Speed Control of Drive Unit in Four-rotor Flying Robot

Stanisław Gardecki, Wojciech Giernacki and Jarosław Gośliński

Institute of Control and Information Engineering, Poznan University of Technology, 3a Piotrowo St., Poznan, Poland

Keywords: UAV, Four-rotor Flying Robot, Speed Control of Drive Unit, Coefficient Diagram Method.

Abstract: In this paper the synthesis of speed controller for drive unit is presented. Its aim is to generate the lift force

of multi-rotor flying robot. Parameters of drive unit model were experimentally determined based on

recorded time characteristics from engine test stand. The use of two alternative controllers: CDM and PID

types was proposed. The CDM controller was tuned in accordance with the Coefficient Diagram Method

and the PID controller in MATLAB’s Simulink Response Optimization tool. The efficiency of both types

control systems was compared for specified conditions. Integral quality indices were adopted as a measure

of assessment. Obtained simulation results were discussed in the context of implementation on a real robot.

1 INTRODUCTION

Many concepts of unmanned aerial vehicles have

been already developed. Usually these robots are

used in tasks of observation, patrolling and

recognition in areas of military and civil (Gertler,

2012), as well as in the science and entertainment

(Augugliaro et al., 2010). The use of several drive

units, often embedded in the same plane, is their

similarity. Such a solution (without the control of

angle of blades attack as it is in helicopters) results

with the stiff construction of whole robot, but it

enforces a specific control – change of the robot's

position and movement is only an effect of the speed

change of appropriate drive unit (DU) - obtained

from the onboard microcontroller, which aim is to

split the thrust into particular drives. A thinking

oriented to obtainment of the simplest possible

mechanical construction supported with advanced

computational unit and onboard sensors, works well

in four-rotor flying robots, but only with effective

control techniques (Gardecki and Kasiński, 2012).

In this paper, attention was focused on the

synthesis of variable speed control of one DU

(described in detail in Gardecki and Kasiński, 2012)

with the brushless DC motor and by the not well

known algorithm of the Coefficient Diagram

Method (CDM) (Manabe, 1998), which has been

already applied with success within the context of

avionics (Budiyono, 2005). The proposed CDM

controller is an alternative to commonly used PID

(Salih et al., 2010). The avionics of considered robot

from Fig. 1 equipped with four DUs (Fig. 2)

involves the use of two control loops – the external

(slower) to control movement and orientation of

robot by the board controller, as well as the inner

loop for variable speed control of each of four DUs.

The determina-tion of rotational speed is conducted

by the change of voltage signal fulfillment - PWM

(Pulse-Width Modulation) on particular DU

controller input.

Figure 1: Hornet robot.

Figure 2: Speed controller (a), drive unit: brushless DC

engine (b) and propeller (c).

The CDM control according with the idea of robust

control does not enforce to obtain complica-ted and

complex mathematical model of the DU, but only

the simplest possible description, which accura-tely

245

Gardecki S., Giernacki W. and Goslinski J..

Speed Control of Drive Unit in Four-rotor Flying Robot.

DOI: 10.5220/0004477002450250

In Proceedings of the 10th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2013), pages 245-250

ISBN: 978-989-8565-71-6

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

reflects the dynamics. The aim of control algorithm

is then (in addition to stability and good quality of

control providing) a correction of impact of

nonmodeled and missed part of plant's dynamics –

therefore it was decided to use the experimental

method for determining DU’s model parameters

from its step response to the transfer function form.

2 ENGINE TEST STAND

For tests of high speed drive units, a special test

stand (TS) was built (Fig. 3), which enabled remote

control and measurements. In order to provide

constant and stable power supply to the DU, the

inRadio IN-450 power supply with high current

efficiency may be used, but during tests controller

drew power from 6000 mAh 11,1 V battery. The TS

was equipped with a set of sensors which allow to

control the power supply voltage of controller and to

measure of the DU current consumption, generated

thrust by the set of engine/propeller and the

rotational speed. The data from measurement system

were transmitted as a report to the computer applica-

tion, which was used as an setpoint adjuster and

controller (to set the same experimental conditions

for various power units). The signal sampling

frequency was equal to 300 Hz.

On the basis of earlier tests (Gardecki and

Kasiński, 2012) it was observed that despite the use

of the same BLDC engines and propellers, recorded

characteristics of drive units differ from each other,

which leads to stabilization difficulties of the robot

during the flight and reduces the flight time by

unfairly increase consumption of electricity. On this

reason authors opted for the synthesis of control

systems (with PID and CDM type controllers) for

particular DU. This paper considered results of

tuning for an exemplary, one of four drive units.

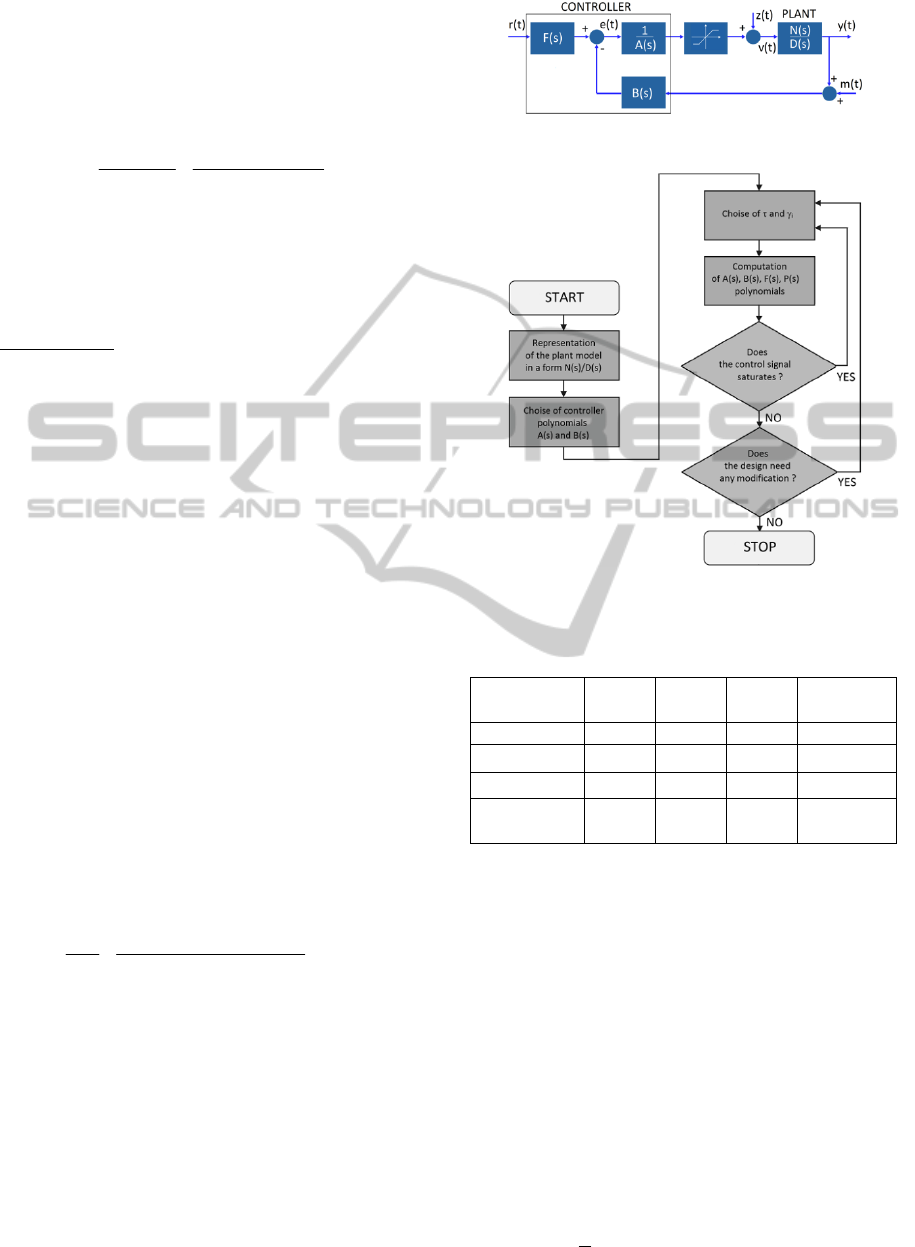

Two tests to provide a maximum knowledge

about modeled object were conducted. In the first

study, by the change of set voltage (fulfilment of

PWM) fed to the engine (in range from 0 to 100%,

step equal to 1%), characteristics of signals shown in

Fig. 4, were recorded. For the mass of the quadrotor

equal to 1,6 kg, the necessary and total thrust which

allows to overcome its force of gravity amounts

15,696 N. It should be noted that the maximum

thrust (19,09 N) of the tested DU is achieved at

PWM=77 %, RPM=8893 r/min and the current is

equal to I=15,551 A, but the maximum speed

RPM=9039 r/min is achieved at PWM=75 %, and

I=14,419 A. These parameters illustrate limits of

useful ranges during the operation of robot.

Figure 3: Engine test stand.

Figure 4: PWM (a), propeller rotational speed – RPM (b),

engine current (c), thrust of engine/propeller unit (d),

power supply voltage (e) in the function of control voltage

change from 0 to 5 V.

Figure 5: Model (smooth line) and robot step responses

matching.

In the second test a step response of modeled DU

has been observed (voltage changed from 0% to

100% PWM) to obtain the simplest plant model,

which is desirable for control system synthesis, but it

has to accurately reflect the particular DU dynamic,

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

246

which useful thrust starts from minimum value

3,924 N (RPM=4492,5 r/min). The time course of

rotational speed from Fig. 5 has been recorded and it

was decided to apply the second-order inertial plant

model (1), which parameters were determined by

step responses matching in experimental way.

22

11

()

0,0016 0,08 1

0,04 1

Gs

s

s

s

(1)

3 SYNTHESIS OF CDM AND PID

CONTROLLERS

CDM Control

The CDM algorithm is based on an idea of the use of

relationship between obtained closed-loop system

time characteristics and the placement of its

characteristic polynomial poles on the complex

plane s (Manabe, 1998). The control system under

consideration is presented in Fig. 6, where F(s) -

input numerator polynomial of controller transfer

function, A(s)/B(s) - numerator/denominator polyno-

mial of controller transfer function, N(s)/D(s) -

numerator/denominator of plant transfer function,

r(t)/y(t) - reference/output signal, e(t) - control error,

z(t) - external disturbance signal, v(t)/u(t) - un/con-

strained control signal, m(t) - measured noise signal.

A characteristic polynomial of closed-loop system

P(s) (of n-th degree) is defined by the equation (2):

0

() () () () () ,

n

i

i

i

Ps DsAs NsBs as

(2)

The synthesis of controller for system from Fig. 6

(with the use of CDM algorithm from Fig. 7) and

CDM procedure (Hamamci and Koksal, 2004) are

presented below.

A. Controller Synthesis

Notation of Plant Model with use of transfer

Function:

1

110

1

110

...

()

,

() ...

ll

ll

mm

mm

ns n s ns n

Ns

Ds d s d s ds d

(3)

where: l – degree of N(s) polynomial (less or equal

to m – degree of D(s) polynomial).

Choice of Controller Structure

Based on analysis of expected disturbances,

degrees of polynomials A(s) and B(s) are chosen

according to Table 1. Controller polynomials,

respectively degree: p and q are written in forms (4):

00

() , () .

pq

ii

ii

ii

A

slsBsks

(4)

Figure 6: Block diagram of CDM control closed loop.

Figure 7: CDM algorithm.

Table 1: The choice of transfer function polynomials

degrees due to expected type of disturbances.

Type of

disturbance

Degree

of A(s)

Degree

of B(s)

Degree

of P(s)

Condition

None m-1 m-1 2m-1 -

Step m m 2m l

0

=0

Ramp m+1 m+1 2m+1 l

0

= l

1

=0

Impulse/

sinusoidal

m-1 m-1 2m-1 -

Choice of

and

i

Values

The CDM uses relationship (5) between the

equivalent of time constant (

) – used to build the

characteristic polynomial (P

T

) and the expected time

of step response (t

s

):

/2,5~3.

s

t

(5)

The advantage of proposed algorithm is Manabe

standard form (6) (vector specifying stability indices

-

i

). It represents system stability on a Coefficient

Diagram (CD) and defines the P

T

(s), which should

be used to ensure requirements of system dynamics

in the first iteration of algorithm. Standard forms

should be treated as initial setting values of each

index of stability - details in (Manabe, 1998).

2,5 2 2 ... 2

T

i

(6)

SpeedControlofDriveUnitinFour-rotorFlyingRobot

247

for i=1,…,n-1;

0

=

n

=

and n is P

T

(s) degree.

To specify numerically and graphically (on CD)

stability limit of system, equation (7) for stability

limits is used:

*

11

11

.

i

ii

(7)

Calculation of P(s), F(s), A(s) and B(s)

The equivalent of time constant and stability

indices building the target characteristic polynomial

(8), which is compared to equation (2), therefore

from diophantine equation (9) numerical values of

controller coefficients (l

i

and k

i

) may be calculated.

1

0

2

1

1

() 1

i

n

i

T

j

i

j

ij

Ps a s s

(8)

() ()

T

Ps P s

(9)

Polynomial F(s) is defined by the equation (10):

0

0

()

() .

()

s

s

Ps

Fs

Ns

(10)

Recurrence of CDM Algorithm

The option of procedure recurrence depends only

on the fact, whether a satisfactory control quality

was obtained (according to previously chosen

criterion e.g. size of the overshoot, saturation of

control signal, settling time of output signal,

specified limit of stability). By reduction of stability

limit or extension of the expected time of step

response, algorithm may be recurred. The CD

analysis is useful in this part of procedure.

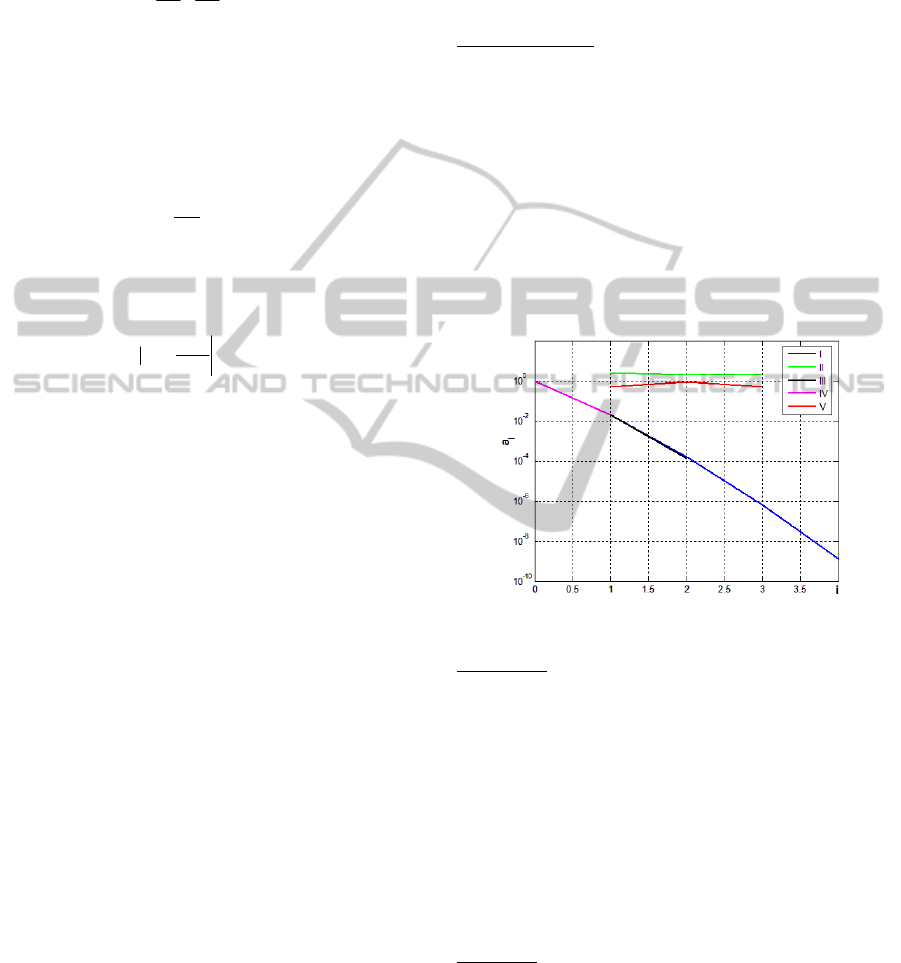

B. Coefficient Diagram

In synthesis and analysis of the control system based

on the CDM algorithm, half-logarithmic coefficient

diagram is used (Fig. 8), where the vertical axis

logarithmically shows coefficients of the

characteristic polynomial (a

i

), stability indices (

i

),

stability limits (

i

*) and the equivalent time constant

(

), while the horizontal axis shows the i values

corresponding to each coefficient.

In Fig. 8 number marks were introduced:

• numerical values (a

i

) of P

T

(s) coefficients – I,

• numerical values of stability indices (

i

) – II,

• numerical values (k

i

) of B(s) coefficients– III,

• equivalent of time constant (

) – IV,

• numerical values of stability limits (

i

*) – V.

By analogy with the Bode and Nyquist plots,

coefficient diagram provides the necessary

information about the system robustness, stability

and dynamics. The degree of convexity, which is

obtained from coefficients of the characteristic

polynomial, gives a measure of stability, while the

general inclination of the curve gives a measure of

the speed of response (Manabe, 1998). The variation

of the shape of the a

i

curve due to plant parameter

variation is a measure of robustness (Hamamci and

Koksal, 2004).

Stability analysis

For values

i

and

i

vertical distance between the II

and V curves is a measure of system stability (if the

distance for each i increases, then the system has

bigger stability limit). Analyzing the situation in the

complex plane s, this corresponds to the placement

of system poles in the left half-plane in larger

distance from the imaginary axis specifying the limit

of stability. It should be noted that the system is

stable only if curves do not cross each other and the

curve II is above the curve V (Manabe, 1998). The

basis of a theoretical analysis of a system stability is

Lipatov and Sokolov criterion.

Figure 8: Coefficient diagram of CDM system model (1).

Robustness

Assessment of system robustness is based on the

mutual position of I and III curves. If the curve III is

below the curve I, then the system is more robust to

parametric uncertainty – robustness increases when

the curves are closer to each other. It was shown in

(Manabe, 2010) that depending on the plant type, in

general, it is possible to design with the use of CDM

algorithm a control system, which is stable due to

the change the i-th characteristic polynomial

coefficient values in the range from 0,5 to 3 times in

relation to the nominal value of this factor.

Dynamics

Dynamics of system is characterized by the time

constant equivalent. The system is characterized by

higher dynamics for smaller values of

- in diagram

it corresponds to a larger angle of the curve IV

inclination. Analysis of the time constant equivalent

is also important in the case of control signal

constraints. If the control signal is saturated, then the

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

248

key issue in the control system synthesis is to return

to the stage of selection of expected equivalent time

constant value to increase this value (to slow down

the expected step response) and retry the algorithm.

The CDM controller was tune for possibility of

step type disturbance appearance (eg., blow of the

strong wind on the DU propellers). After the selec-

tion of appropriate controller structure (according to

the Table 1) for the model transfer function, the

Manabe standard form (6) was assumed. Then for

the chosen (expected) step response time t

s

=0,05

~0,06 sec, equivalent of time constant =0,02 sec

was calculated. The CDM controller was obtained:

2

2

( ) 0,0008 0,36 ,

( ) 0,0001 0,0196 1,

1.

A

sss

Bs s s

Fs

(11)

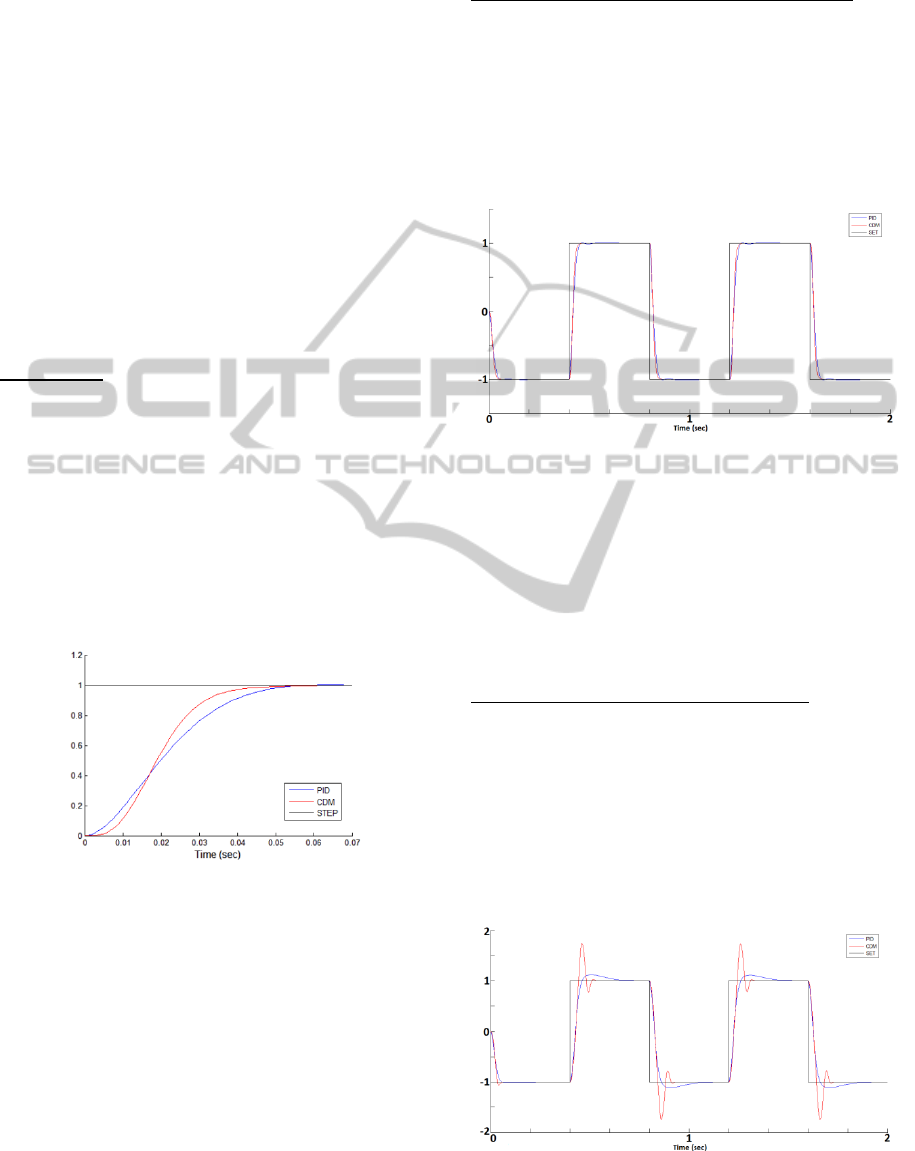

PID Control

To compare the control and tracking quality, the

second controller (PID - proportional-integral-

derivative), was used. Its parameters, namely the

gain of proportional part (k

P

), integral part (k

I

) and

derivative part (k

D

), were set in Simulink Response

Optimization tool – for similar assumptions as for

the CDM control. The optimization algorithm found

solution after 97 iterations (different controller sets)

as: k

P

=3,24, k

I

=49,40, k

D

=0,06. This controller

provides a step response after the time ~ 0,06 sec

with minimal overshoot (Fig. 9).

Figure 9: Step responses for CDM and PID controllers.

4 COMPARATIVE TESTS

Presented above control systems have been

implemented in the MATLAB 7.0/ Simulink under

OS Windows 7 system in default configuration.

Obtained results from numerical tests are presented

below. Parameters of PID and CDM control systems

remained constant in all performed tests. To control

quality assessment of the DU speed, except time

characteristics, integral quality indices were used:

IAE (integral of absolute value of error) and ISE

(integral of error squared).

Tracking of Setpoint Signal in Nominal Systems

In the first stage of numerical tests, in systems

without disturbances and constraint of control signal

amplitude, tracking quality of set rectangular signal

(amplitude equal to 1, period to 0,8 sec, control

horizon to 2 sec), was tested. Signals are presented

in Fig. 10 and values of integral quality indices are:

- 1,925 (IAE) & 1,896 (ISE) for CDM,

- 1,903 (IAE) & 1,869 (ISE) for PID system.

Figure 10: Tracking of SET (setpoint) signal in PID and

CDM nominal systems.

The analysis of signals (Fig. 10) informs that despite

the use of optimization procedure to obtain the PID

controller and fulfilment of assumptions imposed on

the step response (Fig. 9), as well as marginally

lower values of IAE and ISE indices – PID

controller has an undesirable tendency to over-shoot,

which is not present in CDM control.

Tracking of Setpoint Signal at Constraints

In the second simulation test one imposed in both

control systems the same saturation of control signal

amplitude (u

max

=±6). All simulation parameters and

controllers remain unchanged in the relation to the

first test. The results are presented in the form of

reference and output signals (Fig. 11). Integral

quality indices were recorded and are equal

respectively to 1,968 (IAE) & 2,043 (ISE) for CDM

and 1,942 (IAE) & 1,963 (ISE) for PID controller.

Figure 11: Tracking of SET (setpoint) signal in PID and

CDM nominal systems at constraints - u

max

=±6.

SpeedControlofDriveUnitinFour-rotorFlyingRobot

249

Despite the fact that IAE and ISE values are

similar for both controllers, the analysis of Fig. 11

shows the differences in time curves of both output

signals – in the case of ideal (nominal) control

system with constraint of control signal amplitude –

PID controller produces significantly less overshoot,

but it needs almost twice as much time to bring

output signal value to the level of reference signal.

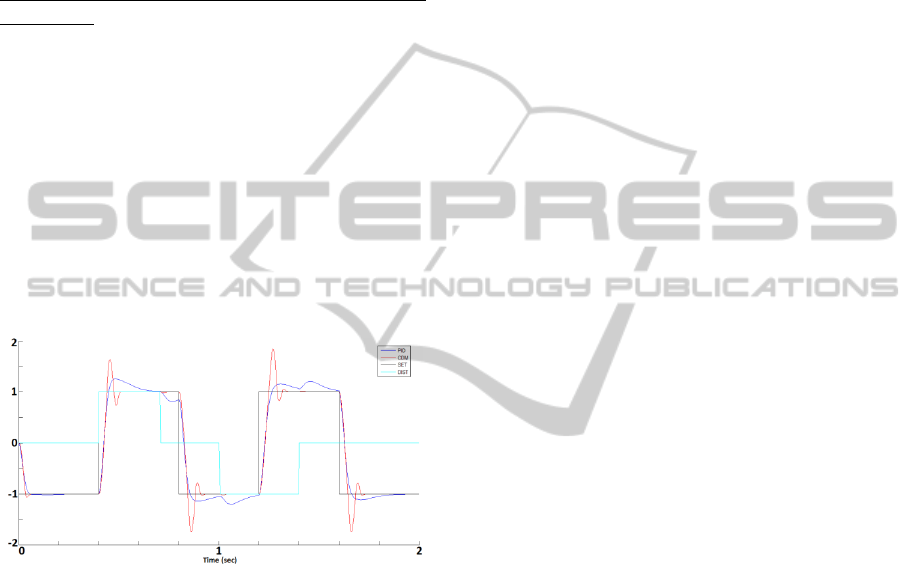

Tracking of Setpoint Signal in disturbed Systems at

Constraints

In the last test, an additional external disturbance

with step change of amplitude level over the time,

has been introduced to CDM and PID systems. The

quality of tracking was verified in the simulation

with similar parameters as in previous test. Values of

integral quality indices are equal respectively to

1,969 (IAE), 2,046 (ISE) for CDM controller and

1,995 (IAE), 2,082 (ISE) for PID. Results of

simulations (with external disturbance signal –

DIST) are presented in Fig. 12. In both cases, the

systems follow a setpoint signal, but for the CDM

control, the quality is definitely better – appearing

disturbances are damped much more quickly.

Figure 12: Tracking of SET (setpoint) signal in PID and

CDM disturbed systems at constraints - u

max

=±6.

5 CONCLUSIONS

Evaluation of the both presented control techniques

efficiency for variable speed control of the flying

robot DU is not easy and unambiguous, because of

robot’s control specificity as a complex dynamic

object. Its speed control is directly associated with

position and orientation, provided by the external

cascade controller which supports all four engines.

In planning of the minimum cost of energy

(minimizing the control signal changes frequency),

which is important from the perspective of the

limited length of flight (approx. 15 minutes) by the

battery power supply used in robot, it is reasonable

to select the PID controller, because it generates a

smooth transfer characteristics. The tendency to

overshoot can be eliminated by different method of

tuning than suggested in this article, such as swarm

optimization algorithm or genetic algorithms.

On the other hand so dynamic object as

quadrotor is very sensitive to transient environment-

tal conditions, such as wind and roll and it requires

very fast reactions. The CDM controller, which is

designed for the presence of step type disturbances,

during the third conducted test ensured generally

faster damping of disturbance effects as well as

better tracking quality through dynamic changes of

control signal. The overshoot that appears, should be

eliminated by the use of modified algorithm of the

CDM method. Such works had been already

conducted with the positive effects for other types of

objects – by using an additional block of pre-filter in

the controller, which parameters may be optimized

by the pole-colouring method (Bir et al., 2005).

The use of above proposed techniques of the PID

and CDM controller sets improvement is now a

starting point for further researches and

implementation tests on the real robot.

REFERENCES

Augugliaro, F., D’Andrea, R., Lupashin, S. and A.

Schöllig, 2010. Synchronizing the Motion of a

Quadrocopter to Music. In Proc. of the IEEE Inter.

Conf. on Robotics and Aut., Alaska, pp. 3355 – 3360.

Bir, A., Öcal, Ö. and M. T. Söylemez, 2005. Robust Pole

Assignment using Coefficient Diagram Method. In

Proc. of ACSE’05 Conf., Cairo, Egypt, CD.

Budiyono, A., 2005. Onboard Multivariable Controller

Design for a Small Scale Helicopter Using Coefficient

Diagram Method. In Proc. of the ICEST, Seoul, CD.

Gardecki, St. and A. Kasiński, 2012. Testing and selection

of electrical actuators for multi-rotor flying robot,

Measurements, Automation & Control, vol. 1, no. 1,

pp. 80-83.

Gertler, J., 2012. U. S. Unmanned Aerial Systems,

Congressional Research Service Report, USA.

Hamamci, S. E. and M. Koksal, 2004. A Program for the

Design of Linear Time Invariant Control Systems:

CDMCAD. Computer Applications in Engineering

Education, vol.12, no.3, pp. 165-174.

Manabe, S., 1998. Coefficient Diagram Method. In Proc.

of IFAC Automatic Control in Aerospace, Seoul, pp.

199-210.

Manabe, S., 2010. Coefficient Diagram Method for

Control system design, unpublished part of the

monograph provided by author.

Salih, A. L., Moghavvemi, M., Mohamed, H. A. F. and K.

S. Gaeid, 2010. Flight PID controller design for a

UAV quadrotor. Scientific Research and Essays, vol.

5, no. 23, pp. 3660-3667.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

250