A Generic Control Architecture for Material Handling Systems

Applied to a Baggage Handling System

S. W. A. Haneyah, J. M. J. Schutten, P. C. Schuur and W. H. M. Zijm

IEBIS, School of Management and Governance, University of Twente, P.O. Box 217, 7500 AE Enschede, The Netherlands

Keywords: Baggage Handling System (BHS), Real-time Scheduling, Control Architecture, Workload Control.

Abstract: This paper is part of research on generic planning and control of automated Material Handling Systems

(MHSs) in different industrial sectors. We build upon previous work to provide a proof of concept for the

applicability of a generic control architecture on a specific MHS. To this end, the baggage handling system

(BHS) of a major European hub represents our business case. We present the control architecture and apply

it to the BHS under study in a simulation environment. This application shows how the generic control

architecture adapts to the specificities of this BHS and how it handles unconventional workstation types,

i.e., robots. Finally, we highlight the lessons learned and make recommendations for future applications.

1 INTRODUCTION

We apply a generic control architecture, which was

developed for Material Handling Systems (MHSs)

by Haneyah et al. (2013a), to a baggage handling

system (BHS). The aim is to provide a proof-of-

concept for the applicability of the generic control

architecture to a specific MHS, while preserving the

generic structure. Moreover, the generic and

standardized methods should handle system-specific

elements in the BHS under study. We provide

modeling and implementation aspects for the BHS

under study, compare the generic control

architecture to the current practice approaches,

discuss the behavior of each approach, and comment

on the architectural design and software complexity.

The paper is organized as follows: Section 2

presents key literature. Section 3 illustrates the BHS

of our business case. Section 4 presents the control

architecture and its application to this specific BHS.

Section 5 provides the experimental setting. Section

6 provides general results and recommendations for

future applications of the generic architecture.

Finally, Section 7 ends with concluding remarks.

2 KEY LITERATURE

Haneyah et al. (2013b) present a comprehensive

literature review on control architectures for MHSs.

They conclude that only few studies attempt to build

a generic control architecture for different industrial

sectors. A common trend is that a control

architecture normally targets a specific sector, or

deals with material handling as part of a

manufacturing environment. Babiceanu et al. (2004)

use a holonic manufacturing systems approach as a

basis to suggest a framework for material handling.

However, this architecture has limitations and does

not address a number of necessary aspects (Haneyah

et al., 2013b). Tařau et al. (2009a) study route

control in BHSs. They find centralized control

approaches computationally expensive and not

robust. Tařau et al. (2009b) pay attention to

hierarchical control for route choice. They design a

hierarchical control architecture and examine multi-

agent systems in the same study, but find them

disadvantageous due to the extensive

communication required between agents. In general,

Tařau et al. study routing problems and how to

control divert switches within BHSs, but they do not

consider other operations, e.g., the early bag storage.

Johnstone et al. (2010) study status-based routing. In

their approach, the status of the bag determines its

processing requirements and triggers the

computation of the route to be followed, depending

on the states of required resources ahead. They

contrast an algorithm that is based on learning

agents with another algorithm using a graph

representation of the network to find possible routes

at switches via Dijkstra’s algorithm. Hallenborg &

121

W. A. Haneyah S., M. J. Schutten J., C. Schuur P. and H. M. Zijm W..

A Generic Control Architecture for Material Handling Systems Applied to a Baggage Handling System.

DOI: 10.5220/0004427201210130

In Proceedings of the 10th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2013), pages 121-130

ISBN: 978-989-8565-70-9

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

Demazeau (2006) find global planning and

scheduling an impossible or inappropriate strategy

for large and complex MHSs. They use multi-agent

technology as a basis for generic software

components to replace traditional system-specific

centralized control software.

3 THE BHS

The core task of any BHS is to deliver each bag

from some point A (related to its source) to some

point B (related to its destination), within a specific

time limit. However, the airport environment of a

BHS is very dynamic and stochastic, which

complicates the delivery job and raises many

additional considerations to take care of. Moreover,

the transport network can be rather complex.

The build for a flight starts a couple of hours

before the scheduled time of departure. Then, at

least one lateral (a type of outfeed conveyor used in

BHSs to gather bags in preparation for loading on

planes) is open to handle the baggage for this flight.

The baggage arrives from the sorter system at one of

the designated laterals. There, workers take the

baggage off the lateral and transport it towards the

airplane, either on ramp carts or inside special

containers called Unit Load Devices (ULDs). This

paper focuses on a terminal in a major European hub

as an application case for the generic control

architecture of Haneyah et al. (2013a). Figure 1

presents a simplified material flow diagram that

gives insight into the main components of this BHS,

which are:

Baggage: bags that can be transported on the

BHS are referred to as conveyables, which represent

the main material flow. On the other hand, non-

conveyables represent a very small portion of the

total number of bags that cannot be loaded on the

BHS because they are too small, too large, too light,

too heavy, too unstable (e.g., a ball), etc. Non-

conveyables are handled with dedicated equipment.

Moreover, there is another flow that we do not

consider as it is not a bottleneck resource for the

performance of BHSs, which is the flow of empty

totes that are used in the storage area to carry bags;

other parts of the BHS use conveyors.

Diverts: diverts can direct the bag to one of two

possible routes. The selected route should eventually

lead to the bag’s next process step (the main sorter

or the bags storage). In this BHS, streams of bags

from check-in desks or transfer belts mix and

proceed to one of a group of 8 diverts (depending on

the source point).

Screening Area: security control occurs in this area.

In this BHS, there are four conveyor loops. Each two

loops lead to one (out of two) cluster of screening

machines. Each cluster has three screening

machines. The design of the screening area with the

upstream diverts is redundant, i.e., a bag can follow

either one of the two route options at the diverts to

go through one of the parallel loops, and then one of

the parallel screening machines within a cluster.

Suspicious bags go to a second screening level by

other machines. However, we model only one

screening level. After the screening machines, the

bags proceed via conveyors to downstream system

areas, e.g., storage and laterals build areas. In this

BHS, the screening machines do not have the same

connections to downstream resources. Each cluster

has one machine giving access only to the storage

area, a second giving access only to the main sorter,

and the third giving access to both areas.

Automated Storage and Retrieval System

(ASRS): the main function of the ASRS is to store

early bags until laterals of the corresponding flights

open. In this BHS, there is a racking system to store

totes with bags or without (empty locations), cranes

with a double load unit device, and pickup and

delivery stations at the end of each storage aisle. The

ASRS has 12 storage racks and 13 cranes, where

each rack is accessible by two cranes.

Main Sorter: This is a conveyor based sorting

system, which sorts bags to corresponding laterals.

Laterals Build Area: this is the main build area,

including the sorter(s) and the laterals. In this BHS,

there is one sorter with 18 build laterals and one

exception handling lateral to collect bags that missed

their flights.

Robots Build Area: in this BHS, robots can be

used to build ULDs for different flights, where each

flight may use robots for 45 minutes, starting an

hour before lateral open time (for the flight). There

are five robots, two of which are fully automated,

while the other ones are semi-automated. The semi-

automated robots can handle bags at a higher rate,

because a number of operators work on them.

Section 4 discusses the build operation further.

Conveyors: system areas and resources are

connected by a network of conveyors, which we take

into account in our control methods, but do not

model explicitly as they are at a low level of control

that mainly execute higher level control decisions.

The key performance indicator (KPI) for BHSs is

the irregularity rate (IR). For a certain plane, the IR

is the number of bags per 1000, which are supposed

to be on the plane but are not. From a practical point

of view, minimizing the IR is most challenging

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

122

Figure 1: A basic Material flow diagram of the BHS.

when dealing with connecting flights. This is

because several things can go wrong when trying to

correctly deliver an arriving bag to the next

connecting plane within a given (often short) time

window.

In large BHSs it is common to have several

resources that can do the same job, e.g., parallel

screening machines and redundant transport

systems. The logistic control must use these

resources as efficiently as possible to minimize the

bag’s flow time in the system.

4 CONTROL ARCHITECTURE

This section presents the control architecture and the

decision-making processes involved in this BHS.

4.1 The Architectural Design

Haneyah et al. (2013a) analyze MHSs in different

industrial sectors and propose the building blocks of

a generic control architecture. Their control

architecture consists of three hierarchical levels:

planning, scheduling, and local traffic control, where

each level contains several generic controllers. Local

traffic control problems are the easiest to deal with,

as they do not affect the overall control structure or

the communications between different controllers.

Control methods for local traffic problems can be

integrated in this control architecture with minimal

difficulty. We focus on the higher levels of control,

i.e., planning and scheduling, which are the levels of

which the functionality highly depends on the

control structure and communication interfaces.

Planning control units, i.e., planners, have an

aggregate view of the system and are not directly

connected to system resources. Scheduling control

units, i.e., schedulers, are directly connected to

system resources, where each workstation or

transport resource has its own controller. Planners

communicate with each other and assign tasks to

subordinate schedulers. Schedulers also

communicate with each other to schedule the

assigned tasks and report to higher level planners.

We now present the controllers involved in this BHS

and their main duties (see Figure 2):

Build Planner: this controller is responsible for

the build areas, i.e., it coordinates the build

workstations being manned-laterals or robots. For a

BHS this means planning the build operations for

flights, i.e., it activates the build of certain baggage

groups on workstations and communicates with the

storage planner to request the release of relevant

bags from the ASRS.

Storage Planner: this controller is responsible

AGenericControlArchitectureforMaterialHandlingSystemsAppliedtoaBaggageHandlingSystem

123

Figure 2: Control structure.

for the storage area, i.e., the ASRS consisting of

cranes and storage racks. The storage planner

assigns retrieval tasks to subordinate crane

controllers based on information from the build

planner. This controller also examines the possibility

of releasing baggage groups to build ULDs at robot-

workstations (see Section 4.2).

Workstation Controller: in the modeled BHS we

have two types of workstations, i.e., laterals and

robots. Flight build times are planned beforehand on

laterals and so laterals are reserved for certain flights

during some time frame. On the contrary, robots are

flexible workstations that can be used to fill a ULD

for any candidate flight. A candidate flight at a

certain moment in time is a flight that is allowed to

use robots at this moment in time and that has a

sufficient number of bags in the ASRS to fill a ULD.

A lateral workstation triggers the build planner when

the planned time to build a flight commences, while

a robot triggers the build planner when it finishes the

build of a certain ULD and can start a new one.

Crane Controller: at the scheduling level, the

main task of the crane controller is to schedule the

retrieval tasks (timing and sequencing). This

scheduling process considers the urgency of retrieval

tasks and the pipeline of destined workstation(s).

Machine Cluster Controller: a machine cluster

controller is responsible for monitoring a group of

parallel machines that are connected to the same

resources upstream and for posting information to

upstream controllers about estimated throughput

times. To this end, information about bags in the

pipeline from upstream controllers is required.

Loop Controller: loop controllers participate in

the routing process by transmitting information from

downstream machine clusters to upstream diverts

and the other way around. In addition, loop

controllers post information about space utilization

on the loop (see Section 4.2).

Divert Controller: using information transmitted

from downstream controllers, the divert controller

makes scheduling decisions on diverting bags to

which downstream system in the screening area.

4.2 Decision-making Processes

Haneyah et al. (2013b) apply a generic control

architecture to a material flow model entailing a

sorter system and an ASRS. Their model can be

configured either as a baggage handling system or as

a distribution system. Haneyah et al. (2013b) report

on interesting results with regard to achieving a high

level of synergy in control over common decision-

making processes in different industrial sectors.

Moreover, they show how uncommon decision-

making processes (which are specific to one

industrial sector) are built as functional add-ons to

the generic control architecture.

In this paper, we detail the generic architecture

further on the BHS at hand, which adds the

screening area and the robots build area (Section 3)

to the material flow model of Haneyah et al.

(2013b). In the following, we describe the decisions

taken at each level of control and communications

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

124

that are taking place between different controllers.

At the Planning level of control, decision-

making processes are: planning the inflow of bags to

the ASRS and planning the outflow from the ASRS

towards build areas.

Inbound flow to the ASRS: When a bag requires

storage, it is announced to the storage planner,

which responds with a destination rack and crane to

perform the storage operation. The storage planner

selects the storage rack with the smallest number of

bags, and with at least one active crane on it.

Outbound flow from the ASRS: In current

practice, cranes trigger a higher level of control that

they are ready to perform a retrieval cycle. At the

higher level of control, two different approaches are

employed to release baggage:

Retrievals for robots are released on an

individual basis considering the pipeline of the

destined robot and the sequence of bags required

in the ULD. Also, robots have priority over

laterals.

Retrievals for laterals are released in baggage

groups considering a limit for the ASRS on the

rate of retrievals for a certain baggage group.

The baggage groups are classified at a high level

of control in different priority classes according

to the number of bags in the ASRS and to the

planned retrievals’ finish times of these bags.

Priority classes of the baggage groups and the

limits on release rates are dynamic and updated

continuously as they depend on time and on the

number of bags in the ASRS. The high level of

control assigns the bags that the triggering crane

has to retrieve in its next cycle. Prioritization

rules within a certain priority class are also

considered.

Figure 3: Communications in planning and scheduling.

In the proposed control approach, we have a

generic release approach that is based on

standardizing the two types of workstations (laterals

and robots). This standardization requires: first,

setting pipeline size limits for all workstations and

second, imposing due times on all crane retrievals

(see Figure 3). Baggage is released from the ASRS

in groups, where a baggage group can be as large as

all bags belonging to a certain flight or a sub-set of

these bags defined by the storage planner. There are

two main sub-processes in outbound flow planning:

Stock reservation: this is a generic planning

process that Haneyah et al. (2013b) use in the

distribution sector to assign product totes to

orders. In baggage handling, this process is often

not needed because each bag entering the system

via check-in desks or as transfer baggage is

already assigned to a specific flight. However, in

our model the extension to the robots build area

requires the use of this process, because the

storage planner has to make a selection of bags

from a possibly larger set to be assigned to a

certain ULD. In other words, when a robot-

workstation announces its availability to build a

ULD, the build planner inquires the storage

planner about candidate flights to build a ULD

for. Candidate flights should have enough

content of bags in the ASRS to fill a ULD and

should be within the time allowed to build ULDs

on robots. The storage planner informs the build

planner about the options. The build planner may

then request to release a baggage group (ULD

content of bags to be selected by the storage

planner) for a certain candidate flight (e.g.,

earliest departing) and assign this group to the

triggering robot.

Order release: workstations trigger the build

planner to activate the build of baggage groups,

based on work progress for robot-workstations

(baggage group is the content of a ULD), or

according to planned build times for lateral-

workstations (baggage group is all bags for the

concerned flight). As soon as a baggage group is

active on a workstation, bags belonging to this

baggage group have to be released from the

ASRS. Therefore, the build planner informs the

storage planner that a certain baggage group is

active. In turn, the storage planner dynamically

assigns relevant bags to candidate cranes as

retrieval tasks, i.e., if the reserved bag is

accessible by more than one active crane, then

the storage planner assigns the retrieval to the

crane with the smallest workload. Moreover, the

storage planner sets due times for retrieval tasks.

The due time for bags going to robot-

AGenericControlArchitectureforMaterialHandlingSystemsAppliedtoaBaggageHandlingSystem

125

workstations is a parameter that we use (see

Section 5), whereas the due time for bags going

to a lateral-workstation is the planned end time

of the flight build.

At the Scheduling level, decision-making

processes are: scheduling crane retrievals, routing by

diverts, and detouring bags.

Scheduling crane retrievals: Given a set of

retrieval tasks, crane controllers schedule these tasks

based on their due times and the pipelines of

destination workstations. The pipeline size of a

workstation is the number of bags that can be in

transport to this destination at any point in time. We

only send bags if the number of bags in the pipeline

is less than the pipeline size, in order to prevent

overloads and congestion. We use the pipeline size

concept often in our control in the following

manner: each workstation receives information

about incoming bags (from cranes or diverts) and in

turn updates the number of empty positions

remaining in its pipeline. This includes scheduled

retrievals that are not physically in the pipeline yet.

Other controllers, e.g., crane controllers, observe the

pipeline capacities and consider this information

when scheduling. For robot-workstations, the flow

has to be strictly controlled, because bags are to be

handled according to a predetermined sequence.

Hence, recirculation of bags due to blocked entry to

a robot is prohibited, and so the pipeline size is

typically equal to the number of locations in the

inbound buffer of the robot-workstation. In this way,

if any problem occurs in the workstation, then all

bags in transport can be accommodated in the

inbound buffer with a preserved sequence. For

lateral-workstations, we set the pipeline sizes

according to Formula 1 as developed and motivated

by Haneyah et al. (2013b) who use a time allowance

parameter (to account for traffic delay and blocking

considerations) and the following variables:

i

PS

= pipeline size of workstation i (bags).

i

TT

= Average transport time from all cranes and

the arrivals divert to workstation i.

i

C

= capacity of workstation i (bags/minute).

*( )

ii i

PS C TT Allowance

(1)

When the pipeline to a certain destination is full,

system controllers react by blocking further bags

from being retrieved or routed to this destination,

which implies a pull-concept for workload control.

Routing bags in networks: Haneyah et al.

(2013a) outline an approach for routing items in

networks with service points, where divert

controllers make the routing decision based on the

state of the system downstream. We apply this

approach in the screening area, where screening

machines (see Figure 1) are available at alternative

systems. In such configurations, a divert controller

has to decide which system to divert an incoming

bag to. Contrary to current practice where static

shortest path algorithms are often implemented, we

propose a dynamic control logic.

Figure 4: Routing bags in networks.

We aim to balance the load on parallel systems

and react to machine failures, i.e., fewer bags should

go to the system having a lower service rate. We

focus on expected throughput time to pass through

the system. As the bag can go either to the laterals

build area or to the storage area, we calculate the

expected throughput time per destination. To this

end, machine cluster controllers post expected

throughput time to pass through (see Figure 4). In

turn, upstream controllers use this information to

make routing decisions. In order to estimate

throughput time, downstream controllers need

information about bags in the pipeline from

upstream controllers. The decision to divert a bag to

system A or to system B is impractical to take for

each bag separately due to the high rate of bags

passing the divert at a high speed, and may cause

excessive switching of diverts (which is undesirable

for the equipment). Therefore, the divert is

positioned to one of the downstream systems until

the difference in throughput times between

downstream systems exceeds a certain threshold.

Then, the divert switches position to react to the

imbalance. As long as throughput times are

balanced, we check whether space occupation on

downstream loops is balanced in the same manner.

We use a dashboard logic to post status updates to

upstream controllers. Each component (cluster, loop,

or divert) has a dashboard that posts accessible

destinations downstream, expected throughput

times, and space occupation on loop(s) downstream.

Upstream flow is blocked when the system has

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

126

completely absorbed the allowed capacity.

We emphasize that the standardized controllers

and interfaces allow the implementation of the same

control logic on different system layouts by merely

defining connected controllers upstream and

downstream for each resource.

Detouring Bags: One screening machine per

cluster has connections to both the main sorter and

to the ASRS. Obviously, bags are routed to the

ASRS when the build for the corresponding flight is

not open yet. Also, if the build is open and the

pipeline(s) of the destined workstation(s) is (are) not

full, then the bags are routed to the main sorter.

However, if the pipeline(s) is (are) full then, in order

to maintain a controlled flow on the main sorter, we

test routing bags to the ASRS and delegate the

scheduling task to crane controllers there. The latter

option is not used for urgent bags as it may cause

them to miss their flight. In this case, bags are better

off recirculating on the main sorter.

At the

local traffic level, we model two local

traffic control processes in an aggregate manner as

they do not affect the overall architecture and merely

execute scheduling decisions. The first process is

space allocation at merge junctions, e.g., the loop

controller has to allocate free spaces on the loop to

bags waiting to enter the loop from outbound buffers

of cranes. For this merge problem, we dedicate

another study (Haneyah et al., 2011). The second is

the crane storage cycle and in-aisle travel optimizer,

which concerns the determination of travel

sequences for a crane within an aisle, e.g., to execute

a storage cycle to store bags waiting on its inbound

buffer. The latter is a simple problem for which a

simple algorithm or control rule can be incorporated

in the architecture. Note that schedulers are

responsible for workload control, because they

decide when to start planned tasks, e.g., retrievals.

Moreover, pipeline size limitations reflect a pull

system for material flow. In contrast, local traffic

controllers have to deal with material physically

moving as a result of scheduling decisions.

5 IMPLEMENTATION

In order to test the performance of the generic

control architecture and compare it to current

practice, we build a simulation model in UGS-

Tecnomatix Plant Simulation that includes the main

building blocks of the BHS under study and of the

architecture. First, we need to tune the control

parameters: threshold values for routing in parallel

systems, the time allowance in Formula 1, and due

times on retrievals to robots.

Experimental setup: The operational scenario

covers a day of operation in each simulation run. We

include common screening machines failures

occurring during normal operation with exponential

distribution for the time to failure (mean = 6 hours)

and an exponential distribution for repair time (mean

=10 minutes). Each simulation run includes: 61

flights where each flight is scheduled to build on two

laterals for 75 minutes, ending 15 minutes before the

scheduled time of departure. There are two operators

working on each lateral at a handling capacity of 120

bags per hour per operator. Automated robots and

semi-automated robots handle bags at a capacity of

200 and 350 bags per hour respectively. Finally, the

number of bags modeled per simulation run is

25,198 including transit and check-in bags.

Model Parameterization: We test the generic

routing logic in parallel screening systems and the

detour option (Section 4.2). We test the detour

option versus always sending bags to laterals when

the build time of the flight is open (even if the

pipelines are full). Routing parameters (see Section

4.2) are selected according to desirable values in

practice. We use a throughput time threshold of one

minute, which means that a divert switches position

only if switching leads to at least one minute saving

in throughput time downstream. Likewise, the space

utilization threshold is set to 20%, which means that,

as long as throughput times are balanced, a divert

switches position only if switching leads an

incoming bag to the loop which is at least 20% less

occupied than the other accessible loop downstream.

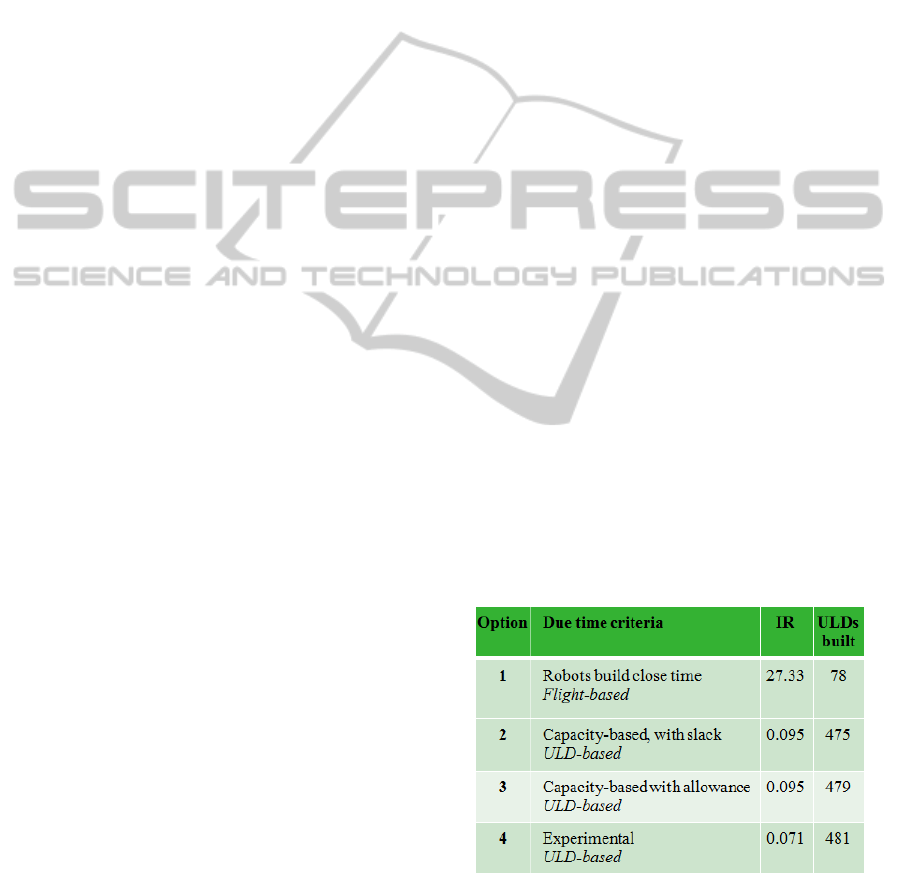

Table 1: Setting due times for retrievals to robots.

We conduct several experiments to configure the

time allowance parameter in Formula (1). The best

value for the time allowance is found to be 100

seconds for both options; with detour and without

detour. We observe that, in this BHS, the detour

AGenericControlArchitectureforMaterialHandlingSystemsAppliedtoaBaggageHandlingSystem

127

option is seldom used (on average 0.4% of all bags

were detoured) and does not have a big effect on the

IR. The causes for this result are: first, the possibility

of the detour option is limited to only two out of the

six screening machines in the screening area due the

design of this particular BHS (see Section 3).

Second, in this BHS, a bag can be detoured if it has

at least 30 minutes until departure.

In Section 4, we state that in order to achieve

standardization among workstations, it is necessary

to impose due times on all retrieval tasks assigned to

cranes. Then, cranes can have a standard approach

for retrievals and do not have to distinguish

retrievals to robots from those to laterals. While due

times on retrievals to laterals are straightforward

(Section 4.2), we have to set due times on retrievals

to robots. We study several options (see Table 1) to

set due times and test the effect of each option on the

IR. We also observe the number of ULDs built by all

robots during a day of operation.

Option 1 builds upon the fact that each flight has

45 minutes allowed to use robots, starting one hour

before laterals open, but gives unacceptable results.

What happens is that a retrieval to a certain flight

may have 45 minutes until its due time, when it is

released early, but another retrieval to the same

flight may have few minutes until its due time, when

it is released towards the end of the time allowed for

the flight to use robots. A resulting behavior is that

crane controllers delay the retrievals to robots as

they had initially long time until they are due. Thus,

robots remain waiting and do not trigger for more

work because the assigned ULD builds were not

processed. Moreover, when retrievals for robots are

due soon, cranes start working on them and delay

retrievals to other flights building on laterals.

Consequently, a due time for each ULD is more

logical. For Options 2 and 3 in Table 1, we propose

a time interval allowed to build a ULD. We calculate

this interval using the number of bags planned for

the ULD divided by robot service rate. To take into

account issues such as transport times, delays and

blockings, we plan for less than 100% robot capacity

(Option 2, best at 60% of capacity), or plan for

100% capacity and add a time allowance (Option 3).

In fact, we found it best to use experimental build

times for ULDs (Option 4). We achieve a 0.071 IR

when 15 minutes is given to build a ULD for any

robot. Although semi-automated robots have a

higher handling capacity than automated robots, we

achieve best results when both robot types are given

the same time to build a ULD. Giving both the same

time to build a ULD at some point in time means

that the due times for all retrievals released at this

point in time are the same. Thus, cranes work on

retrieving bags for all robots in the system, but if due

times for semi-automated robots were few minutes

sooner, then the cranes would serve these robots and

delay the automated robots. So, at the system level,

bags are handled at a lower rate.

6 RESULTS AND DISCUSSION

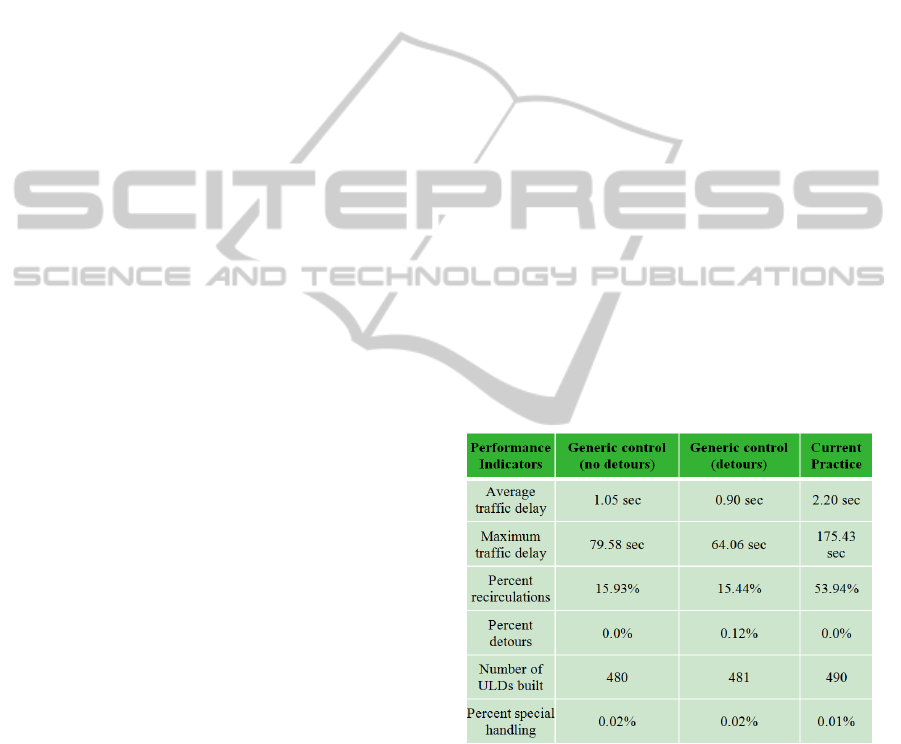

We compare the performance of the generic control

architecture to current practice for this BHS, and

find that both approaches achieve zero IRs under

normal operational conditions. Thus, we analyze

other performance indicators (see Table 2). We

observe that, due to the pull concept, generic control

performs better in minimizing the percentage of bags

that have to recirculate on the main sorter, which

decreases traffic delays. However, current practice

compensates for less output on the sorter by better

utilization of robots (more ULDs are built). This

occurs because retrievals for robots get priority in

current practice, while in generic control there is no

strict distinction between workstations. The

percentage of bags receiving special handling due to

missing the lateral close time is comparable.

Table 2: Generic control versus current practice.

Current practice approaches at the planning level

are customized, complex, and computationally

intensive. On the other hand, the generic control

architecture identifies the decision-making processes

at the right level of control, and handles layout-

specific details by configurable parameters. Hence,

the architecture is scalable and tunable to different

system layouts and designs. Moreover, the

architecture allows for a much faster implementation

and is both flexible and more robust; still without

compromising overall performance. Finally, we

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

128

stress that the comparisons we made are based on

normal operational conditions. When more severe

and unexpected disturbances in the material flow

occur, we expect generic control to outperform

current practice as generic control reacts directly to

problems in material flow and takes actions to avoid

possible congestions and imbalances.

In the following, we list some of the lessons

learned, which are useful when trying to implement

the generic control architecture to other MHSs:

Only use generic modules, e.g., we model any

type of build workstations by the generic

workstation module. Customized modules

hamper the generic structure.

Maintain standard interfaces between different

controllers.

System size and layout characteristics should not

affect the implementation of generic scheduling

processes. This is shown by our application of

the generic dynamic routing in the screening area

of the BHS.

The planning level of control is generic, but may

include system-specific business rules in making

decisions, since it is the interface to the users’

processes. This level can also include some

algorithms to make decisions within certain

controllers. For example, the storage controller

may use an algorithm to make decisions on

which bags in particular are to be assigned to a

certain ULD.

A distributed decision-making structure is

necessary, as it supports the modularity,

robustness, and generic nature of the control

architecture. For example, if a central controller

executes routing decisions, then it would not be

able to easily handle different system layouts.

Specific algorithms can be used for local traffic

control, they can be easily integrated as add-ons

to the control architecture and do not affect

communication at the higher levels of control.

7 CONCLUSIONS

In this paper, we provided a proof-of-concept for the

applicability of generic control for MHSs in

different sectors. One of the advantages is generic

modeling of workstations, being laterals or robots.

This resulted in a simpler control software for the

retrieval process. Moreover, we implemented a

dynamic routing strategy that uses the dashboard

logic to make routing decisions and to react to

breakdowns and congestion. These control methods

have a modular and generic structure, which allows

them to be implemented in different BHSs and

different MHSs in other industrial sectors.

In future research, we will return to the concept

of generic control and apply the generic control

architecture to a large MHS in the distribution

sector. In this MHS, we will study a large ASRS and

a large order picking area. The latter consists of four

order picking stations and a network of conveyors.

For this future implementation, we will test the

applicability of the generic control architecture and

analyze the extent to which we maintain the

structure of standardized control procedures. In

particular, we are interested in studying the

applicability of the generic routing method to a

MHS in the distribution sector, and in comparing the

implementation in the distribution sector with the

implementation in the baggage handling sector.

REFERENCES

Babiceanu, R. F., Chen, F. F., and R. H. Sturges (2004)

Framework for the control of automated material-

handling systems using the holonic manufacturing

approach. International Journal of Production

Research. 42(17): p. 3551-3564.

Hallenborg, K. and Demazeau Y. (2006) Dynamical

Control in Large-Scale Material Handling Systems

through Agent Technology, in Intelligent Agent

Technology, 2006. IAT '06. IEEE/WIC/ACM

International Conference on, pp. 637-645.

Haneyah, S. W. A., Schutten, J. M. J., Schuur, P. C., Zijm,

W. H. M. (2013a) Generic Planning and Control of

Automated Material Handling Systems. Computers in

Industry, 64(3): p. 177-190

Haneyah, S.W.A., Schutten, J. M. J., Schuur, P. C., Zijm,

W. H. M. (2013b) A generic material flow control

model applied in two industrial sectors. Computers in

Industry, in press (DOI: 10.1016/j.compind.2013.03.

007)

Haneyah, S. W. A., Hurink, J. L., Schutten, J. M. J., Zijm,

W. H. M., and Schuur, P. C. (2011) Planning and

Control of Automated Material Handling Systems:

The Merge Module. In: B. Hu, K. Morasch, S. Pickl,

and M. Siegle, editors. Operations Research

Proceedings 2010, Part 8, pages 281-286, Springer

Heidelberg Dordrecht London New York, 2011. ISBN

978-3-642-20008-3.

Johnstone, M., Creighton, D. and Nahavandi, S. (2010)

Status-based routing in baggage handling systems:

Searching verses learning. IEEE Transactions on

Systems, Man and Cybernetics Part C: Applications

and Reviews. 40(2): p. 189-200.

Tařau, A., De Schutter B., and Hellendoorn H. (2009a)

Centralized versus decentralized route choice control

in DCV-based baggage handling systems. In:

Proceedings of the IEEE International Conference on

AGenericControlArchitectureforMaterialHandlingSystemsAppliedtoaBaggageHandlingSystem

129

Networking, Sensing and Control, Okayama, Japan,

March 26-29, 2009.

Tařau, A. N., De Schutter B., and Hellendoorn H. (2009b)

Hierarchical route choice control for baggage handling

systems. In: Proceedings of the 12th International

IEEE Conference on Intelligent Transportation

Systems, St. Louis, MO,USA, October 3-7, 2009.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

130