intensity profile can also be bene-

ficial in revealing any manufacturing defects in the

Figure 8: Far-field intensity scans of waveguide group con-

taining 7 individual waveguides. Graph shows normalised

signal against angle on sample with wafer sawn and pol-

ished end faces with a launch at End B. Also shown are the

calculated numerical apertures of each waveguide.

waveguides. A defect was observed that lay between

the two waveguide tracks, caused during the pho-

tolithographic manufacturing process. This produced

subsequent discontinuities in the associated far-field

scans (See Fig. 9)

Far-Field

Discontinuity

Figure 9: Far-field intensity scans of selected waveguides

5 and 6 affected by identifiable defect along waveguide

length.

8 CONCLUSIONS

We have modified an existing system to investigate

the far-field scatter of planar optical waveguides with

respect to launch condition and end face quality. The

scans have revealed that the dynamic range increases

with polished faces (up to ∼4 dB), which is consis-

tent with the improvement in the total attenuation ob-

tained through polishing the end faces. For each scan

the exit numerical aperture of the waveguides with re-

spect to the launch condition has been calculated from

the far-field scan. Polishing has been shown to give

Far-fieldScatterMeasurementsofPlanarOpticalWaveguidesusingaVariableLaunchSystem

99

no advantage in terms of NA which only increases

slightly when the board ends are polished from ∼0.03

to ∼0.09 NA. An important feature of the work has

been the ability to make use of the scanning process

to detect board defects that can affect the performance

of the waveguides. Discontinuities in the far-field pro-

file relate to identifiable board defects or inclusions

and the method has the potential to provide a rigorous

technique to assess the quality of waveguide manu-

facture. Polishing appears to accentuate any waveg-

uide inhomogeneity with the increased scatter due to

the rougher wafer sawn surfaces masking any waveg-

uide irregularities. There is evidence in the scans that

suggests the waveguide performance is not always bi-

directional. It is intended to use this set up to do

a more systematic study of the transmission quality

of waveguides produced using different methods and

the relationship between launch conditions and the re-

ceive detectors deployed in working boards operating

within data storage systems under a range of environ-

mental conditions.

ACKNOWLEDGEMENTS

We would like to thank Dr. Nikos Bamiedakis, Dr.

Terry Clapp and Professor Richard Penty of Cen-

tre of Advanced Photonics and Electronics, Cam-

bridge, for providing the sample waveguides and Neil

Lockmuller of the Engineering Measurement Ser-

vices Group at NPL for providing surface metrology

support.

This work was supported by the Department for

Business Innovation and Skills at NPL.

REFERENCES

D. R. Selviah, F. A. Fernndez, I. Papakonstantinou, K.

Wang, H. Bagshiahi, A. C. Walker, A. McCarthy, H.

Suyal, D. A. Hutt, P. P. Conway, J. Chappell, S. S. Za-

kariyah and D. Milward ”Integrated optical and elec-

tronic interconnect printed circuit board manufactur-

ing”, Circuit World, vol. 34, pp. 21-26, 2008.

Bamiedakis, N. Hashim, A., Penty, R. V., White, I. H., ’Re-

generative polymeric bus architecture for board-level

optical interconnects’, Optics Express 11625, Vol 20,

No. 11, 21 May 2012.

Kai Su, Jon V. DeGroot, Jr., Ann W. Norris and Peter

Y. Lo., ’Siloxane Materials for Optical Applica-

tions’, Advanced Technologies and Venture Business,

Dow Corning Corporation, 2200 W. Salzburg Road,

Midland, MI, USA 48686. Proc. Of SPIE Vol. 6029

60291C-7, (2005).

Ferguson, R., ’Waveguides Need Characterization, Too’,

Photonics Spectra, February 2012, pp.58-60.

Ives, D., Ferguson, R. A., Harris, S., ’Development of a

variable launch attenuation and isolation measurement

system for optical waveguides’, Applied Optics, Vol.

50, No. 22, 1 August 2011, pp. 4268 - 4275.

R. A. Ferguson and S. Harris, ”Development of an opti-

cal system with controlled launch conditions for the

characterisation of polymer optical fibre (POF)”, Op-

tical Fibre Measurement Conference Digest, 15 Octo-

ber 2007.

Leach, R. Measurement Good Practice Guide Number

37 - The Measurement ofSurface Texture using Sty-

lus Instruments, National Physical Laboratory, Crown

Copyright 2001, ISSN 1368-6550, July 2001.

IEC 60793-1-43 Optical fibres - Part 1-43: Measurement

methods and test procedures - Numerical aperture,

Publication date 26-07-2001.

PHOTOPTICS2013-InternationalConferenceonPhotonics,OpticsandLaserTechnology

100