From e-Supply Chain Capability Generation to Information

Technology Value Co-creation

A Perspective of e-Business Process

Jing Zhao and Yi Jiang

Center for International Cooperation in E-business, School of Economics and Management,

China University of Geosciences, Wuhan, China

Keywords: e-Business Process, e-Supply Chain Capabilities, Inter-firm IT Resources and e-Supply Chain Value.

Abstract: The firms have engaged in initiatives that link e-supply chain processes (e.g., e-procurement) across

enterprises to create Information Technology (IT) value. However, it is not clear how IT is contributing to

value creation across-organization process. The objective of this paper is to investigate the process from e-

supply chain capability generation to IT value creation through e-business process across-organization. A

model of e-supply chain value is developed to investigate what and how e-supply chain capabilities are

realized by usage of inter-firm IT resources integration and how business value of IT is co-created in multi-

firm environments. The paper tests the model using Structural Equation Modeling (SEM) with data

collected from 196 manufacturers in China. Our results provide theoretical support for a dynamic process

that distinctive e-supply chain capabilities embedded in e-business process lead to process performance first

and then financial performance and network performance. We find that e-supply chain capabilities (ESCC)

realize e-supply chain value for all partners (e.g. supplier and customer) via upstream and downstream e-

business process.

1 INTRODUCTION

Over the last decade, e-business technologies,

specifically the Web, have revolutionized supply

chain design, management, and control. IT

infrastructure, process integration and partner

alignment can be blended with inter-organizational

processes to develop higher-order capabilities for

demand sensing, operations and workflow

coordination, and global optimization of resources

(Barua et al., 2004); (Devaraj et al., 2007); (Rai et

al., 2006); (Wu et al., 2006). The firms have engaged

in initiatives that link e-supply chain processes (e.g.,

e-procurement) across enterprises to create IT value

(Boone and Ganeshan, 2007); (Dong et al., 2009).

Consider the example of Haier Group (a world's

fourth largest white goods manufacturer company

and one of the world’s top 500 companies in China) ,

which has automated and streamlined to seek its best

suppliers in a globally competitive market with e-

procurement platform, and processed customized

orders with B2C platform. The effect of e-supply

chain on Haier can be seen from their cycle times

from sales order to procurement order being reduced,

and from more than seven days in 2000 to less than

one hour in 2002 (Li and Chang, 2004).

Despite the widespread adoption of e-business, it

is not clear how IT is contributing to value creation

in supply chain. There are a number of factors that

we accept as important and necessary conditions in

the chain of IT value creation (Kohli and Grover,

2008). From a resource-based perspective, prior

literature has identified that e-supply chain

capabilities can serve as a catalyst in transforming

IT-related resources into higher value for a firm

(Devaraj et al., 2007); (Rai et al., 2006). The thesis

has expanded to examining complementary

resources, capabilities and other mediating factors in

the chain of IT value creation. However, it is unclear

how IT value emanates from digital capabilities in

across-organization process. It raises important new

issues of co-create value from IT in across-

organization process that cannot easily be addressed

by current IT value research.

This paper investigates the process from e-supply

chain capability generation to IT value creation

through upstream and downstream e-business

process. In this paper, the IT value co-creation in e-

153

Zhao J. and Jiang Y..

From e-Supply Chain Capability Generation to Information Technology Value Co-creation - A Perspective of e-Business Process.

DOI: 10.5220/0004531601530159

In Proceedings of the 4th International Conference on Data Communication Networking, 10th International Conference on e-Business and 4th

International Conference on Optical Communication Systems (ICE-B-2013), pages 153-159

ISBN: 978-989-8565-72-3

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

supply chain is viewed as that new e-supply chain

capabilities (ESCC) drive value co-creation via e-

business processes linked with different partners. We

regard e-supply chain value as business value of IT,

which consisted of process performance, financial

performance and network performance. The model

of e-supply chain value is proposed and tested using

SEM with data collected from 196 manufacturing

firms in China. Our results provide theoretical

support for a dynamic process that distinctive e-

supply chain capabilities embedded in e-business

process lead to process performance first and then

financial performance and network performance. We

find that e-supply chain capabilities (ESCC) realize

e-supply chain value for all partners (e.g. supplier

and customer) via upstream and downstream e-

business process.

2 LITERATURE REVIEW

Traditionally, IT impacts in the context of supply

chain management (SCM) have been investigated

with a focus primarily on specific technologies and

innovations linked with partners, such as e-business

(Boone and Ganeshan, 2007), electronic data

interchange (EDI) (Chatfield and Yetton, 2000), and

other inter-organizational information systems(IOS)

(Iskandar et al., 2001). Recent studies using

Resource-based view of the firm (RBV) as a

theoretical base have focused on the relationships

between resources, capabilities and business value

(Kohli and Grover, 2008). These researches can be

divided in two streams.

The first stream of research suggests that a firm’s

overall e-supply chain effectiveness is determined by

its investment in e-business for creating unique

Internet-enabled capabilities (Barua et al., 2004);

(Dong et al., 2009). For example, Barua et al. (2004)

study firms’ abilities to deploy three resources - IT,

processes, and readiness of customers and suppliers -

to create business value. Their empirical results

show that online informational capabilities have a

positive impact on operational and financial

performance.

The second stream of literature suggests that

firms derive e-business benefits through intermediate

business processes (e.g., e-procurement, CRM) (Ray

et al., 2005). Ray et al. (2005) argue that adopting

the effectiveness of business process as a dependent

variable is a more appropriate way to test resource-

based logic than adopting overall firm performance

as a dependent variable. For these reasons, it is

important to focus on process performance as a

feasible path to e-business value. Also, this

perspective is used for analyzing e-supply chain

integration, e.g., Rai (2006) and Barratt and Oke

(2007).

However, the literature is scarce with studies of

the complex process regarding co-creating business

value of IT in e-supply chains. Prior works lack

research for these intermediate factors forming the

linkage and impacting business value of IT in supply

chain.

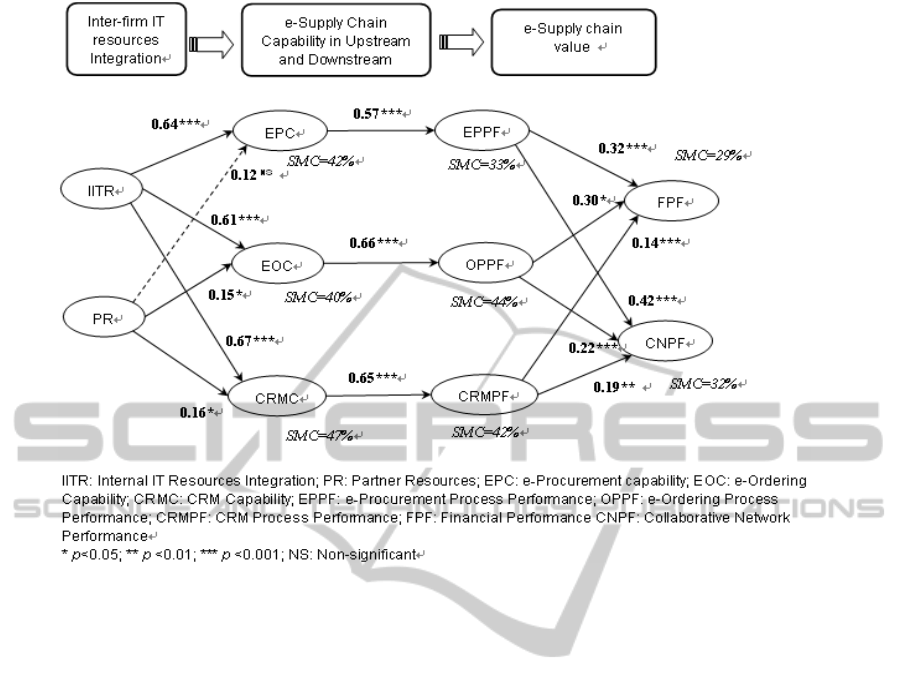

3 RESEARCH MODEL

AND HYPOTHESE

In this paper, we use RBV together with e-business

process view to explain how focal firm and partners’

IT resources integrated in across-organization

process applications to create e-supply chain

capability and further gain co-creation value. The

research model of e-supply chain value will be

developed to investigate the process of e-supply

chain capabilities generation and e-supply chain

value creation. We characterize this model with three

dimensions and six constructs. The definitions of

constructs in the model are summarized in Table 1.

These dimensions include Inter-firm IT Resources

Integration, e-Supply Chain Capability and e-Supply

Chain value.

In order to study in depth the process from e-

supply chain capability generation to value creation

through e-business process, we divide the process

into three stages: (1) Generation of e-supply chain

capability; (2) Creating e-supply chain process

performance; (3) Generation of e-supply chain value.

A series of hypotheses are developed to test the

relationships between constructs.

3.1 Creating e-Supply Chain

Capability

In this stage, the generation of e-supply chain

capability (ESCC) is related to usage of inter-firm IT

resources integration via e-business process.

Melville et al. (2004) ague the IT and non-IT

resources and the business processes of

electronically connected trading partners shape the

supply chain ability to generate operational

efficiencies impacts via IT. In this paper, Inter-firm

IT resources integration includes Internal IT

resources integration for focal firm and Partner

Resources for supply chain partners. Concerning

Internal IT resources integration, prior SCM studies

ICE-B2013-InternationalConferenceone-Business

154

Table 1: Definitions and constructs in the model.

Construct Definitions References

Internal IT Resources

Integration ( IITR)

The extent to which a firm integrates its Internal -organizational IT

resources (including information systems, employees and managers

knowledge) to construct e-business processes in e-supply chains for

online information sharing and transaction execution across the

value chain.

Melville et al.

(2004)

Partner Resources ( PR)

The degree to which a firm's partners (e.g., suppliers, retailers and

customers) are willing and ready to conduct business or service

activities electronically via e-business processes in e-supply chains.

Melville et al.

(2004)

e-Supply Chain

Capability (ESCC)

The ability that a firm uses e-business technology to share

information and accomplish transaction and coordinate activities

electronically with partners (e.g., suppliers, retailers and customers)

through e-business processes in supply chains (e.g., e-procurement,

e-ordering, and CRM).

In this paper, e-Supply Chain Capability consists of three parts in

upstream and downstream supply chain. They are called e-

Procurement capability (EPC), e-Ordering Capability (EOC) and e-

CRM Capability (CRMC).

Zhao et al.(2008)

e-Supply

chain

value

Process

Performance

IT value at e-supply chain process level and emanates from e-supply

chain capabilities via e-business process. In this paper, Process

Performance consists of three parts in upstream and downstream

supply chain. They are called e-Procurement Process Performance

(EPPF), e-Ordering Process Performance (OPPF) and CRM Process

Performance (CRMPF).

Dong et al. (2009)

Dehning et al.

(2007)

Financial

Performance

(FPF)

Improvement in financial performance attributable to e-supply chain

applications

Barua et al. (2004)

Dehning et al.

(2007)

Collaborativ

e

Network

Performance

(CNPF)

Aggregate performance t of collaborative network in e-supply chain Straub et al. (2004)

have realized that IT technology contribute to e-

supply chain capability(Rai et al., 2006); (Wu et al.

2006), For an organization with a high level of

information systems, it should be able to transmit,

combine and process data from business partners,

such as, suppliers/vendors. As noted by Wu et al.

(2007), the organizational learning ability associated

with IT professional knowledge is positively related

to the use of both coordination and transaction e-

procurement applications capability (Wu et al.,

2007).Together these studies suggest the critical role

of IS integration technology and IS application

knowledge in improving the effectiveness of e-

supply chain capability in their e-procurement, e-

ordering, and CRM. This leads to the following

hypothesis:

H1: Internal IT resources integration in focal

firm has a positive impact on the level of e-

procurement capability.

H2: Internal IT resources integration in focal

firm has a positive impact on the level of e-ordering

capability.

H3: Internal IT resources integration in focal

firm has a positive impact on the level of CRM

capability.

Electronic integration of supply chain processes

across organizations requires the development of IT

resources by both the focal firm and its trading

partners (Melville et al., 2004); (Zhao et al., 2008).

Hence, partner resources support (includes suppliers,

retailers) is considered an external resource to

support process connection (Dong et al., 2009) and

develop e-supply chain capability from collaborative

partner relationship perspective (Dewan et al. 1998).

Even if a firm has the necessary IT applications to do

business online with customers and suppliers, a lack

of partner’s readiness on the part of customers or

suppliers will impede the adoption of the technology

and IT value creation (Barua et al., 2004). Thus, we

hypothesize the following:

H4: Partner resources have a positive impact on

the level of e-procurement capability.

Frome-SupplyChainCapabilityGenerationtoInformationTechnologyValueCo-creation-APerspectiveofe-Business

Process

155

H5: Partner resources have a positive impact on

the level of e-ordering capability.

H6: Partner resources have a positive impact on

level of CRM capability.

3.2 Creating e-Supply Chain Process

Performance

In this paper process performance refers to inter-

organizational IT-based value co-created by e-supply

chain capabilities via upstream and downstream e-

business processes. More and more literatures

suggest that process performance should be

considered as a critical competitive power

measurement in recent SCM studies (Dehning et al.,

2007); (Dong et al., 2009). e-Supply chain capability

can improve process performance in operations by

sharing key planning and schedules information and

coordinating fulfilling orders and customer services

(Dehning et al., 2007); (Gunasekaran and Ngai,

2004a). From e-supply chain process level, it is

optimal perspective to take an in-deep look at co-

creation value emanates from robust collaborative

relationships among firms. Therefore, we propose

the following hypotheses:

H7: e-Procurement capability has a positive

impact on e-procurement process performance.

H8: e-Ordering capability has a positive impact

on e-ordering process performance.

H9: CRM capability has a positive impact on

CRM Process performance.

3.3 Generation of e-Supply Chain

Value

In this paper, generation of e-supply chain value

combines two relationships between process

performance, financial performance and

collaborative network performance. On the one

hand, focal firm can capture effects of e-supply

chain process performance improvement to the direct

overall firm financial performance. On the other

hand, through e-supply chain process integration and

collaboration, focal firm also improves collaborative

network outcomes together with their partners to

gain new competitive advantages.

e-Supply chain can improve financial

performance in operations by coordinating

marketing forecasts, production schedules, and

inbound logistics through the availability of

enhanced informational support for operations

planning and control resulting in reduced levels of

work-in-process and higher capacity utilization

(Gunasekaran et al., 2004b). It may be important to

simultaneously consider measuring the full direct

impact of e-supply chain process use on financial

performance. Therefore, we propose the following

hypotheses:

H10: e-Procurement process performance has a

positive impact on firm financial performance.

H11: e-Ordering process performance has a

positive impact on firm financial performance.

H12: e-CRM process performance has a positive

impact on firm financial performance.

In this paper, co-creation of value focuses on

overall e-supply chain operations effectiveness due

to each firm in this network benefits from such

relationships. Collaborative network performance

can be associated with e-supply chain has recently

been demonstrated by Straub et al. (2004). They

argue that degree-symmetric information sharing and

dependence in e-supply chain are positive related to

networked organizational performance. The greater

the degree of process applications between partners

via e-supply chain, the greater its share of net value

from deployment of the usage. This leads to the

following hypothesis:

H13: e-Procurement process performance has a

positive impact on collaborative network

performance.

H14: e-Ordering process performance has a

positive impact on collaborative network

performance.

H15: e-CRM process performance has a positive

impact on collaborative network performance.

4 RESEARCH METHODOLOGY

4.1 Data Collection

This study used the survey method to collect primary

data from senior IS managers and business managers

of manufacturing firms in China. A five-point Likert

scale (from very well to very bad) was used to

collect most responses. The data collection involved

manufacturing firms engaged in e-supply chain that

had the ability to interact with suppliers and

customers over the Web. During the whole process,

we have sent out 600 surveys and received 233 back.

Ten responses had too many missing data and were

discarded. Twenty-seven companies were discarded

because they didn’t adopt information systems for

SCM except Internet access. There were 196 usable

responses and the usable response rate was about

33%. In the sample, 65% of firms belong to

traditional manufacturing group, such as China

Petroleum & Chemical Corporation (Sinoper),

ICE-B2013-InternationalConferenceone-Business

156

Shanghai Volkswagen and Honda China. About 35%

firms belong to high-tech manufacturing group,

example include Lenovo, Samsung China, Benq,

Foxconn, Chinabird Huawei and et al. We found no

significant differences of organizational size and

sales in the two groups by using one-way ANOVA.

4.2 Data Analysis

A covariance-based Structural Equation Model

(SEM) analysis was used for data analysis.

Exploratory factor analysis (EFA) was first

conducted using SPSS 16.0 to validate the proposed

factor structures. EFA showed the presence of ten

factors in the data and the factor structures matched

the ones we identified in the research model. The

results of measuring IT related resources and e-

supply chain capability represented two and three

factors solution with 64% and 77% cumulative

percent of variance extracted respectively. These

items employed in multi-level performance revealed

five factors with 85% cumulative percent of variance

extracted. The values of KMO are all above 0.85

with significant Bartlett’s test of sphericity at 0.05

levels. The factor structures suggested by the EFA

match the one proposed in the research model.

Next, confirmatory factor analysis (CFA) was

conducted to check the reliability and validity of the

measurement model using Lisrel.8.72. Construct

reliability was measured using Cronbach’s alpha and

composite reliability. The Cronbach’s alpha ranges

from 0.79 to 0.92 for the 10 constructs, indicating a

high internal consistency (Straub et al., 2004).

Further, composite reliability was evaluated and

found to be similar, based on which we may

conclude that the reliability for these constructs is

adequate (Straub et al., 2004). Convergent and

discriminant validities were examined by both factor

loadings and a correlation matrix. All estimated

standard loadings are significant (p<0.001),

suggesting good convergent validity. All square root

of AVEs were above 0.707 (AVEs were above 0.50),

and they are much larger than all cross-correlations.

In sum, the results indicate good convergent and

discriminant validity.

The research model was tested with Lisrel 8.72,

results are presented in Fig. 1. Several GFI indexes

of the structural model have been widely used in IS

research arena. The normed 2(2 to degree of

freedom) is 2.4, which is within the recommended

level of 3.0Barua et al. 2004). The incremental fit

indices include the normed fit index (NFI), Non-

Normed Fit Index(NNFI), comparative fit index

(CFI), and incremental fit index (IFI), which are all

higher than 0.9. This implies a good model fit (Hu

and Bentler, 1999). Results suggested that the

structural model fit the data adequately.

4.3 Hypothesis Tests

Out of 15, 14 hypotheses are supported in our study;

we also provide an overall validation of the model of

e-supply chain value shown in Fig. 1.

Since our model proposes that e-supply chain

capability(ESSC) are intermediate transferring

capabilities between inter-firm IT resource

integration and process performance, we test these

effects in three upstream and downstream processes

at the same time. In the e-procurement process, only

Internal IT resources integration of a focal firm have

a positive effect on e-procurement capabilities (EPC)

(β=0.64, p<0.001), while partner resources does not

have a significant impact (β=0.12, p>0.05). Thus, H2

is not supported. In the e-ordering process, the

results indicate the Internal IT resources integration

(β=0.61, p<0.001) is more likely to be associated

with the development of e-ordering capability (EPC)

than partner resources (β=0.15, p<0.05). Similarly,

the results also predict the impact of Internal IT

resources integration (β=0.67, p<0.001) and partner

resources (β=0.16, p<0.05) on the generation of

CRM capability (CRMC). Therefore, these results

support the hypothesis that firms have engaged in

integrating inter-firm IT resources together with

partners to create unique e-supply chain capability

through upstream and downstream e-business

processes.

We further tested the e-supply chain process

performance co-create by e-supply chain capability

in upstream and downstream e-business processes.

Hypotheses H7, H8, and H9 are all strongly

supported at 0.001 significance level, demonstrating

that ESSC involving in procurement (β=0.57,

p<0.001), ordering (β=0.66, p<0.001), and the CRM

process (β=0.65, p<0.001) leads to improved

individual process performance respectively.

We also identify the role of process performance

in transforming from e-supply chain capability to

financial performance (FPF) and collaborative

network performance (CNPF). The model shows a

significantly positive linkage between e-supply chain

process performance and financial performance in

the e-procurement (β=0.32, p<0.001) with higher

magnitude and greater significance than in the e-

ordering (β=0.30, p<0.05) and CRM (β=0.14,

p<0.001). Therefore, H10, H11, and H12 are

supported in this study. H13, H14, and

H15 predicted that process performance also would

Frome-SupplyChainCapabilityGenerationtoInformationTechnologyValueCo-creation-APerspectiveofe-Business

Process

157

Figure 1: Structural model results.

impact on collaborative network performance.

5 CONCLUSIONS

The empirical results provide strong overall

validation of causal relationships between the

constructs in the three stages, forming a dynamic

chain among inter-firm IT resources integration, e-

supply chain capabilities and e-supply chain value.

The results indicate that firms use collectively of

inter-firm IT resources to gain e-supply chain

capabilities which via implementing the e-business

process more efficiently and effectively. We argue

that the core competencies of the e-supply chain, as

associated with e-supply chain processes, are

achieved by e-supply chain capabilities, which are as

integrated process enablers between upstream and

downstream processes to realize benefits for focal

firms and all partners (e.g. supplier and customer).

Furthermore, the impact of financial performance

and collaborative network performance are mediated

by process performances in procurement, ordering,

and CRM process. This research expands our

understanding of the dynamics and completeness of

transformation for the e-supply chain

implementation success.

Finally, we want to point out limitations of this

study. Our data relies on a single Asian country.

Sample data from one or more western countries are

needed to further generalize the findings. This cross-

national comparison may reveal the potential impact

of national differences (e.g., national culture and

country-specific e-supply chain practices).

ACKNOWLEDGEMENTS

This research has been supported by grants from the

National Natural Science Foundation of China under

Grant 70172034, 70672064, 71072080.

REFERENCES

Barua, A., Konana, P., Whinston, A. B., and Yin, F. 2004,

An empirical investigation of net-enabled business

value, MIS Quarterly, 28, 585-620

Boone, T., and Ganeshan, R. 2007, The frontiers of

eBusiness technology and supply chains, Journal of

Operations Management, 25, 1195-1198

Chatfield, A. T., and Yetton, P. 2000, Strategic payoff

from EDI as a function of EDI embeddedness, Journal

of Management Information Systems, 16, 195-224

Dehning, B., Richardson, V. J., and Zmud, R. W. 2007,

ICE-B2013-InternationalConferenceone-Business

158

The financial performance effects of IT-based supply

chain management systems in manufacturing firms,

Journal of Operations Management, 25, 806-824

Devaraj, S., Krajewski, L., and Wei, J. C. 2007, Impact of

eBusiness technologies on operational performance:

The role of production information integration in the

supply chain, Journal of Operations Management, 25,

1199-1216

Dewan, S., Michael, S. C., and Min, C. K. 1998, Firm

characteristics and investments in information

technology: Scale and scope effects," Information

Systems Research, 9, 219-232

Dong, S. T., Xu, S. X., and Zhu, K. X. G. 2009,

Information Technology in Supply Chains: The Value

of IT-Enabled Resources Under Competition,

Information Systems Research, 20, 18-32

Gunasekaran, A., and Ngai, E. W. T. 2004a, Information

systems in supply chain integration and management,

European Journal of Operational Research, 159, 269-

295

Gunasekaran, A., Patel, C., and McGaughey, R. E. 2004b,

A framework for supply chain performance

measurement, International Journal of Production

Economics, 87, 333-347

Hu L., and Bentler, P. M. 1999, Cutoff criteria for fit

indexes in covariance structure analysis: conventional

criteria versus new alternatives, Structural Equation

Modeling, 6, 1-55

Iskandar, B. Y., Kurokawa, S., and LeBlanc, L. J. 2001,

Adoption of electronic data interchange: The role of

buyer-supplier relationships, IEEE Transactions on

Engineering Management, 48, 505-517

Kohli, R., and Grover, V. 2008, Business value of IT: An

essay on expanding research directions to keep up with

the times, Journal of the Association for Information

Systems, 9, 23-39

Li, P. P., and Chang, S. T. 2004, A holistic framework of

e-business strategy: The case of haier in China,

Journal of Global Information Management, 12, 44-62

Melville, N., Kraemer, K., and Gurbaxani, V. 2004,

Review: Information technology and organizational

performance: An integrative model of IT business

value, MIS Quarterly, 28, 283-322

Rai, A., Patnayakuni, R., and Seth, N. 2006, Firm

performance impacts of digitally enabled supply chain

integration capabilities, MIS Quarterly, 30, 225-246

Ray, G., Muhanna, W. A., and Barney, J. B. 2005,

Information technology and the performance of the

customer service process: A resource-based analysis,

MIS Quarterly, 29, 625-652

Straub, D., Rai, A., and Klein, R. 2004, Measuring firm

performance at the network level: A nomology of the

business impact of digital supply networks, Journal of

Management Information Systems, 21, 83-114

Wu, F., Yeniyurt, S., Kim, D., and Cavusgil, S. T. 2006,

The impact of information technology on supply chain

capabilities and firm performance: A resource-based

view, Industrial Marketing Management, 35, 493-504

Wu, F., Zsidisin, G. A., and Ross, A. D. 2007, Antecedents

and outcomes of e-procurement adoption: An

integrative model, IEEE Transactions on Engineering

Management, 54, 576-587

Zhao, J., Huang, V. W., and Zhu, Z. 2008, An empirical

study of e-business implementation process in China,

IEEE Transactions on Engineering Management, 55,

134-147

Frome-SupplyChainCapabilityGenerationtoInformationTechnologyValueCo-creation-APerspectiveofe-Business

Process

159