Fairtrace

A Semantic-web Oriented Traceability Solution Applied to the Textile Traceability

Bruno Alves

1

, Michael Schumacher

1

, Fabian Cretton

1

, Anne Le Calv

´

e

1

, Gilles Cherix

2

,

David Werlen

2

, Christian Gapany

2

, Bertrand Baeryswil

3

, Doris Gerber

4

and Philippe Cloux

4

1

IIG, University of Applied Sciences Western Switzerland, TechnoArk 3, Sierre, Switzerland

2

Institut Icare, TechnoArk, Sierre, Switzerland

3

Fairtrace, Technoark, Sierre, Swtizerland

4

Importexa SA, 1095 Lutry, Switzerland

Keywords:

Traceability, Ontology, Semantic Web, Textile Industry.

Abstract:

This paper presents solutions that leverage Semantic Web Technologies (SWT) to allow pragmatic traceability

in supply-chains, especially for the textile industry. Objectives are the identification of the supply-chain, order

management, tracking and problem reporting (such as dangerous substance detection). It is intended to be a

generic platform supporting potentially any kind of industrial supply-chain, to be usable in harsh environments

(mobile appliances) without any kind of communications possibility and to be fully usable to non-IT people,

including for the modeling of the production processes. The developed solutions also allow the consumer to

benefit from the traceability through information pages available by scanning the QR codes available on the

finished products (clothes, clocks, etc.). This paper presents: i) the methodology applied to achieve those

functionalities, ii) the design and implementation choices, and iii) the test results. The main value of this

paper is the usage of the Semantic Web in real-world industrial traceability solutions, which were tested in real

supply-chains in Switzerland and India. The commercialization of the developed solutions is in preparation.

1 INTRODUCTION

In 2007, a new European regulation on chemicals

called REACH

1

initiated the creation of a catalog

of potentially dangerous substances actively used in

everyday consumer goods. Many of these have been

identified as potentially threats to human health and

are therefore forbidden on the European territory.

REACH puts the responsibility on the industry for

evaluating and managing the risks about chemicals

they use or import. As a consequence, industrial

actors henceforth have the duty of tracing all

substances in use in the products they manufacture or

import in Europe. Unfortunately, in practise this is

barely the case. As an example, during the EURO

2012 soccer championship, Europe’s Consumer

Watchdog revealed unusually high concentrations of

dangerous chemical substances in several team shirts

1

REACH - Registration, Evaluation, Authorization and

Restriction of Chemical Substances - http://ec.europa.eu/

environment/chemicals/reach/reach˙intro.htm

that could potentially be harmful to fans’ health

2

.

Independent tests highlighted high concentrations

of lead, nickel and organotin, a chemical that

can irreversibly damage the human nervous system.

That’s just one example among many others, but it

shows a major failure of brands and the clothing

industry in their capacity of fully capturing or even

understanding their own manufacturing processes.

When a problem is finally discovered, it is often

already too late and the cost of any corrective measure

is usually too high.

The case shown above is unfortunately too

common and stands as a motivation driver for the

work described in this paper. Bringing supply-chain

traceability to the end consumer and to the economic

partners (resellers or brands) is a difficult task.

Information related to the manufacturing process is

usually not made available (obfuscated on purpose

or by lack of sufficient means) or extremely opaque.

2

http://news.stepbystep.com/euro-2012-football-fans-

warned-against-buying- toxic-shirts-313/

36

Alves B., Schumacher M., Cretton F., Le Calvé A., Cherix G., Werlen D., Gapany C., Baeryswil B., Gerber D. and Cloux P..

Fairtrace - A Semantic-web Oriented Traceability Solution Applied to the Textile Traceability.

DOI: 10.5220/0004440900360045

In Proceedings of the 15th International Conference on Enterprise Information Systems (ICEIS-2013), pages 36-45

ISBN: 978-989-8565-59-4

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

However, in order to become REACH-compatible,

industrial actors will have the difficult task of

motivating each participant belonging to the process

to commit to the gathering of the necessary

information.

The work described in this paper provides the

outline of a first answer to the following research

questions: what is the best way to represent data

related to a supply-chain, so that it is flexible for

future adaptations and generic enough to be applied

to several industrial domains? How to design a

software solution that helps non-IT specialists in

defining their supply-chains themselves and that

assists their navigation through the acquired data?

How to provide an easy tool-set for the acquisition of

process information ? How to give a full transparent

access to this information through the entire chain,

so that we can really support traceability? To

tackle those problems pragmatically, we initiated the

Fairtrace project, a generic traceability framework.

The prototype presented in this paper is applied to the

textile industry.

The objectives of the project are primarily the

identification of the supply-chain (activities), order

management and monitoring, as well as problem

reporting (such as dangerous substance detection). It

is intended to be a highly generic platform supporting

potentially any kind of industrial supply-chain

(clock industry, cocoa, ...); to be usable in harsh

environments (mobile appliances) without any kind of

communication facilities and to be usable by non-IT

people (including the modeling of their production

processes). Our solution must also benefit the

final consumer (buyer), allowing him/her to obtain

information on the traceability with a simple scan of

a QR code on finished products (clock, cloth, ...).

To support our objectives, we decided to leverage

Semantic Web Technologies (SWT) in the core of

the Fairtrace software to assess potential advantages

when applied to an industrial setting.

A fully functional prototype has been designed

and implemented. Field tests have been realized in

India in February 2012. We have collected real-time

information triggered by an order for an organic

fair tee-shirt. A startup company founded by our

commercial partner Importexa is currently preparing

the commercialization of a product based on Fairtrace

applied to the textile industry. Other markets will also

follow soon. A part of the technology has already

been patented (a dynamic formular creation system

based on semantic data (Werlen et al., 2012)).

This paper is structured in five parts: the first part

discusses some aspects of research in specific areas

of supply-chain management. In the second part, we

detail in descriptive terms the methodology of our

work. Then, in the third, we present the results of

the project and various discussion issues in the fourth

part. We then conclude with some future directions

and challenges still to overcome.

2 RELATED WORK

Fairtrace aims at achieving an agile traceability

system that can help in the management and

monitoring of supply-chains. Supply-chain

management (SCM) is concerned with the

coordination of activities for producing a

product demanded by a customer (Mentzer et al.,

2001)(Chandra and Kumar, 2001). Because

thoughtful management of the supply-chain often

results in substantial cost savings, the field has seen

considerable industrial and research activity. It is

no surprise then, the literature on the subject is so

abundant that all aspects are well covered. (Lambert

et al., 1998)(Lambert and Cooper, 2000) describe

issues and opportunities of SCM. Other works

propose formal SCM frameworks (Grubic and Fan,

2010), infrastructures (Fox et al., 2000)(Christopher,

2005) and models (Ye et al., 2008b). Logistics is a

very active field where research focuses especially

on optimization patterns (Bowersox et al., 2002).

Supply-chain monitoring (SCMo) is a sub-branch

of SCM that operates on information, inventory

management and cash-flow (Lambert et al., 1998).

The monitoring strives to rapidly identify problems

in the supply-chain and solve them with the help of

established procedures.

The focus of this paper is on supply-chain

traceability (SCMt), which primarily addresses the

problem of tracing goods from raw materials to

finished products. An identifiable trend on SCMt

is the use of external technologies such as RFID

to enable traceability (K

¨

arkk

¨

ainen, 2003)(Kelepouris

et al., 2007), including in the textile industry (Kwok

and Wu, 2009). Many publications also exist on

SCMt processes and implications, such as (Opara,

2003). An important research track has been also

developed on the composition of Web services in the

supply-chain in order to ensure traceability among

the partners of the chain (Kim and Jain, 2005).

These works have been extended by enriching Web

services with Semantic descriptions, in order to

avoid ambiguity among the services and allowing

an explicit meaning of the data interchange (Mocan

et al., 2006). These Semantic Web Services (Paolucci

et al., 2002) and their coordination (Schumacher

et al., 2008) allowed to improve mutual sharing of

Fairtrace-ASemantic-webOrientedTraceabilitySolutionAppliedtotheTextileTraceability

37

information for business-to-business integration.

In order to define a common understanding

of supply-chain models, several research works

proposed the use of supply-chain ontologies (Grubic

and Fan, 2010). For instance, (Ye et al., 2008a)

proposed quite a complex ontology that is not

industry specific. Those work show that Semantic

Technologies can have many advantages for the

interoperability of the business partners in the chain.

Research works also exist to use Semantics with

RFID solutions (Virgilio et al., 2010). (Bechini

et al., 2008) also proposes semantics description to

ensure traceability. Other interesting research papers

describe the usage of autonomous agents to deal

with the information in the supply-chain (Fox et al.,

2000), including its combination with Semantic Web

descriptions (Datta et al., 2007).

In relation to the research above, the work

presented in this paper can be specified as follows:

Fairtrace is meant to trace all activities of the entire

manufacturing process, including documents and

products. It is able to identify the raw materials which

were used, certificates, waste, etc. It can also be

used to identify roles and responsibilities and to keep

track of who did what. It does not currently include

optimization techniques for the logistics. Fairtrace

can track many variables, which can be used as

performance indicators. A customizable chain of

validators also allows to track problems arising along

the supply-chain, such as the detection of dangerous

chemical substances. Businesses can thus react

very quickly to any unexpected condition. From

a technological perspective, Fairtrace was conceived

with a focus on Semantic Web Technologies (SWT).

Every piece of data in the system is related to a

concept in a semantic data repository. All models

use semantic descriptions and traceability information

can be displayed to the user hierarchically.

The next sections explain thoroughly how

Fairtrace was conceived, and its main results.

3 METHODOLOGY

The scoping phase of the project consisted in

capturing and understanding the requirements of

traceability. An analysis of a typical textile

manufacturing chain was made to get a rough idea on

the process. A consultant specialized in the textile

industry was commissioned to analyze Importexa’s

own supply-chain in India. Her mission was to

visit factories, identify and document all activities

throughout the manufacturing process. She captured

information about certificates, delivery challans,

cotton lots, mixing lots and many other documents,

but also took pictures of places and production

machines. Our task was thereafter to analyze all

those paper resources in order to sketch out a formal

description of the longitudinal process. The very

first model was a transcription of the complete,

moderately detailed manufacturing process using the

primitives of BPMN

3

.

The process was complemented by several

additional documents more accurately describing the

information to be captured on the supply-chain. A

critical path — a minimal path from the starting

activity (order) to the end (ginning)— was defined.

The method consisted in searching through pairs

of documents such as orders, challans or bills for

matching identifiers to find a complete and continuous

traceability path up to the origin of the cotton. The

base model was augmented with additional attributes

(GSM, weight, ...) extracted from the documents that

we analyzed. This extra information helps tracking

quantities and waste.

3.1 Requirements

Fairtrace objectives focus on usability, supply-chain

data transparency, genericity and adaptability.

As a consequence of the first requirement,

business partners in the supply-chain needed a simple

way to enter data about their production directly into

our system. Among all alternatives considered, a

system of minimally constrained web formulars was

retained. On one hand, it was important to give users

the freedom to design themselves these formulars

— possibly by drag-dropping GUI components

— without having to resort to any particular IT

knowledge or skills. On the other hand, formulars

needed to the bound to the underlying data model.

Web formulars coupled to a flexible data binding

system offer the kind of usability that was required

in this project. Web forms can be implemented in

pure HTML and are supported natively by all kinds

of devices. They can be adapted to any sort of display

they are affected to, with relatively few lines of CSS

code. They can be edited and pre-filled with data

coming from the repository and customers can mark

fields optional or required at wish.

The formular system was also designed to be

adaptable. Each formular is dynamically linked to the

underlying data model by a dynamic binding system

that uses specific binding names to associate fields

from the formulars to particular objects and properties

in the model. Coupled to an instantiation engine that

3

BPMN - Business Process Modeling and Notation -

http://www.bpmn.org

ICEIS2013-15thInternationalConferenceonEnterpriseInformationSystems

38

creates model instances based on the data acquired,

the whole system provides a very generic framework

that can adapt to almost any model or domain, without

requiring recompilation.

To provide transparency on the data, it is

important that information can be accessed without

any technological barriers. A dashboard system

providing supply-chain monitoring support and

capable of providing easy data exploration was

designed as a consequence. Furthermore, we wanted

the information to be presented to the customer both

horizontally (information for a specific time frame)

and vertically (hierarchy of data). Such a system

would allow anyone entitled to do so, to descend into

any part of the traceability data chain providing them

with a full transparent access to its contents.

3.2 Domain Modelling

The data model in Fairtrace was designed to capture

many different aspects of the supply-chain, including

details on the process itself and on the products

deriving from it. We divided the modeling task into

creating models for both.

To improve on usability, we wanted to empower

the customers (or any one entitled to do so) to design

graphically their supply-chains. We had to provide

the necessary primitives (activity, flow ) to allow it.

For that reason, we did not hard-code the process

into a model for each different customer, but decided

instead to specify a language partly derived from

BPMN describing business process concepts such as

activities, flows, roles, users, partners, authorizations

and collection points. Supply-chains would then be

specified in terms of these primitives.

Currently, our model only provides support for a

tiny subset of BPMN-like constructs. We added a

few more custom primitives (collection points) that

are used by the security granting mecanism. Before

resigning ourserves to model everything from scratch,

we tried on different approaches. We had a look to the

PSL

4

specification and ontogy, M3PO(Haller et al.,

2006) and BPMNO

5

. Unfortunately, the complexity

of the semantics and the verbosity of those models

seemed a bit ”overkill” for our needs.

The product model is strongly bound to the

industrial domain it describes; in this case, the domain

was the textile supply-chain. We searched on-line

for existing ontologies describing domain knowledge

on textile products, but unfortunately, we could not

4

PSL - Process Specification Language - http://

www.mel.nist.gov/psl/

5

BPMO - BPMN Ontology - https://dkm.fbk.eu/

index.php/BPMN˙Ontology

find any that more or less suited our needs. We

decided thus to also model the product domain from

scratch. To do so, we’ve literally analyzed dozens of

documents brought back from India by the consultant.

3.3 Semantic Technologies

The leveraging of Semantic Web Technologies was

a prerequisite in this project. We didn’t have an

extensive knowledge on the subject when the project

started. It was thus important for us to stay simple

and practical at all times. In order to cope with this

requirement at every step, we did a lot of testing on

example datasets. We only started implementing the

ontologies after we felt confident enough that there

would be no uncontrolled side effects (i.e inferences

that were not expected).

Our models didn’t require a high level of

expressiveness, since they were almost one-to-one

mappings from an object-oriented hierarchy. We

didn’t use elaborated constructs like Restrictions,

because we wanted to be sure of the decidability.

We also needed the language to be sound, complete

(all logical consequences are drawn) and monotonic

(i.e all statements remain valid after inserting

new knowledge). We translated the conceptual

models (process, products) to RDFS instead of a

more expressive OWL, not only because it was

easier to work with, but also because semantics

were easier to grasp. Our models are based

on subsumption hierarchies that use sub-class

and sub-property relations (rdfs:subClassOf,

rdfs:subPropertyOf) extensively.

The process model does not put any additional

requirements on the predicates it declares. No

particular semantics are specified, because this

model is very similar to what would be done on an

object-oriented programming language. The product

model however, needs more expressiveness in order

to model the existing links between objects of

different classes, but also to compensate for potential

gaps due to the lack of sufficient data. We had

to model inverse properties (owl:inverseOf) and

property chains axioms (only available in OWL 2).

In order to avoid the extra cost of using OWL, we’ve

decided to take an intermediate route and create extra

entailment rules for these very few specialized cases.

Here are some examples in predicate logic:

Simulating owl:inverseOf:

inOrder(X,Y), Type(X,Batch),

Type(Y,Order) => hasBatch(Y,X)

Simulating property chain axioms:

Fairtrace-ASemantic-webOrientedTraceabilitySolutionAppliedtotheTextileTraceability

39

hasFabric(X,Y), hasYarn(Y,Z),

Type(X,Order), Type(Y,Fabric),

Type(Z,Yarn) => hasYarn(X,Z)

3.4 Infrastructure

The prototype infrastructure was designed to meet

requirements for the three types of customers we

wanted to target: business partners, end users and

supply-chain partners.

The business partners category is mostly

composed of brands and resellers that will license

the future Fairtrace solution for monitoring their

own supply-chain. Their needs are primarily

basic-management controls, extensive information

and problem reporting. Those requirements were

implemented into the prototype as a supply-chain

designer, a graphical formular edition interface and

a dashboard to control all operations, assign users,

roles and authorizations.

To end users we wanted to provid them with

traceability information about a product on scanning

a QR code on the finished product. We had to design

a system to map these codes to specific views on

the information collected from the data store. That

information is then formatted to target the particular

device the user browses on.

Finally, we had to provide a way for the

supply-chain partners to send data to the system.

By partners, we mean any entity working in the

supply-chain to create and finalize the product. These

can be factories, transporters, single users... The

dynamic formular system we designed was meant to

be simple and functional. It supports simple common

controls such as date pickers, file selectors, picture

boxes, text fields, lists, combo boxes and other types

of selectors. It is thus possible to integrate certificates

(such as for biological production) as PDF/A files

as well as other kind of documents. Those binary

resources are stored on the cloud and a link is kept

inside the RDF data store. The formular design

and the dynamic binding systems were thought to

be used by designers not especially proficient with

technology. We favored simplicity and wanted to hide

the technical details (URIs, JSON object, ...).

Furthermore, we also considered both mobile and

browser-enabled applications to display formulars.

The mobile application was designed to manage and

display the formulars in potentially non connected

configurations. We had to take into account that

wireless signal could be a problem in some places

where the application was meant to be used (such

as in cotton fields in India). We designed an offline

mode, that would allow later synchronization with

the Fairtrace server. The browser-enabled application

was meant to be used directly in factories, where

Internet is generally available. We considered this

option too, because it was obviously easier and faster

to input data from a keyboard rather than on a mobile.

3.5 Implementation

The actual implementation phase went surprisingly

well. We opted for an agile development process

with a relatively short feature development cycle (<1

month). We were able to finish both on time and

on budget. We spent extra resources on polishing

important features, so that the prototype would be

ready for a demonstration to potential customers.

The last step of the development was testing the

prototype in a real situation. We modeled Importexa’s

supply-chain and requested them to initiate the

process. Importexa started an order for an organic

fair cotton tee-shirt. When the actual manufacturing

began, we had the consultant in India to teach the

functioning of the system and to check that everything

was going as planned. We wanted to show off that

the prototype was able to trace all the manufacturing

activities and capture all the products of it.

4 RESULTS

This project yielded three main results, which are the

functional prototype, two ontologies created from the

process and product models and the system and the

modeling of a textile manufacturing chain.

4.1 Prototype

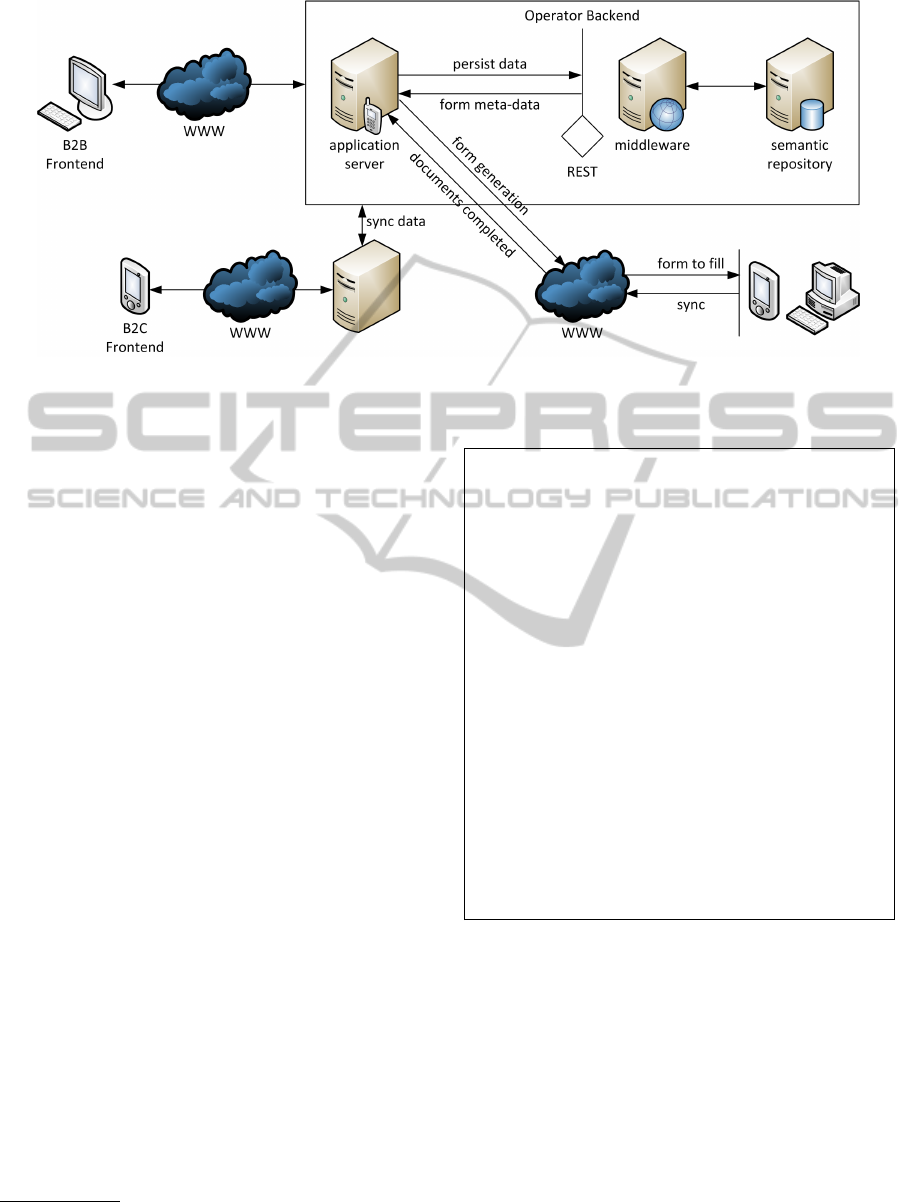

The prototype shown on Figure 1 is a three-tier

infrastructure composed of a data, a business and

a presentation layers and was developed in Java as

a Spring MVC application running on a Tomcat 6

servlet container. The data layer hosts the RDF store

(semantic repository). The middleware is comprised

of the business layer and acts as a message translator

and rule enforcer between the application server

and the RDF store. Finally, the presentation layer

contains both the Business To Business (B2B) and

front-end operators. A Business To Consumer (B2C)

front-end solution maps QR codes that come on the

final products with information views about the whole

upstream chain to be presented to the final consumer.

The semantic functionality (i.e. semantic store)

is provided by the BigOWLim 3.5 engine from

ICEIS2013-15thInternationalConferenceonEnterpriseInformationSystems

40

Figure 1: Overview of the architecture.

OntoText

6

running as an extension of the OpenRDF

7

Sesame 2.4.0 runtime. A set of Data Transfer

Object (DTO) classes provide seamless data access

and querying functionality. The prototype exclusively

uses SPARQL 1.0 queries, since SPARQL 1.1

UPDATE was not supported by the versions of

OWLim and Sesame used in the prototype. Data had

to be programmatically inserted, updated or removed.

Queries for traceability data are made against the

implicit graph containing the inferred triples. Queries

on the process itself are made against the explicit

graph and returned to the API caller via the DTOs.

The business layer is comprised of a set of

classes that receive requests through a series of

REST Web service endpoints. The requests and

responses are encoded as JSON objects. Payloads

are translated, verified, business rules are enforced,

security applied and then forwarded as a data access

requests. Data extraction is done with SPARQL

SELECT and CONSTRUCT queries. Repository

modifications are done in transactions and are rolled

back in case of problem. Service endpoints that

manage process resources (objects) use the CRUD

paradigm (Create, Retrieve, Update, Delete) and

produce JSON-encoded messages. Data requested for

products is returned as a group of properties along

with the identifier of the individual (Listing 1).

The application server was built on the latest

version of Ruby on Rails and coordinates all requests

between the presentation layer components and the

back-end storage. It also enforces a certain number of

business rules, but its role is more to coordinate B2C

and B2B actions, unlike the back-end, which role is

to coordinate data requests. The B2B front-end is the

6

http://www.ontotext.com

7

http://www.openrdf.org

Listing 1: Product object encoded in JSON.

property_set: {

properties: [

{

property: {

name: " order_id " ,

label: {

" en ": " original order number "

} ,

value: " CA16576 "

}

} ,

{

property: {

name: " re f e r e n c e_id " ,

label: {

" en ": " purchase order number "

} ,

value: " 221 9 "

}

}

] ,

object_id: " order001 "

}

Web-based control panel of the system. It is intended

to be customizable to businesses willing to license

the Fairtrace ecosystem. It allows to dynamically

and graphically model the supply-chains, creating

the formulars and binding them to any step of the

associated process. It can monitor order progress by

showing various indicators and track any upstream

issue such dangerous chemical detection. Users can

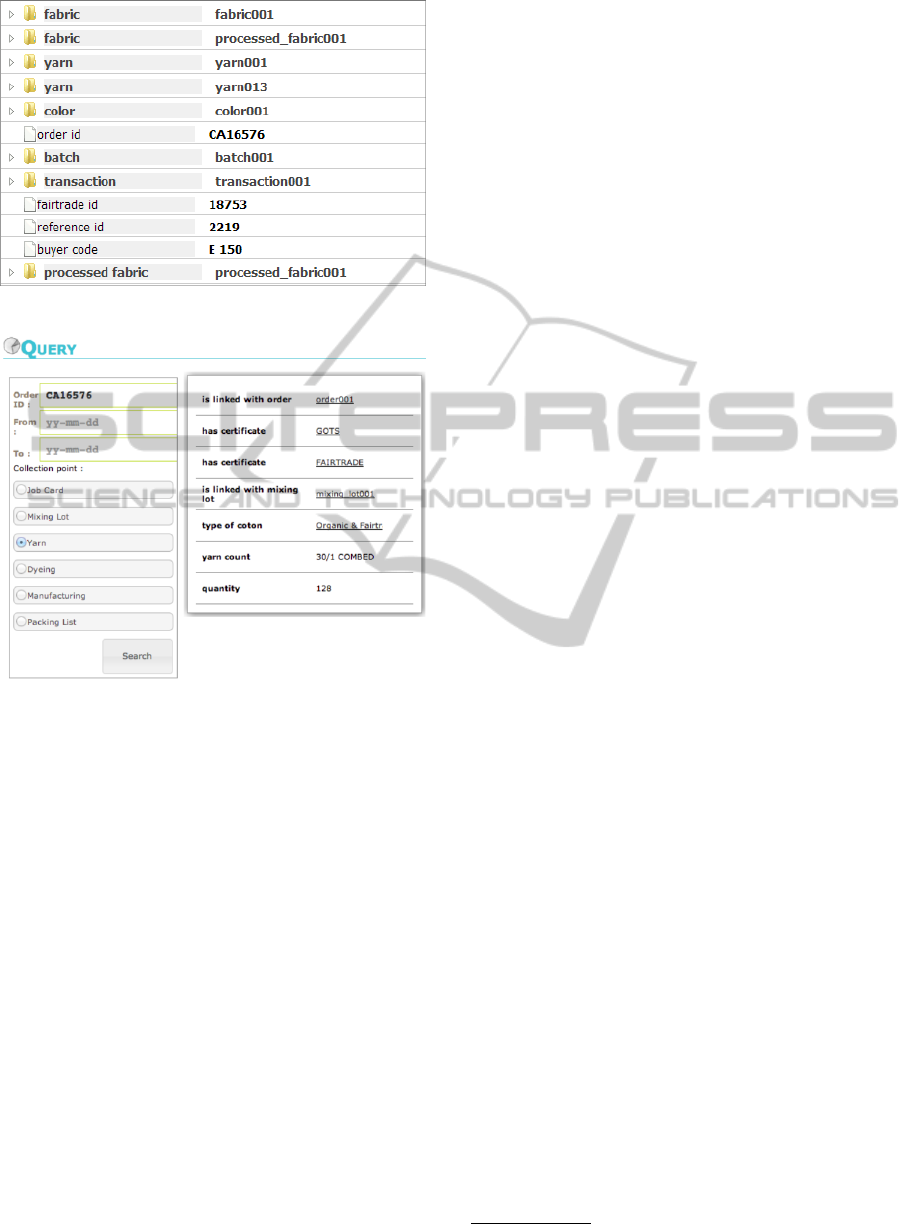

then navigate vertically through traced data (Figure 2)

or horizontally (Figure 3) by querying the date inside

a specific time span.

The Operator front-end is aimed at supply-chain

partners working in coordination. It presents them

Fairtrace-ASemantic-webOrientedTraceabilitySolutionAppliedtotheTextileTraceability

41

Figure 2: Vertical navigation through data hierarchy.

Figure 3: Horizontal navigation through data.

formulars that were previously created in the B2B

front-end for them. It allows them to send data

related to their activities into the system. On

the mobile appliances, the frontend is an HTML5

container application that allows to download pending

formulars created on the B2B front-end, fill them,

update them and synchronize them back with the

application server. It provides support for an offine

mode, where data can be synchronized back later.

In the prototype, the detection of dangerous

substances was not codified in the model ontologies.

We decided to develop that functionality with a

chain a validators. Each validator is created as

a plug-in, which can analyze a subset of the

dataset and generate messages on certain conditions.

There are three types of messages: exception,

warning and informational. Validation can be trigged

manually from the dashboard or can be set to be

triggered automatically upon any modification of

the data. The validator for dangerous chemicals

validates each individual of class ft:Substance by

matching it against a database of known harmful

chemicals. One goal set for the next iteration of

Fairtrace is to use external sources directly integrated

with our models in order to be able to infer the

fto:DangerousSubstance class and take advantage

of the inferencing mechanisms.

4.2 Ontologies

Implementing the models was a bit delicate in

that a clear separation of concerns was necessary.

Having a multi-disciplinary team, we needed a

modularized design in order to allow parallel and

effective development. In order to create the

ontologies based on our models a RDF repository

to store ontology data was required. The choice of

BigOWLim as the semantic repository and reasoner

is the result of an objective test, where different

semantic repositories were compared based on a few

metrics (size, simplicity, ..). The BigOWLim 3.5

engine works as an extension of a SAIL repository

in Sesame. It is easy to setup, provides really

fast inferences on vast amounts of data, supports

geo-spatial and full-text search capabilities.

BigOWLim Triple Reasoning and Rule

Entailment Engine (BigTRREE) uses a total

materialization reasoning strategy that computes

inferences after insert/update/delete cycles. That

kind of strategy has the disadvantage of making

inferences a bit slower (especially on very large

datasets), because it computes the complete closure

(optimizations aside) on each transaction. Even

so, it does allow extremely fast queries, almost on

par with traditional DBMS systems. The Fairtrace

prototype heavily relies on queries, so BigOWLim

was certainly a righteous choice. An additional

feature that also helped in our choice was that it was

actually very easy to deploy and write entailment

rules for. We made an agreement with OntoText to

use their repository technology free of charge in our

research projects.

Almost every object used by the web and mobile

platforms is stored in the repository A-BOX as

an individual from either the process ontology or

the product ontologies. Each ontology is the

implementation of a conceptual model in RDF

Schema

8

.

The process ontology defines the building blocks

for modeling business processes. It is a straight

mapping from an object model to RDF. It does

not define any particular semantics, except the ones

explicitly given in the RDF Schema specification (?x

rdfs:type rdf:Resource for instance). It builds

around concepts like steps (activities), flows (links),

8

http://www.w3.org/TR/rdf-schema/

ICEIS2013-15thInternationalConferenceonEnterpriseInformationSystems

42

users, roles, authorizations, partners, collection

points and formulars. Formulars are assigned to

a particular collection point linked to a specific

step. Authorizations are defined for collection points

to state who and on what role can enter data

and download the formulars. The intent of these

primitives is not to fully map the BPMN specification,

but to present a synthetic view of the supply-chain.

Conditions, loops and other advanced primitives

are not yet supported. We did not reuse existing

ontologies, because we needed a simple and efficient

ontology.

The product ontology models the domain objects.

In contains definitions for textile industry objects,

such as fabrics, parts, dyes, yarns, mixing lots.

Concepts are linked together – in a critical path – so a

customer can eventually navigate through individuals

from the initial order down to the geographical place

where the cotton was produced. Every step and every

product of the supply-chain can thus be identified.

Documents and special objects, such as certificates

are also modeled and can be linked to binary data

(pictures). They can be used to prove that cotton is

really organic and fair and that all authorizations have

been obtained by a partner for instance. Importexa

can enforce that business partners insert them in the

system. In terms of semantics, the model uses mostly

subsumption hierarchies. We assert for example:

fto:Certificate rdfs:subClassOf

fto:Document .

fto:ProcessedFabric rdfs:subClassOf

fto:Fabric .

fto:hasCertificateName rdfs:subPropertyOf

rdfs:label .

Furthermore, to compensate for the lack of

property-chains (only available in OWL 2), we

defined custom rule-sets (see Section 3.3). These are

necessary in order to bridge the gaps in the model that

can occur due to the lack of sufficient data, causing

thus an impossibility to descend in the hierarchy.

4.3 Supply-chain Modelling

We also modeled a simple textile supply-chain

obtained from the analysis of the information taken

in the supply-chains in India. According to our

consultant, our process model, even simple matches

almost 90% of existing real chains. It models all

upstream steps such as Mixing, Spinning, Dyeing,

Processing, Transforming, Weaving, Sewing and

Packaging. Ginning was purposely left aside, since

information about the provenance of cotton was

readily available at the Mixing step.

4.4 Testing

The infrastructure was deployed and tested in India.

The objective was purely to assess its flexibility.

We did not acquire quantitative indicators such as

number of queries for each order, etc., because it was

materially (i.e. financially) not possible to launch

enough real orders to gather enough data for the

results to turn out meaningful. We concentrated

thus on a feasibility study following the project plan

methodology:

• We selected the supply-chain partners in India that

usually work with the textile company Importexa

in Switzerland ;

• A consultant from Importexa visited the partners

on site in order to thoroughly document the

supply-chains ;

• The consultant described formally the

supply-chains using a Business Process Modeling

notation ;

• On the basis of the consultant documentation

(data description, business process model, etc.),

we designed in our Web-based B2B Frontend

the processes and formulars acquiring information

inside those formulars ;

• Those formulars were instantaneously deployed

for data acquisition, both as HTLM5-enabled

mobile and Web formulars ;

• Importexa launched a real order for an organic fair

cotton tee-shirt, whose production data should be

acquired with our solutions ;

• A consultant was then sent to India in order to

teach working partners how to input data on the

forms and send it for treatment ;

• A final report described the results of the tests .

The tests ran for many days and a couple of

formulars had to be re-adjusted to better match the

partner’s requirements. We were reactive and could

almost immediately update the formulars and they

were able to use it straight away. As the tests were

made on a real Importexa order, we could monitor

data incoming from all steps including all chemicals

and certificates (GOTS, Fairtrade, GMO free, and so

on) in realtime.

5 DISCUSSION

Fairtrace is regarded as a success on management,

collaboration and technology support levels. The

project encountered high commercial concrete

Fairtrace-ASemantic-webOrientedTraceabilitySolutionAppliedtotheTextileTraceability

43

Figure 4: Test data acquisition in India.

interest when it was presented and demonstrated

in a technical session to potential customers. One

customer is ready to deploy the solution for his

supply-chains. The project plans to be integrated

in a start-up with the help of the CTI Start-up

9

, an

important Swiss coaching institution. Although we

had no quantitative metrics for the tests, we could

assess on its success in a real scenario. The testing

in India has faced many unexpected real-world

conditions that could not be foreseen. We were able

to respond to problems and modification requests

quickly (in a matter of minutes) and could attest of

the flexibility of the prototype.

Importexa is now heading to the creation of a

start-up that will commercialize the finished product.

Fairtrace is going be improved and adapted to market

segments other than the textile industry. A survey

on potential markets has already been done and first

discussions have already taken place with interested

brands and Swiss resellers, in order to adapt the tool to

brand new markets (clock industry, controlled cheese

production, cocoa, ...). Supply-chain traceability can

be a strong selling argument, because it implies that

companies master the entire production chain, can

react quickly to potential problems (such as to follow

the REACH regulation) and can prove their customers

that they exactly know what they produce.

In this project the use of Semantic Web

Technologies was a prerequisite, because it was a

good opportunity to explore its possibilities for future

projects. We were already a bit familiar with the

tools and techniques, but not sufficiently aware of its

benefits or complexities to apply it in future projects.

We had to work out many issues and carefully think

about our solutions. Still, Fairtrace proved that SWT

are safe for use in commercial projects, because they

9

http://www.ctistartup.ch

are now sufficiently mature. We kept things very

simple at the moment, because we had a real need

for pragmatism, so we only had a glimpse at the full

range of possibilities that Semantic Web has to offer.

Our model was not thought in terms of inferences it

could entail, but rather in terms of object orientation.

We needed to translate RDF data into Java classes and

thereby lost part of the expressiveness power of these

technologies. To compensate for this, the prototype

relied heavily on queries. The lack of SPARQL 1.1

UPDATE support has also somewhat hindered our

efforts. Programmatically inserting/updating/deleting

triples in the store was difficult, verbose and error

prone.

Although we did only use a small subset of

it, Semantic Web Technologies still provided a

real competitive advantage, because they allowed

a greater modeling flexibility in comparison to

other database technologies. Translating the logical

models to RDF Schema was simple and quick.

The expressiveness of the language coupled to

the rule-based OWLIM reasoning engine was good

enough to allow sufficiently complex constructs.

There is still a lot we can do to improve the

current state of things: we can link geographical

places to GeoNames

10

features for instance, redirect

specific concepts to DBpedia

11

definitions or even

automatically categorize items as dangerous by

making use of bridges to external datasets. In next

iteration of Fairtrace, we’ll definitely investigate on

integrating OWL features like (inverse) functional,

symmetric and invese properties, as well OWL2

property chain axioms vs. creating our own rules, also

on integrating geo-spatial extensions (for marking

places) to reason about distances and, of course, the

new SPARQL 1.1 constructs.

6 CONCLUSIONS

This paper presented a pragmatic semantic-based

research solution to the traceability problem in

supply-chains. The first prototype is finished

and has been successfully tested in a Swiss

and Indian supply-chain in the textile industry.

However, Fairtrace is still an ongoing work and

the roadmap contains many improvements. SWT

will continue playing a central role in the future

infrastructure. We are planning to use the

next-generation OWLIM semantic repositories and

take advantage on the new constructs offered by

10

http://www.geonames.org

11

http://dbpedia.org

ICEIS2013-15thInternationalConferenceonEnterpriseInformationSystems

44

OWL2 and SPARQL 1.1 UPDATE. We are also

planning important improvements on the creation

of formulars, on the customization of the system

and on the primitives for modeling supply-chains.

Finally, we consider intelligent agent techniques for

automatically queryingthe semantic repositories to

help the decision support of users.

ACKNOWLEDGEMENTS

We especially thank the Swiss Commission for

Technology and Innovation

12

who financed a big part

of this project under contract number PFES-ES No.

11141.1, and the company Ontotext who supported

us with a research license for BigOWLIM.

REFERENCES

Bechini, A., Cimino, M. G. C. A., Marcelloni, F.,

and Tomasi, A. (2008). Patterns and technologies

for enabling supply chain traceability through

collaborative e-business. Inf. Softw. Technol.,

50(4):342–359.

Bowersox, D., Closs, D., and Cooper, M. (2002). Supply

chain logistics management, volume 2. McGraw-Hill

New York.

Chandra, C. and Kumar, S. (2001). Enterprise architectural

framework for supply-chain integration. Industrial

Management and Data Systems, 101(6):290–304.

Christopher, M. (2005). Logistics and supply chain

management: creating value-added networks.

Pearson education.

Datta, S., Lyu, J., and Ping-Shun, C. (2007). Decision

support and systems interoperability in global

business management. International Journal of

Electronic Business Management.

Fox, M., Barbuceanu, M., and Teigen, R. (2000).

Agent-oriented supply-chain management.

International Journal of Flexible Manufacturing

Systems, 12(2):165–188.

Grubic, T. and Fan, I.-S. (2010). Supply chain ontology:

Review, analysis and synthesis. Comput. Ind.,

61(8):776–786.

Haller, A., Oren, E., and Kotinurmi, P. (2006). m3po:

An ontology to relate choreographies to workflow

models. In Services Computing, 2006. SCC’06. IEEE

International Conference on, pages 19–27. IEEE.

K

¨

arkk

¨

ainen, M. (2003). Increasing efficiency in the

supply chain for short shelf life goods using

rfid tagging. International Journal of Retail &

Distribution Management, 31(10):529–536.

Kelepouris, T., Pramatari, K., and Doukidis, G. (2007).

Rfid-enabled traceability in the food supply

12

http://www.kti-cti.ch

chain. Industrial Management & Data Systems,

107(2):183–200.

Kim, J. W. and Jain, R. (2005). Web services composition

with traceability centered on dependency. In

Proceedings of the Proceedings of the 38th Annual

Hawaii International Conference on System Sciences

(HICSS’05) - Track 3 - Volume 03, HICSS ’05, pages

89–, Washington, DC, USA. IEEE Computer Society.

Kwok, S. K. and Wu, K. K. W. (2009). Rfid-based

intra-supply chain in textile industry. Industrial

Management and Data Systems, 109(9):1166–1178.

Lambert, D. and Cooper, M. (2000). Issues in supply chain

management. Industrial marketing management,

29(1):65–83.

Lambert, D., Cooper, M., and Pagh, J. (1998). Supply chain

management: implementation issues and research

opportunities. International Journal of Logistics

Management, The, 9(2):1–20.

Mentzer, J., DeWitt, W., Keebler, J., Min, S., Nix, N.,

Smith, C., and Zacharia, Z. (2001). Defining supply

chain management. Journal of Business logistics,

22(2):1–25.

Mocan, A., Moran, M., Cimpian, E., and Zaremba, M.

(2006). Filling the gap - extending service oriented

architectures with semantics. In Proceedings of the

IEEE International Conference on e-Business

Engineering, ICEBE ’06, pages 594–601,

Washington, DC, USA. IEEE Computer Society.

Opara, L. (2003). Traceability in agriculture and

food supply chain: a review of basic concepts,

technological implications, and future prospects.

Journal of Food Agriculture and Environment,

1:101–106.

Paolucci, M., Kawamura, T., Payne, T., and Sycara,

K. (2002). Semantic matching of web services

capabilities. The Semantic WebISWC 2002, pages

333–347.

Schumacher, M., Helin, H., and Schuldt, H. (2008).

CASCOM: Intelligent Service Coordination in the

Semantic Web. Birkhäuser Basel, 1st edition.

Virgilio, R., Sciascio, E., Ruta, M., Scioscia, F.,

and Torlone, R. (2010). Semantic-based rfid

data management. In Ranasinghe, D. C. C.,

Sheng, Q. Z. Z., and Zeadally, S., editors,

Unique Radio Innovation for the 21st Century,

pages 111–141. Springer Berlin Heidelberg.

10.1007/978-3-642-03462-6˙6.

Werlen, D., Alves, B., Cherix, G., Gapany, C., and

Schumacher, M. (2012). Proc

´

ed

´

e d’

´

edition de

formulaires pour la saisie de donn

´

ees en diff

´

erents

points de collecte. Swiss patent application

CH00104/12 filed on Jan. 25, 2012.

Ye, Y., Yang, D., Jiang, Z., and Tong, L. (2008a).

An ontology-based architecture for implementing

semantic integration of supply chain management. Int.

J. Comput. Integr. Manuf., 21(1):1–18.

Ye, Y., Yang, D., Jiang, Z., and Tong, L. (2008b).

Ontology-based semantic models for supply chain

management. The International Journal of Advanced

Manufacturing Technology, 37(11):1250–1260.

Fairtrace-ASemantic-webOrientedTraceabilitySolutionAppliedtotheTextileTraceability

45