Surface Cleaning Force Control of Rotating Brushes

for an Air Duct Cleaning Robot

Wootae Jeong

1

, Seung-Woo Jeon

2

, Duckshin Park

1

and Soon-Bark Kwon

1

1

Eco-Transport Research Division, Korea Railroad Research Institute,Gyeonggi-do,Uiwang, Korea

2

Department of Virtual Engineering, University of Science and Technology, Daejeon, Korea

Keywords: Force Control, Compliance Device, Kinematic Analysis, Service Robot, Air Duct Cleaning.

Abstract: Due to the complexity of the air duct and ventilation system, removing accumulated dusts and particular

matters at inner surface of air duct system becomes key issue for improving indoor air quality and

maintaining the green environment of underground facilities. Although various tools and technologies for

air duct cleaning have been developed, mechanical brushing method is evaluated as the most effective

method in cleaning duct and ventilation system. Therefore, automotive duct cleaning robot with rolling

brushes has been developed in this study. In particular, by adding compliant force feedback sensors to the

rolling brushes, the developed cleaning robot can control the cleaning force consistantly between brush and

duct surface. Force feedback control algorithm has been also developed and evaluated through control

simulation tools.

1 INTRODUCTION

The HVAC(Heating, Ventilating, and Air

Conditioning) system that supplies fresh and clean

air from outdoor environment has been utilized in

most of closed spaces such as modern buildings and

subway facilities where people work and spend most

of their daily hours. Due to the complexity of the air

duct and ventilation system and long period of

cleaning and maintenance, various types of

infiltrated particles and dusts are accumulated at

inner surface of the duct without being exhausted.

Figure 1 shows pictures of before and after cleaning

duct. In general, the accumulated dusts and particles

flow into the living space and influence on the

human respiratory system and health. In addition,

the accumulated dusts and particles can reduce the

efficiency of the air conditioning and heating of the

HVAC system reported by Brosseau et al., 2000

Furthermore, the closed structure of ducts provides a

good propagating circumstance of microorganisms

including viruses and bacteria. Recently some

contraries have established the regulation and

guideline for ventilation system cleaning (FiSIAQ,

2001), however, many countries still do not have

legal regulations about cleaning ventilation systems.

Recently, the research and development of duct

Figure 1: Before cleaning Air duct and After Cleaning.

cleaning technology has been conducted widely as

concerns and requests of improving air quality are

increasing. In fact, duct cleaning techniques can be

classified as a dry method such as blowing out with

compressed air and scraping out using mechanical

brush and a wet method spraying water or chemical

solution. Especially, the mechanical brushing is

widely used because of its higher cleaning efficiency

and accessibility. Various types of robots with

mechanical cleaning tools have been developed and

used for specific air duct cleaning. However, many

manual cleaning methods are still broadly being

used in cleaning the HVAC systems.

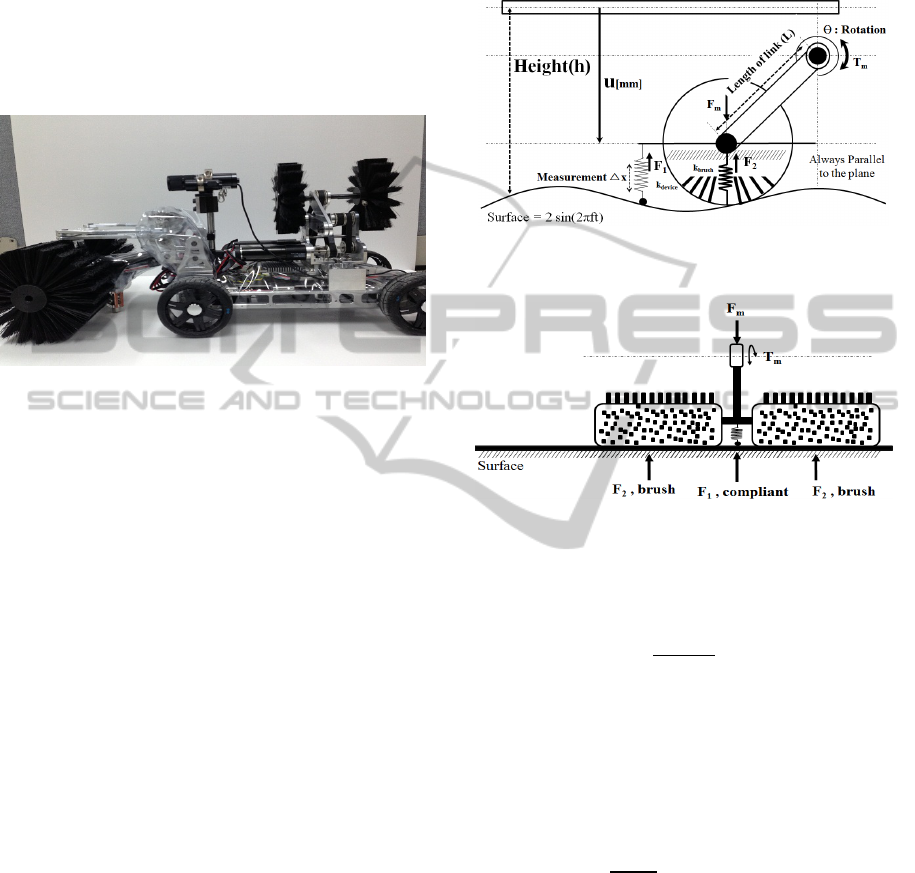

Therefore, in order to provide more efficient and

autonomous mobile cleaning robot platform, a new

mobile robot equipped with mechanical rotating

brushes and sensors has been developed as shown in

Figure 2. In particular, the duct cleaning robot can

clean four sides of inner duct surface simultaneously

453

Jeong W., Jeon S., Park D. and Kwon S..

Surface Cleaning Force Control of Rotating Brushes for an Air Duct Cleaning Robot .

DOI: 10.5220/0004591104530457

In Proceedings of the 10th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2013), pages 453-457

ISBN: 978-989-8565-71-6

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

and utilize spring-based force feedback compliant

device to be adapted at irregular cleaning target

surfaces of ducts.

In this paper, a force feedback control method is

suggested to keep the constant cleaning brush

pressure on the irregular duct surface with simple

spring-based compliant devices. In addition, various

simulations have been conducted to evaluate

performance of the control method.

Figure 2: Prototype of Duct Cleaning Robot.

2 FORCE CONTROL USING

COMPLIANT DEVICE

The pressing force of the rotating brush acting on the

surface of the duct should be sustained constantly to

remove the dusts accumulated firmly on the duct

surface through many years. Higher cleaning

pressure can damage duct surfaces and lower

cleaning pressure may not be enough to remove the

firmly attached dust and contaminants on the duct

surfaces. Therefore, it is important to control the

pressing force of the rotating brush constantly with

respect to irregular surface of inner duct. This

section describes modelling and control of the

rotating brush with a spring-based force compliant

device.

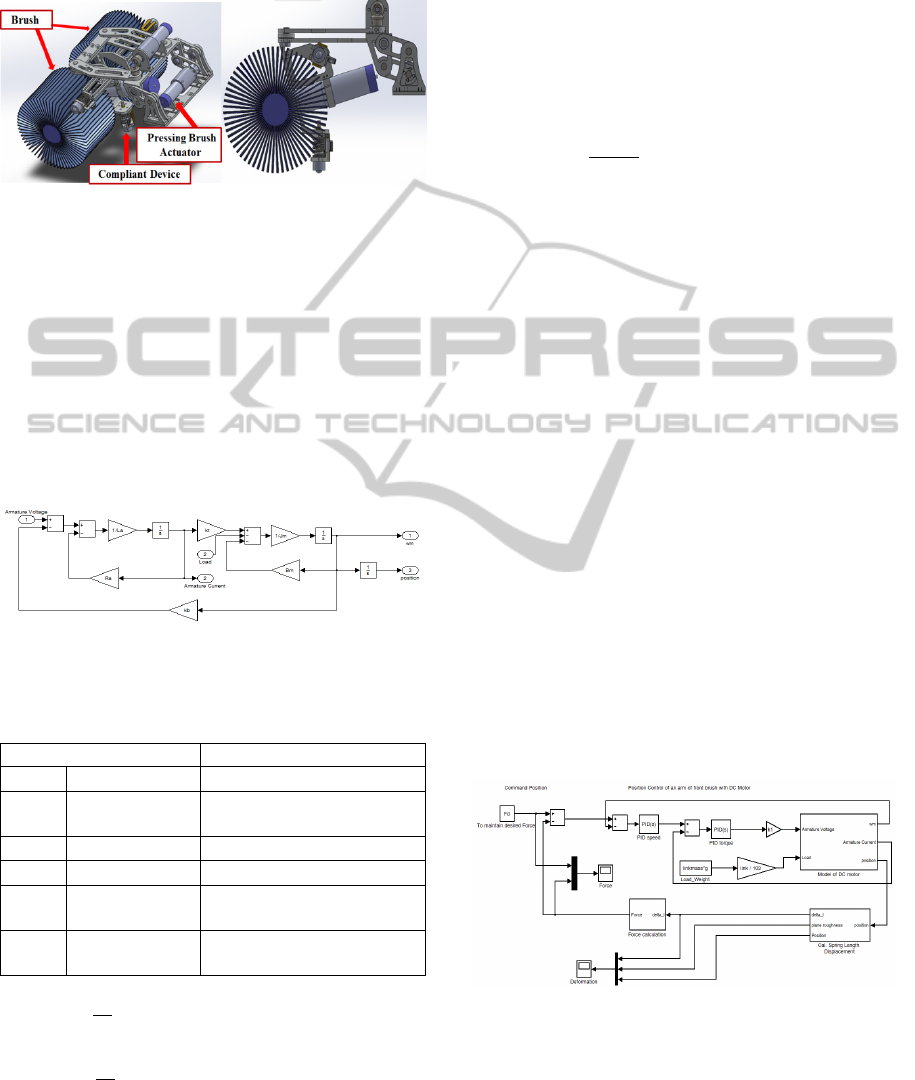

2.1 Modelling of the Mechanical Brush

The compliance device is composed of the linear

spring, linear encoder and ball roller attached at the

end of the spring not to resist for moving with

rotating brush of the robot platform. Figure 3 shows

the free body diagram of the robot arm pressing the

brush to the surface of the duct. Figure 4 illustrates

the forces acting on the surface and brushes. In this

model, only the normal forces to the surface are

considered and tangential force including the friction

force of the surface is neglected. Spring constant of

the compliant device is considered as relatively very

small compared to the elasticity of the brush, which

can also ignore the extra effect for measuring force

caused by the device.

Figure 3: Free Body Diagram of the rotating brush of the

robot arm contacting the surface of the duct.

Figure 4: Frontal View of force equilibrium of pushing the

brush and elastic forces of compliant device and brush.

The force acting on the robot arm(F

m

) can be

expressed by

(1)

where

: the motor torque,

N : gear reduction ratio,

L : effective length of the link.

From Figure 4 the motor torque can be calculated

from the force equilibrium equation given by

2

(2)

T

Lsin

θ

N

F

2F

(3)

where

∆,

.the Δx is a

spring deformation, k is a spring constant of the

compliant device, and

is assumed as the 2

nd

order

displacement of spring by pressing.

Since the actual characteristic of the stiffness of

the brushes shows nonlinear behaviour against

external force, the stiffness of the rotating brush has

been modelled as 2

nd

order polynomial function.

Therefore, simple nonlinearly elastic characteristic is

used to reveal feasibility of the force control with the

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

454

spring deformation feedback. Figure 5 shows the

prototype of the robot arm brush with a compliant

device to measure the deformation of the spring.

Figure 5: Modelling of Robot arm brush with compliant

device.

2.2 Motor Dynamics and Control

The simple DC motor dynamic model shown in

Figure 6 is used in simulation with MATLAB

®

SIMULINK

®

tool. The model is consisted of linear

differential equations of mechanical and electrical

system summarized at Eq.(4) and Eq.(5). Each

motor parameter and values are summarized in

Table 1.

Figure 6: Motor Dynamic Model implemented by

MATLAB

®

SIMULINK

®

.

Table 1: DC Motor Specification.

Parameter Value

Rotor inertia 10.8 g

B

Speed/Torque

gradient

40.3 rpm/mNm

Torque Constant 23.4 mNm/A

Speed Constant 408 rpm/V

Terminal

Inductance

0.238 mH

Terminal

Resistance

2.32 Ω

1

(4)

w

t

l

(5)

(6)

(7)

where

Load from the end of the motor axis,

is

torque proportional to the current

, and

is back

electro-motive force from the coil of the motor

The rotation angle of the motor

is

obtained from angular velocity of

. The load

value for the DC motor is also induced from the

weight of the robot arm brush. Therefore, the torque

generated by the motor Eq.(3) can be calculated as

following

2

(8)

where

: the motor torque,

N : gear reduction ratio,

L : effective length of the link,

M: mass of the robot arm linkage.

2.3 Force Control

Based on the Hooks Law of the spring-based

compliant device, the force of the compliance can be

calculated from the deformation generated by the

brush(robot arm) moving vertically. The relationship

between the position of the brush and deformation of

the spring can be expressed as follows

∆x l

Heightu

(9)

0.1480.002sin2πft

(10)

where

is the initial length of the spring and u is

vertical position of the brush.

The Height variable was defined as the length

from the top of the duct. The irregularity of duct

surface was modelled with sinusoidal function and

sensing disturbance was also added to the control

model shown in Figure 7. Finally, the Figure 7

illustrates the dynamic model of the force control of

the brush with the compliant device.

Figure 7: Force control model with deformation feedback.

The force control model has been simulated with

PID control gains as summarized in Table 2. Figure

8 shows the schematic diagram of the robot control

system including host computer and communication.

SurfaceCleaningForceControlofRotatingBrushesforanAirDuctCleaningRobot

455

Table 2: PID Gains for Force Control of Robot Arm.

Gain

Value

Speed control

P

2.114

I

8.853

D

-0.002

Torque control

P

0.166

I

11.807

D

0

Figure 8: Schematic diagram of the robot control system

and communication.

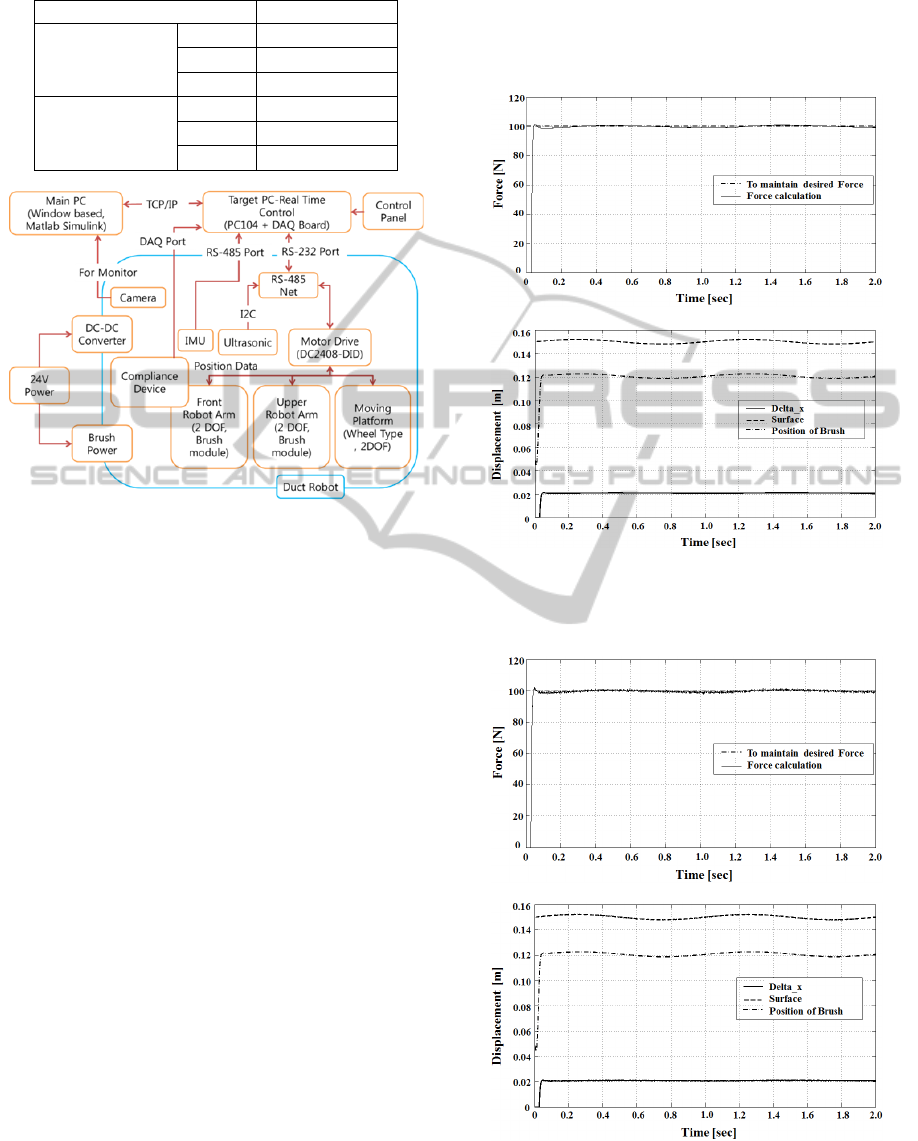

3 SIMULATION RESULTS

The spring constant (k) of the compliant device used

in the simulation is 0.3[N/m], and coefficients for

the nonlinear brush stiffness is assumed as values of

a=2000[N/m

2

], and b=4500[N/m], which is

expressed in the Eq.(2). It is also considered that the

maximum allowable displacement of the spring to

the geometry including the diameter of the brush is

100mm and the height of the duct is 150mm. The k

is exerted by that of value installed to the prototype

robot. However, constants of the nonlinear stiffness

brush are decided arbitrary which is relatively higher

than that of compliant spring. At first, the simulation

results are shown in Figure 9 controlling the force

from deformation feedback to satisfy the desired

force by moving the brush on the sinusoidal surface.

Figure 9(a) shows the result of force control that

of maximum error is 1% to the objective force and

the spring is deformed below the limit (0.05m) of

the geometric interference.

Next, the sinusoidal surface function is changed

by adding disturbances signal whose maximum level

is 1/25 of the magnitude of sinusoidal function.

Results are presented in Figure 10. The error bound

is 1N similar to that of previous results shown in

Figure 8(a). The Pressing force of the brush has been

controlled with the spring-based force compliant

device whose results are depicted in Figure 9, and 10.

In addition, the nonlinear behaviour of the brush

stiffness has not been considered, that is, the brush

stiffness has been modelled as a linear spring.

(a)

(b)

Figure 9: Results of Force Control at 2mm, 1Hz sinusoidal

function of Surface. (a) Measured Force, (b)

Displacement.

(a)

(b)

Figure 10: Results of Force Control at 2mm, 1Hz

sinusoidal function with 1/25 disturbances of Surface. (a)

Measured Force, (b) Displacement.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

456

4 CONCLUSIONS

In this study, the cleaning force control of the

rotating brush has been conducted by utilizing the

spring-based simple compliant device. It is also

assumed that the stiffness of the brush is modelled as

nonlinear function with 2

nd

order polynomials about

displacement to reflect nonlinear characteristics of

the brush. In results, the cleaning force can be

successfully controlled with the simple compliant

device. In future study, some simplifications and

assumptions such as tangential force on the surface

can be partially considered for more accurate results.

Furthermore, it is also necessary to consider

dynamic model of rotating brush. The simulation

results will be further verified under the test-bed

environment using the prototypes of the duct

cleaning robot.

ACKNOWLEDGEMENTS

This research has been conducted as a part of the

subway air duct cleaning robot project (Eco-

Innovation, No. E211-40002-0003-0) partially

funded by the Ministry of Environment in Korea.

REFERENCES

Brosseau, L. M., Vesley, D., Kuehn, T. H., Melson, J.,

Han, H.S. 2000. ‘Duct cleaning: A review of

associated health effects and results of company and

expert surveys’, ASHRAE Trans, 106, 180-187.

Finnish Society of Indoor Air Quality and Climate

(FiSIAQ). 2001. Classification of indoor climate 2000,

Espoo, Finland.

Jeong, W., Jeon, S. W., Park, D., Kwon, S. B., 2012.

‘Force Control of a Duct Cleaning Robot Brush Using

a Compliant Device, 10

th

International Conference on

Informatics in Control, Automation and

Robotics(ICINCO) 2012, Roma, Italy.

Robotics Design, ANATROLLER ARI-100, http://

www.roboticsdesign.qc.ca/mobile-robots, Canada.

Wang, Y., Zhang, J., 2006. ‘Autonomous Air Duct

Cleaning Robot System,’ Proc. of International

Midwest Symposium on Circuits And System, pp. 510-

513, 2006.

Motor Specification, RE ∅25mm, Graphite Brushes, 20W,

http://www.maxonmotor.com/maxon/view/product/mo

tor/dcmotor/re/re25/118752, Switzerland.

Kim, S.H. 2007. ‘Control of DC and AC Motor’. Buk-du

Press, Seoul: 96-103.

SurfaceCleaningForceControlofRotatingBrushesforanAirDuctCleaningRobot

457