Early Energy Estimation in the Design Process

of Networked Embedded Systems

Patrick Heinrich and Christian Prehofer

Fraunhofer Institute for Communication Systems ESK, Hansastr. 32, 80686 Munich, Germany

Keywords: Embedded Systems, Energy-efficiency, Network-wide Optimization, Adaptive Systems, Automotive.

Abstract: This paper focuses on estimating energy consumption in networked, embedded systems during the early

stages of design. In such systems with long development cycles, early decisions regarding hardware and

software have a major impact on energy consumption, which places constraints on the design during later

stages of the development process. The main objective of this paper is to model the energy consumption

throughout the entire design process and to provide a structure for more detailed models and validation. This

requires determining which design decisions and system parameters are available in each of the develop-

ment phases. Using this approach as a basis, energy consumption models are created for each phase. By re-

lying on different estimation techniques, energy consumption estimates are formulated based on the infor-

mation that is available at every development phase. The main goal is to illustrate a design flow that pro-

duces increasingly accurate estimates in each phase.

1 INTRODUCTION

This paper focuses on estimating energy consump-

tion in networked, embedded systems during the

early stages of design. As embedded systems be-

come more prevalent and powerful, they are con-

suming more energy. Our research concentrated on

the area of networked, embedded systems commonly

found in automobiles, aircraft and industrial sys-

tems. In today's luxury-class vehicles for instance,

the electrical and electronic components draw up to

2.5 kW (Little, www.adlittle.com); (Monetti and

Ulshöfer, 2011). Compared to what the engine re-

quires, 2 kW seems small. However, the electrical

components consume energy during every mode of

operation, even when in standby mode. Electrical

engines consume most of their energy during accel-

eration and even here the maximum power is seldom

demanded. An increase of 100 W thus means that

fuel consumption rises by 0.1 liter per 100 km, lead-

ing to an increase in CO

2

emissions of 2.5 g per

km (Monetti and Ulshöfer, 2011). This illustrates the

considerable potential for energy savings, an aspect

that must be factored in during the development

process.

Embedded systems designers, such as those ac-

tive in the automotive industry, are frequently given

energy consumption requirements for the finished

product. This makes it necessary to estimate the

energy consumption early in the design process.

This also makes it possible to evaluate different

designs with respect to energy consumption. Be-

cause the automotive industry has especially long

development cycles, hardware and software choices

must be made very early during the design pro-

cess (Weber, 2009). Optimizing energy consumption

early in the design process can therefore be a major

challenge. Networked systems feature a wide range

of technologies and topologies that significantly

impact energy consumption down the road. For

instance, the placement of functionality within an

ECU impacts partial networking modes, which in-

volves deactivating certain system components that

are not being used. This can reduce energy by as

much as 30 percent (Monetti and Ulshöfer, 2011).

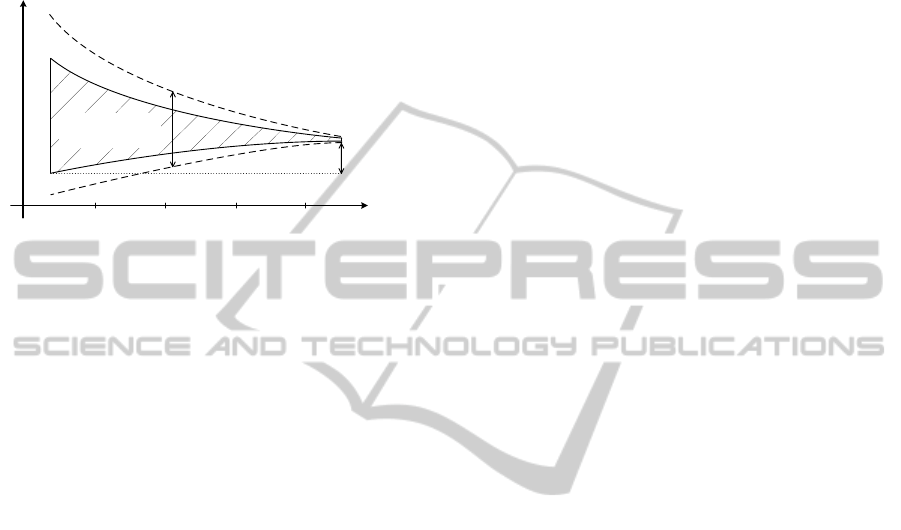

Figure 1, which depicts the various phases of a

typical system development process, reveals that the

energy savings potential gradually decreases over

the course of development. Energy savings estimates

are also imprecise, as shown by the dotted line.

In the early phase, the developer designs the

electronic control unit (ECU) system based only on

the features outlined in the specification. Design

choices such as software components or network

technologies impact the energy consumption. Modi-

fying these design choices at a later point in the

214

Heinrich P. and Prehofer C..

Early Energy Estimation in the Design Process of Networked Embedded Systems.

DOI: 10.5220/0004334502140220

In Proceedings of the 3rd International Conference on Pervasive Embedded Computing and Communication Systems (PECCS-2013), pages 214-220

ISBN: 978-989-8565-43-3

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

process is often difficult or too expensive to carry

out (Ross and Perry, 1999). In many design phases,

the designer has to evaluate different design varia-

tions to realize optimal energy consumption, but a

detailed analysis is not possible in these phases.

Figure 1: Energy Design Space during System Develop-

ment.

The main objective of this paper is to model the

energy consumption throughout the entire develop-

ment process. To do this, we have to determine

which design decisions and system parameters are

available in the various phases. Using this infor-

mation, we can then develop energy consumption

models for each phase. While using several different

estimations, the main goal is to show a design flow

that produces increasingly accurate estimates in each

phase.

A wealth of research has been conducted into de-

signing energy efficient systems comprised of indi-

vidual components. What has been lacking is corre-

sponding research considering the entire networked

embedded systems. With these systems, it is particu-

larly important to examine early on to what extent a

specific design impacts energy consumption.

Our work focuses on systems comprised of mul-

tiple ECUs connected via a communication network.

While this type of system can be found in various

environments, the impetus for our research stems

from the automotive industry. Vehicle systems fea-

ture many technologies with energy-saving designs,

such as the partial networking modes available in

AUTOSAR (www.autosar.org). The next step is to

determine how to use these technologies as efficient-

ly as possible. The aim of this paper is to illustrate

how system developers can easily and accurately

evaluate the impact of their design choices on ener-

gy consumption during the early stages of the design

process. The results can be used beyond automotive

embedded systems.

2 IMPACT OF ENERGY

CONSUMPTION

ON THE SYSTEM

DEVELOPMENT PROCESS

This section outlines the parameters for estimating

energy consumption when developing networked

embedded systems. These parameters are systemati-

cally analyzed with respect to accuracy and availa-

bility during the development process.

Developers have to make design choices in each

phase. These decisions are intertwined and define

the system in more detail as the development pro-

cess moves forward. For example, software design

begins by defining the required features, which are

then evolved into more detailed, intertwined indi-

vidual tasks. This is followed by the definition of the

internal structure of the tasks. After implementation,

the detailed timing parameters are available.

The typical system development processes are

structured into distinct phases as described in the

waterfall model (Boehm, 1981) or V-Model XT (V-

Modell XT: Part 1, www.ftp.tu-clausthal.de). The

relevant phases which influence the energy con-

sumption and the available information to estimate

the energy consumption are discussed below.

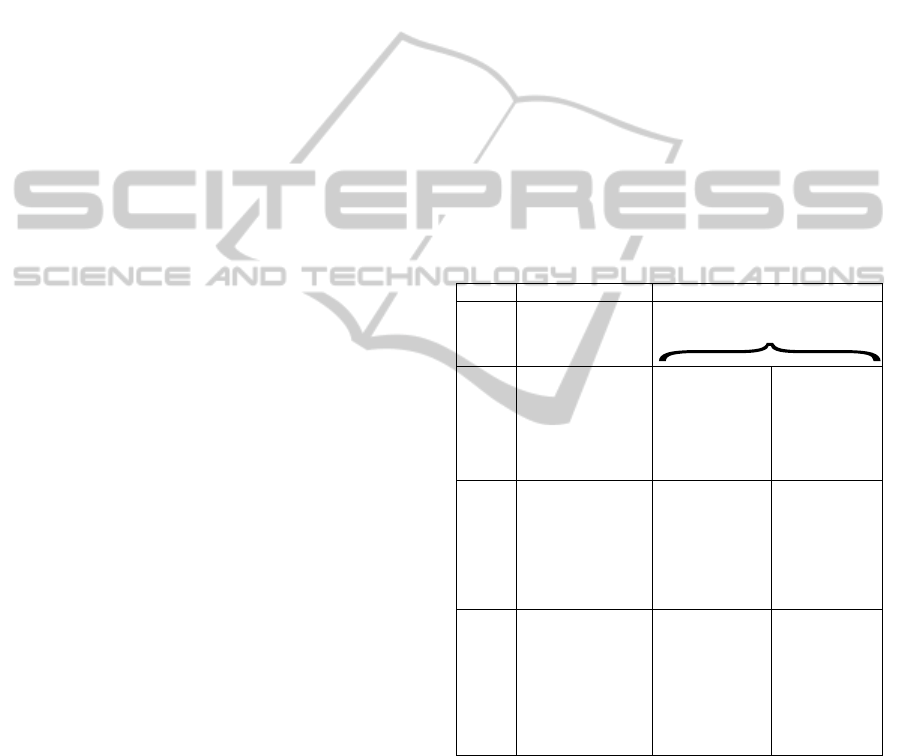

Table 1 summarizes the information available at

every design phase. The objective here is to illustrate

how accuracy increases from phase to phase or how

the available information is replaced by more accu-

rate data in the following phase. The parameters

presented here are used to estimate the energy con-

sumption in the next section. The values of the pa-

rameters are not only influenced by the design

choices (the task allocation), but how the choices are

implemented, such as the chosen hardware or oper-

ating system. While much research has been carried

out in the area of energy-saving technologies at the

component level, less attention has been paid to

understanding the potential for energy saving at the

network-wide level.

2.1 System Requirements

This phase defines the functional and non-functional

requirements of the entire system, such as the num-

ber of features or maximum energy consumption.

Afterwards, developers have a clear picture of the

required features, which allows them to estimate the

number of ECUs and how the features are allocated

to the individual ECUs. (In 2005, automobiles were

equipped on average with around 65 ECUs and 165

features (Little, www.adlittle.com)). Energy con-

system’s energy

consumption

time

System

Requirements

System

Architecture

System

Design

HW/SW

Development

System

Integration

Error Bandwidth of Energy

Consumption Estimation

Possible Energy

Consumption

Unused Energy

Saving Potential

EarlyEnergyEstimationintheDesignProcessofNetworkedEmbeddedSystems

215

sumption can be estimated by classifying each fea-

ture (navigation system, engine controls, electric

windows for instance) based on the required pro-

cessing power, necessary ECU size and what func-

tion the feature is intended to provide. The required

size and purpose of the ECUs are also factored in to

estimate the energy consumption. Large semicon-

ductor manufacturers such as Freescale Semiconduc-

tors already group their microcontrollers according

to the function or application. Freescale has six clas-

ses of automotive applications such as (Freescale’s

portfolio, www.freescale.com) advanced driver

assistance systems, chassis, safety and infotainment.

Each class of microcontroller features specific ener-

gy consumption parameters, which can be used to

define ECU energy classes.

2.2 System Architecture

In embedded systems, the features are implemented

in a distributed fashion to create specialized ECUs

that are installed in close proximity to the function

they serve. One feature consists of several tasks,

which are often allocated across different ECUs.

This phase defines the system architecture, including

hardware, number of ECUs, topology and software.

In other words, it defines how the tasks are allocated

across the ECUs and how they interact. Understand-

ing how the tasks interact also permits the developer

to estimate the required network bandwidth. While

the internal structure of the tasks is unknown, the

developer can estimate the processing power by

relying on various processing power classifications,

e.g. derived from existing tasks.

Industry benchmark tests are already available to

evaluate automotive microcontroller performance.

The Embedded Microprocessor Benchmark Consor-

tium (AutoBench 1.1, http://www.eembc.org) de-

fines 15 benchmark tests that include angle to time

conversion, bit manipulation, fast Fourier transform

and road speed calculation. The classifications can

be formed by grouping tasks that require similar

processing power, thus allowing a more detailed

estimate.

2.3 System Design

This phase specifies the elements of the previous

phase in more detail. With respect to the software,

this means the internal structure of the tasks, includ-

ing the algorithms and operating systems used. This

makes it possible to estimate the execution time of

the tasks, which is carried out using function point

analysis (Albrecht, 1979), cyclomatic complexity

(McCabe, 1976) or equivalent metrics. The actual

execution times are available after the software has

been implemented on specific hardware. After

choosing the processor and other hardware, the de-

veloper can then estimate the energy consumption of

the ECU.

2.4 Hardware/Software Development

This phase involves hardware and software imple-

mentation, which provides more detailed infor-

mation concerning task processing time, worst case

execution time (WCET) and hardware power con-

sumption. The beginning of this phase can be used

to simulate ECU execution and active/sleep times or

to measure the energy consumption using evaluation

boards, assuming they are nearly identical to the

installed hardware. A fairly accurate estimate of the

energy consumption is then possible at this point.

Table 1: Breaking down the information into more detail

during the development process.

Hardware Software

System

Require-

quire-

ments

≈ Number of ECUs

ECU Energy Class

Number of Features

Feature Computation Class

System

Archi-

tecture

Number of ECUs

ECU Energy Class

Topology

≈ Network Band-

width

Software

Architecture

(tasks as black

box):

- Dependencies

- Cycle Times

- Allocation

≈ Numb. of

Tasks

Task Computa-

tion Effort Class

System

Design

Number of ECUs

Topology

Network Bandwidth

≈ ECU- and

Network-specific

Energy Consump-

tion

Software

Architecture

(tasks as black

box):

- Dependencies

- Cycle Times

- Allocation

Numb. of Tasks

Task (internal)

Computation

Effort, e.g.

using function

point analysis

HW/SW

Devel-

opment

Number of ECUs

Topology

Network Bandwidth

ECU- and Network-

specific Energy

Consumption

ECU Active and

Sleep Times

Software

Architecture

(tasks as black

box):

- Dependencies

- Cycle Times

- Allocation

- Active and

Sleep Times

Numb. of Tasks

Task WCET

3 ESTIMATING ENERGY

DURING THE DEVELOPMENT

PROCESS

This section outlines equations for estimating energy

consumption in each of the development phases. The

equations rely on the information that is available in

each phase, building upon each other as the devel-

PECCS2013-InternationalConferenceonPervasiveandEmbeddedComputingandCommunicationSystems

216

opment process progresses. Since information might

be missing or estimated in the various phases, each

equation features a specific degree of accuracy that

improves over time (see figure 1).

3.1 System Requirements

Equation 1 depicts an energy estimates based on the

number of features and ECUs. The number of fea-

tures n

feat

of one feature class is multiplied by the

individual feature computation factor c

feat

. Multiply-

ing by the required energy consumption per ECU,

which is represented by the ECU energy classes

E

HWclass

, then provides the estimated energy con-

sumption per ECU.

,,

∙

,

∙

,

(1)

E

1

represents the energy estimate of the entire sys-

tem within the system requirements phase. The ac-

curacy of this equation is based on the number and

accuracy of the feature computation and hardware

energy classes.

3.2 System Architecture

Equation 2 depicts an energy consumption estimate

using the software and hardware architecture infor-

mation. This means the number of tasks of one class

n

task

is multiplied by the task computation class fac-

tor c

task

. E

HWclass

represents the ECU energy classes

as mentioned above, but is more accurate since the

exact number of ECUs is known. At the system

architecture level, the energy consumption of com-

munication E

com

can be estimated since the hardware

architecture and the allocation of tasks are known

factors. (Note: While equation 1 and 2 appear to be

very similar, it is important to note that one feature

consists of multiple tasks. The sum of the tasks is

therefore much more detailed. This is also caused by

more task classes than feature classes.)

,,

∙

,

∙

,

(2)

E

2

represents the energy estimate of the entire sys-

tem within the system architecture phase. The accu-

racy of this equation is based primarily on the num-

ber and degree of accuracy of the task computation

and hardware energy classes.

3.3 System Design

Equation 3 shows the energy estimate using the

early-stage information regarding hardware power

consumption and task internal software structure.

The equation uses metrics to estimate the evaluation

times of the tasks as mentioned in section 2.3. Fac-

tor n

metric

represents the number of metric-specific

elements within a task, e.g. the number of function

points. The number of metric-specific elements

multiplied by the metric-element-specific computa-

tion time results in an estimation of task execution

time. The estimated computation time multiplied by

the ECU-specific power consumption P

HW

per ECU

results in the energy consumption per ECU. The

energy required for communication is then added to

the aggregate ECU energy consumption. This energy

model results in more accurate energy estimates than

using the above equations.

,,

∙

,

∙

,

(3)

E

3

represents the energy estimate of the entire sys-

tem within the system design phase. The accuracy of

this equation is based primarily on the accuracy of

the task execution time estimation metric and the

hardware power consumption estimate.

3.4 Hardware/Software Development

Equations 4-7 depict a model for estimating the

energy consumption of a system configuration as

outlined in (Heinrich and Prehofer, 2012). The ener-

gy consumption for a specific configuration is mod-

eled by adding together the energy consumed during

task executions (E

task

), sleep periods (E

sleeps

) includ-

ing the associated mode changes n

s

and communica-

tions (E

com

). Energy consumption is calculated using

a common multiplier t

mult

of all task periods, which

also determines the number of sleep states n

s

.

Apart from the ECU power consumption P

HW

at

a specific CPU frequency f

CPU

, the equation also

factors in the energy required to communicate via a

network E

c

per bit (including network overhead), as

well as the energy consumed by components during

sleep states.

The tasks and the communication between the

tasks have specific parameters. The assumption is

that the task execution time at a specific frequency

can be converted to the task execution time t

e

at

another frequency f

te

. The cycle time is specified by

t

c

and the necessary communication per cycle be-

EarlyEnergyEstimationintheDesignProcessofNetworkedEmbeddedSystems

217

tween tasks by c

t

. The sum of the single task execu-

tion times yields the task active time t

tasks

per ECU.

,

,

.

(4)

With

∙

,

∙

,

,

∙

(5)

and

∙

∙

∙

(6)

and

,

∙

,

(7)

The accuracy of these equations depends on the

accuracy of the individual parameters. Some param-

eters are still difficult to specify after system integra-

tion because of cross-influences or because the pa-

rameters are difficult to measure. A good example is

the energy required to execute one task on a com-

plex ECU with many parallel tasks scheduled by an

operating system.

4 RELATED RESEARCH

The method described in (Donnelly et al., 2006)

includes energy estimates during the development

process. The concept relies on a holistic approach to

developing energy-efficient products by using

checklists to ensure that specific energy aspects are

factored in. Our approach differs in that it focuses

specifically on the impact of energy consumption in

networked embedded systems. The paper referenced

in (Seo et al., 2009) discusses the early-stage estima-

tion of energy consumption for communication tasks

based on the architecture of the system. In this case

however, the assumption is that the energy demands

are the same for each device, which is not the case in

our system. The tool referenced in (Tensilica Inc,

http://www.tensilica.com) enables early-stage ener-

gy estimates for system-on-a-chip designs to opti-

mize processor and memory. This approach requires

software source code however. As part of our paper

"Network-Wide Energy Optimization for Adaptive

Embedded Systems" (Heinrich and Prehofer, 2012),

we previously presented models for estimating ener-

gy consumption at the network level. The publica-

tion "Energy Consumption Estimation in Embedded

Systems” (Konstantakos et al., 2008) furthermore

examines ECU-wide energy estimation. While both

of the latter two approaches are carried out during

the system design phase, they do not allow for esti-

mating energy consumption during the earlier devel-

opment phases.

Some of the research activity in this area focuses

on the hardware/software development or system

runtime phases. One approach to simplifying the

implementation of energy saving techniques during

hardware/software development is outlined in (Apel

et al., 2010). This relies on a modular approach in

which energy-saving functions can be selected and

implemented separately. The technique described in

(Shankaran et al., 2009) uses adaptive planning and

resource management to adapt the system to varying

workloads, but without focusing on energy efficien-

cy.

Most energy saving technologies optimize the

energy consumption of one component (i.e. CPU)

after the development phase (at runtime). Examples

include dynamic hardware resource management

and dynamic voltage/frequency scaling. Other meth-

ods focus on resource optimization, such as energy-

efficient task scheduling (Kang et al., 2002); (Hu

and R. Marculescu, 2004) or trade-offs such as re-

ducing quality of service to lower energy consump-

tion (Rusu et al., 2003); (Baker, 2011). A lot of

research concentrates on the reduction of system-

wide energy consumption, which in this paper

equates to component or ECU-wide. Another meth-

od outlined in (Benini et al., 2000) uses dynamic

power management (DPM), which deactivates idle

system components to save energy. The approach

described in (Jejurikar and Gupta, 2004)uses dynam-

ic voltage scaling and DPM to reduce energy con-

sumption across all components. It also factors in the

energy consumption of peripherals, such as memory,

in standby and processor activation/deactivation

periods. The software framework described in (Zeng

et al., 2008)uses various energy-saving techniques

and looks for corresponding trade-offs. While the

objective is to reduce component-wide energy con-

sumption for different applications during runtime,

this approach neglects the energy required for recon-

figuration.

None of these approaches use the possibilities of

optimizing energy consumption at the network level.

The approach discussed in (Heinrich and Prehofer,

2012) looks at the potential for network-wide energy

optimization by analyzing an embedded system via a

case-study. Network-wide optimization within wire-

less sensor networks has also been evaluated, but

with a focus on energy-efficient message routing.

PECCS2013-InternationalConferenceonPervasiveandEmbeddedComputingandCommunicationSystems

218

5 CONCLUSIONS

This paper outlines a phase-by-phase process for

estimating energy consumption in networked em-

bedded systems for typical development processes.

The goal is to integrate energy estimation in the

design process and to give developers the possibili-

ties to evaluate how design variants impact energy

consumption. To make this possible, energy estima-

tion must be enabled in the early phases of design

since every decision further limits the ability to

make design changes during later phases.

In this paper we created formalized energy con-

sumption estimates using various existing techniques

and the information that is available at each stage of

the process. The models we developed for net-

worked embedded system designs, such as for auto-

motive systems, include the effort required for each

task, sleep states and network communication.

Our research focused on the development of a se-

ries of models that factor in the information acquired

during each development phase and refine the model

of the prior phase. To date, other research work has

not considered a systematic analysis and examina-

tion of energy consumption during each develop-

ment phase. Future research will include validation

of the models using measurements during system

design.

REFERENCES

Arthur D. Little, Market and Technology Study Automo-

tive Power Electronics 2015. Available:

http://www.adlittle.com/downloads/tx_adlreports/AD

L_Study_Power_Electronics_2015.pdf.

A. Monetti, T. Otter, and N. Ulshöfer, “Spritverbrauch

senken, Reichweite erhöhen: System-Basis-Chip für

den Teilnetzbetrieb am CAN-Bus,” Elektronik

Automotive, no. 11, pp. 24–27, 2011.

J. Weber, Automotive Development Processes: Processes

for Successful Customer Oriented Vehicle

Development. Berlin, Heidelberg: Springer-Verlag

Berlin Heidelberg, 2009.

J. E. Ross and S. Perry, Total quality management: Text,

cases and readings, 3rd ed. Boca Raton, Fla: St. Lucie

Press, 1999.

AUTOSAR, Automotive Open System Architecture -

Homepage. Available: www.autosar.org.

B. W. Boehm, Software engineering economics.

Englewood Cliffs, NJ: Prentice-Hall, 1981.

V-Modell XT: Part 1: Fundamentals of the V-Modell.

Available: http://ftp.tu-clausthal.de/pub/institute/

informatik/v-modell-xt/Releases/1.3/V-Modell XT

HTML English (2012, Aug. 06).

Freescale’s portfolio of automotive microcontrollers.

Available: www.freescale.com/webapp/sps/site/

homepage.jsp?

code=IFATOATMTV

The Embedded Microprocessor Benchmark Consortium,

AutoBench 1.1: Software Benchmark Data Book.

Available: http://www.eembc.org/techlit/datasheets/

autobench_db.pdf.

A. J. Albrecht, “Measuring Application Development

Productivity,” Proceedings of the Joint SHARE,

GUIDE, and IBM Application Development

Symposium, Monterey, California, October 14–17,

IBM Corporation (1979), pp. 83–92.

T. McCabe, “A Complexity Measure,” IIEEE Trans.

Software Eng, vol. 2, no. 4, pp. 308–320, 1976.

P. Heinrich and C. Prehofer, “Network-Wide Energy

Optimization for Adaptive Embedded Systems,” in

Proceedings of the 4th Workshop on Adaptive and

Reconfigurable Embedded Systems (APRES 2012),

2012, pp. 24–27.

K. Donnelly, Z. Beckett-Furnell, S. Traeger, T.

Okrasinski, and S. Holman, “Eco-design implemented

through a product-based environmental management

system,” Journal of Cleaner Production, vol. 14, no.

15-16, pp. 1357–1367, 2006.

C. Seo, G. Edwards, D. Popescu, S. Malek, and N.

Medvidovic, “A framework for estimating the energy

consumption induced by a distributed system's

architectural style,” in Proceedings of the 8th

international workshop on Specification and

verification of component-based systems - SAVCBS

'09: ACM Press, 2009, p. 27.

Tensilica, Inc, Optimizing for Energy Using the Xenergy

Energy Estimator Tool: Application Note. Available:

http://www.tensilica.com/uploads/pdf/XenergyEstimat

ion.pdf.

V. Konstantakos, A. Chatzigeorgiou, S. Nikolaidis, and T.

Laopoulos, “Energy Consumption Estimation in

Embedded Systems,” IEEE Trans. Instrum. Meas,

vol.

57, no. 4, pp. 797–804, 2008.

S. Apel, D. Batory, K. Czarnecki, F. Heidenreich, C.

Kästner, O. Nierstrasz, N. Siegmund, and M.

Rosenmüller, “Automating energy optimization with

features,” in Proceedings of the 2nd International

Workshop on Feature-Oriented Software Development

- FOSD '10: ACM Press, 2010, pp. 2–9.

N. Shankaran, J. S. Kinnebrew, X. D. Koutsoukas, C. Lu,

D. C. Schmidt, and G. Biswas, “An Integrated

Planning and Adaptive Resource Management

Architecture for Distributed Real-Time Embedded

Systems,” IEEE Trans. Comput, vol. 58, no. 11, pp.

1485–1499, 2009.

Dong-In Kang, S. Crago, and Jinwoo Suh, “A fast

resource synthesis technique for energy-efficient real-

time systems,” in Proceedings of the 23rd IEEE Real-

Time Systems Symposium RTSS 2002, IEEE, Ed, 2002.

Jingcao Hu and R. Marculescu, “Energy-aware

communication and task scheduling for network-on-

chip architectures under real-time constraints,” in

EarlyEnergyEstimationintheDesignProcessofNetworkedEmbeddedSystems

219

Proceedings of the Design, Automation and Test in

Europe Conference and Exhibition (DATE’04), IEEE,

Ed, 2004, pp. 234–239.

C. A. Rusu, R. Melhem, and D. Mosse, “Maximizing the

system value while satisfying time and energy

constraints,” IBM J. Res. & Dev, vol. 47, no. 5, pp.

689–702, 2003.

M. Baker, Topics in power and performance optimization

of embedded systems, Dissertation, Arizona State

University, 2011, Available: http://hdl.handle.net/

2286/jq8f23vj0yh

L. Benini, A. Bogliolo, and G. de Micheli, “A survey of

design techniques for system-level dynamic power

management,” in Transactions on Very Large Scale

Integration (VLSI) Systems, IEEE, Ed, 2000.

R. Jejurikar and R. Gupta, “Dynamic voltage scaling for

systemwide energy minimization in real-time

embedded systems,” in Proceedings of the

International Symposium on Low Power Electronics

and Design (ISLPED’04), 2004, p. 78.

G. Zeng, H. Tomiyama, H. Takada, and T. Ishihara, “A

Generalized Framework for System-Wide Energy

Savings in Hard Real-Time Embedded Systems,” in

Proceedings of the 5th International Conference on

Embedded and Ubiquitous Computing EUC 2008,

2008, pp. 206–213

PECCS2013-InternationalConferenceonPervasiveandEmbeddedComputingandCommunicationSystems

220