Hospital Risk Management using Healthcare Failure Mode

and Effects Analysis

A Case Study on Ventilators Whithin an Intensive Care Unit

M. Alberto Ibarra-Sánchez

1

, Ana B. Pimentel-Aguilar

2

and Martha R. Ortiz-Posadas

1

1

Department of Electrical Engineering, Univerisdad Autónoma Metropolitana Iztapalapa,

Av. San Rafael Altixco #186, Col. Vicentina, C. P. 09340, México City, D. F. Mexico

2

Department of Biomedical Engineering, National Institute of Respiratory Diseases,

Calz. Tlalpan No. 4502, Col. Sección XVI, Deleg. Tlalpan, CP. 14080, México City, D. F. Mexico

Keywords: Hospital Risks Management, Healthcare Failure Mode and Effects Analysis, Mechanical Ventilators,

Intensive Care Unit.

Abstract: The objective of this work was to analyze the potential risks associated to the use of invasive mechanical

ventilators located in the intensive-care unit (ICU) of the Institute of Respiratory Diseases from Mexico.

The study was addressed by applying the Healthcare Failure Mode and Effects Analysis (HFMEA),

identifying possible/potential failure modes and its effects, and determining the severity and the probability

of occurrence for each of these failures. We determine the risk score, and if this score was 8 or higher, we

proposed a preventive action in order to develop an action plan. We identify six types of risks (electrical,

mechanical, due to medical gases, biological, catastrophic and those related to human factor) and 26

potential causes related with these risks. Base on the evidence acquired by the HFMEA, we proposed a

contingency plan for those potential causes.

1 INTRODUCTION

Risk is defined as the probability of harmful

consequences, or expected losses (deaths, injuries,

property, livelihood, economic activity disrupted or

environment damaged) resulting from interactions

between natural or human-induced hazards and

vulnerabilities (WHO, 2007). There are hazards

arise in the use of medical devices due to the

inherent risk of medical treatment, from device

failures (or malfunctions), and from device use.

Hazards resulting from medical devices impact

patients, family members, and professional

healthcare providers (Kaye and Crowley, 2000).

Risk management is defined as the systematic

process of identifying, evaluating and addressing

potential and actual risk. Risk management has

emerged as an integral element in the operational

activities of hospitals. The process is a mechanism

for self-protection in co-operative, self-insurance

arrangements and to secure premium adjustments.

Many trends have been recognized, that would

suggest a predisposition toward the proliferation of

risk management programs (Keddy et al., 1988).

Because of these, patient safety has become a

matter of interest to healthcare professionals,

governments and researchers worldwide. During the

last decade, many studies have been conducted to

assess the prevalence, severity and causes of a large

variety of different types of adverse events in

hospitals, as well as the effectiveness of various

approaches to enhance safety (Wolf et al., 2001;

Oliver et al., 2004; Marwick et al., 2009). The risks

present in the hospital are widespread and complex.

These risks are electrical, mechanical, biological,

environmental and radiological, among others.

The initial steps to develop a risk management

program include assessing current risk, control

activities and implementing structural elements. As

well, a program must address its relationship to

quality assurance activities in the hospital.

The objective of this work was to analyze the

potential risks of invasive mechanical ventilators

(invasive ventilation is defined as mechanical

ventilation via an artificial airway which can either

be via endotracheal tube or tracheostomy tube),

located in the intensive-care unit (ICU) of the

328

Alberto Ibarra-Sánchez M., B. Pimentel-Aguilar A. and R. Ortiz-Posadas M..

Hospital Risk Management using Healthcare Failure Mode and Effects Analysis - A Case Study on Ventilators Whithin an Intensive Care Unit.

DOI: 10.5220/0004536203280335

In Proceedings of the International Conference on Knowledge Discovery and Information Retrieval and the International Conference on Knowledge

Management and Information Sharing (KMIS-2013), pages 328-335

ISBN: 978-989-8565-75-4

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

National Institute of Respiratory Diseases (INER for

its Spanish acronym), which is a third level public

hospital in Mexico City. We address the study

applying the Healthcare Failure Mode and Effects

Analysis (HFMEA) (VA-NCPS, 2013) and propose

a contingency plan in order to manage the risks

associated with the use of this technology.

2 METHODOLOGY

Healthcare Failure Mode and Effects Analysis

(HFMEA) is a prospective methodology that

identifies and improves steps in a process thereby

reasonably ensuring a safe and clinically desirable

outcome. HFMEA has been designed by the

National Center for Patient Safety (NCPS) of the

Department of Veterans Affairs (VA) specifically

for healthcare (VA-NCPS, 2013), and streamlines

the hazard analysis steps found in the traditional

failure mode and effect analysis process (IMCA,

2002). The purpose of the hazard analysis is to

develop a list of hazards that are of such significance

that they are reasonably likely to cause injury or

illness if not effectively controlled. The steps of the

HFMEA are described as follows.

2.1 Healthcare FMEA Steps

Step 1: Define the topic of the HFMEA along with a

clear definition of the process to be studied.

Step 2: Assemble a Multidisciplinary Team

including the subject matter expert(s) and an

advisor.

Step 3: Graphically describe the Process.

Step 4: Conduct a hazard Analysis:

a. List all possible/potential failure modes for the

process. Failure modes include anything that

could go wrong that would prevent the process

from being carried out. Consecutively number

these failure modes.

b. List all possible/potential effects of the failure

mode. Effects include anything that could

happen if the failure actually occurs.

c. Determine the severity (S) of each effect by

using the severity rating (Table 1).

d. Determine the potential causes of each failure

mode. Each failure mode may have multiple

failure mode causes. Document the causes.

e. Determine the probability of occurrence (O) for

each of the potential causes by using the

probability rating (PR) as follows:

Frequent (PR=4). Likely to occur immediately or

within a short period (may happen several times

in one year).

Table 1: Severity rating.

Event Severity rating

Catastrophic (4)

Patient Outcome: Death or major permanent

loss of function (sensory, motor, physiologic,

or intellectual).

Visitor Outcome: Death; or hospitalization of

three or more visitors.

Staff Outcome: A death or hospitalization of

three or more staff.

Equipment or Facility: Damage equal to or

more than $250,000.

Fire: Any fire that grows larger than

incipient/beginning stage cannot be controlled

with portable fire extinguisher or small hose.

Major (3)

Patient Outcome: Permanent lessening of

bodily function (sensory, motor, physiologic,

or intellectual), increased length of stay or

increased level of care, for three or more

patients.

Visitor Outcome: Hospitalization of two or

more visitors.

Staff Outcome: Hospitalization of one or two

staff or three or more staff experiencing lost

time or restricted duty injuries or illnesses.

Equipment or Facility: Damage equal to or

more than $100,000.

Moderate (2)

Patient Outcome: Increased length of stay or

increased level of care for one or two patients.

Visitor Outcome: Evaluation and treatment

for one or two visitors (less than

hospitalization).

Staff Outcome: Medical expenses lost time or

restricted duty injuries or illness for one or

two staff.

Equipment or Facility: Damage between

$10,000 -$100,000.

Fire: Incipient/beginning stage or smaller can

be controlled with portable fire extinguisher or

small hose.

Minor (1)

Visitor Outcome: Evaluation and no

treatment required or refused treatment.

Staff Outcome: First aid treatment only with

no lost time, nor restricted duty injuries or

illnesses.

Equipment or Facility: Damage less than

$10,000 or loss of any utility without adverse

patient outcome.

Occasional (PR=3). Probably will occur (may

happen several times in 1 to 2 years).

Uncommon (PR=2). Possible to occur (may

happen sometime in 1 or 2 years).

Remote (PR=1). Unlikely to occur (may happen

sometime in 5 to 30 year years).

f. Determine the risk score (RS) by multiplying the

probability score by the severity score.

HospitalRiskManagementusingHealthcareFailureModeandEffectsAnalysis-ACaseStudyonVentilatorsWhithinan

IntensiveCareUnit

329

g. Use the hazard decision matrix (Table 2) to

determine if the failure mode warrants further

action. If the score is 8 or higher, strong

consideration should be given to developing an

action plan.

Step 5: Actions and outcome Measures:

a. Identify an action for each failure mode that will

be corrected. Place the corrective actions in the

process at the earliest feasible point. Multiple

actions can be placed in the process to control a

single hazard. An action can be used more than

one time in the process.

b. Identify outcome measures that will be used to

analyze and test the redesigned process.

c. Identify a single, responsible individual by title

to complete the recommended action.

d. Indicate whether top management has concurred

with the recommended action.

e. Record the recommended action, responsibility

and target date.

Step 6: Follow-up on Actions Taken

a. After the target date for the recommended

actions, follow-up to make sure the actions were

implemented and on what date.

b. Now that the recommended actions have been

implemented, the hazard score should be lower.

So, revisit the probability of that failure mode

cause using the probability rating table (Table 2)

and document the new rating.

c. Obtain the new hazard score by multiplying the

severity times the probability and document the

result. The new hazard score should now be <8.

If not, revisit the recommended actions.

Table 2: Risk decision matrix.

Probability Severity of Effect

Catastro

phic (4)

Major

(3)

Moderate

(2)

Minor

(1)

Frequent (4) 16 12 8 4

Occasional

(3)

12 9 6 3

Uncommon

(2)

8 6 4 2

Remote (1) 4 3 2 1

3 RESULTS

This work was developed by a multidisciplinary

team of biomedical engineers, respiratory therapists

and nurses. The knowledge acquisition (the process

of extracting, structuring and organizing knowledge

from one source, usually human experts), was made

through interviews to technology users and by

studying the procedures of handling and use of the

ventilators, and management of medical technology.

Six risk-types associated with mechanical

ventilators in the ICU were identified: electrical,

mechanical, due to medical gases, biological,

catastrophic and those related to human factor. Its

failure modes and effects, and potential causes were

analyzed for every case. The results shown in this

work are only those with a risk score greater or

equal to 8, because according to the hazard decision

matrix (Table 2) these need further corrective

actions. Therefore some operative actions were

proposed and related with the hospital service

responsible for its implementation.

3.1 Electrical Risk

Electrical risk is defined as a dangerous condition

such that contact or equipment failure can result in

electric shock, arc-flash burn, thermal burn, or blast.

(NFPA, 2004).

For this risk one failure mode and effect was

identified and associated to four potential causes,

that got RS=8 (Table 3). This failure means that the

ventilator has discharged battery. For all cases the

potential causes have catastrophic severity (S=4),

because if the ventilator stops working the patient’s

life is threatened, although the probability is

uncommon (P=2).

3.2 Mechanical Risk

Mechanical devices are necessary for many

treatments in the modern hospital. These devices

include mobility aids, transfer devices, prosthetic

devices, mechanical-assist devices, and patient-

support equipment. Each of these devices embodies

numerous life and limb threats to patients as well to

hospital staff. These devices must be subject to

careful design review, failure indication, and the

establishment of complete specifications for safe use

(Freeman, 1979).

For this risk two failure modes and effects were

identified and associated to three potential causes

(Table 3). Note that the potential cause 5 got a

RS=12, because it is related to the localization of the

electrical outlets, hence an infrastructure issue. The

other two potential causes got a minor RS (RS=9),

because these problems are related to the distribution

of the ventilators into the ICU cubicle.

KMIS2013-InternationalConferenceonKnowledgeManagementandInformationSharing

330

Table 3: HFMEA for the risks associated to the ventilators in the Intensive Care Unit.

Risk

Failure mode Failure effect Potential cause S O RS

Electrical

Discharged batteries

The ventilator does not

work

1. The ventilator is unplugged to the

electrical system.

4 2

8

2. The ventilator is plugged to an

electrical outlet that doesn’t work.

4 2

8

3. The ventilator is stored for a long

time without being plugged to the

electrical system.

4 2

8

4. There is not an area for plugging

the ventilators in order to charge

the batteries.

4 2

8

Mechanical

No free access to the

electrical outlets.

By plugging the

ventilator, other device

may be unplugged

(e.g., infusion pumps).

5. The electrical outlets may be in a

high position and the staff may

require a bench to plug the

ventilator.

3 4

12

The ventilator blocks the

free staff’s circulation.

The staff cannot access

to the patient for

emergency procedures.

6. Lack of space in the patient cubicle. 3 3

9

7. Crossed hoses and wires block the

access of the staff to the patient.

3 3

9

Medical Gases

Insufficient medical gases

supply pressure.

The ventilator does not

work.

8. Insufficient gas compressor power. 4 3

12

9. Leaking hoses. 4 2

8

10. Drop of the medical gases supply

pressure.

4 3

12

11. Leaking medical gases outlets or

ventilator connectors.

4 2

8

12. Bad medical gases supply

connection.

4 2

8

The ventilator cannot be

connected to the medical

gases outlets.

The patient could not

receive ventilatory

support.

13. Incompatibility between the

medical gases outlets and the

ventilator’s connectors.

4 3

12

Biological

Contaminated ventilators

not identified.

Use of contaminated

ventilators.

14. Clean and contaminated ventilators

are stored in the same place

(transfer).

3 3

9

15. No label for contaminated

ventilators.

3 3

9

3.3 Risks by Medical Gases

Medical gases are widely used around the hospital

and are supplied in cylinders or piped into wards and

clinical areas. They are safe if handled correctly,

however, misuse or mishandling can have

catastrophic consequences (NHS, 2012).

For this risk two failure modes and effects were

identified and associated to six potential causes

(Table 3). Those related with the gas supply pressure

got the mayor risk score (RS=12), because the

correct operation of the ventilators depends on this;

and the last three, related with the ventilator’s

connection to the gas outlet, got RS=8.

3.4 Biological Risk

Biological health risks are linked to the exposure to

bacteria, viruses, fungi, other micro-organisms and

associated toxins. These micro-organisms are

widespread in nature and represent a potential

danger for public health (EC, 2013).

The main biological risk arises when the staff

cannot identify the contaminated ventilators, as it

may cause a nosocomial infection if one of these

devices is used in another patient. For this case two

potential causes with a RS=9 related to the lack of a

label to identify between contaminated ventilators

that need cleanup and those clean ready for usage

were determined.

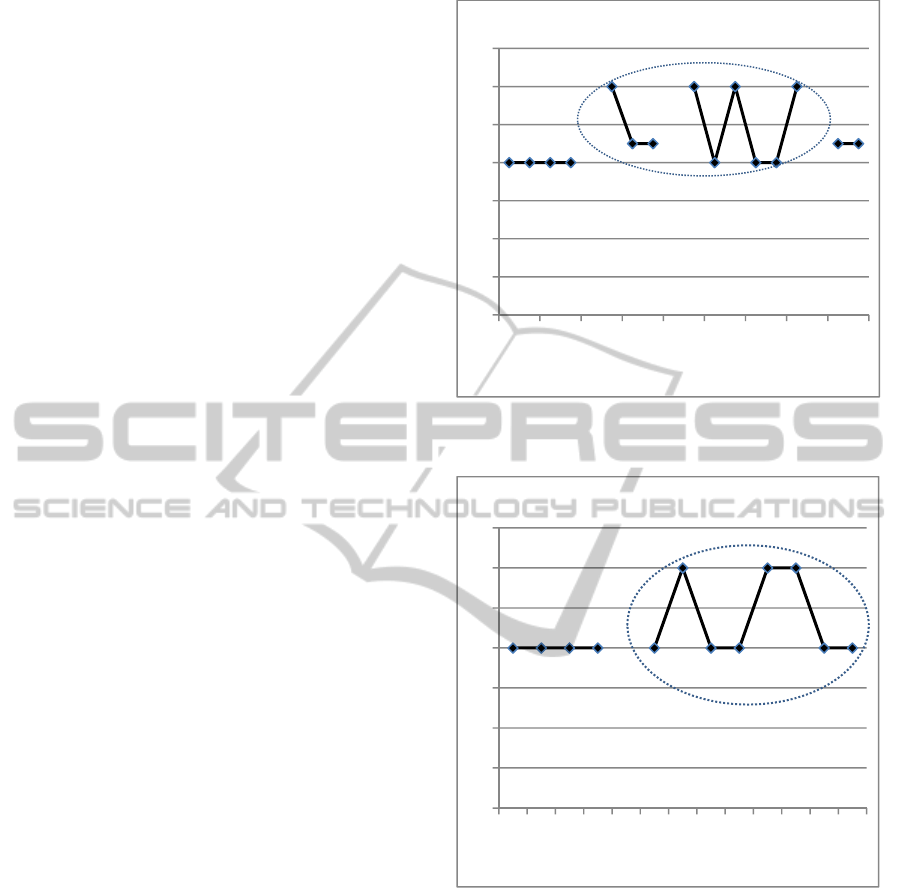

Once the risks were analyzed, with the RS

obtained a plot was made to see how the potential

causes cluster and to define the priority in order to

develop its prevention actions (Figure 1). Note that

the risk by medical gases has the set of potential

causes with mayor RS. It means that the first actions

HospitalRiskManagementusingHealthcareFailureModeandEffectsAnalysis-ACaseStudyonVentilatorsWhithinan

IntensiveCareUnit

331

to develop in the contingency plan will be for the

potential causes of this risk. Then those for

mechanical, biological and electrical risk would

follow.

3.5 Catastrophic Risk (Seismic)

Catastrophic risks are those that can result in

substantial loss of life or livelihood, call an

organization’s existence into question or cause

significant environmental damage. These risks

include a diverse range of events such as floods,

pandemic infections, nuclear accidents, wars,

seismic, economic collapse, etc. (World Economic

Forum, 2012). In this sense, seismic activity occurs

in many areas of Mexico, and Mexico City is

particularly at risk due to unique geological

characteristics coupled with an extraordinarily high

concentration of exposure (USGS, 2012). This is the

reason why we consider the analysis of seismic risk

in this study.

For this risk one failure mode, two effects and

three potential causes related with the infrastructure

and movement of the ventilator in the ICU were

identified (Table 4) and got a RS=8 for the three

cases.

3.6 Risks by Human Factors

Hazards associated with device use are a common

and serious problem. Evidence suggests that the

frequency and consequence of hazards resulting

from medical device use might far exceed those

arising from device failures. Therefore, it is essential

to ensure safe and effective device use if all hazards

are to be controlled effectively (Kaye and Crowley,

2000).

Here we addressed hazards resulting from

interactions between users and the mechanical

ventilators in the ICU. We identify three failure

modes and effects, associated to eight potential

causes (Table 4). The ones with the mayor risk score

(RS=12) were those related with the out-of-order

ventilators and with the lack of staff capacitation in

the correct use and handle of the equipment.

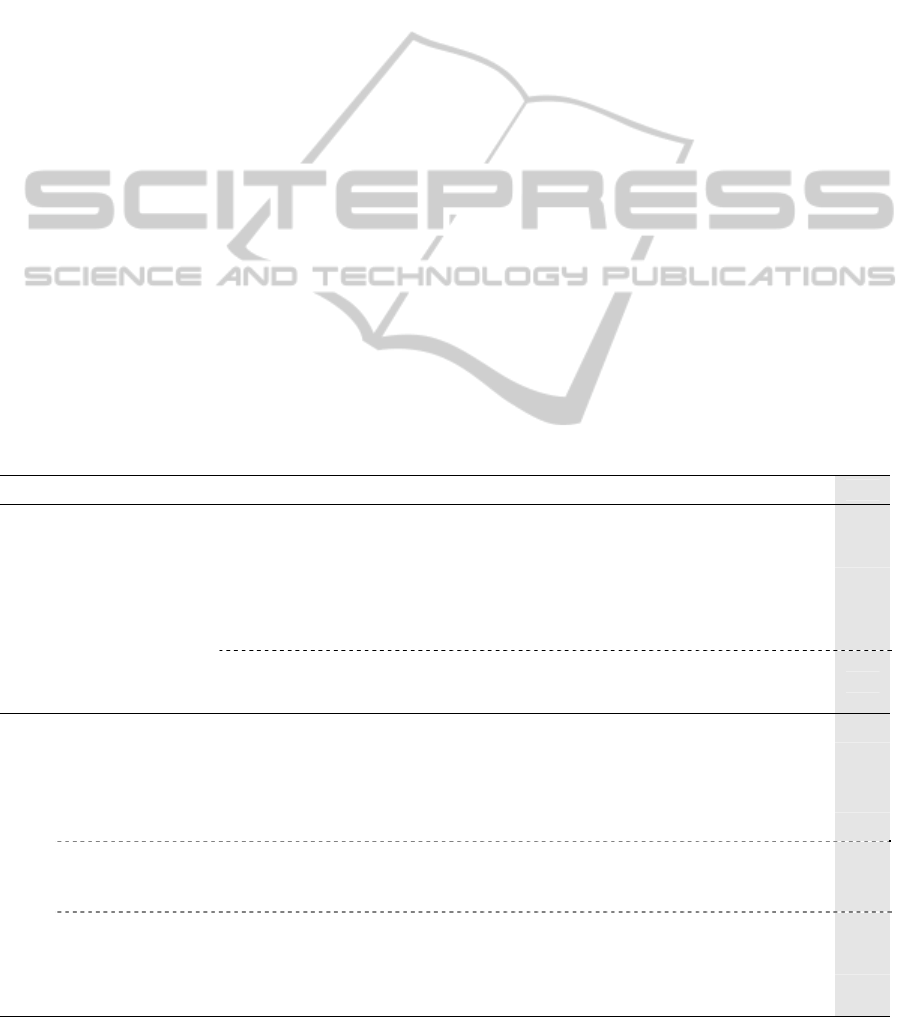

For these two last risks (biological and

catastrophic) a plot with the gotten RS also was

made (Figure 2), in which it’s clearly seen that the

first prevention actions to be developed are those for

the risk related to human factor.

Figure 1: Graphic of the risk scores of the electrical,

mechanical, by medical gases and biological risks.

Figure 2: Graphic of the risk scores for the seismic and

human factors risks.

3.7 Contingency Plan

A contingency plan is a process that prepares an

organization to respond coherently to an unplanned

event. The contingency plan can be also used as an

alternative for action if expected results fail to

materialize. The HFMEA study goes on to make

recommendations on how to address the failure

modes, ranging from better education, better visual

displays, "time outs", bar-codes, etc.

For developing a contingency plan for the risks

associated to the use of the mechanical ventilator in

0

2

4

6

8

10

12

14

1 3 5 7 9 11 13 15 17

Electrical

Risks

Biological

Risks

Risks byMedicalGases

Mechanical

Risks

Riskscore

Potential causenumber

0

2

4

6

8

10

12

14

135791113

Riskscore

Seismic

Risk

RisksbyHumanFactor

Potencialcausenumber

KMIS2013-InternationalConferenceonKnowledgeManagementandInformationSharing

332

the ICU, we used the risk score and the risk matrix

(Table 2) to identify which critical failure modes

need correction, but then is still need to make those

corrections and take more action.

In this case, the Hospital would need to address

26 different potential causes. That doesn't

necessarily mean that 26 separate remedial and

corrective actions need to take place. A single

corrective action might be able to address multiple

failure modes, so a few key changes might address

many failure modes at once.

Following we discuss the corrective actions for

each type of risk, in order to develop the

contingency plan as well as the responsible

department for their implementation.

3.7.1 Electrical Risk

The proposed actions to diminish the electrical risk,

in general, are of surveillance.

Inspect that the ventilator is effectively plugged

to the electrical system, at least once per shift, to

guarantee charged batteries. Respiratory Therapy is

the area in charge for this action.

Supervise that all the electrical outlets in the ICU

have electrical supply, are connected to the

emergency power system and its voltage is

periodically checked. Hospital maintenance is the

area in charge for these actions.

To allocate an exclusive area for ventilators

storage and to have a control strategy for the

batteries charge process. Respiratory Therapy is the

area in charge for this action.

3.7.2 Mechanical Risk

Some infrastructure modifications are proposed in

order to diminish this risk, like to change the place

of the electrical outlets to guarantee the staff free

access to them. Hospital maintenance is the area in

charge for this action.

On the other hand, it is necessary that a correct

distribution of the equipment in the patient cubicles

of ICU be done. The ventilators must be placed near

to the medical gases and electrical outlets, and so

vital signs monitors and infusion pumps must be

correct placed. ICU is the area in charge of this

action.

3.7.3 Risks by Medical Gases

It is important to be aware of pressures at which

gases are stored and used. Therefore the medical

gases supply pressure and each outlet in every

cubicle must be verified, at least once a day, and so

the connectors. Hospital maintenance is the area in

charge of this action.

Table 4: HFMEA for the risks associated to the use of invasive ventilators in the Intensive Care Unit.

Risk Failure mode Failure effect Potential causes S O

RS

Catastrophic

Seismic

The ventilator does not

work.

16. The medical gases supply is

interrupted due to damage to the

hospital infrastructure.

4 2

8

17. The ventilator gets disconnected

from the medical gases supply,

electrical system or breathing

circuit.

4 2

8

The ventilator may hinder

the evacuation of patient and

staff.

18. The ventilator moves and blocks

the staff’s evacuation of the

cubicle.

4 2

8

Human Factors

Lack of available

ventilators.

Patient does not receive

ventilatory support.

19. Contaminated ventilators. 4 2

8

20. Out-of-order ventilators. 4 3

12

21. Not enough accessories (breathing

circuits, hoses, etc.).

4 2

8

22. Cleaning verification not passed. 4 2

8

Not enabled staff in

the use of

ventilators.

Patient does not receive

ventilatory support.

23. Invasive ventilator used for

patient transfer.

4 3

12

24. Lack of capacitation to the user. 4 3

12

The ventilator

stops working

during patient

transfer.

Patient does not receive

ventilatory support.

25. The ventilator sustains a

breakdown during the patient

transfer.

4 2

8

26. Drop of the medical gas tank

pressure.

4 2

8

HospitalRiskManagementusingHealthcareFailureModeandEffectsAnalysis-ACaseStudyonVentilatorsWhithinan

IntensiveCareUnit

333

To check the hose and breathing circuit state at

least once per shift and to have a replacement

strategy in accordance to the manufacturer’s

specifications, also the compatibility between

medical gases outlets and ventilator connectors must

be assured, and those that do not meet this

requirement must be replaced. Respiratory Therapy

is the area in charge of this action.

3.7.4 Biological Risks

In this case developing an infection control plan is

fundamental; it will allow identifying contaminated

ventilators in order to start effective

decontamination procedures. The Respiratory

Therapy is the area in charge of these actions.

3.7.5 Catastrophic Risk (Seismic)

In case of an earthquake, having the sufficient

equipment and accessories to maintain the maximum

technology capacity is necessary.

Also, portable oxygen tanks to keep the

ventilators working until the regular gas supply is

reestablished, enough transfer ventilators and

compatible invasive transfer ventilators circuits to

avoid patients’ re-intubation are required. The

Respiratory Therapy is the area in charge of these

actions.

Furthermore, it is very important to verify the

wheel brakes of both the ventilator and the bed to

avoid displacements during an earthquake. ICU is

the area in charge of this action.

3.7.6 Risks by Human Factors

For these risks the following actions are proposed:

Supervise the effective cleaning of the

ventilators. Acquire enough equipment, accessories

and consumables according to the demand of

ventilators. Use transfer ventilators for patient

mobilization. Respiratory Therapy is the area in

charge of this action.

On the other hand, it is necessary to schedule

daily equipment review routines to guarantee the

availability of verified ventilators. Improve the

ventilators’ preventive and corrective maintenance

response. To develop a continuous training program

for the staff and a continuous ventilators’

functionality test program. The Biomedical

Engineering Department is in charge of these

actions.

Distribute the workload of the ICU according to

the staff available and to promote the recruitment of

more staff.

4 CONCLUSIONS

The HFMEA application showed evidence that

allowed to analyze the potential causes associated to

six identified risks (electrical, mechanical, due to

medical gases, biological, catastrophic and those

related to human factors), in the use of mechanical

ventilators in the ICU.

With the RS obtained for each one of the 26

potential causes, its priority was determined and

preventive actions were proposed, aiming for a risk

management contingency plan development.

Once the contingency plan in the ICU is

established, the tracing and feedback actions that

allow to recalculate the RS and to evaluate the

effectiveness of the preventive measures

implemented will be carried out, and, if so, keep or

modify them. As we know, a common outcome of

risk analysis is to re-emphasize the training and

procedure-following by staff members.

By the other hand, an equipment control program

must be implanted in the ICU, in order to enforce the

contingency plan. The control program provides a

structure for the clinical utilization of equipment in

the hospital, and directs the effort by the entire

institution to apply technical competence,

management techniques, and organizational skills to

the control and application of technology (Furst,

1979).

In this work is shown the usefulness of the

HFMEA for the evaluation and management of risks

associated with mechanical ventilators use in the

ICU. However it is a tool that can be used for

analyzing and evaluating risks of any medical

technology in any clinical service.

As further work, an evaluation of the risk

management framework is going to be conducted by

a pilot program (a preliminary study) to see how part

of the ICU, using the proposed contingency plan

performs better than part of the ICU not using it, in

order to evaluate feasibility, time, cost, adverse

events, and effect size.

REFERENCES

WHO - World Health Organization, 2007. Risk reduction

and emergency preparedness. WHO six-year strategy

for the health sector and community. WHO Document

Production Services, Geneva, Switzerland.

Kaye, R. and Crowley J., 2000. Medical Device Use-

Safety: Incorporating Human Factors Engineering into

Risk Management. U. S. Department of Health and

Human Services. FDA.

KMIS2013-InternationalConferenceonKnowledgeManagementandInformationSharing

334

Keddy, W. R., Johnson M. W. and McKerrow W., 1988.

Hospital risk management: the second decade.

Healthcare Manage Forum, 1 (1):12-7

Wolff, A. M., Bourke, J., Campbell, J. A. and

Leembruggen, D. W., 2001. Detecting and reducing

hospital adverse events: outcomes of the Wimmera

clinical risk management program. Medical Journal of

Australia, 174 (12): 621-625.

Oliver D., Daly F., Martin F. C. and McMurdo M. T.,

2004. Risk factors and risk assessment tools for falls

in hospital in-patients: a systematic review. Age and

Ageing, 33: 122–130.

Marwick, C. and Davey, P., 2009. Care bundles: the holy

grail of infectious risk management in hospital?

Current Opinion in Infectious Diseases, 22:364–369.

VA-NCPS - National Center for Patient Safety. The

Basics of Healthcare Failure Mode and Effect

Analysis (HFMEA). Available at http://

www.patientsafety.gov/SafetyTopics/HFMEA/HFME

AIntro.pdf consulted on March 2013.

IMCA - International Marine Contractors Association,

2002. Guidance on Failure Modes & Effects Analyses.

IMCA-M-166.

NFPA - National Fire Protection Association, 70E

Standard for Electrical Safety Requirements for

Employee Workplaces, 2004 Edition. Available at

http://www.nfpa.org/assets/files/PDF/CodesStandards/

TIAErrataFI/TIA70E-04-1.pdf consulted on March

2013.

Freeman, J., 1979. Safety program. In: Clinical

engineering. Principles and practices, Webster J (Ed.).

Prentice Hall, NJ.

NHS - Salford Royal National Health Service Foundation

Trust, 2012. Design Services, Basic Medical Gas

Safety. Available at: http://elearning.hope-

academic.org.uk/srht_elearn_dept/medical_gases_wor

kbook.pdf consulted on March 2013

EC - European Commission, Biological Risks, Health-EU,

available at http://ec.europa.eu/health-eu/my_

environment/biological_risks/index_en.htm, consulted

on March 2013.

World Economic Forum. Global Agenda Council on

Catastrophic Risks 2012. Available at:

http://www.weforum.org/content/ global-agenda-

council-catastrophic-risks-2012 consulted on March

2013.

USGS - US Geological Survey. Mexico Earthquake

Information. Available at :http://earthquake.usgs.gov/

earthquakes/world/index.php?regionID=3 consulted

on March 2013.

Furst, E., 1979. The equipment control program. In:

Clinical engineering. Principles and practices, Webster

J (Ed.). Prentice Hall, NJ.

HospitalRiskManagementusingHealthcareFailureModeandEffectsAnalysis-ACaseStudyonVentilatorsWhithinan

IntensiveCareUnit

335