Wood Piece Quality Evaluation using Choquet Integral and Fuzzy

Merging

Jeremy Jover

1,2

, Vincent Bombardier

1,2

and Andre Thomas

1,2

1

Universit

´

e de Lorraine, CRAN, UMR 7039, Campus Sciences, BP 70239,

54506, Vandœuvre-l

`

es-Nancy Cedex, France

2

CNRS, CRAN, UMR 7039, Vandœuvre-l

`

es-Nancy Cedex, France

Keywords:

Virtual Quality, RX Computed Tomography, Information Fusion, Fuzzy Operators, Choquet Integral,

Divergent Process.

Abstract:

This paper presents a way to evaluate the wood product quality according to his tomographic image. The use

of X ray computed tomography and ad-hoc software allows to have a representation of an item (a product)

before the first cutting operation. From this representation, we aim to obtain an honest evaluation of their

aesthetic quality. To do that singularity features are extracted and their impact on the product visual quality

is assesed thanks to the Choquet integral. Next, the visual quality is evaluated by merging singularity impacts

and singularity number criterion using suitable operators. Three operators are compared to the mean operator

which is the commonly used one when there are few knowledge on the decision process.

1 INTRODUCTION

Divergent processes have always presented a diffi-

culty for the traceability implementation. The raw

material cutting leads two problems:

• The link between material and production infor-

mation is difficult to establish and to maintain all

along the product cycle life.

• Foresee the finish products features, which are

very useful for traceability and production man-

agement, is full of uncertainty.

Some solutions are proposed to overcome this

problem especially in the food industry. These solu-

tions are based on marking and documenting batches

(Dupuy, 2004). However a part of the root informa-

tion is lost and an unique identification is not still pos-

sible (what is ideally expected).

The wood industry is also concerned by these di-

vergent process problems. From a tree, products sat-

isfying the end customer’s needs must be produced.

Moreover the product origin traces have to be con-

served for traceability reasons (PEFC1, 2010).The

wood, being a heterogeneous material, increases com-

plexity. Structurally, the wood is composed of aligned

fibres following a longitudinal axe. It not reacts in the

same way following the different axes (longitudinal,

radial, tangential). The wood colour is not homoge-

neous too: the growing rings , the singularity presence

or the fungal attacks (blue stain) create heterogeneity

on visual and mechanical points of view.

In sawmills, the optimization, in order to have the

right products, is an important and complicated task.

Sawyers have to saw products which have characteris-

tics needed by customers, from a raw material which

internal characteristics are unknown. Dimensionally,

it is easy to foresee and have the right product dimen-

sion (apply the cutting pattern), but other features as

the colour or the mechanical resistance are more com-

plicated to estimate and to characterize before the log

is sawed due to their subjectivity character and the

wood heterogeneity.

Our researches is concerned by the information

loss reduction in the wood industry. We have pro-

posed a solution to mark and maintain the origin in-

formation of the trees (Jover et al., 2011). In this

study, we propose a way to determine the wood prod-

uct characteristics before sawing operation in order to

satisfy the customer needs and the optimal determi-

nation of the production element (net requirement for

each product quality class). The proposed approach

aims to automate the product qualification process

(quality product estimation) usually done by an op-

erator. The global process is described Fig. 1.

In this article, we shortly present the wood qual-

ity notion, the sawing optimization process and the

249

Jover J., Bombardier V. and Thomas A..

Wood Piece Quality Evaluation using Choquet Integral and Fuzzy Merging.

DOI: 10.5220/0004553002490256

In Proceedings of the 5th International Joint Conference on Computational Intelligence (FCTA-2013), pages 249-256

ISBN: 978-989-8565-77-8

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

virtual sawing concept allowing to extract the virtual

product. Then we explain how we characterise sin-

gularities and calculate their impact on product with

the Choquet integral. Impact calculation is improved

by using learning process to calculate the Choquet ca-

pacities. To finish, we describe a way to estimate the

wood products quality by using the impact singulari-

ties. We demonstrate the feasibility with distinguish

wood pieces.

2 PRODUCTION FORESEE IN

SAWMILL

2.1 The Visual Quality of Wood

Products

Concerning the needs of the first transformation cus-

tomers

1

, there are three kinds of quality: the dimen-

sional quality, the mechanical quality and the visual

(aesthetic) quality. The dimensional quality is easy

to characterize (dimension piece precision). The me-

chanical quality is more skillful to evaluate. The clear

wood has a mechanical resistance which can be re-

duced by the singularities presence (knots, crack, rot

). Techniques based on the vibrations give results as

explained in (Guillot et al., 1996).

The last one is the visual quality. It is the most

complicated to evaluate because the visual quality is

a subjective decision. The visual quality is defined

in the standard NF EN 1611. This standard defines

different classes of qualities based on the singularity

features measurement (size, numbers, type,...). But

the evaluation is done by a Human Expert which has

to estimate the quality within a short time (accord-

ing to the sawmill high production rate). In this short

time, the expert cannot evaluate singularity features

as precisely as the standard define them. So standard

definition is not adapted to the evaluation. More over

the wood is ”intrinsically fuzzy” (Bombardier et al.,

2007). Boundaries between clear wood and singular-

ities are not so easy to determine and impact the char-

acteristic measures. A big part of the price is based

on the quality, so its determination is important for

customer and sawyers.

2.2 Raw Material Optimization

Sawyers optimise wood by estimating which cutting

plan allows to have the best material yield and satisfy

1

The first transformation of the wood is relative to the

first steps of the wood value chain; that is to say, activities

from the living tree in the forest to the output of the sawmill.

the customer requirement. That is why it is essential

to foresee product features which would be cut in the

log.

The Expert (present at the optimization post) es-

timates product features (dimension, mechanical re-

sistance, visual quality) according to the external log

features and his experiment. He is able to determine

approximately which defects are present in the wood

(according to the external log features) and decides

which cutting plan is the most appropriate to obtain

the customer requirement. So final product aspect

and quality are more or less well determined. We

easily understand that all singularities are not visi-

ble on the surface and singularities which are visible

give only incomplete information on their shapes in

wood. Lot of researches have proposed solutions tak-

ing into account the external shapes of logs (Todor-

oki and R

¨

onnqvist, 2002). But these optimisations are

only based on the log dimensional features and do not

take into account the visual and mechanical charac-

teristics. This paper proposed a way (virtual sawing)

to address this issue.

2.3 Virtual Sawing

The use of non destructive control techniques (Bu-

cur, 2003), in particular X ray computed tomography,

allows to have a 3D representation of the log (inter-

nal and external) to be cut. (Almecija et al., 2012)

use volumetric information to improve part log qual-

ity determination and their sorting. In our proposition

we investigate this step and the global process is de-

scribed in the figure 1.

Figure 1: Extraction and exploitation process of virtual

products.

The log representation is virtually sawed with an

ad-hoc software according to a cutting plan. This

leads to obtain a numerical view of all product faces

which should be obtained. The figure 2 shows one

face for one product. The obtained image represents

the face of a product according to the density data.

IJCCI2013-InternationalJointConferenceonComputationalIntelligence

250

Some information cannot be obtained (the colour) and

the distinction between detected object is not so easy.

All of these add imperfection, imprecision and uncer-

tainty and make the quality determination harder.

Figure 2: Example of a face extracted with the virtual saw-

ing.

2.4 Problematic

Our aim is to propose a process to estimate the wood

product quality according to the face picture extracted

by the virtual sawing stage. We consider that the sin-

gularity features are computed in a similar way as

(Bombardier et al., 2007). So we propose a way to

determine quality products from these measurements.

As obtained information is uncertain, incomplete and

imprecise, we use methods allowing taking into ac-

count this imperfection especially the Choquet Inte-

gral and fuzzy fusion operators. In this paper, we de-

cide to estimate the singularity impact on the product

and then to determine the piece quality.

3 SINGULARITY IMPACT

EVALUATION

L

p

Product length

l

p

Product width

I

p

Product grey level

T

s

Singularity size

X

s

Singularity position on product length

Y

s

Singularity position on product width

I

s

Singularity grey level

3.1 Singularity Criterion Measurement

In our study, we evaluate the visual quality of the

wood. So the criteria have to reflect singularity im-

pact on the visual quality. (Almecija et al., 2012) de-

fines forty criteria to evaluate quality. From this forty

criteria, only around twenty concern the final product

and only a dozen the visual quality. To evaluate sin-

gularity impact on density data, we only use the four

of them which are measurable on a grey scale image.

The first criterion u

t

, described by the equation

(1), reflects the singularity size. More a singularity is

big, more the visual quality is down grading. More-

over the expert judgement stipulates a singularity

higher than 50 mm is considered as highly critical.

If l

p

≤ 50 mm,u

t

= 1 −

T

s

l

p

If l

p

> 50 mm and T

s

≤ 50 mm,u

t

= 1 −

T

s

50

If l

p

> 50 mm and T

s

> 50 mm,u

t

= 0

(1)

The second criterion u

x

, described by the equation

(2), reflects the position of the singularity on the prod-

uct length. More a singularity is close to the prod-

uct end, more this singularity lost importance and the

quality becomes higher.

u

x

=

|L

p

/2 − X

s

|

L

p

/2

(2)

The third criterion u

y

, described by the equation

(3), reflects the position of the singularity on the prod-

uct width. More a singularity is close to the prod-

uct edge, more this singularity lost important and the

quality becomes higher.

u

y

=

|l

p

/2 −Y

s

|

l

p

/2

(3)

The last criterion u

c

, described by the equation (4),

reflects contrast between the singularity and the prod-

uct background. More the contrast is weak, less this

singularity is visible and more the quality increases.

u

c

= 1 −

|I

s

− I

p

|

I

p

(4)

In the following part, we proposed a method using

Choquet integral according to the fact that the singu-

larity characteristic measurements are full of imper-

fection and imprecision (see section 2).

3.2 Impact Calculation using the

Choquet Integral

The Choquet integral was proposed by Gustave Cho-

quet in 1954 (Choquet, 1953). Their use in the

multi-criteria decision making domain appears in the

nineties in different context (car industry, strategical

placement, ) and similar classification problems are

usually process with the Choquet integrals (Grabisch

and Labreuche, 2008). They allow taking into con-

sideration importance of each criterion and the inter-

actions existing between each of them.

Let {X} : {x

1

,...,x

n

} be a set of normalized crite-

ria, consider a capacity µ : ℘(X ) → [0,1] on this set,

verifying:

µ(

/

0) = 0

µ(X) = 1

µ(A) < µ(B), ∀A ⊂ B and ∀B ⊂ X

(5)

The capacity defines all weights and interactions.

Then Choquet integral is defined as follow:

C

µ

(u

1

,..., u

n

) =

n

∑

i=1

(u

σk

− u

σk−1

)µ(A

σk

) (6)

WoodPieceQualityEvaluationusingChoquetIntegralandFuzzyMerging

251

Where σ is the indices permutation satisfying:

0 = u

σ0

≤ u

σ1

≤ ... ≤ u

σn−1

≤ u

σn

≤ 1

u

σ1

= Min(u

i

) et u

σn

= Max(u

i

)

(7)

and A

σk

= {g

σk

,..., g

σn

} the features non used in pre-

vious steps.

In our case, C

µ

(u) corresponds to the measure of

the singularity impact on the product when the Cho-

quet integral is apply on the criteria (µ

i

). More the

value tends to 1, less the singularity is important (our

own standards). The Choquet integral is useful when

the knowledge and the learning batches are low. The

greatest challenge is the definition of the capacities

(Grabisch et al., 2008). To do so, some approaches

were developed to learn the capacities. We detail

them in the next subsection.

3.3 Learning Process of the Capacities

In order to have a better definition of the capacities

used in the Choquet integral, we decide to use a learn-

ing process. Different approaches can be used to iden-

tify capacities (Grabisch et al., 2008):

• The Least Square approach (LS): based on the

expert knowledge on each element. The expert

attributes a target impact value to each element

(experted value) in the learning lot and system

searches capacities values that minimise the dif-

ference square between the computed value and

the expected value.

MinF

LS

(µ) :=

∑

x∈O

[C

µ

(u(x)) − y(x)]

2

(8)

• The Linear Programming approach (LP): pro-

posed by Marichal and Roubens in (Marichal and

Roubens, 2000), it is based on the expert knowl-

edge on the global ranking of the batch elements.

The approach looks for the value which satisfy as

closely as possible the ranking establish by the ex-

pert.

MaxF

LP

(ε) := ε

subj. to

∑

T ⊆S

m

ν

(T ∪ i) ≥ 0, ∀i,∀S

∑

T ⊆N

m

ν

(T ) = 1

C

ν

(u(A)) −C

ν

(u(B)) ≥ δ

C

.

.

.

(9)

In (Grabisch et al., 2008), authors explain that the

least square approach is appropriate when it is pos-

sible to attribute precisely the desired value. They

explain too that the linear programming is better for

cases which it is easy to give a pre-order between the

learning lot element. This is our case for the evalu-

ation of the singularity impact because it is hard for

the expert to give a score for each singularities (due

to number and variation of the cases). The expert de-

cides of a pre-order between elements composing the

learning batch (with a δ

C

corresponding to the mini-

mum margin to respect the ranking) . This constraint,

noted E, can be translate by:

C

µ

(a) > C

µ

(b) > ... > C

µ

(k)

with C

µ

(u(i)) ≥ C

µ

(u(i + 1)) + δ

C

(10)

Some conditions can be imposed, over the element

pre-order, on the criterion importance and/or interac-

tion. The expert can expressed the criterion impor-

tance against one another. By the used of the Shapley

indices φ (which indicates the global importance of

each criterion), the expert expresses the equality be-

tween two criteria. The value δ

φ

is the maximal dis-

tance between two Shapley values to consider two cri-

teria are equal. This constraint, noted S, can express

for a couple of criteria A and B as:

−δ

φ

≤ φ

ν

(µ

A

) − φ

ν

(µ

B

) ≤ δ

φ

(11)

More over the Expert can express constraints on

the interaction between the criteria. The interaction

between two criteria can be easily expressed by the

expert because the phenomena is understandable.But

the interaction between more than two criteria is

harder to understand and express. The last condition

(apply on the interaction indices) is only expressed on

interaction between a pair of criteria. This constraint,

noted I, can be:

• negative (redundancy) : I

ν

({A,B}) < 0 − δ

I

• positive (synergies) : I

ν

({A,B}) > 0 + δ

I

• null (no interaction) : I

ν

({A,B}) = 0 ± δ

I

δ

I

is the minimum threshold value in absolute value

to consider the interaction as significant.

Using the software R and the Kappalab R pack-

age, we compute the LP approach in order to deter-

mine the capacities and influence of the calculated

values on the Choquet integral results.

3.4 Result of the Learning Process LP

The learning batch described in the table 1, is com-

posed of singularities which are commonly found in

the wood.

Expert constraints are describe below:

• On the elements batch (E): The singularities are

ranked as they are stored in the table 1 from the

best to the worst with δ

C

= 0.05.

IJCCI2013-InternationalJointConferenceonComputationalIntelligence

252

Table 1: Learning batch.

Singularity T X Y C

a 0.75 0.72 0.2 0.93

b 0.41 0.09 0 0.98

c 0.39 0.27 0.24 0.9

d 0.69 0.36 0.8 0.37

e 0.42 0.75 0.32 0.3

f 0.75 0.81 0.52 0.09

• On the importance criterion (S): criteria [µ

t

,µ

c

]

have the same importance, criteria [µ

x

,µ

y

] too and

criteria [µ

t

,µ

c

] are more important than [µ

x

,µ

y

]

(δ

φ

= 0.1): φ

ν

(µ

t

) = φ

ν

(µ

c

) > φ

ν

(µ

x

) = φ

ν

(µ

y

).

• On the influence among criterion (I): criteria

[µ

t

,µ

c

] are in synergy and [µ

x

,µ

y

] too (δ

I

= 0.05):

I

ν

({µ

t

,µ

c

}) > 0 and I

ν

({µ

x

,µ

y

}) > 0.

The results of the Choquet value, the Shapley val-

ues and the interaction indices are respectively pre-

sented in the table 2, 3 and 4. In table2, the sec-

ond column corresponds to values obtained without

any importance( singleton capacity equal to 0.25) and

constraints (other capacity equal to the sum of the sin-

gleton capacities) between criteria.

Table 2: Results for the LP approach for the different con-

straints.

Singularity

/

0 E E+S E+S+I

a 0.65 0.878 0.878 0.873

b 0.37 0.815 0.815 0.799

c 0.45 0.753 0.753 0.738

d 0.55 0.450 0.569 0.593

e 0.46 0.387 0.422 0.532

f 0.49 0.325 0.359 0.471

Table 3: Shapley indices for the different constraints.

Shapley value T X Y C

E 0.152 0.117 0.069 0.662

E+S 0.397 0.074 0.045 0.484

E+S+I 0.322 0.169 0.098 0.411

Imposed Constraints are respected at each steps

(E, E+S,E+S+I). We can see in the table 2 the order

of the singularity is the same as the expert ranking.

The first constraint (based on the elements rank-

ing) accords lot of importance to the contrast (Shap-

ley value φ

ν

(µ

c

) =0.762) and few on the other cri-

teria. Moreover interaction between the criteria [T

C] is negative (that is not corresponding to the expert

choice). The figure 3 shows the variation of the Cho-

quet integral value function of [X Y]. The criterion Y

have few influence except up to 0.75. This translate

an expert view: the singularity position on the width

upgrade the singularity only when it is very close to

the side.

Table 4: Interaction indices for the different constraints

(symmetric matrix).

↓ constraints: E ↓

Interaction T X Y C

T NA 0.006 -0.138 -0.119

X NA 0.131 -0.137

Y NA 0.007

↓ constraints: E+S ↓

Interaction T X Y C

T NA -0.133 -0.090 0.113

X NA 0.179 -0.133

Y NA -0.090

↓ constraints: E+S+I ↓

Interaction T X Y C

T NA -0.219 0.032 0.050

X NA 0.050 -0.285

Y NA -0.226

Figure 3: Influence of the X and Y criteria modification

on the Choquet value with the weights obtained under E

constrain and no variation of the T and C criteria (u =

(0.75,4(X),4(Y ),0.09)).

The addition of the constraint S (on Shapley in-

dices) offers a positive interaction between [T,C] but

not on [X,Y]. Moreover the importance of the criteria

[X,Y] are so little that they have few influence on the

Choquet value. The figure 4 shows the Choquet value

variation function of X and Y variation for a singular-

ity (u = (0.75,4(X),4(Y ),0.09)). The criteria have

no action when theirs values are bellow 0.75. This

comportment means that singularity position is im-

portant only when a singularity is close to the end and

the side of the product.

The addition of the last constraint gives capacities

which allow the respect of the constraints given by

the expert. Moreover all criteria have impact on the

calculation result. The figure5 translates the [X,Y]

impact. Thereafter we use this weight for the product

quality estimation.

WoodPieceQualityEvaluationusingChoquetIntegralandFuzzyMerging

253

Figure 4: Influence of the X and Y criteria modification

on the Choquet value with the weights obtained under E+S

constrains and no variation of the T and C criteria (u =

(0.75,4(X),4(Y ),0.09)).

Figure 5: Influence of the X and Y criteria modification on

the Choquet value with the weights obtained under E+S+I

constrains and no variation of the T and C criteria (u =

(0.75,4(X),4(Y ),0.09)).

4 PRODUCT QUALITY

EVALUATION

Once singularity impacts are determined, an estima-

tion of the quality product is evaluated by merging

these impact and the criterion evaluating the singular-

ity number. In this part, we describe this criterion and

the fusion operation.

4.1 Singularity Number Criterion

In the quality evaluation, the number of singularities

is important. A product with a lot of singularities is

more down grading because the clear wood homo-

geneity is broken.

To evaluate the number, we used the criterion R

nb

defined by (12). This criterion represents the expert

vision: more there are singularities, more the product

is down grading. Moreover when the number reaches

towards a particular value, the criterion reaches to-

wards 0. We choose to used an exponential function.

Following the particular number of singularities fixed

by the expert, the k coefficient can be changed. In

our case we determine that up to 20 singularities, the

value starts to become constant (k=1.1).

u

nb

= k

−(NB

s

)

with k = 1.1 (12)

4.2 Quality Determination by Data

Fusion

In order to determine the quality product, we merge

singularity impacts and the singularity number cri-

terion. There are three kinds of merging operators

(Bloch, 1996):

• The severe operators which satisfy

F(a,b) ≤ Min(a, b)

• The indulgent operators which satisfy

F(a,b) ≥ Max(a, b)

• The compromise operator which satisfy

a ≤ Fa,b ≤ b, if a ≤ b

b ≤ Fa,b ≤ a, if b ≤ a

In the quality evaluation, Expert never evaluates

products on the best singularities. So indulgent oper-

ators cannot be used. The two others operators trans-

late different visions from the expert in the quality

evaluation. We propose to compare different opera-

tors which appear us to be well adapted to the used

and Expert quality evaluation.

The first operator which can be used is the opera-

tor defined by Perez-Orama in (Perez Oramas, 2000)

and describe by 13. This operator (PO) is a compro-

mise operator when the minimum value is under 0.5,

otherwise it is an indulgent operator. This character-

istic can be interesting to isolate product with few sin-

gularities and evaluate the worst product.

F(a,b) = Min(1,

min(a,b)

1 − Min(a,b)

) (13)

The Hamacher operator, described in 14, is a se-

vere operator. That means this operator gives result

under the worst singularity. This can be useful to eval-

uate quality for product where visual quality is very

important (joinery, cabinet, ...) because only products

with high quality are highlighted.

F(a,b) =

ab

a + b − ab

(14)

The Ordered Weight Average(OWA) adapted to

our situation too, described in 15, is a compromised

operator. Usually the product quality is based on a

part of the worst singularities (represented by the α

which represent the percent of product fusion). The

OWA allows to attribute weight only on this part of

the singularities impact C

i

.

F(C

1

,...C

n

) =

n

∑

i=1

w

i

C

i

and C

1

≥ C

2

≥ ... ≥ C

n−1

≥ C

n

with

w

i

= 0, ∀i ∈ [1, bαnc]

w

i

=

1

α∗NB

s

∀i ∈ [dαne, n]

(15)

IJCCI2013-InternationalJointConferenceonComputationalIntelligence

254

The results provided by these three operators will

be compared to the arithmetic mean (used as a bench-

mark) which is a classical operator when the aggrega-

tion comportment is unknown.

4.3 Operators Comparison by the use of

Real Case Study

The proposed methodology is then applied on the

batch described in the table 5. These data is taken

in into our partner sawmill. The first column indi-

cates the piece number, the second the criterion R

nb

(function of the number of singularities), the third, all

the singularities impact present on the product and the

last the product aesthetics class gives by the sawmill

Expert. The aim is to compare some fusion operators

to the expert vision so as to find the closest.

Table 5: Pieces used to compare fusion operators.

Prod R

nb

C

u

Q

a 0.91 0.888 0

b 0.91 0.439 1

c 0.42 0.888 0.866 0.826 0.776 1

0.748 0.746 0.674 0.601

0.520

d 0.75 0.814 0.740 0.259 1

e 0.75 0.888 0.372 0.332 2

f 0.51 0.814 0.740 0.694 0.601 2

0.565 0.432 0.312

g 0.51 0.725 0.667 0.587 0.479 3

0.423 0.372 0.332

• Piece 1: only one singularity with few impact

(value close to 1), used for cabinet work.

• Piece 2: only one singularity with high im-

pact,used for joinery work.

• Piece 3: lot of singularity with few impact, func-

tion of the use, the quality can be high or not

thanks to the singularities number. in our case the

expert class the product for joinery.

• Piece 4 and 5: the same number of singularities

but one with more singularities with few impact

(4) used for joinery work and the other the oppo-

site (5) used in industrial carpentry.

• Piece 6 and 7: more singularities than 4 and 5.

Used respectively in industrial carpentry and tra-

ditional carpentry.

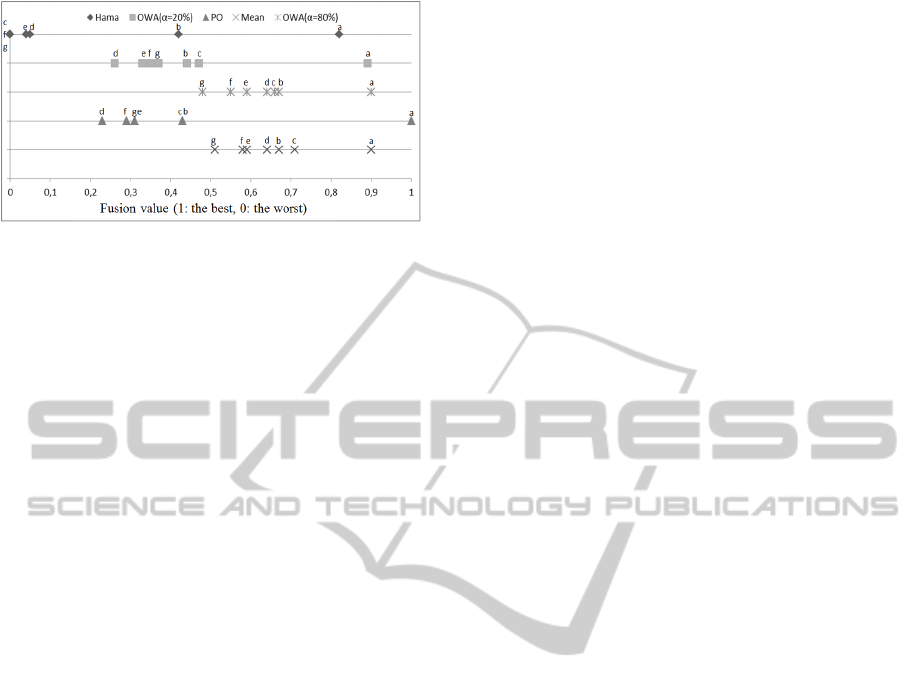

To compare the operators, two features are stud-

ied: the products ranking (cf. table 6) and the dis-

tance between them (cf. figure 6). Operators have

to be compared on the distance between ranked prod-

uct and the products groups they do. If the ranking is

good but groups are totally different from the Expert

choice (two products by in the same aesthetic class

on the Expert judgement have to be close one to the

other) the operator is less efficient than an operator

which wrong ranks but keeps the right group of prod-

ucts.

Table 6: Piece ranking for each fusion operator.

Rank Exp Hama OWA OWA PO Mean

(α =.2) (α =.8)

1 a a (.82) a (.89) a(.90) a (1) a (.90)

2 b b (.42) c (.47) b(.67) b (.43) c (.71)

3 c c (.05) b (.44) c(.66) c (.43) b (.67)

4 d e (.04) f (.37) d(.64) e (.31) d (.64)

5 e c (.0) g (.35) e(.59) g (.31) e (.59)

6 f f (.0) e (.33) f(.55) f (.29) f (.58)

7 g g (.0) d (.26) g(.48) d (.23) g (.51)

The Hamacher operator, as it is the only pessimist

operator, gives the lowest results. This operator his

very efficient to highlight product which have good

features. When there is a lot of singularities, this oper-

ator reaches towards highly downgrade product (up to

2 singularities, maximum value is 0.5). Three groups

of product are made: (a,b) on the top as the expert,

(e,d) and (c,f,g) on the low. These seconds two groups

mix quality product express by the Expert.So this op-

erator is useful to evaluate high quality products.

The Perez-Orama operator gives high importance

to product with all singularity impacts up to 0.5 and

downgrade the others. It assumes that products with

less than 8 singularities with an impact up to 0.5, have

a quality equal to 1. This operator is particularly use-

ful for a first ranking and extracts products described

above (less than 8 singularities with impact up to 0.5).

The operator place on opposite ends a and d and does

two groups, (b,c) and (e,f,g). This classification is

close to the expert choice (apart for d). This opera-

tor is efficient to class low quality products.

The α factor in the OWA operator may change

value. We propose to compare α = 0.2 and α = 0.8.

In the α = 0.2 case, the ranking gives, as the PO op-

erator, four classes ((a),(c,b),(e,f,g,) and (d)) and the

same observation as the previous operator. In the

α = 0.8 case, the ranking is the same than the ex-

pert one. Moreover, product groups provided by this

operator are the same than the expert classification

((a),(b,c,d),(e,f),(g)). Classes are close to one another

but allowed to classify product as the expert estima-

tion. The Expert which choose this ranking should

have a decision process following this vision.

The last is the mean operator. It gives differ-

ent ranking than the expert ranking but the products

groups are respected. This operator may be used to

group product with the same features without respect

the ranking. This behaviour is interesting for carpen-

try product for which the ranking is not important.

WoodPieceQualityEvaluationusingChoquetIntegralandFuzzyMerging

255

Figure 6: Product ranking for each operator.

5 CONCLUSIONS

In this article, we present a way to determine the prod-

uct quality in the wood industry. We decided to base

the product quality evaluation on the singularities im-

pact. As the information used to determine the sin-

gularity impact and the quality product are uncertain,

imprecise, imperfect, we have to use operators which

take into account of them.

The singularity impact is evaluated on criteria

which are linked by interaction. Moreover, the poor-

ness of the sample and the knowledge on the process

decision, lead us to use the Choquet integral to de-

termine impact. The quality determination is done by

merging the singularity impact and the number of sin-

gularities. The use of different operators allows us

to cover the majority of cases concerning the prod-

uct quality determination. The comparison with the

expert ranking and classification allows to conclude

OWA operator with α = 0.8 reflects his choice.

This quality have a virtual nature. Moreover it is

expressed with a regression value while Experts use

linguistics quality classes. To take into account the

virtual nature and the linguistics class representation,

a fuzzyfication step may be used to obtain the belong-

ing to quality classes as expressed by Expert.

All of that allows to conclude to the pertinence of

our proposition. In perspective, other decision ways

will be used and in particular the evaluation of the

quality from the singularity characteristics (only one

step). To do so, other fusion operators will be used as

the Fuzzy Rule Classifier or classification operators.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the financial sup-

port of the CPER 2007-2013 Structuration du P

ˆ

ole de

Comp

´

etitivit

´

e Fibres GrandEst (Competitiveness Fi-

bre Cluster), through local (Conseil G

´

en

´

eral des Vos-

ges), regional (R

´

egion Lorraine), national (DRRT and

FNADT) and European (FEDER) funds.

REFERENCES

Almecija, B., Bombardier, V., and Charpentier, P. (2012).

Modeling quality knowledge to design log sorting sys-

tem by x rays tomography. In Information Control

Problems in Manufacturing, volume 14, pages 1190–

1195.

Bloch, I. (1996). Information combination operators for

data fusion: A comparative review with classification.

Systems, Man and Cybernetics, Part A: Systems and

Humans, IEEE Transactions on, 26(1):52–67.

Bombardier, V., Mazaud, C., Lhoste, P., and Vogrig, R.

(2007). Contribution of fuzzy reasoning method to

knowledge integration in a defect recognition system.

Computers in industry, 58(4):355–366.

Bucur, V. (2003). Techniques for high resolution imaging of

wood structure: a review. Measurement Science and

Technology, 14(12):R91.

Choquet, G. (1953). Theory of capacities. In Annales de

l’institut Fourier, volume 5, page 87.

Dupuy, C. (2004). Analyse et conception d’outils

pour la trac¸abilit

´

e de produits agroalimentaire afin

d’optimiser la dispersion des lots de fabrication. PhD

thesis, Institue National des Sciences Appliqu

´

ees de

lyon.

Grabisch, M., Kojadinovic, I., and Meyer, P. (2008). A re-

view of methods for capacity identification in choquet

integral based multi-attribute utility theory: Applica-

tions of the kappalab r package. European journal of

operational research, 186(2):766–785.

Grabisch, M. and Labreuche, C. (2008). A decade of ap-

plication of the choquet and sugeno integrals in multi-

criteria decision aid. 4OR: A Quarterly Journal of Op-

erations Research, 6(1):1–44.

Guillot, J., Lanvin, J., and Sandoz, J. (1996). Classement

structure du sapin/

´

epic

´

ea par r

´

eseaux neuronaux

`

a par-

tir des mesures sylvatest. In Sciences et industries du

bois. Colloque, pages 377–384.

Jover, J., Thomas, A., and Bombardier, V. (2011). Mar-

quage du bois dans la masse : int

´

er

ˆ

ets et perspectives.

In 9e Congr

`

es International de G

´

enie Industriel, CIGI

2011, St Sauveur, Canada.

Marichal, J.-L. and Roubens, M. (2000). Determina-

tion of weights of interacting criteria from a refer-

ence set. European journal of operational Research,

124(3):641–650.

PEFC1 (2010). Pefc st 1003:2010: Sustainable forest man-

agement.

Perez Oramas, O. (2000). Contribution une m

´

ethodologie

d’int

´

egration de connaissances pour le traitement

d’images. Application

`

a la d

´

etection de contours par

r

´

egles linguistiques floues. PhD thesis, universit

´

e

Henry Poincar

´

e.

Todoroki, C. and R

¨

onnqvist, M. (2002). Dynamic control

of timber production at a sawmill with log sawing op-

timization. Scandinavian Journal of Forest Research,

17(1):79–89.

IJCCI2013-InternationalJointConferenceonComputationalIntelligence

256