RFID based Data Mining for E-logistics

Yi Wang

1

, Quan Yu

2

and Kesheng Wang

2

1

School of Materials, University of Manchester, Manchster, U.K.

2

Department of Production and Quality Engineering, Norwegian University of Science and Technology,

Trondheim, Norway

Keywords: RFID, Data Mining, Association Rules, E-logistics, System Integration.

Abstract: Radio Frequency Identification (RFID) is a useful ICT technology for E-logistics Enterprises. One of the

standards used for RFID is Electronic Product Code Information Services (EPCIS). However, it is non-

trivial to get effective knowledge from massive data to improve the existed production or logistic system

comparing with convenient data collection. In this paper, we develop an intelligent platform which

combines RFID for data acquisition, Data Mining for knowledge discovery and enterprise applications in

the field of E-logistics. Especially association rule is applied to mine the associations between the

distribution nodes and product quality within a product distribution logistic network on the basis of RFID

datasets. The analysis result is the same as in the problem hypothesis, which concludes that it will be

applicable for such kind of product distribution network analysis.

1 INTRODUCTION

Electronic Logistics (E-logistics) is concerned with

the efficient integration of suppliers, factories,

warehouses and stores, so that products are

distributed to customers in the right quantity and at

the right time. Efficient and reliable supply chain is

important to trade and industry. The ICT enables

significant development of the supply chain. New

ICT can change the business process models and can

give speed to the growth of the e-logistics.

The

integration of ICT have become competitive

necessities in most industries (Patterson et al., 2003).

In recent years, Radio Frequency Identification

(RFID) technology has become a mainstream

application for handling manufactured goods and

materials. As an important driver in today’s

information-based industries and economics, RFID

enables identification from a distance without

requiring close-contact as the bar code technology.

RFID tags support a larger set of unique IDs than

bar codes and can incorporate additional data such

as manufacturer, product type, and even measure

environmental factors such as temperature.

Furthermore, RFID systems can discern many

different tags located in the same general area

without manual assistance.

RFID technology has been applied to many areas

such as supply chain, logistics, libraries and

agriculture (Laniel et al., 2008); (Amador et al.,

2009); (Abad et al., 2009); (Koutsoumanis et al.,

2005); (Emond and Nicometo, 2006). Combining

with Data Mining approaches, research fields cover

such as object tracking (Cabanes et al., 2008),

customer purchasing behaviour analysis (El-Sobky

and AbdelAzeim, 2011), supply chain management

(Ho et al., 2010) and outlier detection (Masciari,

2011).

In this paper, we develop an intelligent platform

which combines RFID for data acquisition, Data

Mining for knowledge discovery and enterprise

applications in the field of E-logistics and supply

chain management. We propose a RFID based

logistic network. The RFID data is acquired

following to the EPCIS standard, which is fabricated

but reasonable. Combining with Data Mining

approaches – in this paper the association rule is

applied, the relevance between the network nodes

and product quality are managed to be deduced by

analysing the product flow and the quality.

The paper is organized as the following: Section

1 introduces the features and applications of e-

logstics and the importance of integrating RFID

technology and Data Mining approaches. Section 2

gives a glimpse of an RFID system briefly. Section 3

introduces the definition and application of Data

371

Wang Y., Yu Q. and Wang K..

RFID based Data Mining for E-logistics.

DOI: 10.5220/0004508303710378

In Proceedings of the 4th International Conference on Data Communication Networking, 10th International Conference on e-Business and 4th

International Conference on Optical Communication Systems (ICE-B-2013), pages 371-378

ISBN: 978-989-8565-72-3

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

Mining. Section 4 proposes an platform of

intelligent integrated RFID system, which consists

of 6 levels, and describes each level respectively.

Section 5 gives a detailed introduction to a typical

Data Mining approach - Association Rules. Section

6 describes a detailed implementation of the

intelligent RFID based integrated system. Section 7

comes to the conclusion of the feasibility of the

intelligent RFID system.

2 RFID IN E-LOGISTIC

2.1 RFID System

Radio-frequency identification (RFID) is one of

numerous technologies grouped under the term of

Automatic Identification (Auto ID), such as bar

code, magnetic inks, optical character recognition,

voice recognition, touch memory, smart cards,

biometrics etc. Auto ID technologies are a new way

of controlling information and material flow,

especially suitable for large production networks

(Elisabeth et al., 2006). RFID is a wireless non-

contact radio system, which transfers data from a tag

attached to an object, for the purposes of

identification and tracking. It is a means of

identifying a person or object using a radio

frequency transmission. The technology can be used

to identify, track, sort or detect a wide variety of

objects (Lewis, 2004). RFID system can be

classified by the working frequency, i.e. Low

Frequency (LF), High Frequency (HF), Ultra High

Frequency (UHF) and Microwave. Different

frequency works for various media, e.g. UHF is not

applicable to metal but HF is metal friendly. Thus,

the working frequency has to be used on the basis of

tracked objects.

Hardware of RFID system includes RFID tag,

RFID reader and RFID antenna. RFID tag is an

electronic device that can store and transmit data to a

reader in a contactless manner using radio waves,

which can be read-only or read-write. Tag memory

can be factory or field programmed, partitionable,

and optionally permanently locked, which enables

the users save the customized information in the tag

and read it everywhere, or kill the tag when it will

not be used anymore. Bytes left unlocked can be

rewritten over more than 100,000 times, which

achieves a long useful life. Moreover, the tags can

be classified by power methods i.e. passive tags

without power, semi-passive tags with battery and

active tags with battery, processor and i/o ports. The

power supply increases the cost of the tag but

enhance the readable performance. Furthermore, a

middleware is required as a platform for managing

acquired RFID data and routing it between tag

readers and other enterprise systems. Recently,

RFID become more and more interesting technology

in many fields such as agriculture, manufacturing

and supply chain management.

2.2 The Role of RFID in E-Logistics

Applying RFID technology can lead to large gains in

the overall supply chain effectiveness (Agrawal et

al., 2009); (Dutta et al., 2007) conclude that RFID

integration through E-business architectures

provides more benefits than technology integration

in current business processes. The roles of RFID in

E-logistics include warehouse management,

counterfeiting and efficient response to changing

demand. (Kärkkäinen, 2003) E-logistics

measurement such as store compliance, trend rates,

and recovery rates and return inventory turnover can

be collected with RFID technology (Payaro, 2004).

Since 2006, Airbus has applied RFID to save

millions of euros for cutting process cycle times,

eliminating paperwork, and reducing inventory

(Wasserman, 2007). Zaharudin et al. (2006) indicate

that RFID can reduce the bullwhip effect through

information sharing between all supply chains.

Saygin et al. (2007) suggests that RFID can reduce

the bullwhip effect by a better visibility obtained

through real-time information of product’s locations.

3 DATA MINING (DM)

3.1 Definition

DM is an integration of analysis and modeling

technologies developed over the last twenty years.

DM is often defined as the process of extracting

valid, previous unknown, comprehensible

information from large data bases in order to

improve and optimize business decision-making

process. (Wang, 2007)

Many traditional reporting and query tools and

statistical analysis systems use the term "Data

Mining" in their product descriptions. It leads to the

question, “What is a DM and what isn't?” The

ultimate objective of DM is knowledge discovery

and DM methodology is a technique to extracts

predictive information and knowledge from

databases. With such a broad definition, however, an

On-line Analytical Processing (OLAP) product or a

statistical package could qualify as a DM tool, so

ICE-B2013-InternationalConferenceone-Business

372

some have narrowed the definition. In my option, a

DM method should unearth knowledge

automatically. By this definition DM is data-driven,

whereas by contrast, traditional statistical, OLAP,

reporting and query tools are user-driven. It is best

to define them as Business Intelligence (BI) tools

rather than DM tools.

Using the narrowed definition of DM mentioned

above, we would like to follow that DM techniques

are at the core of DM process, and can have different

functions (tasks) depending on the intended results

of the process. In general, DM functions can be

divided into two broad categories: discovery DM

and predictive DM.

(1). Discovery Data Mining

Discovery Data Mining is applied to a range of

techniques, which find patterns inside a dataset

without any prior knowledge of what patterns exist.

The following examples of functions of discovery

Data Mining: (1). Clustering; (2). Link analysis; and

(3). Frequency analysis; etc.

(2). Predictive Data Mining

Predictive Data Mining is applied to a range of

techniques that find relationships between a specific

variable (called the target variable) and the other

variables in your data. The following are examples

of functions of predictive Data Mining: (1).

Classification; (2). Value predication; and (3).

Association rules; etc.

3.2 Techniques

This paper will focus on the Associations mining

techniques. However, a variety of techniques are

available to enable the above functions. Each

technique contains numerous algorithms, for

example, there are more than 100 different models

of Artificial Neural Networks. With systems

increasing complexity, it is clear that the DM

techniques should be used concurrently rather than

separately. (Wang and Wang, 2012) A hybrid DM

system in which several techniques with different

functions can be integrated to achieve a desired

result are often more effective and efficient than a

single one. For example, in order to identify the

attributes that are significant in a manufacturing

process, clustering can be used first to segment the

process database into a given predefined number of

categorical classes and then classification can be

used to determine to which group a new data

belongs.

3.3 Procedures

The generic DM procedure from IBM viewpoint

(Baragoi et al., 2001) involves seven steps as the

following:

1. Defining the business issue in a precise

statement,

2. Defining the data model and data requirements,

3. Sourcing data from all available repositories and

preparing the data

4. Evaluating the data quality,

5. Choosing the mining function and techniques,

6. Interpreting the results and detecting new

information, and

7. Deploying the results and the new knowledge

into your business.

To understand how DM can overcome a variety

of problems in manufacturing, we consider some

activities in a manufacturing company.

4 INTEGRATED RFID SYSTEMS

A RFID system is used to trace and track objects

with RFID tags. However, it is far from sufficient to

only acquire the RFID data. It will be more valuable

to combine an RFID system with Data Mining

approaches and construct an intelligent integrated

RFID system, with the ability to convert data into

knowledge and assist managers to make decisions.

The E-business system is designed on the basis of

RFID system and introduced in the following sub-

sections.

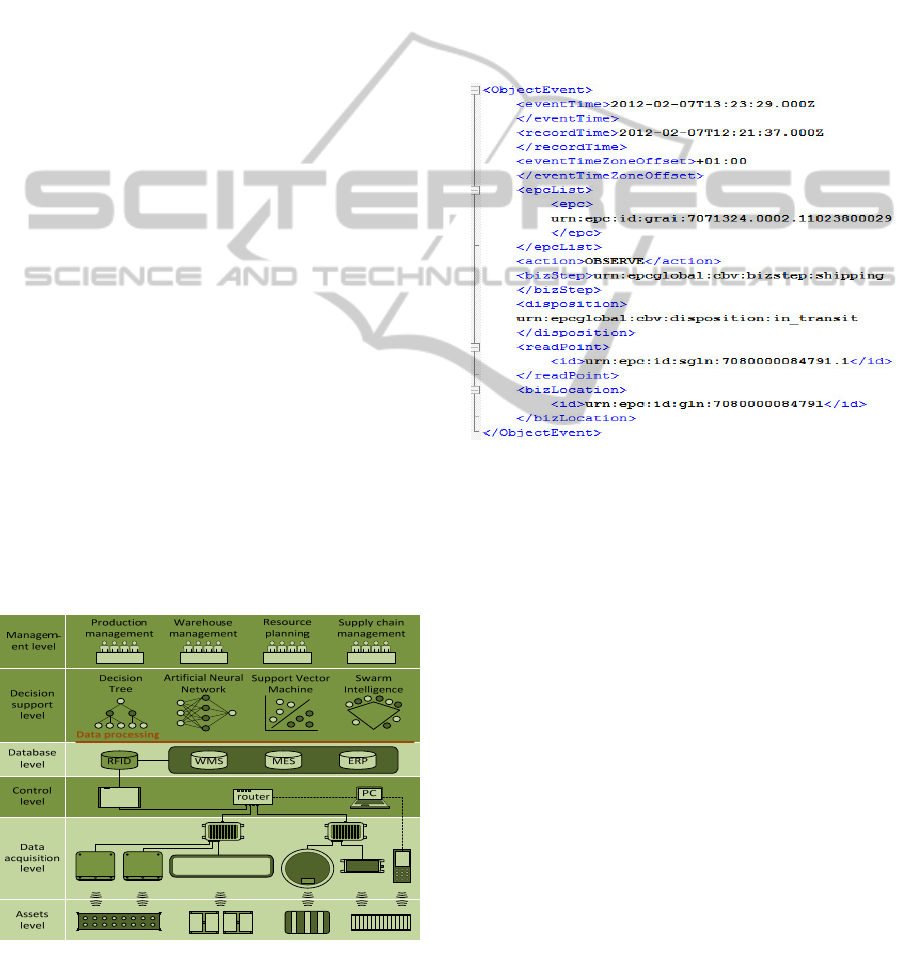

4.1 System Models

The integrated e-business system developed in

Knowledge Discovery Laboratory at NTNU is

architecturally based on RFID system, decision

support system and enterprise applications as shown

in Figure 1. The intelligent integrated system

consists of 6 levels:

1. Assets level,

2. Data acquisition level,

3. Control level,

4. Database level,

5. Decision support level, and

6. Business Management Level

4.1.1 Assets Level

On the basis of production and logistic system, the

assets level of the intelligent integrated RFID system

contains products (from materials to finished goods),

RFIDbasedDataMiningforE-logistics

373

conveyor belts, machines, pallets, packages and

shelves etc.

4.1.2 Data Acquisition Level

The hardware of a RFID system consists of RFID

tags, antennas, readers and middleware.

4.1.3 Control Level

A router or switch is used to build up the connection

between the devices. A PC is used to configure the

equipment at the data acquisition level. During the

deployment of the RFID system, the RFID tags are

attached to the objects, which are carried by the

products or pallets and pass through the conveyor

belt, then are packed and stored on the shelves.

RFID antennas with various properties are installed

respectively at different positions to construct a

network of read points. When the object with a

RFID tag passes through a read point, it will be

detected by the antenna automatically.

4.1.4 Database Model

Thus, as the system runs, the middleware organizes

the RFID tag information and forwards it to RFID

database. Moreover, the integration of RFID

database with other advanced database (e.g. WMS

database, MES database and ERP database) is also

performed by the middleware.

4.1.5 Decision Support Level

It is vital in the integrated e-business system.

The function of decision support level has beed

described in section 3 in detail.

Figure 1: Structure of the intelligent integrated RFID

systems.

4.2 EPCIS Standard

Electronic Product Code (EPC) provides a unique,

serialized identifier for any kind of object, which is

defined in the EPCglobal Tag Data Standard

(EPCglobal Inc

TM

, 2007). Electronic Product Code

Information Services (EPCIS) is an EPCglobal

standard for sharing EPC related information

between trading partners. EPCIS provides important

new capabilities to improve efficiency, security, and

visibility in the global supply chain, and

complements lower level EPCglobal tag, reader, and

middleware standards.

Figure 2: A section of an XML dataset following the

EPCIS.

EPCIS supports a detailed representation of the

location and state of material as it moves between

organizational boundaries. It provides important

business information including the time, location,

disposition and business step of each event during an

item life, which means 4W – What (product), Where

(location), When (time) and Why (business step and

status). The information is stored in an XML

database.

By gathering datasets during an item in a supply

chain and sorting on the basis of EPC and time

information, the product flow is able to be extracted

for data mining.

5 ASSOCIATION RULES

Association rule is one of the data mining

approaches for analysing associations among the

items (Han et al., 2012). According to Mild and

Reutterer (2003), Boztuğ and Silberhorn (2006) and

ICE-B2013-InternationalConferenceone-Business

374

Boztuğ & Reutterer (2008), there are two types of

association approach; exploratory and explanatory.

The exploratory approach aims to uncover and

summarise the interrelationships within categories or

between items often purchased together (Boztuğ and

Reutterer, 2008). Under exploratory approaches,

Julander (1992) and Dickinson et al. (1992) used

pairwise association measures to identify

relationships between item pairs while Agrawal and

Srikant (1994), Buechter and Wirth (1998) and

Hildermand et al. (1999) discovered association

rules between subsets of categories purchased

together using data mining technique.

Exploratory approach presents previously

undiscovered category relationships in a more

aggregate manner, whereas explanatory approach is

more targeted, with known variables to be analysed

(Mild and Reutterer, 2003). Explanatory approach

aims to study the effect of marketing mix and

demographic variables on choice across multiple

categories (Mild and Reutterer, 2003); (Hoch et al.,

1995).

Let

12

,,,

m

III I

be a set of items. Let D be

a set of transactions where each transaction T is a set

of items such that

TI

. An association rule is an

implication of the form

A

B

, where

A

I

,

BI

and

AB

. The rule is evaluated with

support value and confidence value. Two measures

are usually applied. The support s is the percentage

of transactions in D that contain

A

B

, which is

taken to be the probability

P

AB

.

⟹

∪

∪

The confidence c is the percentage of transactions in

D containing A that also contains B, which is taken

to be conditional probability

P

BA

, the

relationship between c and s is shown below

s

upport A B

confindence A B P B A

support A

In general, association rule mining consists of two

steps:

Find all frequent itemsets, which will occur at

least as frequently as a predetermined minimum

support

Generate strong association rules from the

frequent itemsets, which must satisfy minimum

support and minimum confidence.

6 IMPLEMENTATION

By analyzing the product flow, potential factors

could be referred, which are related to the

qualification; meanwhile, possible solutions are also

expected to improve the existed logistic network.

6.1 Problem Description

In this paper, a flowchart-like structure is supposed

to simulate a product distribution network. Products

are distributed to retailers through the designed

network, such as milk is delivered to supermarkets

from the factory. The supposed distribution network

includes 4 layers and 12 nodes totally as shown

below.

Figure 3: The supposed distribution logistic network.

The 4 layers are respectively the Producer layer, the

Distributor level 1, the Distributer level 2 and the

Retailer layer. Each layer consists of nodes

represented with Biz, which are corresponding to the

“business location” in EPCIS. The numbers

represent the amount of distributed products in each

distribution; moreover, the numbers in parentheses

mean the amount of unqualified products included in

corresponding branch. In the model design, most

unqualified products are delivered through the path

which consists of the nodes of Biz1, Biz3, Biz5 and

Biz10. The object of the hypothesis is to find the

most related nodes in the network if given the

product qualification and RFID data of products.

Two reading-points are set at each business

location in the middle layers, where one is for the

products in while another is for the product out. The

time duration is also designed to be independent for

each branch in the supposed network, where T

_in

means the arrival time of product to the

corresponding business location while T

_out

means

the departure time of the products. In the terminal

Retailer layer, only arrival time is considered

because we suppose the products are inspected to be

RFIDbasedDataMiningforE-logistics

375

bad after the deliveries to the retailers.

Regarding this problem, known parameters

consist of the quality of the products when they are

delivered to the retailers and RFID datasets recorded

at each read point. The RFID datasets are fabricated

for the products according to EPCIS standard on the

basis of the supposed network. For simplicity, only

four keywords of the EPCIS tag are kept, including

EventTime, EpcList, ReadPoint and BizLocation as

shown in table 1.

Figure 4: A time-based logistic network as an

experimental case.

Supposing that all the RFID datasets are collected

from the read points and put together, the delivery

path of products are able to be derived according to

the parameters of EpcList .

Table 1: The fabricated RFID datasets at one of the

readpoints.

EventTime EpcList ReadPoint BizLocation

19.03.2012

09:04

7071371.0001.00000001 7080000000419.1 7080000000419

19.03.2012

09:04

7071371.0001.00000006 7080000000419.1 7080000000419

19.03.2012

09:03

7071371.0001.00000007 7080000000419.1 7080000000419

19.03.2012

09:04

7071371.0001.00000009 7080000000419.1 7080000000419

19.03.2012

09:04

7071371.0001.00000010 7080000000419.1 7080000000419

19.03.2012

09:01

7071371.0001.00000011 7080000000419.1 7080000000419

19.03.2012

09:04

7071371.0001.00000014 7080000000419.1 7080000000419

19.03.2012

09:01

7071371.0001.00000019 7080000000419.1 7080000000419

19.03.2012

09:01

7071371.0001.00000020 7080000000419.1 7080000000419

EventTime, constructing a vector with the form of

[EPC, (l

1

, t

1

), (l

2

, t

2

),…, (l

k

, t

k

)], where l

k

means the

location k and t

k

means the time spent on k. The

datasets are organized as shown in Table 2.

Table 2: RFID Datasets are organized according to EPCIS

keywords.

EpcList 7071371.0001.00000001 7071371.0001.00000002 …

EventTime

19.03.2012 08:02 19.03.2012 08:30

…

BizLocation

7080000000418 7080000000418

EventTime

19.03.2012 09:04 19.03.2012 09:30

BizLocation

7080000000419 7080000000420

EventTime

19.03.2012 13:01 19.03.2012 14:34

BizLocation

7080000000419 7080000000420

EventTime

19.03.2012 14:32 19.03.2012 16:03

BizLocation

7080000000422 7080000000423

EventTime

19.03.2012 17:01 19.03.2012 18:00

BizLocation

7080000000422 7080000000423

EventTime

19.03.2012 18:03 19.03.2012 19:30

BizLocation

7080000000426 7080000000429

6.2 Data Preparation and Analysis

As the first step of flow analysis, only the location is

considered while the time domain is ignored in this

paper. We do the association rule analysis in IBM

SPSS Modeler® to find the relevance between the

product quality and the business locations, and also

the most relevant path in the network. The datasets

are organized according to the requirement for the

data import of the software, as shown in Table 3.

Table 3: Data preparation for association rule analysis.

EPC biz1 biz2 biz3 biz4 biz5 biz6 biz7 biz8 biz9 biz10 biz11 biz12 Q

Code 1 T T F F T F F F T F F F F

Code 2 T F T F F T F F F F F T F

Code 3 T F T F T F F F F T F F T

Where T (True) means Event occurs and F (False)

means not.

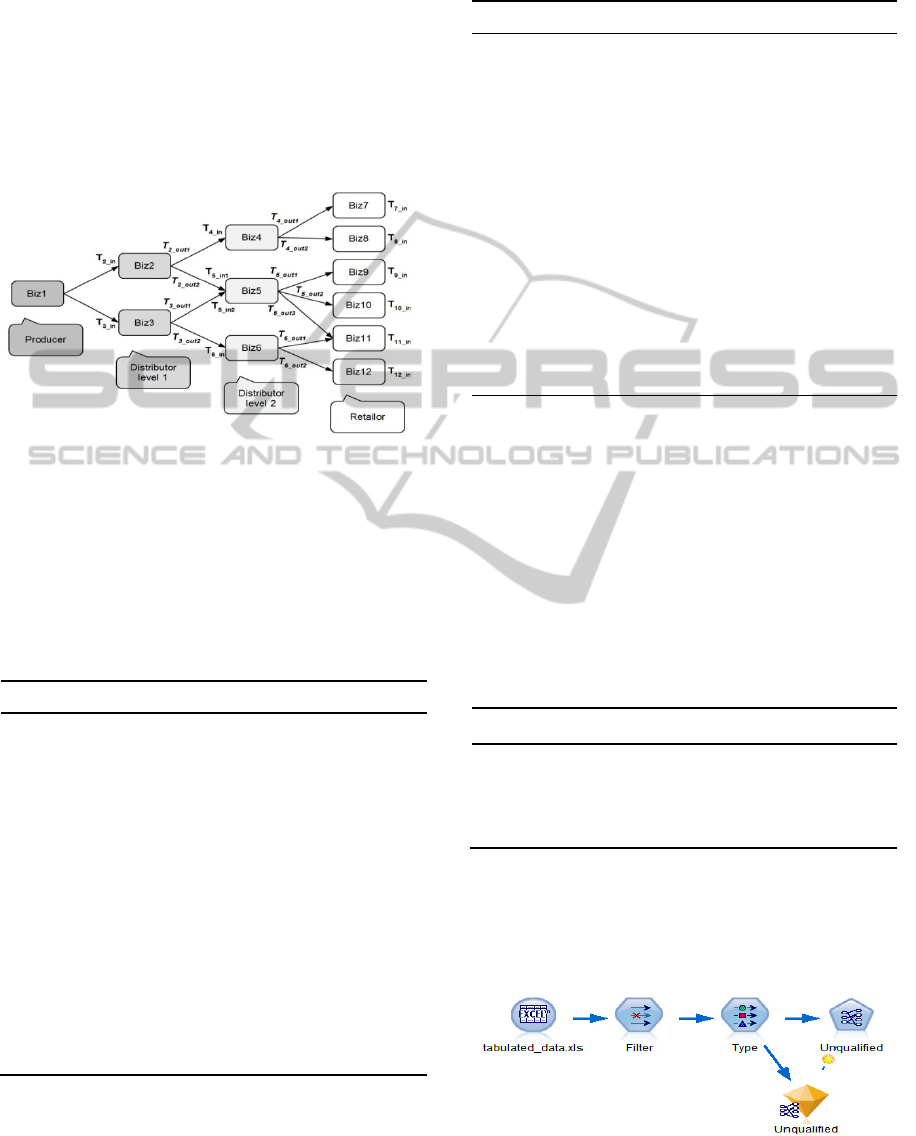

The association rule analysis is performed using

the Apriori algorithm in IBM SPSS Modeler®. The

model is setup as Figure 5.

Figure 5: Model setup in IBM SPSS Modeler®.

ICE-B2013-InternationalConferenceone-Business

376

After the calculation, the relevance between the

nodes and the quality is represented by the

confidence and rule support, which is listed in Table

4. By sorting the rule support value and confidence

value, the importance of the nodes are able to be

deduced.

First, we filter the result using a threshold of

Rule support value. Supposing that it is set to be 9,

only the first 4 rules are included. Then the

confidence value is considered, a high value means a

strong relevance. Thus, Rule 3 and Rule 4 are the

strongest rules with the highest confidence value.

Meanwhile, regarding the model design, products of

biz3 are all delivered from biz1, so rule 3 is the same

as Rule 4. Then the nodes most relevant to the

quality defect are founded which includes biz5, biz3

and biz1. On the other hand, the longest rule is the

Rule 12 which includes 4 nodes, the same as in the

design model. The association rule data mining

successfully acquired most relevant nodes and the

most relevant path are both deduced the same as the

design.

Table 4: Association rules generated.

Rule

ID

Antecedent Confidence %

Rule

Support %

1 biz5 21.78 9.80

2 biz5, biz1 21.78 9.80

3 biz5, biz3 30.83 9.25

4

biz5, biz3 and

biz1

30.83 9.25

5 biz10 24.00 4.80

6 biz10 and biz5 24.00 4.80

7 biz10 and biz3 24.00 4.80

8 biz10 and biz1 24.00 4.80

9

biz10, biz5 and

biz3

24.00 4.80

10

biz10, biz5 and

biz1

24.00 4.80

11

biz10, biz3 and

biz1

24.00 4.80

12

biz10, biz5, biz3

and biz1

24.00 4.80

7 CONCLUSIONS

In this paper, we develop an intelligent integrated

platform for e-business, which consists of 6 levels:

1. Assets level, 2. Data acquisition level, 3. Control

level, 4. Database level, 5. Decision support level,

and 6. Business Management Level. The main focus

of this paper is on (1) RFID system that is used for

data acquisition automatically and (2) Data Mining

(knowledge discovery) model that is applied for

optimizing decision support processes.

An E-logistic network for product distribution is

proposed. The RFID data is acquired following to

the EPCIS standard, which is fabricated but

reasonable. The RFID datasets are generated

following EPCIS standard. The product flow is

acquired via analyzing the whole datasets. Given the

quality of the products, association rule is applied to

mining the associations between the distribution

nodes and the product quality. After the support and

confidence is calculated, the most relevant nodes

and path have been deduced, as the description in

the problem design. It concludes that association

rule mining is applicable to find potential quality

related factors within existed logistic network

combining with RFID technology. The further

research will be done for flow analysis for a real

company.

REFERENCES

Agrawal, R.N. Sengupta, K. Shanker, 2009. Impact of

information sharing and lead time on bullwhip effect

and on-hand inventory, European Journal of

Operational Research, 192, pp. 576–593

Abad, E., Palacio, F., Nuin, M., Zárate, A. González de,

Juarros, A., Gómez, J.M and Marco, S., 2009. RFID

smart tag for traceability and cold chain monitoring of

foods: demonstration in an intercontinental fresh fish

logistic chain, Journal of Food Engineering, 93 (4) ,

pp. 394–399.

Amador, C., Emond, J.P. and Nunes M.C.N., 2009.

Application of RFID technologies in the temperature

mapping of the pineapple supply chain, Sensing and

Instrumentation for Food Quality and Safety, 2009 (3),

pp. 26–33.

Baragoin, C., Andersen, C.M., Bent, G., Lee, J. and

Schommer, C., 2001. Mining your own business in

telecoms using DBM intelligent miner for data, IBM

Redbooks, Corinne Baragoin and International

Business Machine Corporation.

Boztuğ, Y. and Silberhorn, N., 2006.

Modellierungsansätze in der Warenkorbanalyse im

Überblick, Journal für Betriebswirtschaft, Vol. 56, No.

2, pp.105-128.

Boztuğ, Y. and Reutterer, T., 2008. A Combined

Approach for Segment-Specific Analysis of Market

Basket Data. European Journal of Operational

Research, Vol. 187, pp. 294-312.

Buechter, O. and Wirth, R., 1998. Discovery of

association rules over ordinal data: A new and faster

RFIDbasedDataMiningforE-logistics

377

algorithm and its application to basket analysis.

Research and Development in Knowledge Discovery

and Data Mining, pp. 36-47.

Cabanes, G., Bennani, Y., Chartagnat, C. and Fresneau,

D., 2008. Topographic connectionist unsupervised

learning for RFID behavior data mining, Secondary

Topographic connectionist unsupervised learning for

RFID behavior data mining, pp. 63-72.

Dutta, A., Lee, H., Whang, S., 2007. RFID and operations

management: technology, value, and incentives,

Production and Operations Management, 16 (5), pp.

646–655.

Dickinson, R., Harris, F. and Sircar, S., 1992.

Merchandise compatibility: An exploratory study of

its measurement and effect on department store

performance. International Review of Retail,

Distribution and Consumer Research, 2 (4) (1992), pp.

351–379

Emond, J. P. and Nicometo, M., 2006. Shelf-life

prediction and FEFO inventory management with

RFID. In: Cool Chain Association Workshop.

Temperature Measurements-When, Where and How?

Knivsta, Sweden.

Elisabeth, I., Zsolt, K., Péter, E. and László, M., 2006. The

RFID Technology and Its Current Applications.

Proceeding of The Modern Information Technology in

the Innovation Process of the Industrial Enterprise-

MITIP, pp.29-36.

El-Sobky, H. and AbdelAzeim, M., 2011. A novel model

for capturing and analyzing customers' preferences for

ceramic tiles, Secondary A novel model for capturing

and analyzing customers' preferences for ceramic

tiles, pp. 460-465.

EPCglobal Inc

TM

, 2007. EPC Information Services

(EPCIS) Version 1.0.1 Specification.

Han, J., Kamber, M. and Pei, J., 2012. Data mining:

concepts and techniques, Amsterdam: Elsevier.

Hilderman, R., Hamilton, H. and B. Barber, 1999.

Ranking the interestingness of summaries from data

mining systems. In Proc. of the 12th International

Florida Artificial Intelligence Research Symposium

(FLAIRS'99), pp.100-106, Orlando, FL, May 1999.

Ho, G. T. S., Choy, K. L. and Poon, T. C., 2010. Providing

decision support functionality in warehouse

management using the RFID-based fuzzy association

rule mining approach, Secondary Providing decision

support functionality in warehouse management using

the RFID-based fuzzy association rule mining

approach, pp. 1-7.

Hoch, S. J. and Kim, B. D., Montgomery, A. L. and Rossi,

P. E. 1995. Determinants of Store-Level Price

Elasticity. Journal of Marketing Research, Vol. 32,

No. 1 (Feb., 1995), pp. 17-29.

Julander, C., 1992. Basket Analysis: A New Way of

Analysing Scanner Data. International Journal of

Retail & Distribution Management 20 (7), pp. 10-18.

Koutsoumanis, K., Taoukis, P. S. and Nychas, G. J. E.,

2005. Development of a safety monitoring and

assurance system for chilled food products,

International Journal of Food microbiology, 100

(1–3), pp. 253–260.

Kärkkäinen, M., 2003. Increasing efficiency in the supply

chain for short shelf life goods using RFID tagging

International Journal of Retail and Distribution

Management, 31 (10) pp. 526–536.

Laniel, M., Emond, J. P., Altunbas, A. E., 2008. RFID

behavior study in enclosed trailer/container for real

time temperature tracking. In: Food Processing

Automation Conference. Providence, Rhode Island,

USA.

Lewis, S., 2004. A Basic Introduction to RFID technology

and Its Use in the Supply Chain. Laran RFID, White

Paper.

Masciari, E., 2011. Trajectory Outlier Detection Using an

Analytical Approach, Secondary Trajectory Outlier

Detection Using an Analytical Approach, pp. 377-384.

Mild, A., and Reutterer, T., 2003. An improved

collaborative filtering approach for predicting cross-

category purchase based on binary market basket data.

Journal of Retailing and Consumer Services, 10, pp.

123–133.

Patterson K. A, Grimm, C. M. and Corsi T. M. (2003).

Adopting new technologies for supply chain

management Transportation Research Part E:

Logistics and Transportation Review, 39 (2), pp. 95–

121

Payaro, A., 2004. The role of ict in reverse logistics: A

hypothesis of rfid implementation to manage the

recovery process. In Proceedings of the 2004

eChallenges conference, Vienna, Austria, 27–29th

October.

Saygin, C., Sarangapani, J., Grasman, S. E., 2007. A

Systems Approach to Viable RFID Implementation in

the Supply Chain. Springer Series in Advanced

Manufacturing.

Wang, K., 2007. Applying data mining to manufacturing:

the nature and implications, Journal of Intelligent

Manufacturing, Vol. 18, No. 4, pp.487-495.

Wang, K, and Wang, Y., 2012. Data Mining for Zero-

Defect Manufacturing, Tapir Academic Press, 2012.

Wasserman, E., 2007. Airbus Grand Plans for RFID.

RFID Journal, (<http://www.rfidjournal.com/

article/articleview/3661/1/80/>. Last viewed

2013,01,25)

Zaharudin, A. A., Wong, C. Y., Agarwal, V., McFarlane,

D., Koh, R., Kang, Y. Y., 2006. The intelligent

product driven supply chain, Tech. Rep. 05, AUTO-ID

LABS.

ICE-B2013-InternationalConferenceone-Business

378