Multi-Agent System Model for Container Management Simulation

Houda Zouhaier

1

, Fahem Kebair

1

, Fr

´

ed

´

eric Serin

2

and Lamjed Ben Said

1

1

Laboratoire SOIE, Higher Institute of Management of Tunis, Le Bardo, Tunis, Tunisia

2

Laboratoire LITIS, University of Le Havre, Le Havre, France

Keywords:

ATN, Container Management, Multi-Agent System, MESSAGE/UML, Simulation.

Abstract:

This paper discusses an approach to build a multiagent system for simulating container management in a hub

port logistics. The simulator has as goal to help assessing and defining container management strategies. This

allows to plan and to control the management of containers while minimizing the waiting time and the parasite

shifts and insuring the consistency of the performed tasks sequence. The proposed model involves the multi-

point of view and the emergence of behavior specific to the theory of complex systems. The paper is structured

as follows: first we present related works, then we expose the multiagent model of the simulator, after that we

present the internal structure of the agents and finally we provide and discuss first implementation and results.

1 INTRODUCTION

Supply chain is considered as a network in which a

range of actors involved throughout the chain between

the origin point (suppliers) and the destination point

(clients) for manufacturing goods taking into account

many constraints in time and space. Tasks of the chain

must be designed to satisfy the needs of customers. In

the delivery phase, goods are redirected through a net-

work of intermodal transport from a logistics hub to

another until their destinations at the lowest cost and

as soon as possible (Govil and Proth, 2001). A logis-

tics hub treats thousands of daily shifts of which man-

agement should be optimized as for the internal move-

ments performed by machines. A shift includes three

operations: picking up, transporting and putting-on

container. The implementation of a strategy for man-

agement and decision making is necessary therefore

in order to ensure container treatment.

Decisions for container management take into

consideration several constraints such as customer re-

quests (turn-around time, low risk delivery and a min-

imum of handling possible) and resource availability.

To improve the port hub performance, decisions are

made by evaluating various planning policies. In this

field, researchers have defined some productivity in-

dicators for evaluating the decisions performance as

service time

1

, container terminal capacity, berth uti-

1

Service time is a period of time in which the ship is

berthed. (Henesey, 2006)

lization, waiting time

2

and dwell time

3

, etc. (Hene-

sey, 2006). A logistics hub is characterized by its

dynamicity and the intervention of several actors (eg.

containers, engines, planner, etc.). The dynamicity is

defined by the movements number that can occur, the

containers arrival and departure, the unexpected ap-

pearance of new missions, etc. (Psaraftis, 1995).

To deal with this dynamicity and given the ne-

cessity of coordinating between different actors, we

propose in this paper a distributed approach using the

Multiagent Systems (MAS) technology (Wooldridge,

2009). This approach allows us to share the plan for

tasks accomplishment and to treat the dynamic as-

pect of containers in the terminal. The multi-agent

approach proved their efficacity in container manage-

ment for port terminals. Indeed, Bin in (Bin et al.,

2011), proposes a MAS model of container terminal

scheduling and management system, focusing on how

to coordinate the scheduling of different resources in

a container terminal. Lawrence in (Henesey et al.,

2003) describes an approach (supported with MAS-

CommonKADS) enabling decision makers to simu-

late various port policies and analyze the multitude of

“what if” scenarios to model the system architecture

and the role of different parts which compose it. We

cite also the work of Kefi in(Kefi et al., 2009)who uses

an informed algorithm to describe the behaviour of

2

waiting time is time during which the vessel must wait

for an available berth. (Henesey, 2006)

3

dwell time is the time spent by the container in the port.

(Henesey, 2006)

498

Zouhaier H., Kebair F., Serin F. and Ben Said L..

Multi-Agent System Model for Container Management Simulation.

DOI: 10.5220/0004453404980505

In Proceedings of the 15th International Conference on Enterprise Information Systems (ICEIS-2013), pages 498-505

ISBN: 978-989-8565-59-4

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

the container agents in storage areas introducing intel-

ligence degree to reduce significantly the total number

of unproductive movements.

The work presented in this paper enhances these

researches by proposing an innovative model which

integrates the multipoint of view and the emergence

of behavior specific to the theory of complex systems.

We propose to study the evolution of container agents

behaviour from their arrival until their shipments. The

final goal is to build a container management sim-

ulator that enables decision makers to analyse dif-

ferent port policies and to define container manage-

ment strategies. We opt for an individual-centered

approach to focus the management on the container

life cycle, and to let emerge consequently a global be-

havior. Each agent of the system is a microscopic rep-

resentation. We consider that the container is an indi-

vidualized agent provided with an active behaviour. It

seeks its satisfaction by moving optimally in the ter-

minal to reach their destinations. The engines are also

considered agents to ensure the mobility of contain-

ers and respond to their requests. To model the sys-

tem architecture and the role of different parts which

compose it, we use the agent-oriented methodology

MESSAGE / UML (Caire et al., 2001).

This paper is structured as follows: first, container

management in hub port logistics and their related

problems are discussed. Then, the multi-agent model-

ing using the agent-oriented methodology MESSAGE

/ UML as well as the internal structure of the agents

are presented. In the next section, an implementation

of the model using the NetLogo simulation platform

and the different results are detailed. Finally, we pro-

vide a general conclusion which includes the contri-

butions of this work and the prospects that enrich it.

2 MANAGEMENT OF

CONTAINERS IN A HUB PORT

LOGISTICS

Mocellin in (Mocellin, 2006) defines a hub as a “place

where we receive the goods for the resend in a very

short time.” Unlike a warehouse, Mocelin (Mocellin,

2006) considers that it is infrequent to apply repack-

aging operations on a platform as it aims to tranship

goods from one mode to another and redirect them

to another destination. From the introduction of con-

tainers in the 50s, the international network has given

rise to a multitude of modes, as the rail, road and sea

mode. Thus, we can design transport systems in two

conceptual ways including more than one transport

mode: The multimodal transport which is the goods

transport using at least two modes. The intermodal

transport which is, according to The United Nations

Economic Commission for Europe (ECE), the deliv-

ery of goods in one and the same loading unit (such

as a container) or one and the same vehicle using suc-

cessively several transport modes without loading or

unloading (CEMT, 2006).

2.1 Delivery of Containers via

Intermodal Network

Intermodal transport containers is maintained by a set

of operations. In fact, the displacement of containers

typically begins with the road mode from the freight

terminal to a multimodal transport terminal where

containers are transferred then from road to rail. Con-

tainers are transported for a long distance to the ar-

rival terminal where they are transshipped onto a car-

rier. Containers are transferred by road to the port of

the exporting country. After customs clearance opera-

tions and temporary storage, the containers are loaded

onto container ships and then transported to the arrival

port. Upon their arrival, the containers are unloaded

from the container ships and transported by road in

the importing country. The same procedure of trans-

port is repeated from the arrival terminal until the ar-

rival at the final customer (E.C.M., 2005).

2.2 Container Life Cycle Management

The life cycle of a container includes a set of pro-

cesses that operate together. Their rapid chaining im-

proves the delivery of goods in an appropriate time

which progressively improves productivity. In this pa-

per, we consider the mode ship to ship for delivery

and receipt of containers. The four main processes

are receipt, transfer, storage and delivery containers.

When a ship arrives, it must be assigned to an op-

timal position along the quay which is equipped with

a number of cranes for the tasks of loading and un-

loading containers. This number varies depending on

the number of containers to be treated and the length

of the ship. Containers are transferred from a berthing

area to a storage area near to the place where they will

be transshipped next using a set of trailers or strad-

dle carriers. After their transfer, containers are raised

by stacking cranes or straddle and piled one on top

of other. Operations of stacking provide the perfor-

mance of a terminal by the segregation of containers

in various strategies. To identify a container, a plan-

ner uses a computerized management system based

on four coordinates which are the number of stor-

age area, the bay number, the line number and the

level of stacking. Additional moves are performed

Multi-AgentSystemModelforContainerManagementSimulation

499

between empty stock, sheds, and import and export

container stocks if sheds and/or empty depots exist

within a terminal (Steenken et al., 2004). Accord-

ing to the request of a customer, the container will

be delivered out of the terminal respecting the desired

delivery date. A container is removed from the stor-

age area, transported then by a transport vehicle to the

ship operation area and finally loaded on a ship. The

ship leaves the terminal after loading containers.

2.3 Types of Decisions in Container

Management

Researchers use a set of indicators to evolve perfor-

mance decisions. They contributed by the invention

of several strategies for improving various tasks in the

terminal. There are two types of decisions: planning

and control. A planning decision is more concerned

for the design and development process to be carried

out in the implementation effective containers man-

agement. A control decision aims to ensure a high

level of productivity and to monitor the process. Deci-

sion problems are divided into three levels: strategic,

tactical and operational. Strategic decisions are long-

term decisions that include the structure of the ter-

minal, handling procedures and resource types to be

chosen. Tactical decisions are medium term decisions

which include the resources number to allocate. Op-

erational decisions are short term which include the

process to be followed by resources (Henesey, 2006).

2.4 Management and Decision

Problems of Container Management

Given the large number of treated movements daily in

a terminal, the decision is made by a set of constraints

of time or space to plan and control the containers

handling. We include the emergence of new mis-

sions during the day although planning is already es-

tablished. The departure and arrival unpredictable of

containers which complicates their location and dis-

tribution in the storage areas. This affects the strate-

gic decision-making for planning storage. The unex-

pected appearance of breakdowns affects the alloca-

tion of resources to do the tasks which generates a

rectification on the tactical decision to plan and con-

trol the containers handling. This leads an increase

in the waiting time in the supply chain. The limited

resources availability, which complicates the synchro-

nization of tasks sequence. This leads to a problem of

making operational planning. Due to the imperfection

of classic tools to solve and to schedule the dynamic-

ity and the complicated managing of containers in a

terminal, we have used a distributed resolution using

agent-oriented methodology.

3 MULTIAGENT MODEL FOR

SIMULATING CONTAINER

MANAGEMENT

3.1 Environment Characterization

We consider several assumptions in the problem res-

olution. Indeed, An elapsed time for the container

treatment is measured to determine if the service is

provided in a determined time. Moreover, ship depar-

ture date should be known in advance. The first agent

resource that responds to the container agent request

is the most appropriate. The containers number to

be processed simultaneously is obtained by the quay

cranes number allocated per vessel. The container sat-

isfaction is to perform the unloading, the transfer and

the loading operation as soon as possible. The con-

tainers priority depends on several factors.

• The containers number to be processed by quay

cranes is obtained by dividing the containers total

number ( to be loaded and unloaded by vessel) by

quay cranes number.

• The service time per container is obtained by di-

viding the service time by the containers number

to be processed per quay cranes. It corresponds to

the deadline for processing container.

• The containers priority depends on the ship ser-

vice time whereby it arrived ts

1

and the ship ser-

vice time whereby will be shipped ts

2

.

• Therefore, the containers priority is defined by the

shortest sum of service time per each container.

p = ts

1

+ts

2

We also identified several parameters in our mod-

els which are:

• c: means the resource capacity. It is measured by

the containers number handled in the same pro-

cess;

• p: is the container priority;

• d: it the distance between two points and is mea-

sured by a time interval;

• t: the service time is the time interval set between

arrival date and departure date of a ship. It corre-

sponds implicitly to the limit time of the process-

ing of all containers;

ICEIS2013-15thInternationalConferenceonEnterpriseInformationSystems

500

• tc: the current processing time of a container that

is initiated to zero and evolves in time until the

end of treatment.

• ts: the average service time per container is the

period fixed for processing each container.

3.2 System Design and Architecture

MESSAGE / UML is a methodology for agent-

oriented software engineering for describing and

modeling agents. It allows to study the dynamic evo-

lution of the behaviour of each agent by the incre-

mental development of links between the agent and its

properties (goals, services, roles, resources, etc.). We

use this methodology in order to define and to charac-

terize the multiagent model that we propose. Indeed,

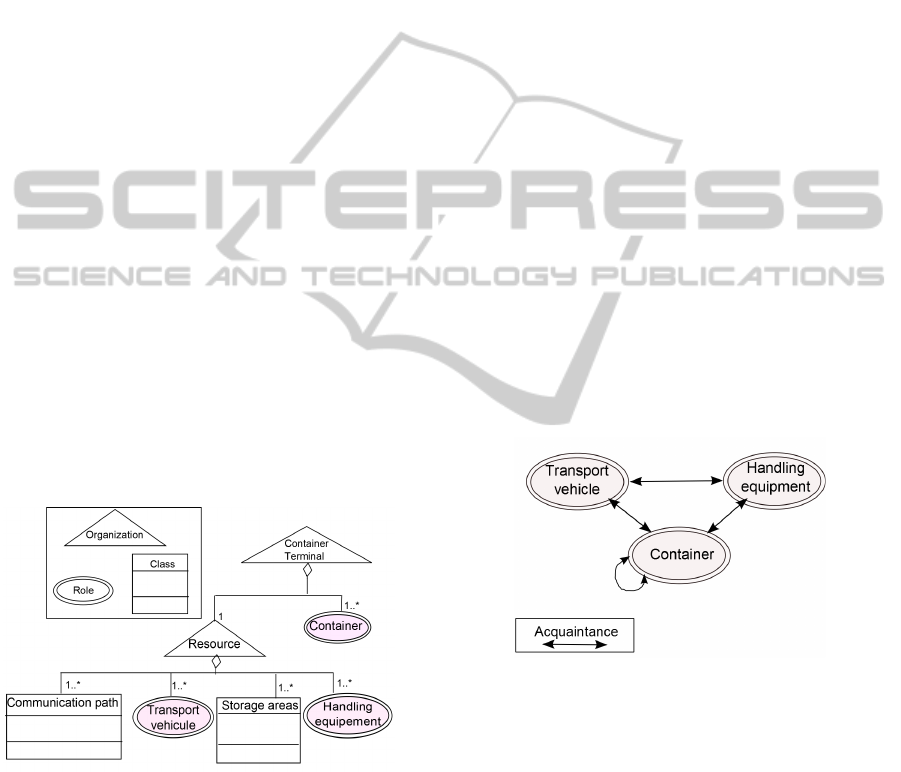

figure 1 shows the structural relationships of the orga-

nization model. An Organization is represented by an

isosceles triangle. The Role that represents an agent

is schematically drawn by ellipses. The Class formu-

lates objects that are used in the port hub. In fact, the

container terminal is the main organization in which

run the port operations. It is composed of a set of

containers with different types and dimensions. Con-

tainers to treat, require services from a resource or-

ganization comprising handling equipment and trans-

port vehicles. A machine is a resource agent. Storage

areas and communication lines are treated as objects

to be consumed in the terminal. It should be noted

that the appropriate icons have been associated with

different stereotypes.

Figure 1: Structural relationships.

The inter-agent interaction is an important concept

in multiagent systems and the establishment of social

organizations. According to (Ferber, 1995), it is ex-

pressed by a set of actions that have an influence on

the future behavior of agents. Interaction can provide

the possibility of communication between agents in

order to coordinate and to avoid the encounter that

leads to a collision (such as moving vehicles causing

a collision).

Figure 2 shows the acquaintances relationship be-

tween the system entities where different stereotypes

are schematized by the same icons of figure 1. An

acquaintance is shown by a double arrows. A con-

tainer agent interacts with resource agent to determine

the set of tasks of a requested service in two cases.

It communicates with a resource agent to establish

the process of resource sharing using the Contract

Net protocol or to determine the allocation resource

through the planner agent using the request protocol.

According to (Ferber, 1995), the type of interaction

between the resource agent and the container agent

is “Collaboration coordinated “. It is characterized

by a compatible goals between entities (answer to the

containers satisfaction) and insufficient skills. Agents

must coordinate their actions in order to ensure the

realization of all requested services by a container

agent.

Agents resources communicate with each other

using the request protocol to ensure the consistency

and the synchronization of tasks to accomplish.

Container agents interact with each other using the

Contract Net protocol to negotiate the resources shar-

ing on condition that they have the same destination

and the same size. The interaction between container

agents is defined by goals incompatibility which re-

quires negotiation to achieve their satisfaction. So,

we can name the interaction type by “Pure individual

competition” (Ferber, 1995).

Figure 2: Acquaintance relationships.

In MESSAGE methodology, each agent owns

tasks, interactions and goals in its environment. A

task is executed when a precondition is valid and

when is completed by a post-condition. A composite

task is expressed in terms of causality between sub-

tasks. It can be modeled by a state machine. We mod-

elise it therefore by a state machine using the ATN

(Augmented Transition Network) (Woods, 1970), we

discuss this in the next section.

3.3 Internal Structure of Agents

ATN is the main internal element of an agent. ATN

is a finite state machine that describes the agent be-

Multi-AgentSystemModelforContainerManagementSimulation

501

haviour where each transition is marked by one or

more conditions and corresponding actions. Its role

is to reflect the dynamicity and to insure the agent re-

activity and proactivity. According to (Cardon, 2003),

an agent is structured by the following modules:

• Knowledge module: contains the agent knowl-

edge which may be static or dynamic. Static

knowledge represent environmental data whereas

dynamic knowledge represent environmental vari-

ables that are used by agents to negotiate with

other system entities.

• Communication module which is composed

mainly of “acquaintances Network” and that en-

ables agent to interact with other agents.

• Behaviour module, which is composed of an

ATN, manages the agent behavior based on his

knowledge.

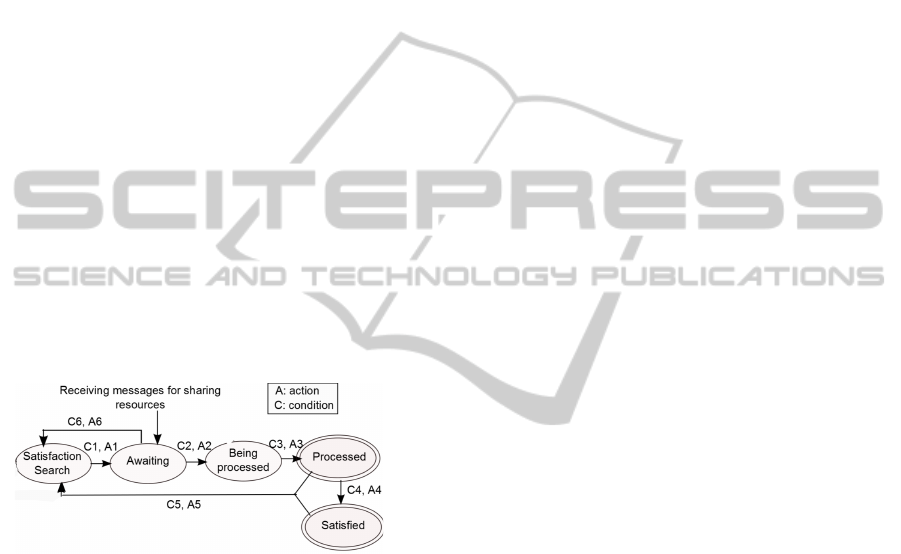

3.3.1 Container Agent

The container is the principal agent of the system.

It changes state while executing a set of actions to

achieve its internal goal. An ATN is used to model its

behaviour and which comprises an initial state, a final

state and a finite set of states as shown in figure 3.

Figure 3: ATN of a container agent.

Satisfaction Search State. When a container agent

needs a resource to be treated (C1), it starts negoti-

ation with other agents having a resource. It broad-

casts therefore a call for proposals indicating its des-

tination, its dimension and its priority (A1) and goes

to state “Awaiting state”. In return, the assigned

container agent, that receives the message, checks

whether the resource sharing will affect its remaining

processing time. This process is performed using the

following equation to select calls. We note that ts

A

is

the service time per affected container and ts

NA

is the

service time per non affected container.

Z = ts

A

− (ts

NA

+ d

A,NA

)

There are two cases:

• If Z < 0, ie if the remaining processing time of

unaffected container adding the elapsed time of

the distance between the affected and unaffected

container agent exceeds the remaining processing

time of affected container , then it rejected the

call.

• If Z ≥ 0, then the affected container agent asks the

resource agent for sharing. The latter accepts or

rejects the request indicating its capacity. Next,

the container agent chooses among the selected

calls the highest priority calls and sends proposals

proportionally to the capacity of agent resource.

Awaiting State. It waits proposals (C2), then col-

lects them and finally accepts the most appropriate

one (A2). In return, the affected container agent sends

a confirmation to resource agent indicating the con-

tainers number that have accepted the proposal of

sharing resource and their identifiers. Then, the re-

source agent broadcasts an information indicating that

it is ready to container agents sharers the resource

agent (C2).

On failure (it does not find proposals for its re-

quest (C6) or it refuses all proposals that do not pos-

sess an adequate destination (A6)), it returns there-

fore to “Satisfaction Search state” (A6). In this state,

it proceeds the coordination with resource agents

through a planner agent by sending a message to the

scheduler indicating its destination, the operation type

and the remaining processing time and switches after

that to “Awating state” (A1). When it receives an in-

formation from planner indicating its assignment to a

resource (C2), it sends a confirmation message to the

resource agent (A2). It receives an information from

resource agent indicating that it is ready (C2) and it

transits to “being processed ”.

Being Processed, Processed and Satisfied States.

In this state the container agent is being processed.

As soon as the treatment is finished (C3), it informs

the scheduler about the end of treatment (A3). Fi-

nally, the container passes from “Processed state” to

“Satisfied state” that presents the final state in which

the container will be processed before the deadline to

ensure their satisfaction (A4) and in which it tries to

stay. If it is satisfied (C5), it returns to the initial state

(A5).

Knowledge module: consists of acquaintances of

container agent are composed of:

• Static knowledge: container id, dimension and na-

ture.

• Dynamic knowledge: Destination, service time,

number of containers to be treated, current pro-

cessing time and operation type.

ICEIS2013-15thInternationalConferenceonEnterpriseInformationSystems

502

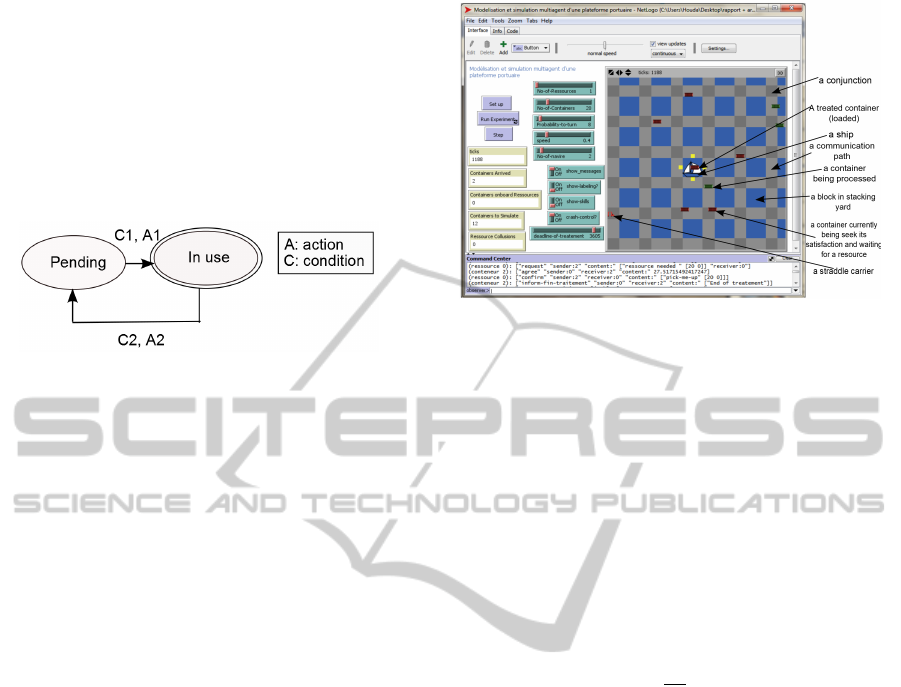

3.3.2 Resource Agent

The resource agent, which is responsible to provide

services is of two types: handling equipment and

transport vehicle. A container treatment is a coher-

ent sequence of a set of tasks. Each state carries roles

and brings a specific version of each service in differ-

ent processes. The ATN of the resource agent has two

states which are (figure 4):

Figure 4: ATN of resource agent.

Pending State: presents the initial state in which the

resource agent is still waiting container requests to en-

sure its satisfaction (C1). When it receives a request

from container agent, it responds to requests accord-

ing to its capacity, the container dimensions and the

type of authorized terrain. In case resource agent ac-

cepts the request (A1), it receives confirmation to start

treatment (C1) and goes to state “In use”.

In Use State: presents the final state in which a re-

source agent moves to the location of the container

and, sends information indicating that it is ready to

the container (A1) and then begins processing. Fi-

nally, when it finishes its processing (C2), it returns to

the initial state “Pending” and informs planner about

the end of treatment (A2).

The knowledge module of a resource agent is

composed of:

• Static knowledge: which are the resource Id, the

resource type, the speed and the capacity.

• Dynamic knowledge: which contains the con-

tainer coordinates, the type of operation and the

location of the ship.

4 RESULTS

Figure 5 shows the entities of the simulation environ-

ment. Entities are composed of straddle carriers that

represent the resource agent, containers that represent

the container agent, ship, communication routes and

junctions. Entities are coded in color to help under-

standing the evolution of the state entities as well as

the system state.

To treat the coordination among agents, we have

established a dialogue between the container agent

and the resource agent using the formalism FIPA /

Figure 5: Simulated container management Layout.

ACL. We chose to simulate the loading operation

to validate the model and to understand the differ-

ent policies in the containers management by altering

some parameters in the purpose of taking and evalu-

ating different decisions. The instance is repeated in

each hour to control the evolution of container behav-

ior as well as the rate of its satisfaction during the sim-

ulation by changing the speed of resource agent and

the number of containers to be processed. The rate

of satisfaction (RoS) is obtained by dividing the num-

ber of satisfied requests per the number of required

requests. We note that N is the number of required

requests and Ns is the number of satisfied requests.

RoS =

Ns

N

∗ 100

Moreover, given the dynamicity of the container

terminal, we investigate the perturbations that can be

made during the treatment of containers. We evalu-

ated , for this purpose in two scenarios, the number of

collisions depending on the speed of resource agent.

According to the results in table 1, scenario 1 and 2

has successively a satisfaction rate of 60% and 36%.

We note, basing-on scenario 1 and 2 that the num-

ber of containers to be treated has a great impact on

the rate of containers satisfaction. In other hand, ac-

cording to a study done by ECMT on 34 terminals,

the number of containers to be treated has a big influ-

ence on the cranes productivity and on the quay ca-

pacity (Chambreuil, 2011). So we can interpret that

the greater a number of containers to be processed

per ship is, the more a number of unsatisfied contain-

ers increases and the more the waiting time increases.

In practice, a quay is considered saturated when it is

used more than 60%. So we have a waiting time at

berth (queuing theory). Also, the number of allocated

cranes depends on the size of container ship and the

number of container to be treated, so the number of

allocated cranes is proportional to the number of con-

Multi-AgentSystemModelforContainerManagementSimulation

503

Table 1: Quality of the solution for the instance # 1.

Sc N speed NoC RoS(%)

Sc 1 20 0.3 0 60

Sc 2 30 0.3 0 36

Sc 3 20 0.6 0 70

Sc 4 30 0.6 0 53

Sc 5 30 1 61 46

Sc 6 30 1.2 73 17

N : number of required requests

NoC: number of collusions

RoS: rate of satisfaction

tainer to be treated. Moreover, according to the hy-

potheses, priority of container p depends on the num-

ber of containers and the number of cranes. Thus,

we can take a decision concerning the setting of the

number of cranes with the aim to increase the pro-

ductivity of cranes and consequently to improve the

rate of satisfaction. We take Scenario 2 and 4 which

integrate two different speeds, Scenario 4 possesses

a higher satisfaction rate comparing with scenario 2.

We were able to validate that the vehicle speed is an

important factor in planning. It varies according to

the vehicle type and the terrain type where it moves.

This explains that the choice of equipment plays an

important role in strategic decision making for an ef-

ficient management of containers. The work of Hene-

sey (Henesey et al., ) implement the different policies

for sequencing, berthing, and stacking on the perfor-

mance of CTs includes additional variables such as

the number of equipment used in a terminal and the

allocated road by the transport vehicle. Finally, if we

take scenario 5 and 6, we note that more the speed in-

creases, greater the number of collusions increases in

the terminal. On the other hand, although the speed

is higher, the rate of satisfaction is lower due to the

disturbances that can happen during treatment of con-

tainers.

5 CONCLUSIONS

In this paper, we modeled a multiagent model to sim-

ulate container management. The model aims to de-

liver goods to customers in time to satisfy them. It in-

volves only container agents and resource agents that

cooperate and negotiate with each other to distribute

tasks among resources and to organize their achieve-

ments over time according to containers priority. We

choose the ATN to describe the internal structure of

agents and MESSAGE method to describe the sys-

tem architecture. We implemented a first prototype

and we extracted a first results in order to test and to

validate the proposed approach. Currently, we pro-

ceed to extend our model using cellular automata for

modeling the location of the containers in a container

terminal.

REFERENCES

Bin, S., Junqing, S., and Qiushuang, C. (2011). On con-

tainer terminal logistics operational and scheduling

management system based on mas. In Control Confer-

ence (CCC), 2011 30th Chinese, pages 5484 –5489.

Caire, G., Garijo, F., Gomez, J., Pavon, J., and Vargas, E.

(2001). Agent oriented analysis using message/uml.

pages 119–135. Springer-Verlag.

Cardon, A. (2003). Mod

´

eliser et concevoir une machine

pensante : approche constructible de la conscience

artificielle. Automates intelligents. Automates intelli-

gents, Paris. Lexique des d

´

efinitions.

CEMT (2006). Terminologie en transports combin

´

es (fran-

cais, anglais, allemand, russe).

Chambreuil, A. (2011). Productivit

´

e des terminaux

`

a con-

teneurs. Le CETMEF.

E.C.M., T. (2005). La s

ˆ

uret

´

e du transport intermodal de

conteneurs. OECD Publishing.

Ferber, J. (1995). Les Syst

`

emes Multi Agents: vers une intel-

ligence collective. Paris, France, intereditions edition.

Govil, M. and Proth, J. (2001). Supply Chain Design

and Management: Strategic and Tactical Perspec-

tives. Academic Press Series in Engineering. Aca-

demic.

Henesey, L. (2006). Multi-agent systems for container ter-

minal management. Blekinge Institute of Technol-

ogy doctoral dissertation series. Blekinge Institute of

Technology.

Henesey, L., Davidsson, P., and Persson, J. Evaluating con-

tainer terminal transhipment operational policies: an

agent-based simulation approach. WSEAS Transac-

tions on Computers, 2006:2090–2098.

Henesey, L. E., Notteboom, T. E., and Davidsson, P.

(2003). Agent-based simulation of stakeholders rela-

tions: An approach to sustainable port and terminal

management. In International Association of Mar-

itime Economists Annual Conference, 2003(a, pages

314–331.

Kefi, M., Ghedira, K., Korbaa, O., and Yim, P. (2009). Con-

tainer handling using multi-agent architecture. Int. J.

Intell. Inf. Database Syst., 3(3):338–360.

Mocellin, F. (2006). Gestion des entrep

ˆ

ots et plates-formes:

Assurez la performance de votre supply chain par

la ma

ˆ

ıtrise des zones de stockage. Fonctions de

l’entreprise. S

´

erie Performance industrielle. Dunod.

Steenken, D., VoB, S., and Stahlbock, R. (2004). Container

terminal operation and operations research, a classifi-

cation and literature review. OR Spectrum, 26:3–49.

ICEIS2013-15thInternationalConferenceonEnterpriseInformationSystems

504

Woods, W. A. (1970). Transition network grammars for nat-

ural language analysis. Commun. ACM, 13(10):591–

606.

Wooldridge, M. (2009). An Introduction to MultiAgent Sys-

tems. John Wiley & Sons.

Multi-AgentSystemModelforContainerManagementSimulation

505