Knowledge in Construction Processes

Carlo Argiolas

1

, Giulio Concas

2

, Marco di Francesco

3

, Maria Ilaria Lunesu

2

, Filippo Melis

1

,

Filippo Eros Pani

2

, Emanuela Quaquero

1

and Daniele Sanna

3

1

Department of Civil Engineering and Architecture, University of Cagliari, Piazza d'Armi, Cagliari, Italy

2

Department of Electrics and Electronics Engineering, University of Cagliari, Piazza d'Armi, Cagliari, Italy

3

FlossLab Srl Viale Elmas 142, Cagliari, Italy

Keywords: Knowledge Management, Building Process, Bottom-up Analysis, Top-down Analysis, Knowledge

Management System.

Abstract: The growing complexity of the construction sector – due to the proliferation of products, techniques, and

needs related to side, not secondary, aspects of objects (environmental impact, energy efficiency, durability,

safety, etc.) – means that the current management styles in construction processes are no longer appropriate

to their context. Therefore, the construction sector faces an inevitable process of growth in which

knowledge is an indispensable resource. The purpose of this paper is to show how knowledge associated

with construction processes can be represented using Knowledge Management techniques. The analysis of

such knowledge uses a mixed top-down and bottom-up approach, which can formalize it and make it ready

for easy access and search. The underlying goal is the rational organization of large amounts of data using

the knowledge that characterizes the various stages of a construction process. Elementary Products could be

the core concepts that can group the objects associated with such process, guiding the management of

relevant information and knowledge involved in construction processes. The formalization was used to

define a prototype implementation of the Knowledge Management System using DSpace.

1 INTRODUCTION

The amount of information needed by all the

operatives involved in a construction process to

work properly and successfully is always growing.

For this reason, construction processes – while still

largely relying on intuition and experience – need to

be rationalized through new procedures and tools for

a strict formulation and implementation of efficiency

criteria.

The purpose of this paper is to show how

Knowledge Management (KM) techniques may be

one of those tools, supporting those activities

through a rational organization of the large quantity

of data/information and a capitalization of

consolidated knowledge.

KM is described as follows: “The Knowledge

Management is the systematic, explicit and

deliberate organization, application and renewal of a

company internal knowledge, aiming at maximizing

the effectiveness of the cognitive ground and of the

related advantages” (Wiig, 1999).

This definition makes it easy to understand why

including a KM policy in an organization means

considering knowledge as a key resource to develop,

capitalize, and share, that will determine the future

of its operating strategy. “Knowledge is the

information that changes and modifies the

organization, making the agent capable of new

and/or effective actions” (Drucker, 1996).

Introducing a KM policy into a company means

making knowledge into a key wealth, to develop,

capitalize, and share, and to use as a base for a

company’s operational strategy. The aim of KM is,

in fact, to express, making it accessible to the entire

company, all the knowledge that every operative has

gained with their work, so that the company can gain

an advantage both economically and from a service

quality point of view. An increase in performance

and competitive advantage are the main benefits of

KM; this is the reason why more and more effort

and resources are being spent to define and

implement knowledge management policies into

397

Argiolas C., Concas G., di Francesco M., Lunesu M., Melis F., Pani F., Quaquero E. and Sanna D..

Knowledge in Construction Processes.

DOI: 10.5220/0004549403970404

In Proceedings of the International Conference on Knowledge Discovery and Information Retrieval and the International Conference on Knowledge

Management and Information Sharing (KMIS-2013), pages 397-404

ISBN: 978-989-8565-75-4

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

companies (Alavi and Leidner, 1999; Firestone,

2001).

Some of the applicative uses of this research may

involve third-party inspection services (verification

and validation of the project, technical control of the

building) in the construction sector. In fact, tools

that can manage elementary products as defined are

the foundation of good quality in project validation

for public works, thus being vital for a systematic

approach by contracting authorities.

One of the instruments of KM is its knowledge

base (a knowledge base is an information repository

that provides a means for information to be

collected, organized, shared, searched and utilized):

developing a knowledge base means rationalizing

and clearly conveying the dynamics and know-how

structure of a company (Malhotra, 1998; Stankosky,

2005; Maier, 2010).

This work sought a rational organization of large

amounts of data using the knowledge that

characterizes the various stages of a construction

process. The approach used to formalize the

knowledge is based on the top-down and bottom-up

analysis.

The first step to implement a KM system is to

define its base content, schemes, and structures, in

order to enter and offer the knowledge collected by

all the participants to a project. We suggest the

concept of elementary product, described further

below, as the basic unit needed to create the

knowledge base of a construction project.

The paper is structured as follows: in Section

Two we present an overview about the state of the

art and in Section Three we propose the research

questions, the knowledge base, the analysis method

and the prototype implementation using KMS. In

Sections Four and Five we describe the top-down

and bottom-up analysis. Lastly, Section Six includes

the conclusion and reasoning about the future

evolution of the work.

2 RELATED WORK

According to some researches, knowledge exchange

in the construction industry is based on non-

developed models (Egbu and Suresh, 2008), and

studies for the application of Knowledge

Management techniques to the sector were

developed only recently, as proven by (Alsakini et

al., 2008) and (Loforte Ribeiro, 2008).

An essential aspect of that is the development of

tools to support management of variables in

construction processes (Argiolas and Quaquero,

2008).

Tools are being defined that could make the flow

of information pertaining a construction project

more efficient and univocal, outlining a new model

that includes both a qualitative description of the

work and its production.

It means structuring projects so that the

information they contain can flow efficiently,

without letting construction site the option of

inferring things that could cause substantial changes.

The research starts from the development of

preliminary concepts, described also in (Argiolas,

2008), functional to the innovative approach

introduced above. Limiting the chances of inferring,

in fact, is giving an objective value to the project,

which now can register all those reasoning the

designer does not report for brevity’s sake but that

would offer a univocal interpretation to all the other

professionals (designers, commissioners, builders).

It actually means borrowing the approach from the

techniques of Project Management: it starts from the

description of the building through a multi-level tree

structure (i.e., creating a Project Breakdown

Structure, PBS). This approach allows for a

description where components are listed in detail,

down to the most basic ones.

Currently, many international researches have

been developed, using different approaches: the use

of Knowledge Management techniques and the

theorization of virtual models suggested that

knowledge sharing and the ability to manage the

whole cycle of knowledge is indispensable for the

process, so that no knowledge is lost.

A hierarchical knowledge structure is defined in

(Beckman, 1999), starting from information and

applying it to a specific context. Contextualization

of information is one of the pre-requisites of the

construction sector, so approaches to safety during

manufacturing (Argiolas et al., 2008), and timing

and budgeting algorithms (Rigamonti, 2001; Bove,

2008), were developed with that focus.

Knowledge Management is based on information

tools and cutting-edge technologies, defined and

developed in the last 15 years, where knowledge has

become the real added value, and as such, the real

competitive advantage for those companies that

choose to organize it (Tronconi, 2005).

3 RESEARCH DESIGN

Our proposed approach for knowledge formalization

and management, gathered in an annotated

KMIS2013-InternationalConferenceonKnowledgeManagementandInformationSharing

398

electronic corpus in an IR based on the OAI model,

will be described below.

3.1 Research Questions

The research questions are:

RQ1: How can we manage knowledge in a

construction process? Which information can be

formalized?

RQ2: What types of information are more suitable as

metadata, useful for search? Can these types of

information be managed with a KMS?

A construction process is a very complex process,

with many legal constraints and technical elements,

like plans, design, construction site pictures, product

data sheets, construction notes, etc.

Each construction project has many associated

objects: a simple house construction project could

produce 100 different objects. A more complex

construction project, like that of a hospital, could

produce 1,000-2,000 different objects during its life.

Many of those objects are multimedia objects.

3.2 The Knowledge Base

The knowledge base started from the experience in

building projects of the Department of Civil

Engineering and Architecture team, which had

information and objects from many real building

projects. We selected for the analysis a

representative subset of that project for different

kinds of buildings: Hospitals, Primary Schools,

Houses, University Departments, etc.

3.3 Analysis Method

We used an approach that mixed top-down, to

formalize already well-defined knowledge, and

bottom-up to extract information embedded in the

objects produced in the construction process (Civi,

2000; McKeen and Zack, 2006).

The top-down phase started by splitting this

process into subprocesses in an iterative approach, in

order to define the elementary components and

objects involved in the process. The analysis can

work orthogonally with a breakdown process of the

building objects in sub-elements.

The bottom-up phase analyzed the objects created in

the construction process and the information

associated to them. The objects are varied and with

different kinds of information.

We started from the Knowledge Base described

above, which contained several thousands of

elementary objects and 80 building projects. For

example, a data sheet is a document summarizing

the performance and other technical characteristics

of a product, component, material, in sufficient

detail to be used by a design engineer to integrate

the component into a system. Depending on the

specific purpose, a data sheet may offer typical

values, tolerance, colors. Specific materials have

technical data in individual sheets, such as Ethanol:

this includes subjects such as structure and

properties, thermodynamic properties, spectral data,

vapor pressure, etc.

We had too many basic objects to manage and

we had to organize them for knowledge management

purposes. Using the mixed approach, we could

group the objects analyzed during the bottom-up

phase in elements with a semantic meaning based on

the Elementary Product concept defined in the top-

down phase.

3.4 Prototype Implementation using

KMS

The formalized knowledge could be managed using

a KMS, using defined metadata and the multimedia

objects as defined with the analysis method

introduced above. Our choice has fallen on DSpace,

because we had to manage many multimedia objects

and we wanted to promote availability of that

information also for maintenance purposes. DSpace

is an open source software package developed in

2000 in the context of a joint project of the MIT2

Massachusetts Institute of Technology with Hewlett-

Packard. It is a very efficient tool easy to use,

customizable and flexible to allow the management,

the classification and the storage of a vast amount of

knowledge, as proven, for example, by University of

Cagliari in the context of an industrial project that

aimed to create the Analytic Sound Archive of

Sardinia (Pani et al., 2012). DSpace is designed as a

central storage facility able to collect various types

of digital resources: text, images, video, audio,

articles, technical reports, working papers, datasets,

etc.

4 TOP-DOWN ANALYSIS:

DEFINING THE ELEMTARY

PRODUCT

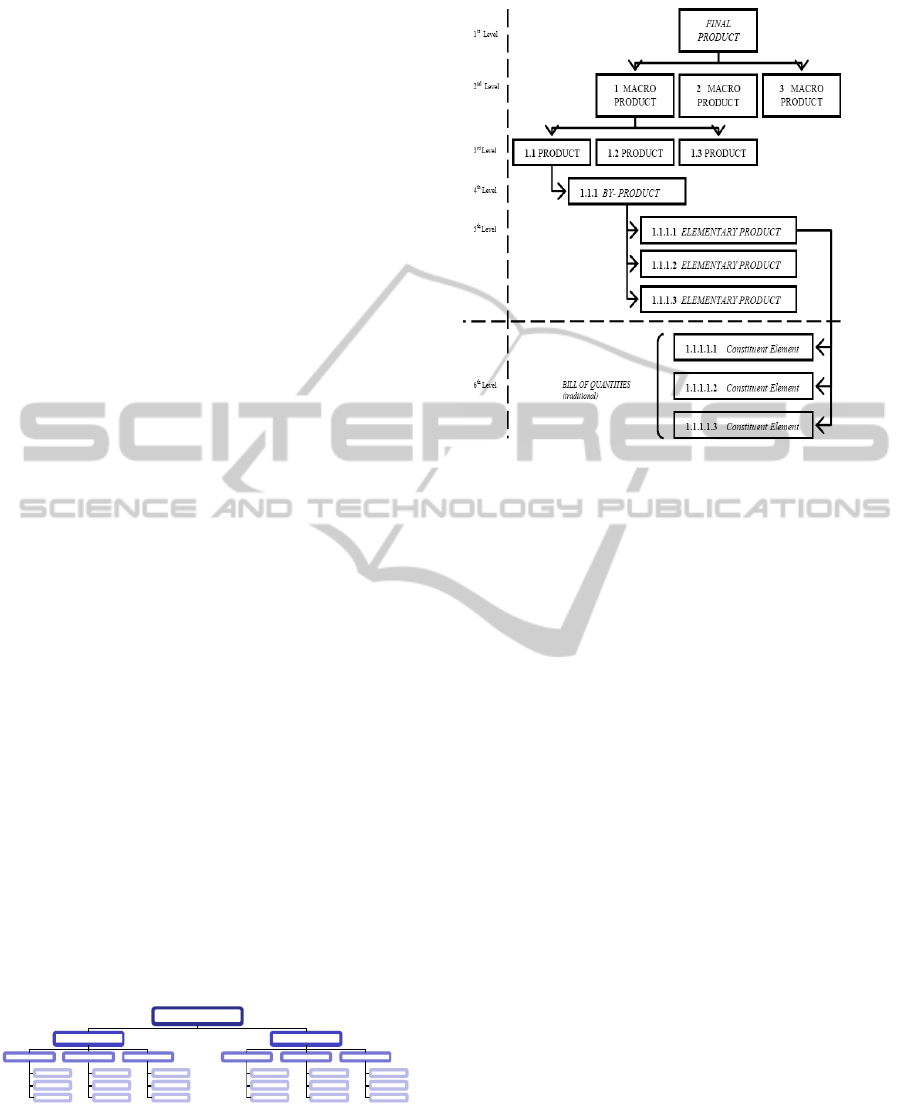

The top-down phase started from the theory to split

the construction process in subprocesses in a logic

that uses an iterative approach, to define the

Elementary Products (EP) and objects that are

KnowledgeinConstructionProcesses

399

involved in the different phases of the building

process. We proceeded with an orthogonal

breakdown of the building objects in sub-elements.

Describing the building object as a tree structure

with several levels, following the top-down

technique (Nepi, 1997), lead to a representation that

defines all of its components down to the most

elementary ones. The building object was resolved

into three elements, called macro products. They

were further subdivided into products and by-

products, progressively less complex, to the level of

desired breakdown. Such a procedure allowed us to

work on smaller and smaller portions, more easily

controllable and manageable, coordinated by a

production simulation. The levels at the base of that

hierarchical tree showed an in-depth and detailed

definition of the work needed for the final product;

moreover, they had an identification code that

highlighted their sequential order in the structure.

The object is broken down into less complex

units, until it reaches an optimal level: it is possible

to operate on smaller and simpler portions (the so-

called “elementary products”), coordinated through

a production simulation. The optimal breakdown

level appears to be the one where the elements are:

flexible, interchangeable with other elementary

products of different quality; identifiable, and

assigned to a manager; manageable: of a

determinable duration and cost; misurable in their

results; significant and interfaceable in their specific

requirements.

Should we make an example, it is easy to

understand how destructuring and performing PBS

(through production simulation) a building leads to

mark the elementary products as pillars. They are

included into the structure as a group of vertical

elements, placed in a given position, with a given

dimension, made with formwork, etc. All these

pieces of information, despite belonging to the same

elementary product, are not to be conveyed to every

person involved in the project, but are organised in a

structure through which each person can access them

differently.

Figure 1: Tree-like breakdown (P.B.S.).

The creation of the PBS and its efficacy in a

process are directly influenced by the level of

accuracy used to identify all the parts of the building

object. The breakdown process finishes when the

Figure 2: Hierarchical breakdown diagram (P.B.S.).

required level of appropriate accuracy is reached. It

is important to remember that the breakdown level

varies according to the characteristics of the work to

carry out. In fact it is correct to say that the PBS can

be divided into any number of levels, according to

the intervention complexity. Nevertheless, if the

destructuring is extreme, it is difficult to keep track

of the general state of the work, particularly if it has

a long-term planning. The products that belong to

the lowest level of the breakdown are called

elementary products (Argiolas et al., 2011).

The breakdown level, which the elementary

product belongs to, allows for an effective

management and control of the process in regard to

the economic, time, and quality properties. So the

project becomes the conception of a building object

in relation to the production possibilities and

methods, and to its employment and maintenance.

The elementary product, which represents the

basic unit of the knowledge base, is configured as

the sum of four basic knowledge units, defined as

follows:

EPd: elementary design product;

EPe: elementary executive product;

EPc: elementary constructional product;

EPm: elementary managerial product.

According to the four views of the EP, the building

process is divided into four phases:

1. Definition of architecture;

2. Project engineering;

3. Construction;

4. Management.

KMIS2013-InternationalConferenceonKnowledgeManagementandInformationSharing

400

Phase 1: Definition of Architecture

Based on a set of needs expressed by the

customer, the designer defines the architecture of the

building object, that is broken down and described

as a set of elementary design products (EPd) related

to each other. In order to meet both the constraints

and the needs, the technical and performance

characteristics are specified. Therefore, at this stage

EPds are structured as a real storage of architectural

design data, information and knowledge.

Phase 2: Project Engineering

After capitalizing on the information and the

knowledge about the object in terms of EPd, each

identified elementary product is defined, and as a

consequence, the building itself is interpreted in

terms of production techniques, technologies,

resources, activities, etc. EPes are structured to

contain all data, information and knowledge related

to this stage.

Phase 3: Construction

Thanks to the capitalization of all the

information on the specific products and materials

selected and used to meet performance and

requirements declared in EPe, EPe evolves in EPc

during the accomplishment of the building process.

Phase 4: Management and Maintenance

EPcs are reliable and updated storages of

information and knowledge, and a starting point to

run and maintain the building object. Building

deterioration, due to time, requires a planned

ordinary and/or extraordinary maintenance, and

consequently it is essential to record all information

related to the life of the building and to its

elementary products. The EPm is the basic unit to

capitalize on the information and the knowledge

concerning the building management and

maintenance.

The building process gradually progresses, and

EPd first becomes EPe, then EPc and finally EPm.

Such a development is the integration of the

information and the knowledge acquired during the

Project Engineering and Construction stages. The

EP is the outcome of the four structures defined

above. Therefore, the EP has to keep track of all

information and knowledge of a specific building

process, including As Built documents and

feedbacks on use. With respect to this aspect, in

Italy, as in most European countries, authorities

require drawings of the object to be built

immediately after the design phase, while as-built

drawings are not mandatory after construction.

However, many changes occur during the

construction phase, and a lack of information on

such changes makes maintaining and/or renovating

existing buildings particularly difficult and onerous.

Moreover, the lack of users’ feedback is an obstacle

to innovate and develop new and more appropriate

products and/or construction criteria for future

building activities.

During the whole building process, EP is the

basis for all parties involved. In fact, at any time

they can dialogue and cooperate, and be kept up to

date about the evolution of the process in terms of

elementary products. Moreover, each involved actor

can modify and/or add data, information and

knowledge concerning each EP. Each Elementary

Product is analysed from different aspects (EPd,

EPe, EPc, and EPm), that are complementary, since

they represent different development stages of a

specific building process.

5 BOTTOM-UP ANALYSIS: THE

BUILDING OBJECTS

The BU analysis started from the objects produced

in the construction process and the information

associated to them. These objects are varied and rich

in many kinds of information. We start to analyze

these very different objects. We have many different

kind of objects gathered during the different phases

of the construction process, such as designs,

pictures, technical sheets/specifications (tables 1 and

2), notes, etc.

Table 1: Brick wall - Technical data sheet (example).

Density DIN 53420 Av 33 kg/m3

Compressive Strength

10%

25%

50%

ISO 3386

0.024 N/mm2

0.043 N/mm2

0.100 N/mm2

Compression Set

(22h,25%, 230C)

½ Hr recovery

24 Hr recovery

ISO 1856

14%

6%

Tensile Strength ISO 1798 0.25 N/mm2

Elongation at Break ISO 1798 100%

Tear Resistance DIN 53575 1.28 N/mm

Thermal Conductivity

ASTM C-

177

0.038 W/mK

Water Absorption

28 days immersion

DIN 53428

0.8 vol %

Water Vapour

Transmission

230C (0-85%rh)

DIN 53429 23 μg/(m2s)

Permeability ISO 1663 10 ng/(Pa.sm2)

KnowledgeinConstructionProcesses

401

Table 2: PVC window - Technical data sheet (example).

Density

(lb/in³)

(g/cm³)

0.048

1.38

Tensile Strength (psi) 10,200

Tensile Modulus (psi) 425,000

Tensile Elongation at Break (%) 36

Flexural Strength (psi) 14,000

Flexural Modulus (psi) 425,000

Compressive Strength (psi) 12,000

IZOD Impact Notched (ft-lb/in) 0.52

Coefficient of Linear Thermal Expansion

(x 10-5 in./in./°F)

7.0

Heat Deflection Temp (°F / °C) at 264

psi

138 / 59

Vicat Softening Temp (°F / °C) 152 / 67

Max Operating Temp (°F / °C) 130 / 54

Surface Resistivity (ohms/square) at 50%

RH

10^6- 10^8

3mm Transparent Clear Transmittance -

Total (%)

69

Haze (%) 6

The analysis shows that we have a knowledge base

with too much very heterogeneous associated

information, multimedia information, design

information, products attributes (as thermal

resistance, insulating capability, etc.) and other

information. All of this information can be

represented using metadata, but and their number

changes depending on the object which we are

analyzing, as shown in the data sheets in table 1 and

table 2.

The main goal of the study is to make available

the knowledge also for searching purpose in a smart

mode. Make a system that manage all these

information can be a solution for a database of all

the element involved in the construction process, but

can't be a solution to manage the knowledge using a

knowledge management approach. We need to

manage the information at a higher level, we have to

group this information in a single object and manage

it as knowledge element. We use the semantic

concept of Elementary Products to aggregate this

information and make available the information

using this level of abstraction.

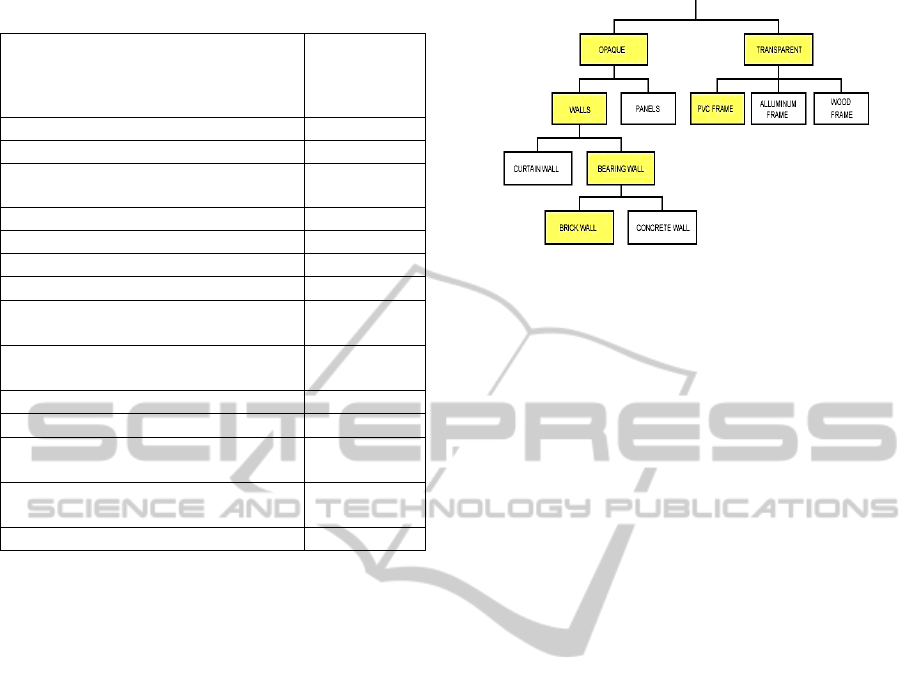

The fig. 3 shows Elementary Product (as part of

WBS) PVC window, which can contain the

information in the data sheet of a PVC window in

table 2 and brick wall which can group all the

information in the table 1.

Moreover, each EP keeps, together with its

attributes, different data gathered during the

Figure 3: The Elementary Products PVC window and

brick wall.

different phases of the construction process, such as

designs, pictures, technical sheets/specifications,

notes.

An analysis on which kind of information is

actually described is then necessary. Properties,

considered as attributes, which could be searched in

the context are stored in two bulk metadata fields

called “General Description” and “Technical

Description”, where the information is not managed

as structured metadata, but with a free logic like in

Folksonomies (what is considered more interesting

is tagged). The technical sheet becomes then the tool

through which information is not transformed into

structured metadata but left as information

belonging to an object, so that is can be searched

according to the most peculiar attributes of that same

object. We select only two important, according with

the semantic of the Elementary Products, metadata

for searching purpose: “ProjectName” and Phase.

This information qualifies the Elementary Product as

the Elementary Product associated with a Project

Phase of a specific project, qualifying the single EP

for a specific project. The other important

information has to be stored in the bulk metadata

fields 'General Description' and 'Technical

Description'. The experts storing the objects decide

which kind of information has to be stored in these

fields as folksonomies.

Where “thermal resistance” is important, it is

marked with a proprietary tag (like in Folksonomies)

inside the general description, while most other

attributes are stored inside the object. Naturally,

important attributes vary depending on each case,

and on each EP, so the description could show

“designer name”, “planning supervisor name”, etc.

A simple management system is thus created, where

knowledge elements are classified following

Folksonomies logic, instead of structured

information, but are available also full text search in

these fields.

KMIS2013-InternationalConferenceonKnowledgeManagementandInformationSharing

402

6 CONCLUSIONS

In this section we discuss the validity threats and the

information gained with the analysis by providing

answers to our research questions.

6.1 Threats to Validity

In the following, threats to internal (whether

confounding factors can influence the findings),

construct validity (relationship between theory and

case study) and external (whether results can be

generalized) are illustrated.

As for internal validity, we analyzed the objects

and verified the structure, and the factors were all

well defined and analyzed. There is no analyzed

element. Regarding the external validity, the

knowledge base that we used is very big and

representative of the general knowledge. The

analysis can be replicated on different data.

Regarding the construct validity, it was assumed that

breakdown of building products in the top-down

phase and the analysis of objects in bottom-up phase

had been applied in the case study. The results are

compliant with the general theory of mixed approach

to analyze knowledge.

6.2 Research Questions

RQ1: How can we manage knowledge in a

construction process? Which information can be

formalized?

The breakdown process of building components in

Elementary Products defines the reference elements

that can manage the multimedia objects.

The Elementary Product:

- is a classification that can be used to define

formalized metadata;

- groups all the multimedia objects in a single

semantic object;

- has associated users select information in form of

Folksonomies tag;

- can be connected with other concepts like

Designer, Project Manager, etc.

The Elementary Product is the core concept of this

knowledge; every instance of a single building

project and the construction process can be managed

using this semantic concept.

The formalized information is the metadata defined

for the Elementary Product.

All other information, like technical data or data

sheet (a PVC window), is present in the multimedia

objects associated with the Elementary Product, and

the interesting information regarding the project can

be represented as a Folksonomy tag.

RQ2: What type of information is more suitable as

metadata, useful for search? Can this type of

information be managed with a KMS?

The structural information of the Elementary

Product is represented as metadata, as well as the

“Project Name”, “Technical description” and

“General Description” where the relevant

information of the project selected by the user can be

found. With this approach and formalization we can

manage all the relevant and embedded information

using DSpace.

6.3 Discussion

The management of very complex knowledge is a

big problem in Knowledge Management research;

the proposed approach reaches its main goal to find

a rational organization of such large amounts of

information. The technical and multimedia

information are very various and contain interesting

information embedded. The solution proposed is

based on the very interesting concept of Elementary

Product, which guides the organization of the

knowledge. The implementation of this

formalization in a KMS like DSpace demonstrates

that this knowledge base can be represented using

this formalization. Further studies could analyse the

results of the use of this system and the result of the

experience could be used to define further

interesting information that can be formalized as

metadata associated with the Elementary Product.

ACKNOWLEDGEMENTS

This research is supported by Regione Autonoma

della Sardegna (RAS), Regional Law No. 7-2007,

project CRP-17938 LEAN 2.0

REFERENCES

Alavi, M. and Leidner, D. E. (1999). Knowledge

management systems: issues, challenges, and benefits.

In Journal Communications of the AIS, Vol. 1, Issue

2es, Article No. 1.

Alsakini, W., Kiiras, J. and Huovinen P. (2008). An

integrated information system of a virtual construction

management service company, Joint CIB Conference

W102 Information and Knowledge Management in

Building W096 Architectural Management, ISBN:

978-951-758-492-0.

KnowledgeinConstructionProcesses

403

Argiolas, C. (2008). Raccontando il dettaglio: ricerca e

sperimentazione nel processo di produzione e

management edilizio, Lithos Grafiche Editore,

Cagliari, ISBN: 978-88-95398-04-4.

Argiolas, C., Melis, F. and Quaquero, E. (2008).

Knowledge Management as a safety management

strategy in building sites, Joint CIB Conference W102

Information and Knowledge Management in Building

W096 Architectural Management, ISBN: 978-951-

758-492-0.

Argiolas, C., Melis, F. and Quaquero E. (2011).

Knowledge management in building process, Joint

CIB Conference W078-W102 Computer, Knowledge,

Building, Sophia Antipolis, France, ISBN: 978-90-

6363-068-3.

Argiolas, C. and Quaquero, E. (2008). L’elaborazione

dell’offerta economicamente più vantaggiosa. In

Argiolas, C. (a cura di), L’edilizia disegnata dal

Decreto Legislativo n.163 del 2006: Analisi dei punti

critici per gestire la complessità, Lithos Grafiche

Editore, Cagliari, pp. 119-147, ISBN: 978-88-95398-

03-7.

Beckman, T. (1999). The current state of Knowledge

Management, Knowledge Management Handbook, J.

Liebowitz (Editor). CRC Press LCL, Boca Raton (FL).

Bove, A. (2008). Project Management: la metodologia dei

12 step, Hoepli.

Civi E. (2000). Knowledge management as a competitive

asset: a review, Marketing Intelligence & Planning,

Vol. 18, Issue 4, pp.166-174.

Drucker, P. F. (1996). Il grande cambiamento, Sperling &

Kupfer.

DSpace, http://www.dspace.org

Egbu, C. and Suresh, S. (2008). Knowledge Mapping

Techniques Within The Construction Industry: An

Exploratory Study, Joint CIB Conference W102

Information and Knowledge Management in Building

W096 Architectural Management, ISBN: 978-951-

758-492-0.

Firestone, J. M. (2001). Key issues in knowledge

management. In Knowledge and innovation, 1(3), pp.

8-17.

Loforte Ribeiro, F. (2008). Knowledge management in

construction sites: a comparative case study, Joint CIB

Conference W102 Information and Knowledge

Management in Building W096 Architectural

Management, ISBN: 978-951-758-492-0.

Maier, R. (2010). Knowledge Management Systems:

Information and Communication Technologies for

Knowledge Management, Springer London, ISBN:

3540714081, 9783540714088.

Malhotra, Y. (1998). Knowledge Management for the new

world of business. In Journal for Quality and

Participation, pp. 58-60.

McKeen, J. D. and Zack, M. H. (2006). Knowledge

Management and Organizational Performance: An

Exploratory Survey. In Proceedings of the 39th

Annual Hawaii International Conference on System

Sciences (HICSS '06), Vol. 7.

Nepi, A. (1997). Introduzione al project management. Che

cos'è, come si applica, tecniche e metodologie,

Edizioni Angelo Guerini e Associati.

Pani, F. E., Lunesu, M. I., Concas, G., Stara, C. and

Tilocca, M. P. (2012). Optimization of Knowledge

Availability in an Institutional Repository,

International Conference on Knowledge Engineering

and Ontology Development

, KEOD 2012, Barcelona,

Spain.

Pani, F. E., Lunesu, M. I., Concas, G., Stara, C. and

Tilocca, M. P. (2012). Knowledge Formalization and

Management in KMS, International Conference on

Knowledge Management and Information Sharing,

KMIS 2012, Barcelona, Spain.

Rigamonti, G. (2001). La gestione dei processi di

intervento edilizio, UTET.

Stankosky, M. (2005). Creating the Discipline of

Knowledge Management, Elsevier, Burlington, MA.

Tronconi, O. (2005). Tecnologie informatiche e imprese di

costruzioni, Il Sole 24 Ore.

Wiig, K. (1999). Introducing Knowledge Management

into the Enterprise. In Knowledge Management

Handbook, J. Liebowitz (Ed.), CRC Press LCL, Boca

Raton (FL).

KMIS2013-InternationalConferenceonKnowledgeManagementandInformationSharing

404