Pitch Control for Variable Speed Wind Turbines

A. I. Roussos, V. E. Ntampasi and O. I. Kosmidou

Department of Electrical and Computer Engineering, Democritus University of Thrace, GR-67100 Xanthi, Greece

Keywords: Wind Turbine, Power Coefficient, Power Extraction, Pitch Control, PID Control.

Abstract: The main thrust of this paper is to present an efficient method for the pitch control of large scale wind

turbines. After an investigation in wind turbine working regions, the “optimum” working levels are

determined. A PID controller is designed based on the Ziegler – Nichols method. By appropriately tuning

the controller gains, the proposed controller ensures achieving a rapid convergence to the extracted power

set point with the minimum of fluctuations even in extreme wind conditions.

1 INTRODUCTION

Wind energy is one of the most promising sources of

electrical energy in years to come. Modern wind

farms can produce serious amounts of energy

without catastrophic climate issues, such as green

house gas emissions. Hence, a serious research over

the wind turbines is required nowadays more than

ever before (Asharif et al., 2011).

However, wind energy has to overcome some

technical as well as economical barriers, if it should

produce a substantial part of electricity. There are

several ways to control a wind turbine system

(Munteanu et al., 2008). Pitch, passive stall, active

stall and yaw control techniques are some of them.

The pitch control system monitors constantly the

extracted power; the controller is designed to

regulate the pitch angle such that a desired power

amount is obtained from a given level of wind

energy. On the other hand, the main characteristic of

a passive stall control system is that the wind turbine

blades are placed steady on the rotor. Their

geometry allows the wind to turn the rotor, provided

it remains within a desired range. If not, an amount

of friction is developed at the side of the blade

opposite to the wind flow and that makes the wind

turbine to decelerate (Strazisar and Bright, 2004).

In yaw control systems the rotational speed and

power output are regulated by the whole rotor

mechanism (Hansen, 2008). This technique is used

for small wind turbines of 1kW rated power or less.

Large wind turbines with yaw control would be

subjected to cyclic stresses that could lead to the

failure of the entire structure. Finally, the active stall

control systems (Leinhos et al., 2002) differ from the

pitch control systems in that their control method

uses the gradation of the pitch angle. For low values

of the wind the two approaches work in the same

way. However, when the generator of a wind turbine

with active stall control reaches its set point, the

system turns the blades in the opposite direction

with respect to the one of the pitch control system.

Hence, the control system increases the blades angle

of attack in order to decelerate the rotor and thus

wasting the excess of wind energy.

In the next sections, PID control schemes are

studied for the pitch control of wind turbines. The

paper is organized as follows: In Sections 2, 3 the

aerodynamic energy conversion as well as the

system description are given. The proposed

controller design is presented in Section 4 and

compared with previous control techniques via

simulation in Section 5. Finally Section 6 provides

concluding remarks.

2 POWER CAPTURE OF WIND

TURBINES

In order to construct an efficient controller, it is

necessary to investigate the way the wind turbine

converts the wind energy into mechanical energy.

Furthermore, a research on the turbine’s working

regions is needed in order to achieve the maximum

power extraction in every wind scenario.

43

I. Roussos A., E. Ntampasi V. and I. Kosmidou O..

Pitch Control for Variable Speed Wind Turbines.

DOI: 10.5220/0004391000430049

In Proceedings of the 10th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2013), pages 43-49

ISBN: 978-989-8565-70-9

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

2.1 Power Coefficient

Through the blades of the wind turbine an amount of

wind energy is converted to electrical power. The

mechanical torque P

m

produced by the wind turbine

axis is (Zhang et al., 2008)

3

mpw

P=0.5×ρ ×A×C (λ, β)×U

(1)

The parameters in (1) denote

ρ: the air density

A: the area swept by blades

U

w

: the wind speed and

C

p

: the power coefficient with

λ: the tip speed ratio and

β: the blade pitch angle.

The tip speed ratio is defined as the ratio between

the blade tip speed and the wind speed

tip

r

w

w

V

R×ω

λ ==

VV

(2)

with

ω

r

: the rotor speed and

R: the radius of the wind turbine blade.

Equation (1) is valid when the airflow is constant,

but in practice this is not the case. In fact, the steep

alternations of wind produce power deviation from

its expected value.

The power coefficient C

p

represents the

percentage of the kinetic energy that is contained in

the wind and rotates the wind turbine blades. The

value of C

p

depends on the factors λ and β. Its upper

theoretical bound, called Betz limit is equal to 0.593.

In actual situations the Betz limit varies into the

range [0.4, 0.5] and depends on the wind turbine

type. The dependence of the power coefficient on λ

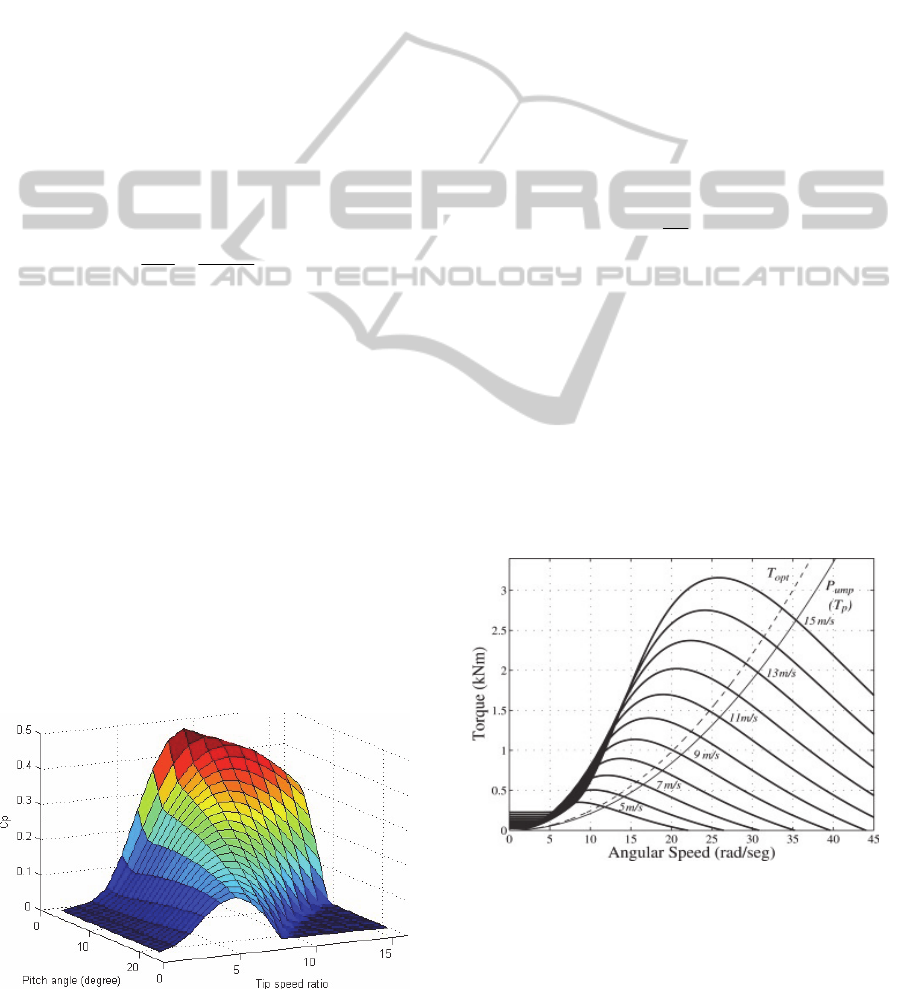

and β is shown in Fig. 1.

Figure 1: Power coefficient 3D curve.

Several studies (Ackermann, 2005) have shown

that in variable speed wind turbines the “optimal”

mechanical power is obtained whenever the turbine

works with the maximum Cp. Besides, the

maximum value of Cp is obtained for a specific

value of tip speed ratio λopt. Obviously, the

mechanical torque (1) is later converted into

electrical torque.

2.2 Maximum Power Extraction

In order to achieve the optimal power extraction

operation points for a wind turbine system one has to

follow a procedure related to λ: In equation (2) the

value of λ is kept constant and then, for each wind

speed value, the optimal rotor speed is calculated

(Zhang et al., 2008). The mathematical model used

is

P

T=

ω

m

m

r

(3)

and has the internal mechanical torque T

m

as input.

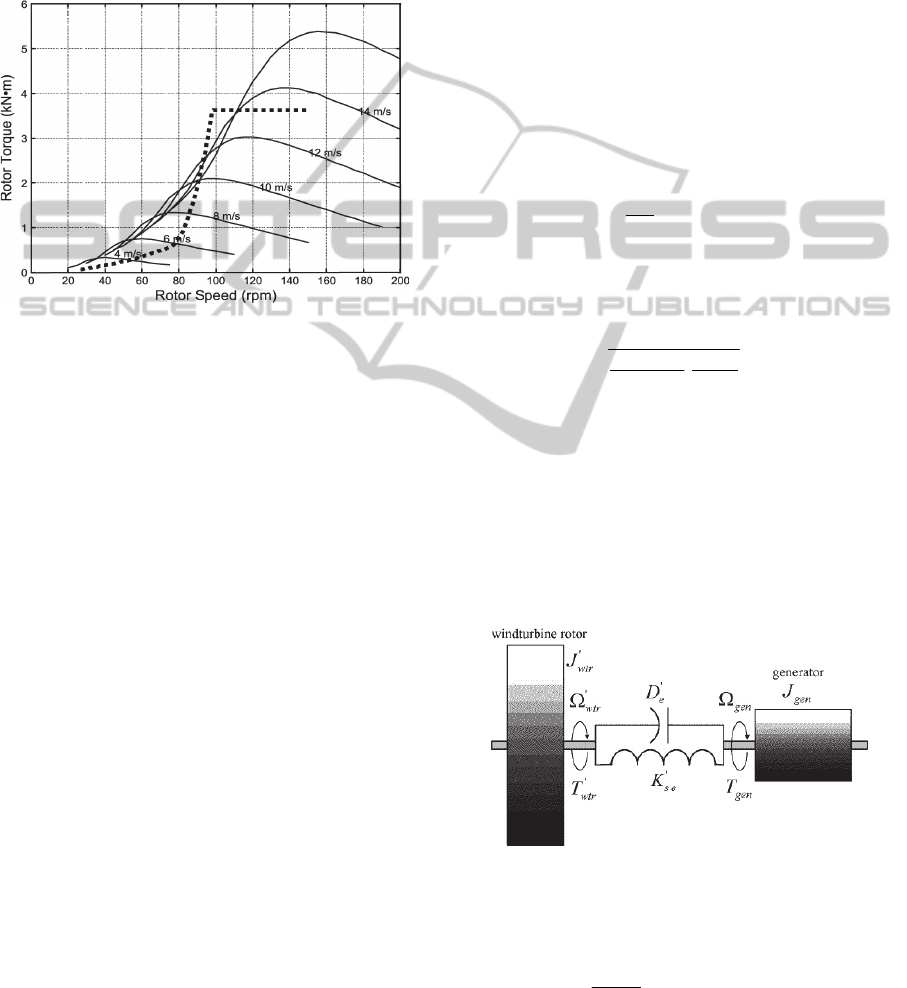

In Fig. 2 the T

m

waveforms for different wind

speeds ω

r

are illustrated. The maximum power for

each waveform is achieved when the product T

m

ω

r

is maximized, as well. Relating all points of

maximum power one can create the dashed

waveform shown in the right bottom of Fig. 2.

Obviously, the control action should ensure the wind

turbine to work as close as possible to the dashed

waveform, in order to achieve the maximum power

extraction.

Figure 2: Wind turbine rotor torque - speed waveforms.

In real life cases the dashed waveform is used

only for low power values. For upper power values

the system should protect itself by limiting the rotor

speed under its set points. The proposed operation

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

44

waveform for the wind turbine under consideration

is illustrated in Fig. 3. One can observe that the

dashed waveform in Fig. 3 is composed from (i) an

initial region with low incline that follows the

optimal power extraction (ii) the steep region that

limits the rotor speed up to 100 rpm and (iii) the

horizontal region where the controller takes action

and decelerates the system.

Figure 3: Proposed wind turbine rotor torque - speed

waveform.

3 MODEL DESCRIPTION

A variable speed wind turbine is generally composed

of several components, namely the wind model, the

rotor, the gearbox and the generator that are

described in this section.

3.1 Wind Model

Wind speed is calculated as an average of the fixed-

point wind speed over the whole rotor; the tower

shadow and rotational turbulences are also taken into

account. The component of main importance in this

model is the normally distributed white noise

generator. A problem that occurs when using white

noise generators is that different simulation tools use

different algorithms and thus different wind time

series are obtained. In order to overcome this

drawback, a normally distributed white noise

generator has been implemented in (Marsaglia and

Tsang, 2000);

it is based on the Ziggurat Algorithm

and uses the so-called ‘C’ S-Function.

The simulation wind model depends on the

following parameters:

Average Wind Speed: 10 m/s

Length Scale: 600 m

Wind Turbulence Intensity: 30% or 50%

3.2 Wind Turbine Rotor

The rotor is a component that extracts the energy

from the wind and converts it into mechanical

energy (Slootweg et al., 2003). The aero-turbine

model has two inputs, namely the wind speed and

pitch angle. The following parameter values have

been used to extract the internal mechanical torque.

Blade Radius: 22.5 m

Air Density: 1.25 Kg/m

3

Cut In Speed: 3 m/sec

Cut Out Speed: 25 m/sec

Besides, numerical approximations for given values

of λ and β (Ackermann, 2002)

have been used to

calculate the power coefficient C

P

. More precisely,

i

2.14

p

i

151

C λ,β = 0.73( - 0.58β - 0.002θ -

λ

-18.4/λ

-13.2)e

(4)

with

i

3

β

1

λ =

10.003

-

λ-0.002β

+1

(5)

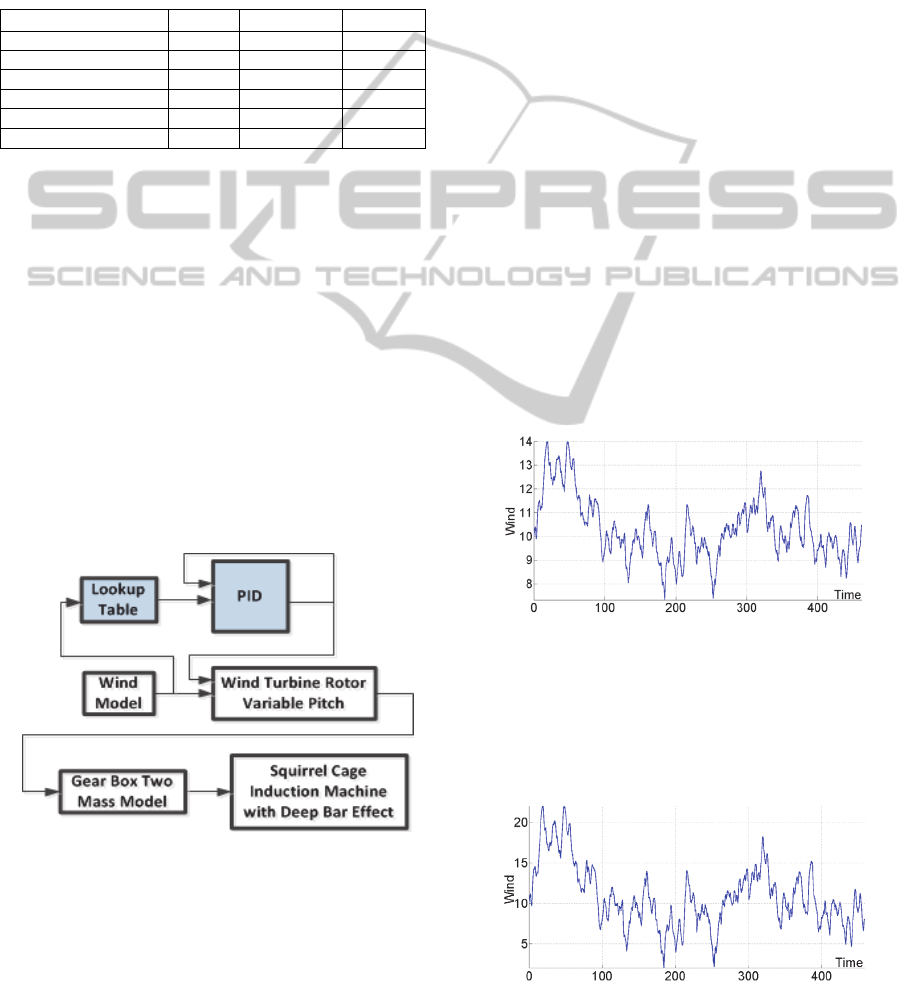

3.3 Gearbox

At this step the low angular speed produced by the

wind turbine rotor is converted into high speed in

order to reach the generator nominal values (Iov et

al., 2004). The gearbox is a two-mass model as

shown in Fig. 4. Let T

wtr

and T

gen

be the

corresponding rotor and generator torques.

Figure 4: Two-mass gearbox.

The dynamic equations of the drive-train written on

the generator side are

wtr

wtr wtr e wtr gen

wtr gen

se

dΩ

T=J +DΩ - Ω

dt

+k θ - θ

(6)

PitchControlforVariableSpeedWindTurbines

45

wtr

wtr

=

dθ

Ω

dt

(7)

gen

gen gen e gen wtr

-

se gen wtr

dΩ

-T = J + D Ω - Ω

dt

+k θθ

(8)

gen

gen

=

dθ

Ω

dt

(9)

where the equivalent stiffness is given by

wtr

gense

2

gear

11 1

=

k

kk

k

+

(10)

and the equivalent moment of inertia for the rotor is

wtr wtr

2

gear

1

JJ

k

(11)

where

Moment of inertia (Electric Machine Side): J

gen

=

90 kg*m

2

Moment of inertia (Turbine Rotor Side): J

wtr

=

49.5*10

5

kg*m

2

Shaft Stiffness: k

se

= 114*10

6

N*m/rad

Damping Coefficient of Shaft:

D

e

= 755.658*10

3

N*m*sec/rad

Gearbox Ratio: 83.531

3.4 Generator

The generator of the wind turbine under

consideration is a squirrel cage induction machine

with deep bar effect (Boukhezzara et al., 2007). The

generator has two inputs, namely the angular

velocity from the gearbox Ω

gen

and an amount of

voltage from the electric network required to start

working. The nominal value of the generator

extracted power is 2 MW.

The parameters of the generator are:

Rated Voltage per Phase: 960 Volts

Rated Current per Phase: 1310 A

Base Frequency: 50 Hz

Number of Polar pairs: 2

Starting Current: 8.8 A

Phase angle at Standstill: 79.5 deg.

Stator Resistance: 0.005 Ohm

Stator self-induction: 4.074*10

-4

H

Rotor Resistance: 0.0089 Ohm

Rotor Self-Induction: 2.992*10

-4

H

4 PID CONTROLLER DESIGN

The controller design of a wind turbine requires

determining the physical quantities to be taken into

account i.e. wind speed, mechanical torque of the

rotor, angular speed of the machine and the amount

of extracted power. In our approach the extracted

power has to converge to its set point. Besides, the

fact that the wind speed is of crucial importance to

the wind turbine operation makes the controller

construction quite difficult, since wind speed is a

non-linear variable transferred into the system. Thus,

the controller should take into account the wind

speed and continuously adjust the blades such that

the stability of the wind turbine system is

guaranteed.

PID control is one of the most popular methods

in controlling systems as wind turbines. Such

controllers are developed either independently or as

a combination with other methods (Ebrahim et al.,

2010). Recall that the transfer function of the PID

controller has the form

K

G(s)=K +K s+

s

I

cPD

(12)

where K

P

, K

D

and K

I

denote the proportional,

derivative and integral gains to be determined during

the design procedure.

4.1 PID Controller Tuning

There is no standard algorithm for tuning of the PID

controller parameters (Hara et al., 2006). The most

popular of the proposed experimental methods is the

well known Ziegler – Nichols rule (Ziegler et al.,

1942). It is performed by first setting the integral

and derivative gains to zero. Then, the proportional

gain K

P

is increased (starting at zero) until it reaches

the ultimate value K

u

for which the output of the

control loop oscillates with a constant amplitude.

The value K

u

and the oscillation period T

u

are used

to set the PID controller gains, for a specific type of

controller, according to Tab. 1.

For the wind turbine model described in Section

3 it was found that K

u

= 3.33 and T

u

= 2.65sec.

According to Tab.1, the values of the PID gains are:

K

P

= 2, K

I

= 1.51 and K

D

= 0.66. Since the above

method is an experimental one, the gain values can

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

46

be further improved for the system under

consideration. Improved gain values should lead to

more accurate closed-loop performances and, in

some sense, “optimize” the control action. Since in

this procedure it is not possible to keep constant two

of the gains and adjust the third one, one needs to

find a combination of adjustments in order to

achieve the “optimal” tuning.

Table 1: Ziegler - Nichols method.

Control Type K

P

K

I

K

D

P K

u

/2 - -

PI K

u

/2.2 1.2K

p

/T

u

-

Classic PID 0.6K

u

2K

p

/T

u

K

p

T

u

/8

Pessen Integral Rule 0.7K

u

2.5K

p

/T

u

0.15K

p

/8

Some overshoot 0.33K

u

2K

p

/T

u

K

p

T

u

/3

No Overshoot 0.2K

u

2K

p

/T

u

K

p

T

u

/3

In the light of the above observations, the

system’s operation has been tested with gain value

sets obtained from the “optimal” tuning. More

precisely, the gain values have been adjusted by

considering that the wind model follows the same

wind curve. It has been found that for K

P

=2, K

I

=

0.01 and K

D

= 2 the power extraction curve was

converging tightly to its reference value.

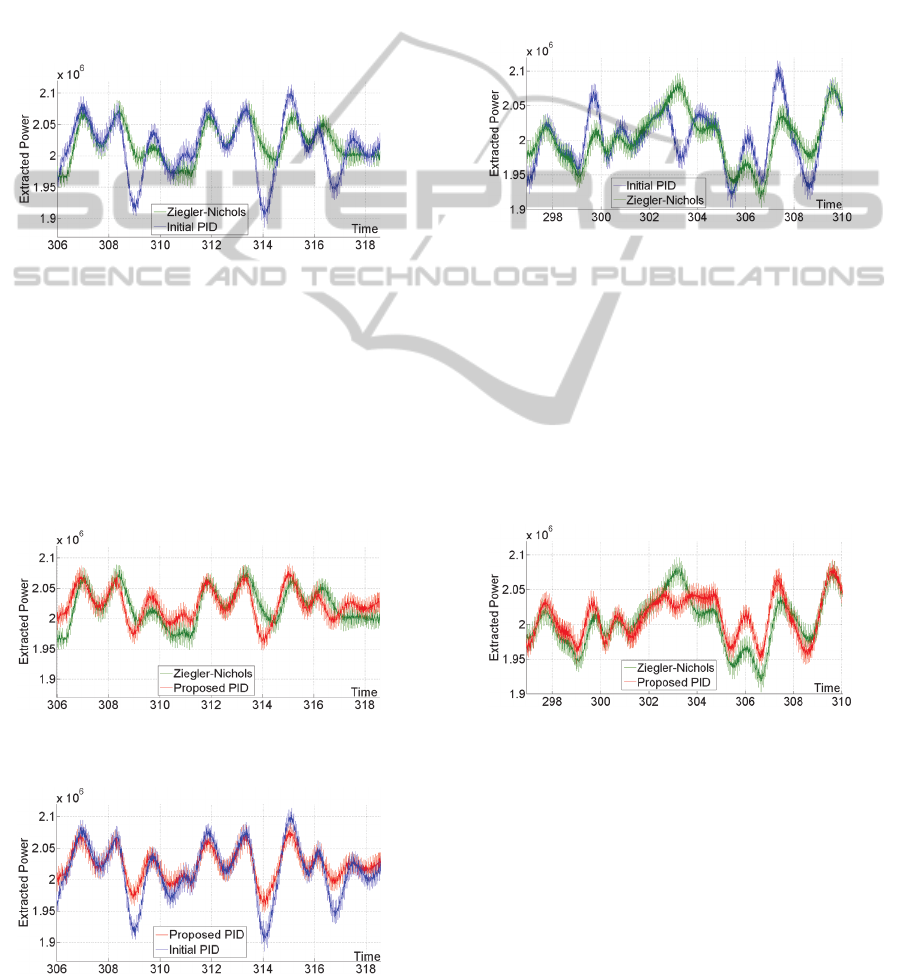

4.2 Controller Description

The block diagram of the closed-loop system is

given in Fig. 5. The look-up table and PID controller

blocks are created for the control design of the wind

turbine.

Figure 5: Wind turbine simulation model.

The look-up table block is used to determine the

appropriate pitch angles with input the real-time

wind value as described in Section 2.2.

The PID controller block contains the blocks

necessary to create the controller resulting from the

gain value tuning of Section 4.1.

5 SIMULATION RESULTS

The wind turbine under consideration has been

simulated in the Matlab

®

Simulink programming

environment using the Wind Turbine Blockset

(WTB) Toolbox (Iov et al., 2004). For the

simulation purposes, the PID controller design

proposed in Section 4.1 has been compared with (i)

the PID controller resulting according to the Ziegler

– Nichols rules and

(ii) the one proposed in the

literature and called from here on “initial PID”.

More precisely, in (Abbas and Abdulsada, 2010)

a

PID controller has been designed by using the

rotational speed to control the wind turbine

performance. In order to assess the controller

performance, the root mean square error between the

actual rotational speed and the desired one indicated

the capability of the controller to reject the wind

speed fluctuations. The PID controller parameters

tuned according this approach were: K

P

= 15, K

i

=

20 and K

d

= 0.1.

5.1 Wind Waveforms

The performance of the three abovementioned

controllers has been tested for both, normal and

extreme wind conditions. First, a normal wind was

considered as in Fig. 6.

Figure 6: Normal wind waveform.

It was assumed to vary in the range [7m/s –

15m/s]; its turbulence was similar to real-time wind

fluctuation values. A second group of simulations

were obtained for an extreme wind scenario as

shown in Fig. 7.

Figure 7: Extreme wind waveform.

PitchControlforVariableSpeedWindTurbines

47

Wind speed values vary into the range [2m/s –

22m/s] and are characterized by high turbulence. It

should be noted that such a wind waveform is rarely

encountered in nature.

5.2 Normal Wind Case

Let us first compare the closed-loop system

performances obtained by applying (i) the PID

controller resulting from the Ziegler – Nichols rules

and (ii) the initial PID controller. Simulations are

given in Fig. 8.

Figure 8: Ziegler - Nichols / Initial PID controller

behaviour in normal wind conditions.

It is clear that in this situation the Ziegler –

Nichols controller waveform converges more tightly

to the set point. It should be noted that small

deviations between curves are in fact very important,

since the extracted power is measured in MW.

In the sequel, one can see that closed-loop

behavior is further improved by the PID controller

tuning of the proposed method, Fig. 9.

Figure 9: Ziegler - Nichols / Proposed PID controller

behaviour in normal wind conditions.

Figure 10: Proposed PID controller / Initial PID controller

behaviour in normal wind conditions.

Finally, simulations of the proposed PID

controller and the initial one are compared in Fig.

10. An improved convergence is obtained by the

proposed method.

5.3 Extreme Wind Case

Analogous performances were obtained in the case

of extreme wind conditions. The initial PID vs

Ziegler – Nichols controller performances are given

in Fig. 11.

Figure 11: Ziegler - Nichols / Initial PID controller

behaviour in extreme wind conditions.

Since in this case the wind turbulence is

significantly higher, the distance of the two

waveforms is clearly larger. However, it is to be

noted that the Ziegler – Nichols PID ensures a better

convergence to the set point; moreover, in several

time steps like 307sec, 309sec the deviation is

almost avoided.

Comparison of Ziegler – Nichols and the

proposed PID controller is given in Fig. 12.

Figure 12: Ziegler - Nichols / Proposed PID controller

behaviour in extreme wind conditions.

Even for relatively high turbulence, the proposed

method ensures improved performances. Note that

the convergence in the time interval 302sec to

308sec remains better.

Finally, comparison of the proposed controller

with the initial one is given in Fig. 13. It is noted

that unnecessary fluctuations are avoided by using

the proposed PID controller. In time steps like

303sec, 304sec minimum fluctuations are produced

by using the proposed controller.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

48

Figure 13: Proposed PID controller / Initial PID controller

behaviour in extreme wind conditions.

Furthermore, in waveform regions where

fluctuations cannot be avoided, due to the extreme

wind’s nature, the proposed controller ensures an

acceptable performance and convergence to the set

point.

6 CONCLUSIONS

In this paper, a design approach for the control of a

variable speed wind turbine system is proposed. The

extracted power has to achieve a desirable set point

of 2MW, despite wind speed fluctuations. By

appropriately adjusting the PID controller gains, the

proposed control scheme ensures the closed-loop

system’s stability and an acceptable tracking, even

under extreme wind conditions. The output

convergence to the set point has been shown to be

faster and tighter, as compared with existing PID

methods. Different control schemes for the variable

speed wind machine are presently under

investigation.

REFERENCES

Abbas F. A. R., Abdulsada M. A., 2010. Simulation of

Wind-Turbine Speed Control by MATLAB,

International Journal of Computer and Electrical

Engineering

, Vol. 2, No. 5.

Ackermann T., 2002. Transmission systems for offshore

wind farms,

IEEE Power Engineering Review.

Ackermann T., 2005.

Wind Power in Power Systems, John

Wiley & Sons, Ltd.

Asharif F., Tamaki S., Nagado T., Nagtata T., Asharif M.

R., 2011.

Analysis of Non-linear Adaptive Friction

and Pitch Angle Control of Small-Scaled Wind

Turbine System, Springer-Verlag, Berlin Heidelberg.

Boukhezzara B., Lupua L., Siguerdidjanea H., Handb M.,

2007. Multivariable control strategy for variable

speed,

Renewable Energy, Vol. 32.

Dunney F., Y. Paoz L. Y., Wrightx A. D., Jonkman B.,

Neil Kelle N., 2010. Combining standard feedback

controllers with feed forward blade pitch control for

load mitigation in wind turbines,

Proceedings of the

48th AIAA aerospace sciences meeting

, Orlando.

Ebrahim M. A., Metwally A. E., Bendary F., Mansour W.

M., Ramadan H. S., Ortega R. and Romero J., 2010.

Optimization of Proportional-Integral-Differential

Controller for Wind Power Plant Using Particle

Swarm Optimization Technique,

IJETSE International

Journal of Emerging Technologies in Sciences and

Engineering, Vol.2, No.2.

Geyler M., Caselitz P., 2007. Individual blade pitch

control design for load reduction on large wind

turbines,

Proceedings of the European Wind Energy

Conference,

Milan, Italy.

Hansen M. O. L., 2008.

Aerodymanics of Wind Turbines,

Second Edition, Earthscan.

Hara S., Iwasaki T., and Shiokata D., 2006. Robust PID

Control Using Generalized KYP Synthesis

, IEEE

CONTROL SYSTEMS MAGAZINE

.

Iov F., Hansen A. D., Sørensen P., Blaabjerg F., 2004.

Wind Turbine Blockset in Matlab/Simulink, General

Overview and Description of the Models,

Institute of

Energy Technology,

Aalborg University.

Jonkman J. M., 2007.

Dynamics modeling and loads

analysis of an offshore floating wind turbine

,

Technical report.

Leinhos D. C., Scheidler S. G., Fottner L., 2002.

Experiments in Active Stall Control of a Twin-Spool

Turbofan Engine

, Proceedings of ASME TURBO

EXPO

, Amsterdam, The Netherlands.

Marsaglia G., Tsang W.W., 2000. The ziggurat method for

generating random variables,

Journal of Statistical

Software

, Vol. 5, No. 8. (5)

Munteanu I., Bractu A. I., Cutululis N. A., Ceanga E.,

2008. Optimal Control of Wind Energy Systems,

Towards a Global Approach, Springer

Slootweg J. G.

, Haan S. W. H., Polinder H., Kling W.

L.

,2003. General Model for Representing Variable

Speed Wind Turbines in Power System Dynamics

Simulations, IEEE TRANSACTIONS ON POWER

SYSTEMS, Vol. 18, No. 1.

Strazisar A. J., Bright M. M., 2004. Compressor Stall

Control Through Endwall Recirculation

, Proceedings

of ASME Turbo Expo Power for Land

, Sea, and Air,

Vienna, Austria.

Wilson D. G., Berg D. E., Resor B. R., Barone M. F., Berg

J. C., 2009. Combined individual pitch control and

active aerodynamic load controller investigation for

the 5MW upwind turbine,

AWEA WINDPOWER 2009

Conference and Exhibition

, Chicago.

Ziegler J. G., Nichols N. B., Rochester N. Y., 1942.

Optimum Settings for Automatic Controllers

,

Transactions of the A.S.M.E.

Zhang J, Cheng M., Chen Z., Fu X., 2008. Pitch Angle

Control for Variable Speed Wind Turbine,

DRPT2008,

Nanjing China.

PitchControlforVariableSpeedWindTurbines

49