Effects of Wall Roughness, Impeller Blades and Diffuser Vanes

on the Performances of a First Stage Centrifugal Pump

Nicolas La Roche-Carrier, Guyh Dituba Ngoma and Walid Ghie

University of Quebec in Abitibi-Témiscamingue, School of Engineering 445,

Boulevard de l’Université, Rouyn-Noranda, Quebec, J9X 5E4, Canada

Keywords: Centrifugal Pump, Multistage, Impeller, Diffuser, Computational Fluid Dynamics (CFD), Modeling and

Simulation.

Abstract: In this study, the first stage of a multistage centrifugal pump was numerically investigated to improve its

design. The continuity and Navier-Stokes equations with the k- turbulence model and standard wall

functions were used. The effects of the wall roughness height, impeller blade height and diffuser vane

height, and the number of diffuser vanes on the performances of the first pump stage were analyzed. The

results achieved demonstrate that the selected parameters affect the pump stage head, brake horsepower and

efficiency in a strong yet different manner. To validate the approach developed, the results of the numerical

simulations were compared with the experimental results.

1 INTRODUCTION

Multistage centrifugal pumps are widely used in

industrial and mining enterprises. One of the most

important components of a multistage centrifugal

pump is the impeller (Peng, 2008). For a more

performing multistage pump, its design parameters

must be determined accurately. Given the three-

dimensional and turbulent liquid flow in a multistage

centrifugal pump, it is very important to be aware of

the liquid flow’s behavior when flowing through a

pump stage accounting for the wall roughness. This

can be achieved by taking all stage components into

consideration in the planning, design and

optimization phases in design and off-design

conditions.

Many experimental and numerical studies have

been conducted on the liquid flow through a

multistage centrifugal pump. A three-dimensional

turbulent flow through an entire stage of a

multistage centrifugal pump was numerically

simulated using a CFD code (Huang et al., 2006),

including flows in a rotating impeller and stationary

diffuser. It was found that the reverse flows existed

near the impeller outlet, resulting in the flow field

being asymmetric and unstable. Moreover, the

impacts of the return vane profile on the

performances of the multistage centrifugal pump

were experimentally investigated to optimize the

stationary components in the multistage centrifugal

pump (Miyano et al., 2008). It was found, among

other things, that the return vane, whose trailing

edge was set at the outer wall radius of the

downstream annular channel and discharged the

swirl-less flow, had a positive impact on pump

performances, while the effects of the diffuser vane

on the performances of the multistage centrifugal

pump were experimentally investigated (Kawashima

et al., 2008), accounting for the interactions among

the diffuser vane, return vane and next stage

impeller. The relevance in matching the diffuser

vane and return vane properly to improve the pump

efficiency of the multistage centrifugal pump was

shown. In addition, the multistage pump problems in

conjunction with the axial thrust were

experimentally examined (Gantar et al., 2002), the

Laser Doppler Anemometry (LDA) was used to

determine the fluid rotation in the impeller side

chamber and its impact on the impeller hydraulic

axial thrust for different leakage flow regimes.

Deepened analysis of previous studies clearly

demonstrated that the research results obtained are

specific to the design parameters and configuration

of the rotating and stationary components in

multistage centrifugal pumps, and thus cannot

always be generalized. Therefore, in this study, to

improve the design and performances of multistage

361

La Roche-Carrier N., Dituba Ngoma G. and Ghie W..

Effects of Wall Roughness, Impeller Blades and Diffuser Vanes on the Performances of a First Stage Centrifugal Pump .

DOI: 10.5220/0004486903610368

In Proceedings of the 3rd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2013),

pages 361-368

ISBN: 978-989-8565-69-3

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

centrifugal pumps, accounting for the particularities

of the geometry and configuration of the impeller

and diffuser with return vanes, a numerical

investigation was conducted using the ANSYS-CFX

code (Ansys inc., 2011) based on the finite volume

method and Rhie Chow algorithm for the pressure-

velocity coupling. This was done to gain further

insight into the characteristics of the three-

dimensional turbulent liquid flow through a stage of

a multistage centrifugal pump while also considering

various flow conditions, the height of the wall

roughness, the heights of the impeller blade and

diffuser vane, and the number of diffuser vanes.

Moreover, the pump stage head, brake horsepower

and efficiency were represented as a function of the

flow rate in order to identify the values of selected

design parameters that might enhance pump stage

performances with respect to their value ranges.

2 GOVERNING EQUATIONS

Fig. 1 shows the model of the first stage of a

multistage centrifugal pump considered in this study.

It consists of an impeller, diffuser with return vanes

and casting.

a) Pump stage b) Stage components

Figure 1: Model of a centrifugal pump stage.

To run the numerical simulations, the used domain

fluids of the impeller and diffuser with return vanes

are shown in Fig. 2.

Suction side (inlet) Discharge side (outlet)

Figure 2: Domain fluids of impeller, diffuser and pump

stage.

In the centrifugal pump stage’s governing equations

for liquid flow, the following assumptions were

made: (i) a steady state, three-dimensional and

turbulence flow using the k- model was assumed;

(ii) it was an incompressible liquid; (iii) it was a

Newtonian liquid; and (iv) the liquid’s

thermophysical properties were constant with the

temperature (density, viscosity, etc.).

To account for these assumptions, the theoretical

analysis of the liquid flow in the impeller passages,

diffuser vane passages and diffuser return vane

passages was based on the continuity and

Navier-Stokes equations (Tropea et al., 2007). For

the three-dimensional liquid flow through these

components of a centrifugal pump stage as shown in

Fig. 2, the continuity equations are expressed by:

0V.

vel

,

(1)

where

z,y,xw,z,y,xv,z,y,xuVV

velvel

is the

liquid flow velocity vector.

Using the coordinate system, Eq. 1 can be rewritten

as:

0

z

w

y

v

x

u

(2)

and the Navier–Stokes equations are given by:

B p

))V(V.()VV.(

T

velveleffvelvel

(3)

where p is the pressure, is the density,

eff

is the

effective viscosity accounting for turbulence, is a

tensor product and B is the source term, which is

equal to zero for the flow in the stationary

components like the diffuser.

For flows in an impeller rotating at a constant speed

, the source term can be written as follows:

rxxVx2B

vel

(4)

where

r

is the location vector,

vel

Vx2

is the

centripetal acceleration and

rxx

is the Coriolis

acceleration.

Using the coordinate system, Eq. 3 can be rewritten

as:

Inlet

Back stage side

Outlet

Return vanes

Blades

Vanes

Impeller

Diffuser with

Return vanes

Casing

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

362

22

22

2

2

22

22

2

2

eff

x

eff

uu u uu

uvw

xy z xy

up

B

xz

vv v vv

uvw

xy z xy

v

z

22

22

2

2

y

eff

z

p

B

y

ww w ww

uvw

xy z xy

wp

B

zz

(5)

where

.0B and u2rB ,v2rB

zzy

2

zyzx

2

zx

Furthermore,

eff

is defined as

teff

, where

is the dynamic viscosity and

t

is the turbulence

viscosity, it

is linked to turbulence kinetic energy k

and dissipation ε via the relationship:

12

t

kC

where C

is a constant.

The values for k and stem directly from the

differential transport equations for turbulence kinetic

energy and turbulence dissipation rates:

k

k

t

vel

p]k).[()kV.(

(6)

)CpC(

k

]).[()V.(

2k1

t

vel

(7)

where C

1

, C

2

and

are constants. p

k

is the

turbulence production due to viscous and buoyancy

forces, which is modeled using:

)kV.3(V.

3

2

p )VV.(Vp

veltvel

kb

T

velvelveltk

(8)

.gp

t

kb

(9)

where p

kb

can be neglected for the k- turbulence

model.

Additionally, for the flow modeling near the wall,

the logarithmic wall function is used to model the

viscous sub-layer (Tropea et al., 2007).

To solve equations 2 and 5 numerically while

accounting for the boundary conditions and

turbulence model k-, the ANSYS-CFX code. In the

cases examined involving the pump stage, the

boundary conditions were formulated as follows: the

static pressure provided was given at the stage inlet,

while the flow rate provided was specified at the

stage outlet. The frozen rotor condition was used for

the impeller-diffuser interface. A no-slip condition

was set for the flow at the wall boundaries.

The pump stage head is determined as follows:

g

pp

H

tito

(10)

where p

ti

is the total pressure at the pump stage inlet

and p

to

the total pressure at the pump stage outlet as

shown in Fig. 2. They are expressed as:

2

vel

iti

i

V

2

pp

and

2

vel

oto

o

V

2

pp

(11)

Moreover, the hydraulic power of the pump stage is

given by

QgHP

h

, where Q is the flow rate and H

is the pump stage head.

In addition, the brake horsepower of the pump stage

is expressed as P

s

= C, where is the angular

velocity and C is the impeller torque.

From the hydraulic power and the brake horsepower,

the efficiency of the pump stage can be written as

s

h

P

P

. It can also be formulated in terms of the

hydraulic efficiency (

h

), the volumetric efficiencies

(

v

), and mechanical efficiency (

m

) as =

h

v

m

.

3 RESULTS AND DISCUSSION

Water at 25 °C was used as the working liquid for all

simulation runs in this study. The main reference

data used for the impeller were 195 mm for the inner

diameter, 406 mm for the outer diameter, 6 for the

number of blades and 1750 rpm for the rotating

speed. For the diffuser, the main reference data were

407.016 mm for the inner diameter, 571.5 mm for

the outer diameter, 11 for the number of vanes and 8

for the number of return vanes. The numerical

simulation results presented in this work were

obtained with the highest accuracy by conducting

mesh-independent solution tests in each case study

using different numbers of mesh elements.

3.1 Impact of Wall Roughness Height

To analyze the impact of the wall roughness height

of the impeller, diffuser and casting on the pump

stage performances, two wall roughness heights (0

mm, and 2 mm) were chosen, while the other

EffectsofWallRoughness,ImpellerBladesandDiffuserVanesonthePerformancesofaFirstStageCentrifugalPump

363

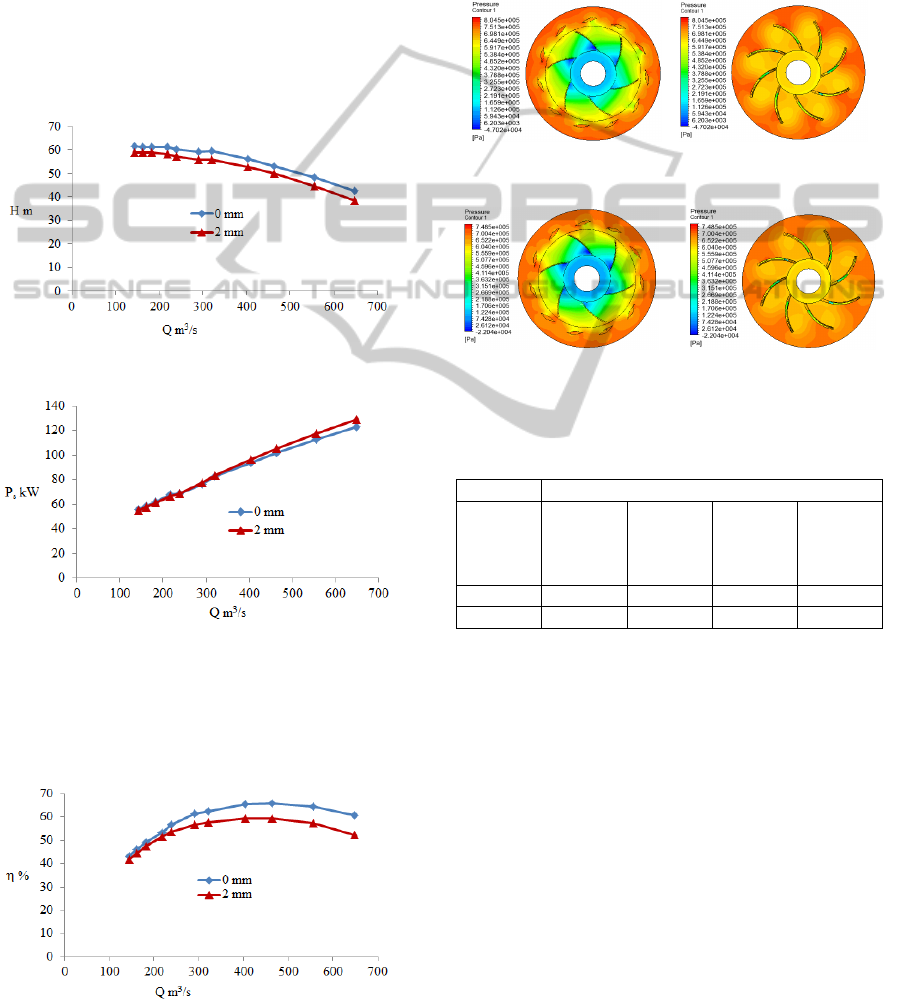

parameters were kept constant. Fig. 3 shows the

head as a function of the flow rate, where it is

observed that the head is not affected by the value of

the wall roughness height at 0 mm. On the contrary,

it decreases when the wall roughness height

increases further. This is explained by the fact that

the friction loss rises with significantly increasing

wall roughness height. In other words, the wall

roughness increases the flow resistance in turbulent

flow. As shown in Fig. 4, the brake horsepower rises

with increasing wall roughness height for large flow

rates due to the increase in the friction loss with

increasing wall roughness height for large flow

rates. Thus, the requested pump torque increases.

Figure 3: Pump stage head versus flow rate.

Figure 4: Brake horsepower versus flow rate.

In addition, Fig. 5 shows the efficiency as a function

of the flow rate, where it is observed that the

efficiency decreases with increasing wall roughness

height due to the increase in friction loss.

Figure 5: Efficiency versus flow rate.

Moreover, Fig. 6 shows the corresponding static

pressure contour for Q = 464 m

3

/h, which

demonstrates the distribution of static pressure in the

impeller and diffuser with return vanes. Also, Tab. 1

presents the pressure differences in the impeller,

diffuser and diffuser return vane passages obtained

for the wall roughness heights of 0 mm and 2 mm.

There, the decrease in total pressure difference with

increasing wall roughness height is shown.

Diffuser return vane passages

a) 0 mm and ∆p = 519683 Pa

Diffuser return vane passages

b) 2 mm and ∆p = 486555 Pa

Figure 6: Static pressure contour.

Table 1: Distribution of pressure difference.

Pressure difference ∆p Pa

Wall

rough.

height

mm

Impeller Diffuser Diffuser

return

vane

passages

∆p

total

0 512751 108942 -102010 519683

2 486786 79951 -80182 486555

3.2 Impact of the Height of Impeller

Blades and Diffuser Vanes

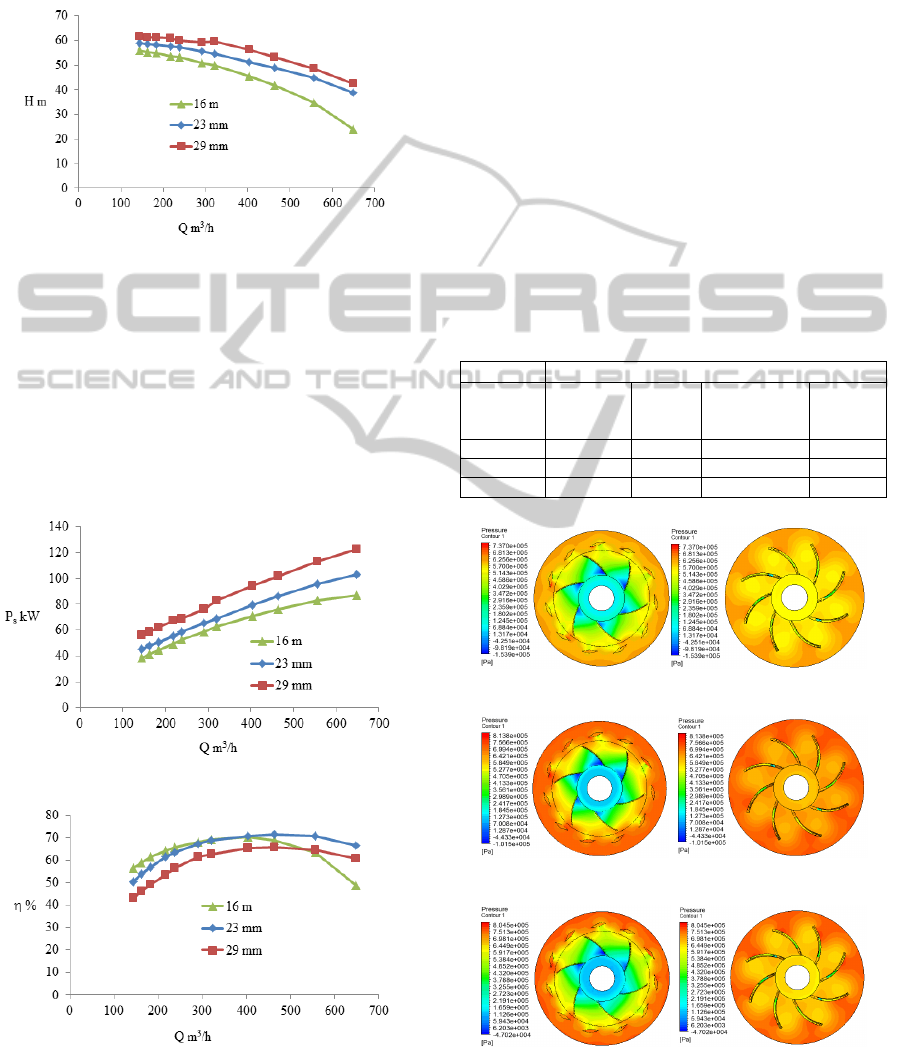

To investigate the impact of the height of impeller

blades and diffuser vanes on the pump stage

performances, the values of 16 mm, 23 mm and 29

mm were selected for the impeller blade height and

diffuser vane height, while keeping the other

parameters constant. Fig. 7 shows that the pump

stage head decreases with increasing flow rate due to

decreasing liquid pressure. In addition, the pump

stage head increases with increasing blade height

and vane height. This is explained by the fact that

when the flow rate is kept constant, the increased

blade height leads to the decreasing meridional

velocity, which increases the pump stage head since

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

364

the outlet tangential velocity and outlet blade angle

remain constant. In other words, the liquid pressure

drops in the impeller and the diffuser decreases as a

function of the increase in the blade height and vane

height.

Figure 7: Pump stage head versus flow rate.

Furthermore, the curves expressing the pump stage

brake horsepower as a function of the flow rate are

shown in Fig. 8, illustrating that the brake

horsepower increases with increasing flow rate. This

is explained by the additional decrease in liquid

pressure relative to the flow rate. Also, the brake

horsepower increases relative to the impeller blade

height due to the requested increase in pump shaft

torque relative to the increased blade height.

Figure 8: Brake horsepower versus flow rate.

Figure 9: Efficiency versus flow rate.

In addition, Fig. 9 shows that the efficiency for the

blade height and vane height of 16 mm decreases

rapidly to the right of the BEP. The efficiency of the

blade height and vane height of 23 mm is highest at

large flow rates, whereas the efficiency of the blade

height and vane height of 29 mm is lowest at flow

rates ranging between 150 m

3

/h and 550 m

3

/h.

Figs. 10 and 11 represent the corresponding

contours for static pressure and liquid flow velocity

vectors for Q = 464 m

3

/h. Fig. 10 clearly shows that

the static pressure increases with increasing blade

height and vane height. This is due mainly to the

decrease in liquid flow velocity at the impeller outlet

as depicted in Fig. 11, where the average liquid flow

velocities at the impeller outlet decrease from 18.43

for 16 mm to 15.67 m/s for 29 mm. Also, the

recirculation phenomenon is observed in the diffuser

return vane passages. Furthermore, the distribution

of pressure difference (∆p = p

o

- p

i

) in the stage

components is presented in Tab. 2.

Table 2: Distribution of the pressure difference.

Pressure difference ∆p Pa

Blade or

vane height

mm

Impeller Diffuser

Diffuser return

vane passages

∆p

total

16 424908 74626 -91742 407792

23 485468 92713 -98754 479427

29 512751 108942 -102010 519683

Diffuser return vane passages

a) Height = 16 mm and ∆p = 407792 Pa

Diffuser return vane passages

b) Height = 23 mm and ∆p = 479427 Pa

Diffuser return vane passages

c) Height = 29 mm and ∆p = 519683 Pa

Figure 10: Static pressure contour.

EffectsofWallRoughness,ImpellerBladesandDiffuserVanesonthePerformancesofaFirstStageCentrifugalPump

365

Diffuser return vane passages

a) Height

= 16 mm

Diffuser return vane passages

b) Height

= 23 mm

Diffuser return vane passages

c) Height

= 29 mm

Figure 11: Liquid flow velocity vector.

3.3 Impact of the Number of Diffuser

Vanes

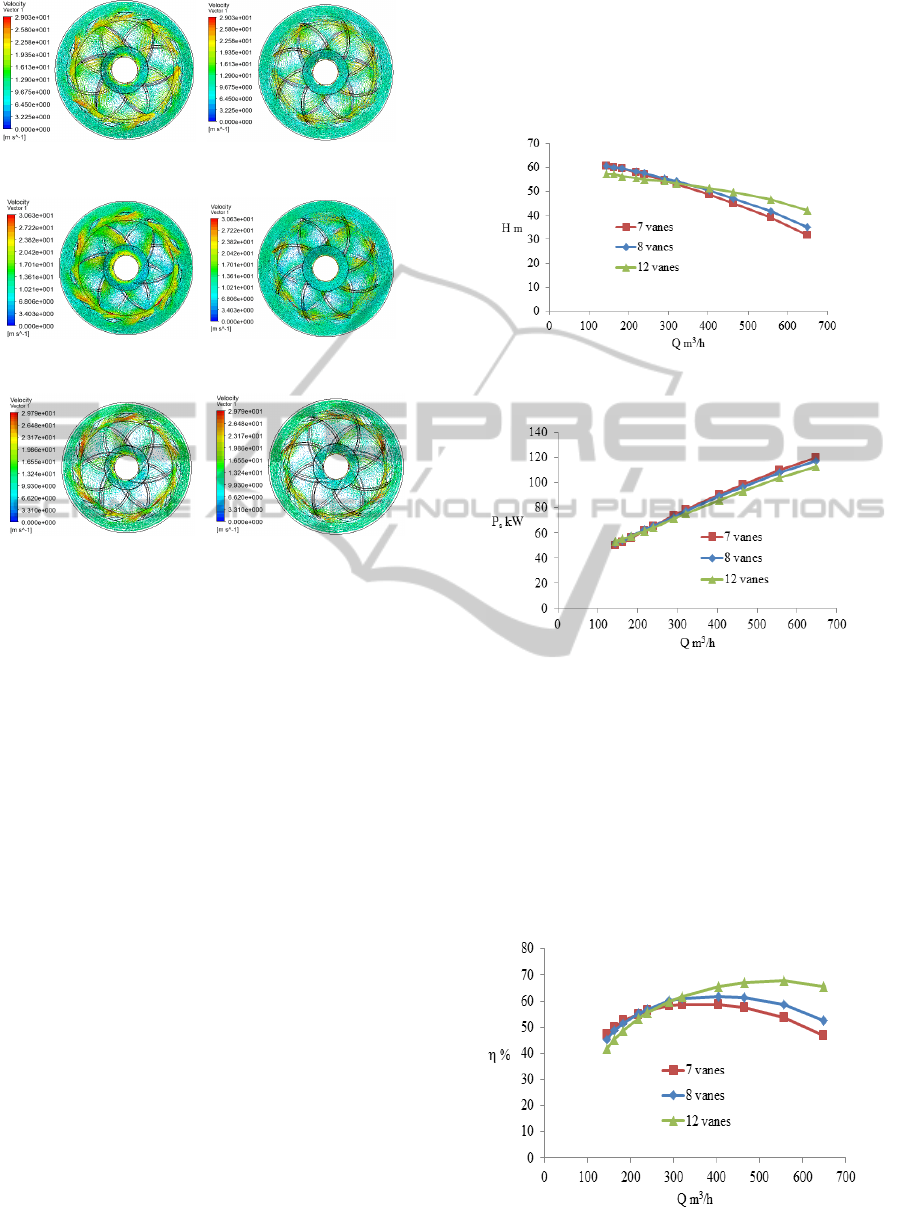

To examine the impact that the number of diffuser

vanes has on the pump stage head, brake horsepower

and efficiency, three diffuser models (with 7, 8 and

12 vanes, and 8 return vanes) were selected

considering an impeller with 5 blades, while other

parameters were kept constant. Fig. 12 shows the

head as a function of the flow rate, where it is

observed that the head obtained with diffusers with 7

and 8 vanes is almost the same for a flow rate

smaller than 320 m

3

/h, whereas the head with the

diffuser with 12 vanes is smallest. For large flow

rates, the head with the diffuser with 12 vanes is the

highest. This is due to a rise in static pressure

through the reduction in flow velocity in a diffuser.

The flow guidance and friction effect depend on the

number of diffuser vanes, and the flow rate. When

the number of diffuser vanes increases, the diffuser

vane passages become narrower. This leads to better

fluid guidance. In other words, flow loss decreases

as the number of diffuser vanes increases. Friction

loss increases with an increasing number of diffuser

vanes. Furthermore, flow guidance, friction loss and

static pressure conversion are affected by the flow

rate. Thus, there is an antagonistic impact between

the diffusion impact and the friction loss in the range

of the flow rate considered. As depicted in Fig. 13,

brake horsepower variation due to the number of

diffuser blades is also small, even if the lowest brake

horsepower is reached with 12 diffuser blades.

Figure 12: Pump stage head versus flow rate.

Figure 13: Brake horsepower versus flow rate.

In addition, Fig. 14 shows that for low and high flow

rates, the efficiency of 12 diffuser vanes is highest

whereas the efficiency for 7 and 8 diffuser vanes is

nearly the same for a flow rate smaller than 320

m

3

/h. This figure also indicates that the efficiency is

lowest for 7 diffuser vanes for a flow rate higher

than 320 m

3

/h. Moreover, the BEP moves towards

large flow rates and rises as the number of diffuser

vanes increases.

Figure 14: Efficiency versus flow rate.

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

366

Furthermore, Figs. 15 and 16 show the

corresponding static pressure contour and liquid

flow velocity vector for Q = 403 m

3

/s, respectively,

illustrating that for these figures, there is a

correlation between increased static pressure

difference and decreased liquid flow velocity at the

diffuser outlet, with an increased diffuser vane

number. The average liquid flow velocity values at

the diffuser outlet of 13.94 m/s, 13.14 m/s and 11

m/s were found for 7, 8 and 12 vanes respectively,

as shown in Fig. 16. Also, Tab. 3 indicates the

pressure difference in the impeller, diffuser and

diffuser return vane passages.

a) 7 vanes b) 8 vanes c) 12 vanes

∆P = 482224 Pa ∆P = 498668 Pa ∆P = 500843 Pa

Figure 15: Static pressure contour.

a) 7 vanes b) 8 vanes c) 12 vanes

Figure 16: Vectors of liquid flow velocity.

Table 3: Distribution of pressure difference.

Pressure difference ∆p Pa

Vane Impeller Diffuser

Diffuser

return vane

passages

∆p

total

7 5 10556 70817 -89149 482224

8 496559 87279 -85170 498668

12 476198 103252 -78607 500843

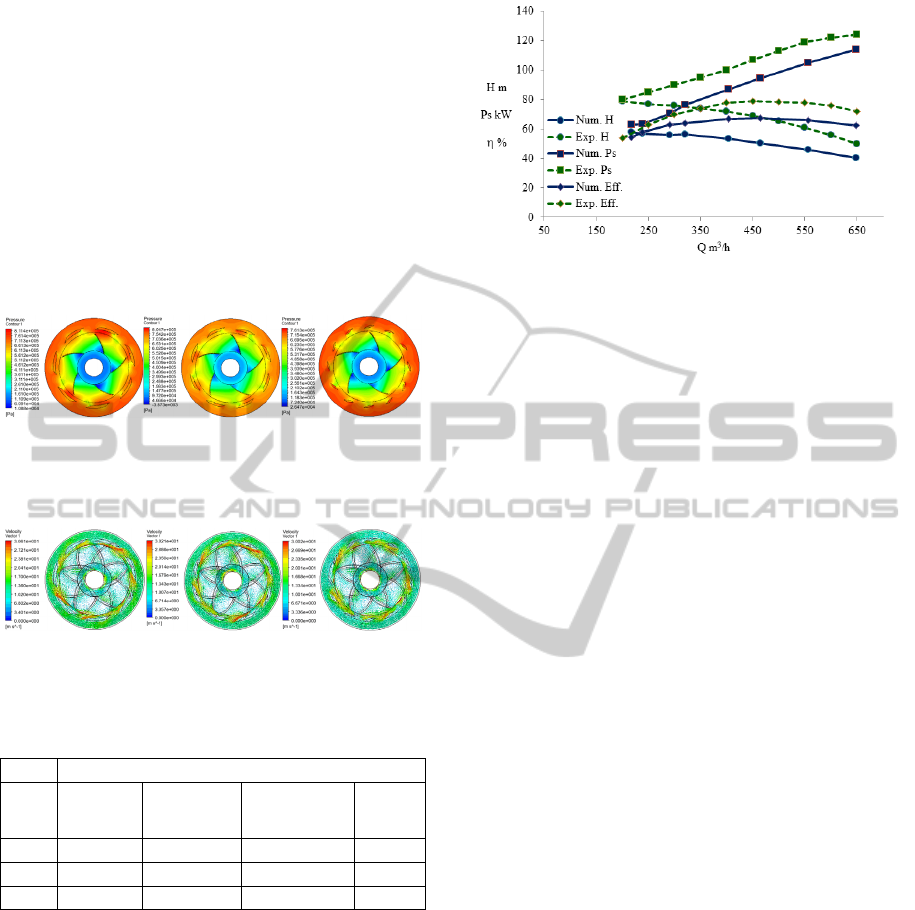

3.4 Model Comparison

To validate the model developed for the first pump

stage, the numerical simulation results were

compared with the experimental results (Technosub

inc.), as shown in Fig. 17, where it is observed that

all the numerical curves for the head, brake

horsepower and efficiency follow the trend of the

experimental curves; however, additional

parameters, which affect the gap between the

numerical results and experimental results are being

more thoroughly investigated in the experimental

and numerical sides to increasingly enhance the

approach developed for the first pump stage.

Figure 17: Comparison between the numerical and

experimental results.

4 CONCLUSIONS

In this work, a liquid flow in the first stage of a

multistage centrifugal pump was numerically

examined. A model of a first pump stage was

developed to analyze the impacts of the wall

roughness height; the height of the impeller blades

and diffuser vanes, and the number of diffuser vanes

on the pump stage performances. The results

achieved reveal, among other things, that higher wall

roughness heights of the impeller and diffuser

negatively affect the pump stage head, brake

horsepower and efficiency; the pump stage head and

brake horsepower increase as the height of the

impeller blades and diffuser vanes increases.

Moreover, the pump stage head and efficiency rise

for large flow rates with increasing numbers of

diffuser vanes, whereas the brake horsepower hardly

varies at all regardless of the number of diffuser

vanes. In all, the numerical curves obtained for the

head, brake horsepower and efficiency well follow

the trend of the experimental results.

NOMENCLATURE

B source term (Nm

-3

)

C torque (Nm)

g acceleration of gravity (ms

-2

)

H head (m)

P power (W)

p pressure (Nm

-2

)

p

turbulence production due to viscous and

buoyancy forces

Q flow rate (m

3

s

-1

)

r radial coordinate (m)

V velocity (ms

-1

)

u flow velocity in x direction (ms

-1

)

EffectsofWallRoughness,ImpellerBladesandDiffuserVanesonthePerformancesofaFirstStageCentrifugalPump

367

v flow velocity in y direction (ms

-1

)

w flow velocity in z direction (ms

-1

)

x x-coordinate (m)

y y-coordinate (m)

z z-coordinate (m)

Greek symbols

difference

turbulence dissipation (m

2

s

-3

),

efficiency

turbulence kinetic energy (kg m

-2

s

-2

)

fluid density (kg m

-3

)

dynamic viscosity (Pa s)

eff

effective viscosity (Pa s)

t

turbulence viscosity (Pa s)

Ω angular velocity (rad s

-1

)

Subscripts

1 inlet

2 outlet

h hydraulic

i inlet

m mechanical

o outlet

s shaft

t total

v volumetric

vel velocity

ACKNOWLEDGEMENTS

The authors are grateful to the Foundation of

University of Quebec in Abitibi-Temiscamingue

(FUQAT) and the company Technosub inc.

REFERENCES

Peng W., 2008. Fundamentals of turbomachinery.

Hoboken, New Jersey, John Wiley and Sons

.

Huang S., Islam M.F., Liu P., 2006. Numerical simulation

of 3 D turbulent flow through an entire stage in a

multistage centrifugal pump.

International Journal of

Computational Fluid Dynamics,

Vol. 20, Issue 5,

Pages 309-314.

Miyano M., Kanemoto T., Kawashima D., Wada A., Hara

T., Sakoda K., 2008. Return Vane Installed in

Multistage Centrifugal Pump.

International Journal of

Fluid Machinery and Systems

Vol. 1, No. 1.

Kawashima D., Kanemoto T., Sakoda K., Wada A., Hara

T., 2008. Matching Diffuser Vane with Return Vane

Installed in Multistage Centrifugal Pump.

International Journal of Fluid Machinery and

Systems

, Vol. 1, No. 1.

Gantar M., Florjancic D., and Sirok B., 2002. Hydraulic

Axial Thrust in Multistage Pumps - Origins and

Solutions.

Journal Fluids Engineering, Vol. 124, Issue

2, 336-341.

Ansys inc., 2011.

ANSYS-CFX (CFX Introduction, CFX

Reference Guide, CFX Tutorials, CFX-Pre User's

Guide, CFX-Solver Manager User's Guide, CFX-

Solver Modeling Guide, CFX-Solver Theory Guide)

,

release 14.0, USA.

Tropea C., Yarin A. L., Foss J. F., 2007.

Handbook of

experimental fluid mechanics

. Springer-Verlag, Berlin,

Heidelberg.

Technosub Inc., www.technosub.net.

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

368