3D Realtime Simulation Framework for a Wall-climbing Robot using

Negative-pressure Adhesion

Daniel Schmidt, Jens Wettach and Karsten Berns

Robotics Research Lab, University of Kaiserslautern, Gottlieb-Daimler-Str. 48, Kaiserslautern, Germany

Keywords:

Simulation, Wall-Climbing Robot, Negative-Pressure Adhesion, Thermodynamic Model, Visualization.

Abstract:

Simulation frameworks are wide-spread in the range of robotics to test algorithms and analyze system behavior

beforehand – which tremendously reduces effort and time needed for conducting experiments on the real

machines. This paper addresses a component based framework for simulating a wall-climbing robot that uses

negative pressure adhesion in combination with an omnidirectional drive system. Key aspect is the adhesion

system which interacts with the environmental features such as surface characteristics (e. g. roughness) or

defects. An elaborate thermodynamic model provides the basis for a realistic simulation of the airflow between

the virtual environment and the vacuum chambers of the robot. These features facilitate the validation of

closed-loop controllers and control algorithms offline and in realtime.

1 INTRODUCTION

In robotics, simulation frameworks are important

tools to evaluate algorithms e. g. for path-planing

or obstacle avoidance without executing them on the

real machine. This avoids unnecessary stress on the

hardware, reduces testing time and enables develop-

ers to analyze system behavior without endangering

persons, the environment or the robot itself.

State-of-the-art frameworks facilitate a physically

realistic 3D simulation of all kinds of robots, e. g.

wheel-driven systems, walking machines, flying and

underwater robots, as well as sensor systems and ma-

nipulators. But so far, support for the simulation of

airflow and resulting negative pressure adhesion in the

context of climbing robots is still missing.

This paper presents a framework for simulating

CROMSCI

1

– a complex wheel-based climbing robot

with an omnidirectional drive, active sliding suction

cups and environmental sensors. Its key aspects are

seven individual adhesion chambers, inflatable seal-

ings for leak-tightness, built-in suction engines evac-

uating a large vacuum reservoir and three unsprung

steerable driven wheels (Schmidt et al., 2011). In ad-

dition to experiments performed with a real prototype,

especially the simulation of the interaction between

adhesion system and surface allows extensive tests of

safety strategies and closed-loop controllers.

1

http://agrosy.cs.uni-kl.de/cromsci/

The paper is organized as follows: Section 2 gives

an overview of existing 3D simulation tools and appli-

cations related to the adhesion mechanism of climb-

ing robots. The general concept of the simulation

is presented in section 3. Section 4 describes the

setup of the virtual environment and robot model us-

ing the SIMVIS3D framework. Afterwards, section 5

presents the thermodynamic model, leakage simula-

tion and physical aspects of the drive system. Sec-

tion 6 shows the interaction of all simulation compo-

nents in terms of some experiments. The final conclu-

sion follows in section 7.

2 RELATED WORK

Gazebo (Koenig and Howard, 2004) is a simulator

for multiple robots in arbitrary 3D environments with

an interface for the control framework ROS. It sup-

ports realistic noisy data for different kinds of sen-

sors, e. g. sonar, laser scanners, cameras, Kinect,

GPS, RFID and inertial systems as well as rigid-body

dynamics for object manipulation via the ODE or

Bullet engine. SimRobot (Laue and R

¨

ofer, 2008)

is a similar tool based on ODE that focuses mainly

on the RoboCup Soccer scenario via a realistic sim-

ulation of camera disturbances and actuator friction.

USARSim (Wang et al., 2003) is the simulation tool

for the RoboCup Rescue scenario. It is based on the

Unreal game engine and uses Karma for physics.

184

Schmidt D., Wettach J. and Berns K..

3D Realtime Simulation Framework for a Wall-climbing Robot using Negative-pressure Adhesion.

DOI: 10.5220/0004444401840191

In Proceedings of the 10th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2013), pages 184-191

ISBN: 978-989-8565-71-6

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

Concerning commercial tools, Webots (Michel,

2004) focuses on research robots as Aibo, Pioneer or

Kuka youBot. It uses ODE and provides support for a

rather complete set of sensors and actuators. Vortex

2

is tailored to heavy industrial equipment as cranes, ex-

cavators and military vehicles. It comes along with

its own physics and particle simulation for fluids, dust

and shapeable soil. Finally V-REP (Freese et al., 2010)

is a feature-rich 3D simulator for wheel-driven, walk-

ing and flying robots with support for different kinds

of manipulators, sensors and dynamic particles for jet

engines, either based on ODE or Bullet.

All these tools have the restriction of system dy-

namics to rigid bodies in common. Although suffi-

cient for collision detection and pick-and-place tasks,

negative pressure adhesion as in the case of CROMSCI

cannot be modeled. Even the support for particle sys-

tems is not suited for simulating the airflow in the vac-

uum chambers since this is a thermodynamic problem

and not related to the particle impulses.

Consequently in the context of climbing robots

there only exist individual solutions for computing the

adhesion forces. (Longo et al., 2005) uses Simulink

to simulate the drive system of the Alicia

3

robot, but

only with a simplified model for the wheel-wall con-

tact and none for the suction cups. (Pretto et al., 2008)

calculates the contact forces between the feet of a six-

legged climbing robot and a set of adhesive objects

via continuous mechanics theory.

(Wettach et al., 2005) presents the thermodynamic

model of a wall-climbing robot with 7 vacuum cham-

bers and one reservoir. To evaluate its power a sim-

ple 2D simulation had been developed where leakages

are only caused by artificial cracks of a certain depth,

bounded by two parallel infinite lines. Hence the leak-

age areas are calculated geometrically as intersection

of crack borders and curved line segments of the dif-

ferent sealing sections. Besides the model had been

evaluated on a prototype with only one suction cup.

Compared to that work the paper at hand describes

a rather realistic simulation of sealing leakages caused

by any kind of surface defect (e. g. holes, steps,

grooves) modeled in a virtual 3D environment. Their

effects are calculated efficiently via a virtual depth

camera. Furthermore the dynamics of the drive sys-

tem are now simulated via a physics engine that takes

the downforce resulting from the vacuum chambers

and wheel slippage into account. Finally the whole

simulation has been evaluated on a highly sophisti-

cated prototype which had been constructed in the

meanwhile as 1:1 implementation of the proposed

seven chamber model (see figure 10).

2

http://www.vxsim.com/en/software

3 CONCEPT

The software of CROMSCI has been implemented

within the MCA framework

3

as depicted in figure 1.

The embedded simulation is divided into four logical

blocks illustrated as gray boxes. On the highest level

ideal actuators are simulated for the drive system, the

tool center point (TCP), suction engines and negative

pressure valves. User commands are executed by the

actuators with a certain delay and within individual

velocity limits. The state of the drive units (orien-

tation and velocity of each wheel) can optionally be

used as input for a physics engine like Nvidia PhysX

to determine wheel slippage, collisions and the result-

ing robot pose based on collision and friction mod-

els. Otherwise the robot odometry has to be computed

manually as input for subsequent simulation steps.

Figure 1: Components of the simulation framework (gray).

Afterwards, the calculated robot pose is given

to the SIMVIS3D framework containing the visual

scene representation. Via this framework it is possi-

ble to both simulate environmental sensors like laser

scanners or to visualize the scene. In the context of

adhesion simulation SIMVIS3D is used to create a

depth image of the surface below the robot, which is

the basis for calculating sealing leakages. The sim-

ulated leakage values as well as the state of suction

engines and chamber valves are given to a thermo-

dynamic simulation. Based on the simulated airflows

and negative pressure values an overall adhesion force

can be determined which acts as robot downforce in

the physical simulation. The modular structure of the

simulation framework allows it to replace single com-

ponents by real hardware to test e. g. the real chamber

valves via simulated pressure values. The following

sections introduce these components more detailed.

3

http://rrlib.cs.uni-kl.de/mca-kl/

3DRealtimeSimulationFrameworkforaWall-climbingRobotusingNegative-pressureAdhesion

185

4 SIMULATION FRAMEWORK

SIMVIS3D

4

is a framework for simulating and visu-

alizing the interaction of objects in a 3D scene based

on the OpenInventor standard (OIV) using COIN3D

5

.

Its core data structure is a scene graph for arranging

elements in the simulated environment and for man-

aging scene changes at runtime. Scene elements are

all kinds of OIV nodes: Visual 3D bodies as well as

modifiers (i. e. transform nodes) that influence the rel-

ative pose of the bodies.

4.1 Scene Descriptions

SIMVIS3D consists of an easy-to-use XML scene de-

scription for setting up the scene at simulation startup

and of a sound API for applying changes online.

These changes are classified as structural if elements

are added to or removed from the scene and as para-

metric if attributes of existing scene elements are

changed, e. g. the six values of the transform node

that defines the 3D pose of a robot. All elements that

are specified in the XML file or added at runtime are

addressed by a unique name through the SIMVIS3D

API. Each non-modifier node contains a hook (de-

noted as insertion point) to define the connection of

scene elements. This hook is used to locate the cor-

rect position in the scene graph. Besides, it serves to

make element names unique in the scene so that they

can be accessed by the user.

The following excerpt of CROMSCI’s XML de-

scription illustrates these scene elements:

<part file="outdoor_scene.iv" name="WORLD"

attached_to="ROOT" offset="0 0 0 0 0 0"/>

<part file="cromsci.iv" name="CROMSCI"

attached_to="WORLD" offset="-1 8 7 0 -90 0"/>

<part file="drive_unit.iv" name="DRIVE_FRONT"

attached_to="CROMSCI" offset=".3 0 0 0 0 0"/>

<part file="manipulator.iv" name="TCP"

attached_to="CROMSCI" offset="0 0 0 0 0 0"/>

<part file="empty_node.iv" name="DEPTH_CAMERA"

attached_to="CROMSCI" offset="0 0 .1 0 0 0"/>

Visual elements are specified by the part token.

The file attribute indicates the source of the OIV

subtree that represents the new element. It is mounted

into the scene graph as child of the insertion point

node given by the attached_to parameter, taking the

given static pose offset into account. The ROOT node

is the default top node of the scene graph. Finally the

name parameter identifies the added part. The use of

capital letters is just a convention to highlight parts

since they are mainly used as hooks.

4

http://rrlib.cs.uni-kl.de/software/

simvis3d/

5

https://bitbucket.org/Coin3D/coin

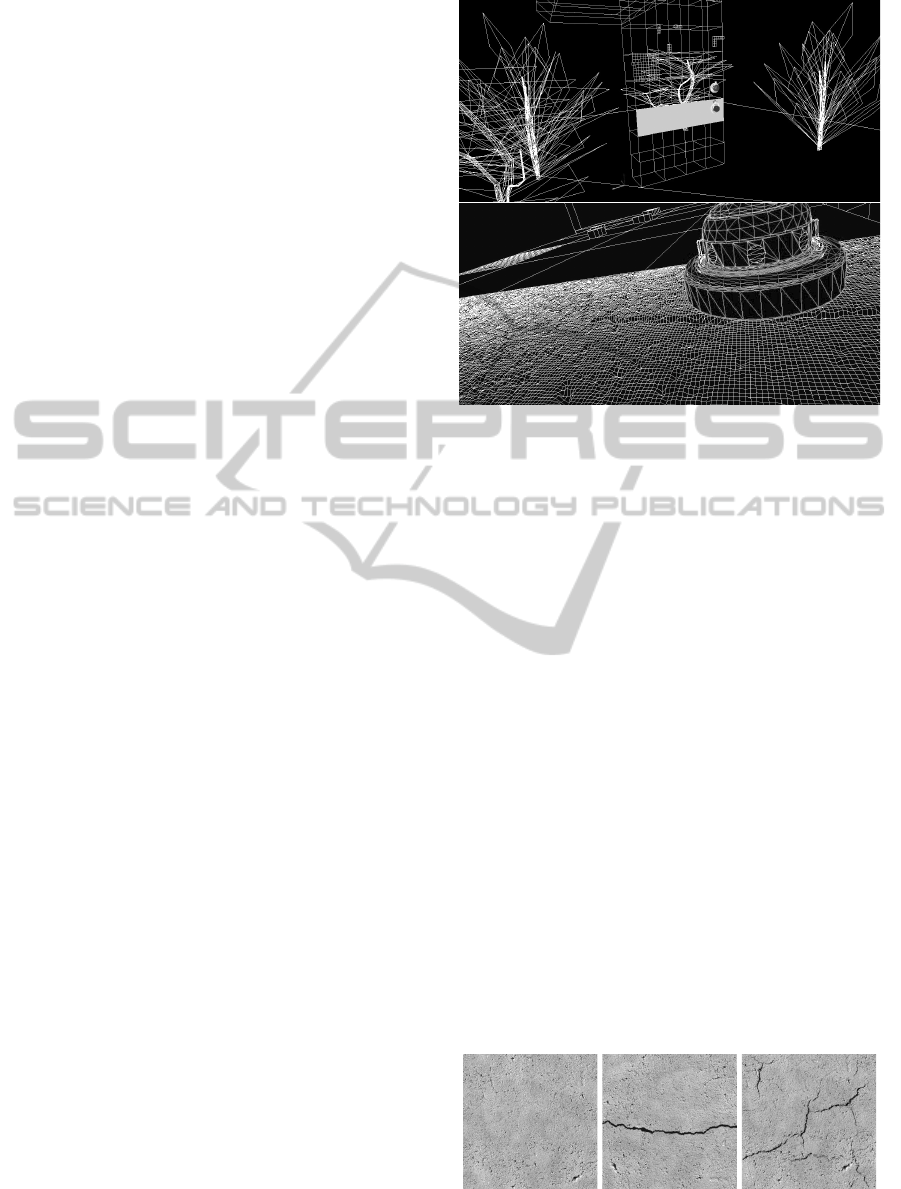

Figure 2: Wireframe model of CROMSCI and a bridge in-

cluding a band of rough structured surfaces (top) and ren-

dered visualization (bottom).

In the example first an outdoor scene (floor, plants,

bridge, pylon) is added to the root as WORLD, then

the robot is added to the scene as CROMSCI. Its

drive mechanism consists of three units, each with a

driven wheel. They are equally distributed on a cir-

cle (see figure 6). Here, only the front drive unit is

shown. Actually, the same OIV file is added twice

more as left and right unit with corresponding names.

For example, the front drive is identified distinctly

as ROOT:WORLD:CROMSCI:DRIVE_FRONT. Afterwards

the manipulator is put into action as TCP and then an

empty node is applied as anchor for a depth camera.

The latter does not represent a visible node since it

just serves as virtual hook for the respective sensor.

In figure 2 the wireframe model and rendered view of

the scene are shown exemplarily.

Whereas the visual objects represent the static part

of a scene, modifier elements define the relative pose

of subgraphs. Thus they set up the animation of a

scene. The modifiable attributes of the elements, i. e.

numeric values of transform nodes, are collected in

a data array. A link to the values of a specific ele-

ment can be retrieved via its unique name through the

SIMVIS3D API. Therefore, scene changes may be

applied from any point in the user code.

In case of CROMSCI the following elements are

defined in the XML file:

<element name="cromsci_pose" type="3d Pose"

angle_type="rad" attached_to="CROMSCI"/>

<element name="drive_fr_pose" type="3d Pose"

angle_type="rad" attached_to="DRIVE_FRONT"/>

<element name="tcp_pose" type="3d Pose"

angle_type="rad" attached_to="TCP"/>

<element name="switch" type="Switch"

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

186

switch_mode="-3" attached_to="CROMSCI"/>

Each element is attached to one of the parts in-

troduced above. The 3d Pose elements define the

(x,y,z) position and (roll, pitch,yaw) orientation (an-

gle values in radians) of their hook. The switch el-

ement is used to temporarily deactivate parts of the

scene during rendering (according to the original OIV

SoSwitch node ’-3’ means ’on’ and ’-1’ means ’off’).

With this setup the climbing robot, its wheels and

manipulator can be moved arbitrarily in the scene and

the result can be visualized online via a plugin in

the MCA user interface. The natural kinematic con-

straints have to be calculated outside SIMVIS3D. In

case of CROMSCI this is done in the Drive and TCP

Simulation block shown in figure 1.

4.2 Sensor Data

Apart from the animated 3D scene simulation and

visualization the main benefit of SIMVIS3D is the

generation of close-to-reality sensor data. So far,

cameras and distance sensors (ultrasound, laser scan-

ners, depth cameras) are supported. In the case of

CROMSCI the following sensors are relevant:

<distance_sensor name="laser_scanner"

max_distance="4" scan_angle_range="240"

angular_resolution="0.352423"

offset="0 0 0.35 0 20 0" attached_to="TCP"/>

<camera name="depth_cam" type="orthographic"

near_limit="0.1" attached_to="DEPTH_CAMERA"/>

The first one is a simulated 2D laser scanner with

angular range of 240

◦

and resolution of 0.35

◦

, cor-

responding to the real Hokuyo URG-04LX scanner.

It is attached to the TCP with the given static offset.

Hence, the scanner moves over the ground as soon as

the robot and/or the manipulator is actuated. The sec-

ond sensor is an orthographic depth camera attached

to the virtual hook. Its data is not exported as from a

real sensor, but used internally to calculate the leak-

age situation of the vacuum chamber sealings arising

from the roughness of the ground (see section 5).

4.3 Climbing Robot Scene

The virtual environment of CROMSCI contains differ-

ent components for simulation and decoration. Fig-

ure 3 shows the basic wireframe model of the robot

and its surroundings (trees, bridge elements, ground).

The bridge pylon consists of single cubes, each with

an edge length of 2 m and one structured face. Its de-

fects are modeled as indentations of the rigid body

and visualized via textures. This enables to exchange

single parts of the bridge for different test conditions.

Figure 3: Wireframe model of the environment including

the cube elements of the bridge (top) and detailed view of

CROMSCI on a rough structure mesh (bottom).

Once created, one can insert a cube at any position

and rotate it via the XML scene description as follows:

<part file="cube_crack_01.iv" name="CUBE"

attached_to="BRIDGE" offset="2 0 0 0 0 0"/>

<part file="cube_crack_02.iv" name="CUBE"

attached_to="BRIDGE" offset="4 0 0 0 0 270"/>

<part file="cube_concrete_01.iv" name="CUBE"

attached_to="BRIDGE" offset="6 0 0 0 0 0"/>

Again, each CUBE is attached to the BRIDGE hook

with a certain pose offset. Since these parts do not

have to be addressed within the simulation for ma-

nipulation, they do not need unique names. For vi-

sualization, some additional components are added to

the scene in order to create a nice view on the virtual

environment. Previous figure 2 shows the wireframe

model of CROMSCI and the bridge surface as well as

the rendered view including trees, textured surfaces

and backgrounds. This visualization is rendered in

realtime and is used to observe the simulated scene.

So far, more than 50 different cubes have been cre-

ated using the modeling tool Blender and integrated

into the scene description as OpenInventor files. Ex-

amples are given in figure 4.

Figure 4: Surface patches with a general roughness, a

straight crack and a complex crack structure (from left).

3DRealtimeSimulationFrameworkforaWall-climbingRobotusingNegative-pressureAdhesion

187

5 INTERACTION OF ROBOT

AND ENVIRONMENT

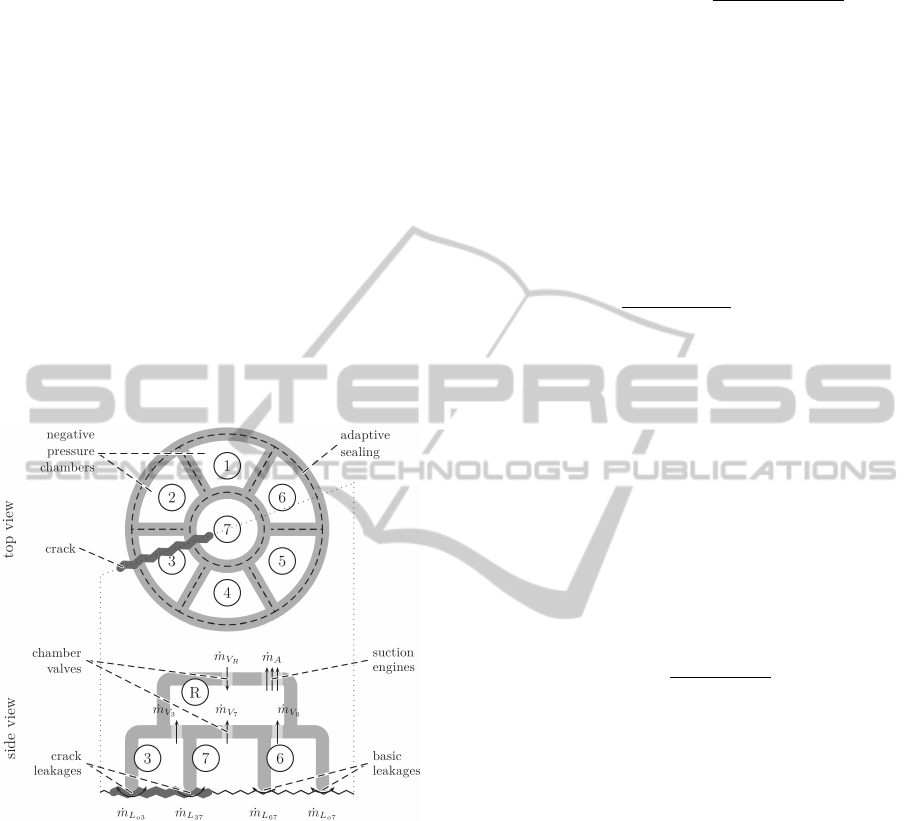

The simulation of robot interaction has to consider

different aspects. The most interesting components

are those which are responsible for robot adhesion,

namely the internal airflow and the occurring leak-

ages. Figure 5 gives a structural view on the adhe-

sion components of CROMSCI. The top view shows

the seven negative pressure chambers with one cen-

tral chamber. Below, the side view illustrates the dif-

ferent mass flows via valves ˙m

V

i

and leakages ˙m

L

i j

at

the sealing areas. ˙m

A

denotes the amount of air which

is taken out of the vacuum reservoir by the suction

engines (Wettach et al., 2005). In general, basic leak-

ages occur even on a perfect flat structure due to the

type of sliding coating of the sealing. This leakage

increases with surface roughness, defects and gaps.

Figure 5: Structural setup of CROMSCI’s adhesion compo-

nents: Adhesion chambers 1 to 7 and reservoir R with an

exemplary crack below chambers 3 and 7.

5.1 Airflow and Adhesion Forces

Basis of the interaction model between robot and en-

vironment is the first fundamental theorem of ther-

modynamics and Bernoulli’s equation describing the

steady state flow of an ideal fluid. The mass flow

˙m

i j

between two volumes i and j depends, accord-

ing to equation 1, on the current pressure values p

i

and p

j

and the area of airflow A

i j

between both vol-

umes. This can e. g. be the sealing leakage connecting

one chamber to the ambient air, or the valve opening

area between chamber and negative pressure reser-

voir. Here, ρ

air

is the density of air.

˙m

i j

= sgn(p

i

− p

j

) ·A

i j

·

q

2 ·ρ

air

·

p

i

− p

j

(1)

It is now possible to determine the pressure

change ˙p

i

of volume i based on the airflow ˙m

i j

ac-

cording to equation 2. In here, κ

air

= 1.402 denotes

the adiabatic index of air, R

air

is the specific gas con-

stant, T

air

the temperature and V

i

the volume of i. The

sum goes over all other volumes k including the ambi-

ent air. In case of no direct connection between both

volumes k and i (if they are no neighbors) the area A

ik

and, therefore, also the mass flow ˙m

ik

is zero.

˙p

i

=

κ

air

· R

air

· T

air

V

i

∑

k

˙m

ik

(2)

To simplify the thermodynamic model, some of

these parameters are assumed to be constant for

simulation purposes: Density ρ

air

= 1.1883 kg/m

3

,

gas constant R

air

= 287.058 J/(kg K) and temperature

T

air

= 293.15

◦

K. More details about the modeling it-

self can be found in (Wettach et al., 2005). Based

on the given pressure values p

i

of each chamber it is

possible to calculate the total affecting downforce F

(equation 3) and its point of action

~

P

F

(equation 4):

F =

7

∑

i=1

F

i

=

7

∑

i=1

((p

o

− p

i

) ·A

i

) (3)

~

P

F

=

7

∑

i=1

~

P

i

·

(p

o

− p

i

) ·A

i

F

(4)

Here, p

o

denotes the pressure value of ambient air

(≈ 100000 Pa), A

i

is the suction area of chamber i and

~

P

i

is the chamber center point related to robot coordi-

nates. The general goal of the closed-loop adhesion

controller is to guarantee a certain downforce and to

balance the force equally among the three wheels so

that the point of action lies in the robot center.

5.2 Sealing Leakages

The leakage between sealing and surface depends on

two aspects: The structure of the surface and on the

sealing adaptability. Since the interaction between ad-

hesion system and surface is not sufficiently known

– especially with respect to friction and sliding char-

acteristics as well as for the influence of different

surfaces on the sealing leak tightness – a simplified

sealing model is used. The idea is to take a picture

via a simulated orthographic camera (see section 4)

of the ground below the robot and to transform the

depth-buffer from rendering into height data. The

depth camera has a resolution of 256× 256 pixels and

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

188

Figure 6: Depth image including sealing area and drive

units (left) and resulting leakages (right).

surveys an area of 80 × 80 cm

2

as depicted in exam-

ple figure 6, which corresponds to the dimensions of

the real robot. Here, one can see the surface height

as grayscale image with an overlay of the individual

sealing edges (as black and white lines). In the mid-

dle of the white marked chambers the three wheels

are visible. The other components of the robot chas-

sis have to be removed temporarily by the described

switch to take the depth image, otherwise the robot

interior would be in sight. The height resolution de-

pends on the near and far limits of the simulated cam-

era. In the present case the observed range is ±5 cm

resulting in a z-resolution of 0.39 mm.

The next step is to simulate the sealing adaption

to this height. In reality, the leak tightness depends

on the rubber material of the sealing, the induced air

pressure and the sliding coating of the sealing. Since

these characteristics cannot be emulated completely,

an approximation is used which allows the simulated

sealing to adapt only a specific portion from one point

to another. Depending on a maximum height differ-

ence between one pixel and another the height values

of each sealing pixel are calculated:

1. set all sealing pixel heights to surface

. heights below sealing

2. repeat

3. reset changed flag

4. for each sealing pixel

5. if difference to highest neighbor pixel

. larger than maximum height difference

6. set current sealing pixel height to

. highest one minus maximum difference

7. set changed flag

8. until not changed

The result of this calculation is shown in figure 6

on the right side. Leak-tight sealing pixels (the dis-

tance between ground and sealing is nearly zero) are

drawn solid black whereas permeable sealing pixels

are colored gray to white depending on the size of the

gap. Of course, the total amount of maximal indenta-

tion and extrusion of the sealing is limited and has to

be considered depending on the real sealing setup. In

the present case the maximum capability of the seal-

ing lies at about ±5 mm. Therefore, cracks deeper

than this cause a gap which cannot be proofed. Based

on these sealing pixels the final leakage L

i

of each

sealing section S

i

can be calculated (equation 5).

L

i

= l

i

·

L

basic

+ κ ·

∑

j∈S

i

h

s

( j) − h

g

( j)

|S

i

|

!

(5)

Here, l

i

is the length of the sealing segment, L

basic

a basic leakage caused by the sliding coating (the seal-

ing must not be 100% leak-tight otherwise the robot

would be stuck), κ is a multiplication factor normally

set to 1 which can be adapted for debugging purposes.

The sum goes over all pixels j which belong to seal-

ing segment S

i

and depends on the height value of

the sealing pixel h

s

( j) and of the ground pixel h

g

( j)

divided by the total amount of pixels |S

i

| of that seg-

ment.

The pressure change ˙p

i

of a chamber is then cal-

culated according equation 2 with the leakage areas

of the sealing segments of that chamber and the valve

area connecting this chamber to the reservoir. In the

case of chamber 1 one receives five areas for inter-

changing air pressure resulting in the sum of airflow

given in equation 6 (compare figure 5).

∑

k

˙m

1k

= ˙m

L

12

+ ˙m

L

16

+ ˙m

L

17

+ ˙m

L

1o

+ ˙m

V

1

(6)

Here, ˙m

V

1

denotes the support of negative pressure

from the reservoir which is controlled via the valve.

On the other side, ˙m

L

1o

is the amount of air lost to

the outside ambient air. If all chamber pressures are

balanced equally, the remaining airflow between the

chambers is zero. Otherwise, also these areas produce

a certain loss or support of pressure, depending on the

individual chamber pressures in left and right neigh-

bor ( ˙m

L

12

and ˙m

L

16

) or the center chamber ( ˙m

L

17

).

5.3 Actuators and Robot Behavior

Depending on the real hardware settings all actuators

are simulated with certain limitations of acceleration,

velocity or position. Therefore, all desired commands

for drive steering or valve positioning are executed

with a certain delay. Despite this, the actuators are re-

garded as ideal hardware without tolerances, runtime

errors or defects. But it is possible to replace these

simulation elements by those producing errors with

given failure rates to analyze their effect.

To simulate the system behavior on affecting

forces and motions it is possible to apply a physics

engine. So far, the climbing robot simulation frame-

work uses PhysX

6

from Nvidia, but other engines like

6

http://developer.nvidia.com/physx

3DRealtimeSimulationFrameworkforaWall-climbingRobotusingNegative-pressureAdhesion

189

Newton Game Dynamics

7

could be used in combina-

tion with SIMVIS3D as it has been done in other re-

search projects before (Wettach et al., 2010). In gen-

eral, the physics engine has to consider and contain

the following aspects: Collision models of robot and

environment, affecting forces (gravity and adhesion

force), friction models and wheel orientation and ve-

locity for locomotion.

Due to simplicity, CROMSCI does not use the

same rough structured mesh for physical simulation.

The ground surface is assumed to be plane to simplify

the wheel-ground interaction. The friction caused by

the sealing is also not considered here which affects

the robot in real life. Depending on the selected fric-

tion values between wheels and surface and on the

generated downforce one receives a different robot

behavior relative to its motion direction and gravity.

For instance, the wheel slip is high while driving up,

since the robot has to overcome gravity. In the same

way it falls down if the adhesion force is too low.

For debugging purposes it is possible to observe

the current state of the physical simulation during run-

time via a visualization window showing the complete

scene with all actors. One can pause the simulation,

walk through the scene and read out current values

like pose or velocity of each component. It is also

possible to change e. g. the gravity value during run-

time or apply an impact to a simulated body.

6 APPLICATION

The presented simulation framework has been created

to test control algorithms of CROMSCI offline without

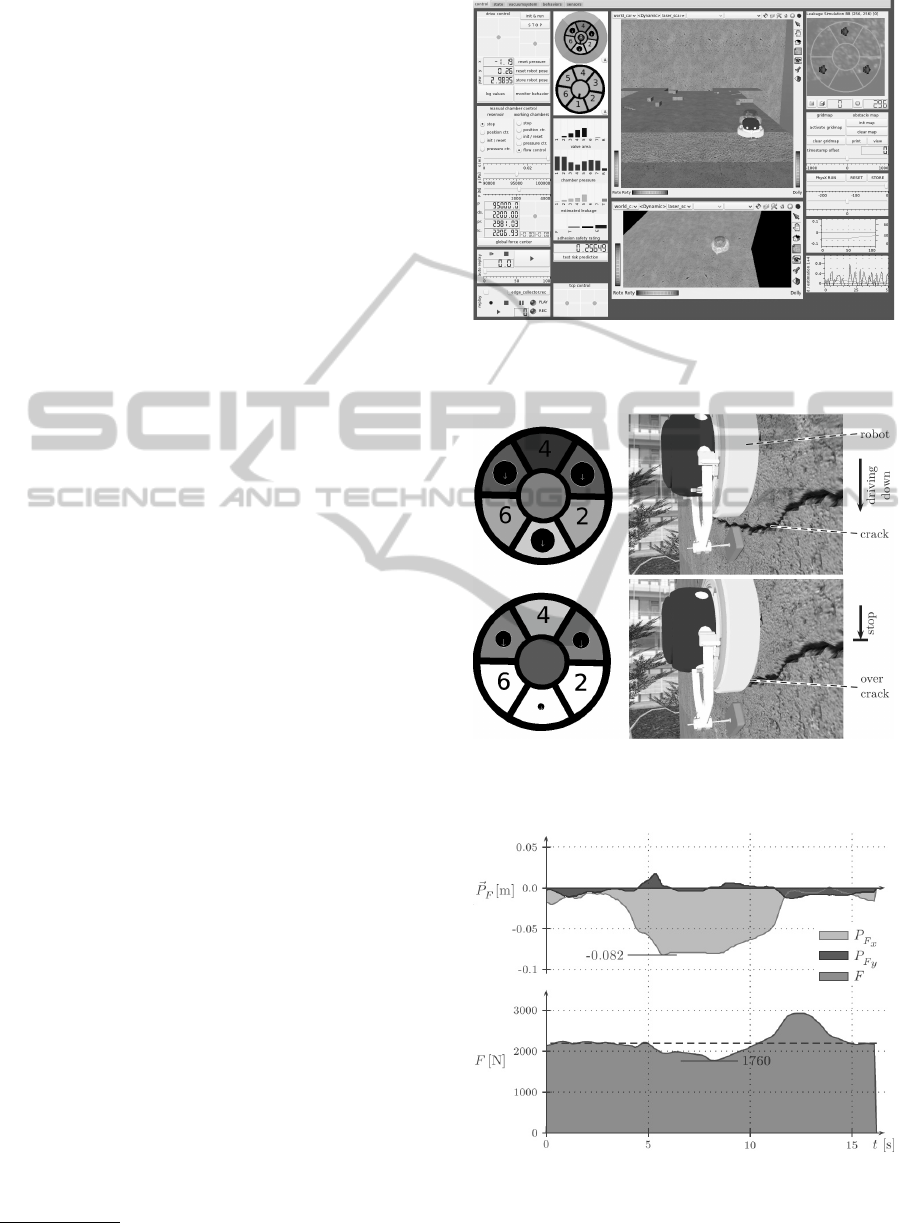

the real machine. Figure 7 shows the graphical user

interface (GUI) of CROMSCI with a view on the 3D

scene and the current robot state. One main appli-

cation is the validation of closed-loop adhesion con-

trollers. In figure 8 one can see an experimental run

in which the simulated robot is driven downwards the

rough wall facing a deep crack. The left circular view

shows the state of the seven chambers of the adhesion

system. The darker the color, the lower the pressure.

Numbers 2, 4 and 6 indicate the associated chambers,

whereas the dimensions of the black circles in non-

labeled chambers 1, 3 and 5 illustrate the downforce at

the corresponding wheel. In the first line, this down-

force is balanced out by a stronger adhesion at the top

chambers (darker color of chambers 3, 4 and 5 com-

pared to 1, 2 and 6) to counteract robot tilt. In the

second row, the bottom chambers are located on the

crack and lose negative pressure (white chambers).

7

http://www.newtondynamics.com

Figure 7: GUI with visualization plugins of the simulated

scene (middle), control elements (left), and state informa-

tion of adhesion (top left) and sealing simulation (top right).

Figure 8: Screenshots of experiment showing the simulated

robot CROMSCI driving to a deep crack (right) and current

states of the negative pressure chambers (left).

Figure 9: Progress of simulated downforce F and its point

of action

~

P

F

during the presented experiments. Robot tilt

leads to a shifted point of downforce in vertical direction

from seconds 4 to 12.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

190

Figure 9 illustrates the progress of the downforce

value F and its point of action

~

P

F

. It can be seen

that the resulting values are very realistic: The to-

tal amount of downforce F is reduced from desired

2 200 N to 1 760 N and the x position of the point of

action (P

F

x

) moves about 8 cm below the robot center.

Figure 10: Real climbing robot CROMSCI navigating on a

concrete wall.

In the latest history, the simulation system has

e. g. been used to validate safety measures and risk

prediction methods (Schmidt, 2013) or to perform a

foresighted analysis of the terrain. The accuracy of

the thermodynamic model of the vacuum system it-

self has been proven in earlier experiments (Wettach

et al., 2005). The complete simulation framework

is accurate enough to optimize the control software

in the simulation, so that only some fine-tuning is

needed to apply these algorithms on the real machine

depicted in figure 10. Some demonstration videos

8

of CROMSCI in operation prove this transferability of

control algorithms from simulation to reality.

7 CONCLUSIONS

This paper presented a novel framework on the ba-

sis of SIMVIS3D for simulating a climbing robot

using negative pressure adhesion and an omnidirec-

tional drive system. It could be shown that the system

is able to simulate the airflows and pressure changes

of a complex vacuum system with seven suction cups

and one reservoir. The structure of the ground has a

direct impact on the leakage values in order to model

different surface characteristics. Hence, this tool fa-

cilitates the development of control algorithms inde-

pendent of the real robot and enables an offline and

realtime validation in arbitrary 3D environments.

Further work will focus on a porting to FINROC

9

and an easier handling of the physical simulation,

8

http://agrosy.cs.uni-kl.de/en/galerie/

cromsci-medien/

9

http://www.finroc.org

since the Blender export of collision objects does not

include joints. Additionally, a new robot prototype is

under construction: Its control software will be opti-

mized using this tool first, before executing and fine-

tuning it on the real system.

ACKNOWLEDGEMENTS

This research was funded by the German Bundesmin-

isterium f

¨

ur Wirtschaft und Technologie (BMWi), Zen-

trales Innovationsprogramm Mittelstand (ZIM).

REFERENCES

Freese, M., Singh, S., Ozaki, F., and Matsuhira, N. (2010).

Virtual robot experimentation platform v-rep: A ver-

satile 3d robot simulator. In International Conference

on Simulation, Modeling and Programming for Au-

tonomous Robots (SIMPAR).

Koenig, N. and Howard, A. (2004). Design and use

paradigms for gazebo, an open-source multi-robot

simulator. In International Conference on Intelligent

Robots and Systems (IROS).

Laue, T. and R

¨

ofer, T. (2008). Simrobot - development and

applications. In International Conference on Simu-

lation, Modeling and Programming for Autonomous

Robots (SIMPAR).

Longo, D., Muscato, G., and Sessa, S. (2005). Simula-

tion and locomotion control for the alicia3 climbing

robot. In International Symposium on Automation and

Robotics in Construction (ISARC).

Michel, O. (2004). Webots: Professional mobile robot sim-

ulation. International Journal Of Advanced Robotic

Systems, 1(1).

Pretto, I., Ruffieux, S., Menon, C., Ijspeert, A., and

Cocuzza, S. (2008). A point-wise model of adhe-

sion suitable for real-time applications of bio-inspired

climbing robots. Journal of Bionic Engineering, 5.

Schmidt, D. (2013). Safe Navigation of a Wall-Climbing

Robot - Risk Assessment and Control Methods. Dr.

Hut Verlag, Munich, Germany.

Schmidt, D., Hillenbrand, C., and Berns, K. (2011). Om-

nidirectional locomotion and traction control of the

wheel-driven wall-climbing robot cromsci. Robotica

Journal, 29(7).

Wang, J., Lewis, M., and Gennari, J. (2003). A game engine

based simulation of the nist urban search and rescue

arenas. In Winter Simulation Conference.

Wettach, J., Hillenbrand, C., and Berns, K. (2005). Thermo-

dynamical modelling and control of an adhesion sys-

tem for a climbing robot. In International Conference

on Robotics and Automation (ICRA).

Wettach, J., Schmidt, D., and Berns, K. (2010). Simulating

vehicle kinematics with simvis3d and newton. In In-

ternational Conference on Simulation, Modeling and

Programming for Autonomous Robots (SIMPAR).

3DRealtimeSimulationFrameworkforaWall-climbingRobotusingNegative-pressureAdhesion

191