Increasing Efficiency of ISO 26262 Verification and Validation

by Combining Fault Injection and Mutation Testing with Model

based Development

Rakesh Rana

1

, Miroslaw Staron

1

, Christian Berger

1

, Jörgen Hansson

2

,

Martin Nilsson

3

and Fredrik Törner

3

1

Computer Science & Engineering, University of Gothenburg, Gothenburg, Sweden

2

Computer Science & Engineering, Chalmers University of Technology, Gothenburg, Sweden

3

Volvo Car Corporation, Gothenburg, Sweden

Keywords: Fault Injection, Mutation Testing, ISO 26262, Simulink, Model based Development, Automotive Domain,

Safety Critical Software.

Abstract: The rapid growth of software intensive active safety functions in modern cars resulted in adoption of new

safety development standards like ISO 26262 by the automotive industry. Hazard analysis, safety

assessment and adequate verification and validation methods for software and car electronics require effort

but in the long run save lives. We argue that in the face of complex software development set-up with

distributed functionality, Model-Based Development (MBD) and safety-criticality of software embedded in

modern cars, there is a need for evolving existing methods of MBD and complementing them with methods

already used in the development of other systems (Fault Injection and Mutation Testing). Our position is

that significant effectiveness and efficiency improvements can be made by applying fault injection

techniques combined with mutation testing approach for verification and validation of automotive software

at the model level. The improvements include such aspects as identification of safety related defects early in

the development process thus providing enough time to remove the defects. The argument is based on our

industrial case studies, the studies of ISO 26262 standard and academic experiments with new verification

and validation methods applied to models.

1 INTRODUCTION

Nowadays, a typical premium car has up to 70 ECUs

which are connected by several system buses to

realize over 2000 functions (Broy, 2006). As around

90% of all innovations today are driven by

electronics and software, the complexity of car’s

embedded software is already high and expected to

grow further. The growth is fuelled by cars

beginning to act more proactively and provide more

assistance to its drivers, which requires software to

interact with hardware more efficiently and making

more decisions automatically (e.g. collision

avoidance by braking, brake-by-wire or similar

functions). In total with about 100 million lines of

code (SLOC), premium segment vehicles carry more

software code than in modern fighter jets and

airliners (Charette, 2009).

Software for custom functionality in modern cars is

usually developed by multiple suppliers although it

is largely designed by a single OEM (Original

Equipment Manufacturer) like Volvo Cars. The

distributed development and use of standards like

AUTOSAR aims to facilitate reuse of software and

hardware components between different vehicle

platforms, OEMs and suppliers (Fennel et al., 2006).

However, testing of such systems is more complex

and even today testing of software generally

accounts for almost 50% of overall development

costs (Boehm and Basili, 2001).

ISO-26262 in automotive domain poses stringent

requirements for development of safety critical

applications and in particular on the testing

processes for this software. These requirements are

intended to increase the safety of modern cars,

although they also increase the cost of modern cars.

251

Rana R., Staron M., Berger C., Hansson J., Nilsson M. and Törner F..

Increasing Efficiency of ISO 26262 Verification and Validation by Combining Fault Injection and Mutation Testing with Model based Development.

DOI: 10.5220/0004592002510257

In Proceedings of the 8th International Joint Conference on Software Technologies (ICSOFT-EA-2013), pages 251-257

ISBN: 978-989-8565-68-6

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

The position for which we argue in this paper is that

efficient verification and validation of safety

functions requires combining Model Based

Development (MBD) with fault injection into models

with mutation testing. This position is based on the

studies of the ISO 26262 standard (mainly chapter 6

that describes requirements on software

development but also chapter 4, which poses

requirements on product development (ISO 26262 -

2011, 2011)). It is also based on previous case

studies of the impact of late defects on the software

development practices in the automotive domain

(e.g. (Mellegård et al., 2013))

The requirements from the ISO 26262 standard

on using fault injection techniques is challenging

since it relates to the development of complete

functions rather than components or sub-components

of software. The current situation in the automotive

sector is that fault injection is used, but it is used at

the level of one electronic component (ECU) or one

software system and rarely at the function level

(Hillenbrand et al., 2010; Schätz, 2010).

The current state of art testing is not enough for

detecting safety defects early in the automotive

software development process since fault injection is

done late in the development (when ECUs are being

developed), which usually makes the detection of

specification-related defects difficult and costly

(Mellegård et al., 2013). As much possible this

detection should be done at the model level when the

ECUs’ functionality is still under design and thus, it

is relatively cheap to redesign/reconfigure. The

evidence from literature on successful use of fault

injection shows that the techniques are indeed

efficient in finding dependability problems of

hardware and software systems when applied to

compute (Hsueh et al., 1997). Finally, to be able to

increase the effectiveness of the fault injection

strategies and identify whether the faults should be

injected at the model, software or ECU level -

Mutation testing should be applied to verify the

adequacy of test cases and finally how the

combination of these approaches when applied at the

model level will enhance the detection of safety

defects right at the design stage.

In this paper, we provide a roadmap, which

shows how to introduce fault injection and mutation

testing to modelling of automotive software in order

to avoid costly late defects and increase the safety of

modern and future cars.

The remaining of the paper is structured as

follows: In the next section (2) we provide an

overview of software development in automotive

domain and associated concepts. This is followed by

brief discussion on related work in section 3 and our

position is presented and discussed in section 4.

Section 5 concludes our work.

2 BACKGROUND

In this section we take a brief overview on the

current state of automotive software development

process and environment, how safety is important in

safety critical applications and overview of

theoretical background on fault injection techniques

and mutation testing.

2.1 Automotive Software

Development & ISO 26262

Various software functions/applications developed

within the automotive industry today are classed as

safety critical, for example Volvo’s City Safety

feature consists of components that are safety

critical.

Figure 1: Volvo Cars city safety function, image provided

by Volvo Car Corporation.

(Broy, 2006) gives examples of functions/areas

within automotive domain with recent development

which includes crash prevention, crash safety,

advanced energy management, adaptable man-

machine interface, advanced driver assistance,

programmable car, car networking etc., much of

these also fall within the safety critical functionality

and thus demands high quality and reliability. Also a

number of on-going projects are directed towards the

goal of self-driving cars.

Software development in automotive sector in

general follows the ‘V’ process, where OEMs take

the responsibility of requirement specification,

system design, and integration/acceptance testing.

This is followed by the supplier, which develops the

actual code that runs on ECUs. Although the code is

tested at the supplier level (mainly unit testing), the

ICSOFT2013-8thInternationalJointConferenceonSoftwareTechnologies

252

OEMs are responsible for the final integration,

system and acceptance testing to ensure that the

given implementation of a software (SW) meets its

intended functional and safety goals/demands.

Figure 2: The V-model in the automotive industry with

distinction between the OEM and supplier contributions.

In this model of software/product development

(see Figure 2) testing is usually concentrated in the

late stages of development, which also implies that

most of the defects are discovered late in the

development process. In a recent study using real

defect data from an automotive software project

from the industry (Mellegård et al., 2012) showed

that late detection of defects is still a relevant

problem and challenge yet to overcome. The defect

inflow profile presented in this study is reproduced

in Figure 3 for reference, which exhibits a clear peak

in number of open defects in the late stages of

function development/testing.

Figure 3: Defect inflow profile for automotive software

project, as given in (Mellegård et al., 2012).

Testing the software is an important tool of

ensuring correct functionality and reliability of

systems but it is also a very resource intensive

activity accounting for up to 50% of total software

development costs (Jones, 2001) and even more for

safety/mission critical software systems. Thus

having a good testing strategy is critical for any

industry with high software development costs. It

has also been shown that most of the defects

detected during testing do not depend on actual

implementation of code, about 50% of defects

detected during testing in the study by (Megen and

Meyerhoff, 1995), were found during the test

preparation, an activity independent of the

executable code. And since automotive sector has

already widely adopted MBD for the software

development of embedded systems, a high potential

exists for using the behavioural modes developed at

the early stages of software development for

performing some of the V&V (Verification &

Validation). Early V&V by helping to detect defects

early will potentially save significant amount of cost

for the projects and reduce the cycle time.

2.2 ISO 26262

ISO/IEC 26262 is a standard describing safety

requirements. It is applied to safety-related systems

that include one or more electrical and/or electronic

(E/E) systems. The overview of safety case and

argumentation is represented in Figure 4, based on

(ISO 26262 - 2011, 2011).

Figure 4: Overview of ISO-26262 safety case &

argumentation process.

Written specifically for automotive

domain/sector, the ISO-26262 standard is adapted

for the V-model of product development

corresponding to the current practice in the industry.

The guidelines are laid out for system design,

hardware and software design & development and

integration of components to realize the full product.

ISO-26262 includes specifications for MBD and

provides recommendations for using fault injection

techniques for hardware integration and testing,

software unit testing, software integration testing,

hardware-software integration testing, system

Item

•Theitemrepresentingasystemorafunctionis

defined.

PHA

•APreliminaryHazardAnalysis&RiskAssessmentis

donetoassignanappropriateASILlevel.

SG

•SafetyGoalsarederivedfromtheHazardAnalysis

andtheyinherittheassignedASILlevel.

FSR

•FunctionalSafetyRequirementsaredrawnsuchthat

thesetSafetyGoalsaremet.

TSR

•TheTechnicalSafetyRequirementsareformulated

describinghowtoimplementFSR.

Doc

•Furtherdevelopmentincludesimplementation,

integrationanddocumentationofsafetycases.

IncreasingEfficiencyofISO26262VerificationandValidationbyCombiningFaultInjectionandMutationTestingwith

ModelbasedDevelopment

253

integration testing and vehicle integration testing, for

overview on fault injection recommendations in

ISO-26262 see (Rana et al., 2013). Although the

functional safety standard specifies clearly the

recommendations for using fault injection during

various stages of testing but it does not recommend

anything with respect to using mutation testing. This

also reflects the current standard practice within the

automotive industry where mutation testing is not

widely adopted yet.

2.3 Fault Injection

Fault injection techniques are widely used for

experimental dependability evaluation. Although

these techniques have been used more widely for

assessing the hardware/prototypes, the techniques

are now about to be applied at behavioural models of

software systems (Svenningsson et al., 2010) - thus

enabling early verification of intended functionality

as well as enhancing communication between

different stakeholders. Fault injection techniques

applied at models level offer distinct advantages

especially in an industry using MBD for its software

development, but use of these techniques at model

level in automotive industry is currently at its

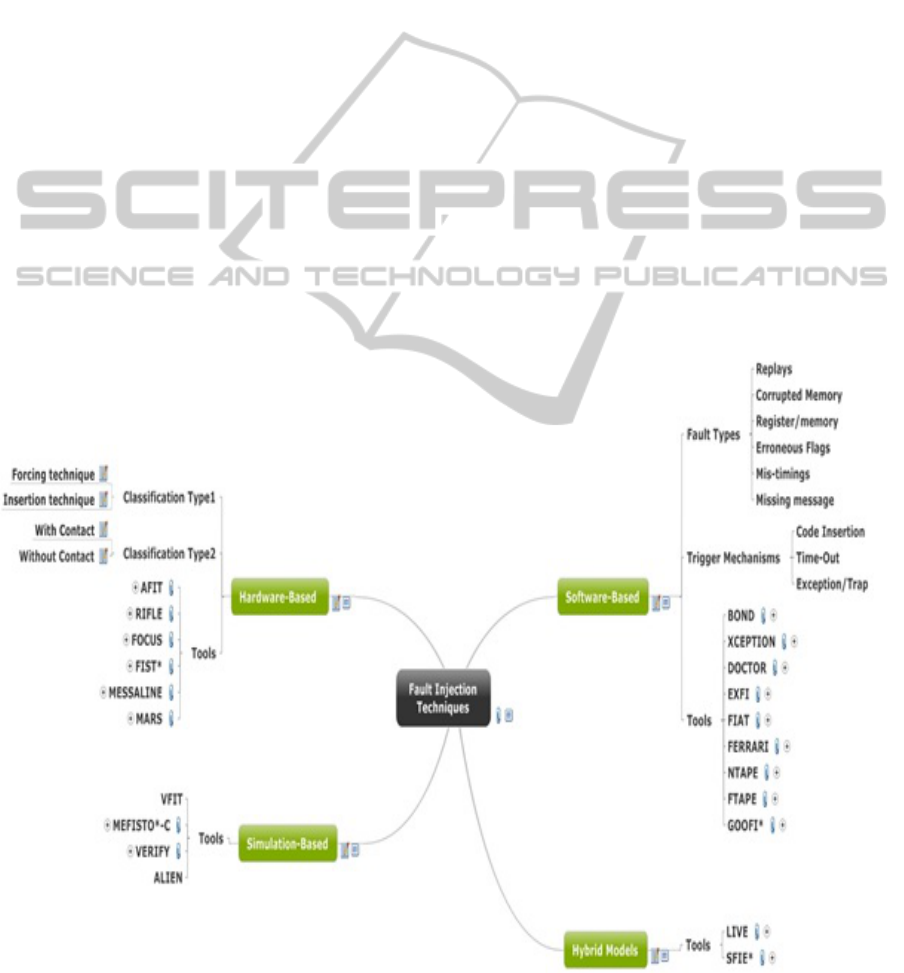

infancy. Figure 5 shows a mind map of classification

of fault injection techniques based on how the

technique is implemented; some of the tools which

are developed based on given approach are also

listed for reference. For a good overview of fault

injection techniques readers are referred to (Hsueh et

al., 1997; Ziade et al., 2004).

2.4 Mutation Testing

Mutation testing is technique for assessing the

adequacy of given test suite. Mutation testing

includes injection of systematic, repeatable seeding

of faults in large number thus generating number of

copies of original software artefacts with artificial

fault infestation (called a mutant). Percentage of

mutations detected by the given test cases/suite is a

metrics (called “mutation adequacy score” (Jia and

Harman, 2011)) used for measuring effectiveness of

the given test suite. The variants of code (faults) can

be introduced by hand or auto-generated using tools

like Insure++, Plextest, Certitude, ESPT for C/C++

codes. It has been shown that the use of mutants

Figure 5: Common classification of fault injection techniques and implementation tools, description available in (Ziade et

al., 2004; Hsueh et al., 1997).

ICSOFT2013-8thInternationalJointConferenceonSoftwareTechnologies

254

yields trustworthy results (Andrews et al., 2005), i.e.

mutants do reflect characteristics of real faults.

Mutation theory is based on two fundamental

hypotheses namely Competent Programmer

Hypothesis and the Coupling Effect, both introduced

by (DeMillo et al., 1978). The Competent

Programmer hypothesis reflects the assumption that

programmers are competent in their job and thus

would develop programme close to correct version

(although making a number of mistakes) while the

Coupling Effect hypothesis means that complex

mutants are coupled to simple mutants in such a way

that a test data that detects large percent of simple

faults is also effective in detecting high percentage

of the complex defects” (Offutt, 1992).

3 RELATED WORK

A number of European Union sponsored projects,

within the area of embedded software development

and safety critical systems have looked at and

developed techniques to effectively use fault

injection for safe and reliable software development.

The examples include the ESACS (Enhanced Safety

Assessment for Complex Systems) (Joshi and

Heimdahl, 2005) and the ISAAC (Kakade et al.,

2010)(Improvement of Safety Activities on

Aeronautical Complex systems). These projects

have used the SCADE (Safety-Critical Application

Development Environment) modelling environment

to simulate hardware failure scenarios to identify

fault combinations that lead to safety case violations.

A model-implemented fault injection plug-in to

SCADE called FISCADE is introduced in (Vinter et

al., 2007). The plug-in tool utilizes approach similar

to mutation based testing, where it replaces the

original model operators by their equivalent fault

injection nodes. The derived models are then used to

inject the fault during execution and log the results

which are analysed later. Dependability evaluation

of automotive functions using model based software

implemented fault injection techniques have also

been studied in (Plummer, 2006).

A generic tool capable of injecting various types

of faults on the behavioural/functional Simulink

models is also developed and introduced in

(Svenningsson et al., 2010). The tool called MODIFI

(or MODel-Implemented Fault Injection tool) can be

used to inject single or multiple point faults on

behavioural models, which can be used to study the

effectiveness/properties of fault tolerant system and

identify the faults leading to failure by studying the

fault propagation properties of the models.

Another work (Brillout et al., 2010) with its root in

the European CESAR (Cost-efficient methods and

processes for safety relevant embedded systems)

project provides a good theoretical overview of how

fault and mutation based test coverage can be used

for automated test case generation for Simulink

models. We provide a practical framework on how

fault injection combined with mutation testing

within an MDB environment can be used in the

industry. And how will this practice enhance the

verification and validation of software under

development, its functional validation that would

generates statistics for the effective argumentation of

ISO 26262 compliance.

4 ROAD MAP FOR EARLY

DEFECT DETECTION

We contend that fault injection can be effectively

used at the model level to verify and validate the

attainment or violation of safety goals. We also

propose that it should be complemented with

mutation testing approach at the model level to

provide enough statistical evidence for argumenting

the fulfilment of safety goals as per the ISO-26262

safety standard requirements.

A major challenge in successful argumentation

of ISO-26262 compliance is to provide statistical

evidence that safety goals (SGs) would not be

violated during operation and collecting the

evidence for this argumentation within reasonable

testing efforts.

If we are able to differentiate early between

defects that can cause the violation of SGs and those

that cannot cause the violation, the amount of testing

required will be manageable. With MBD the

functional testing could be done using fault injection

techniques and this can be complemented with later

system testing of the actual code using the mutation

testing approach.

The framework on how this could be achieved in

practice is as follows:

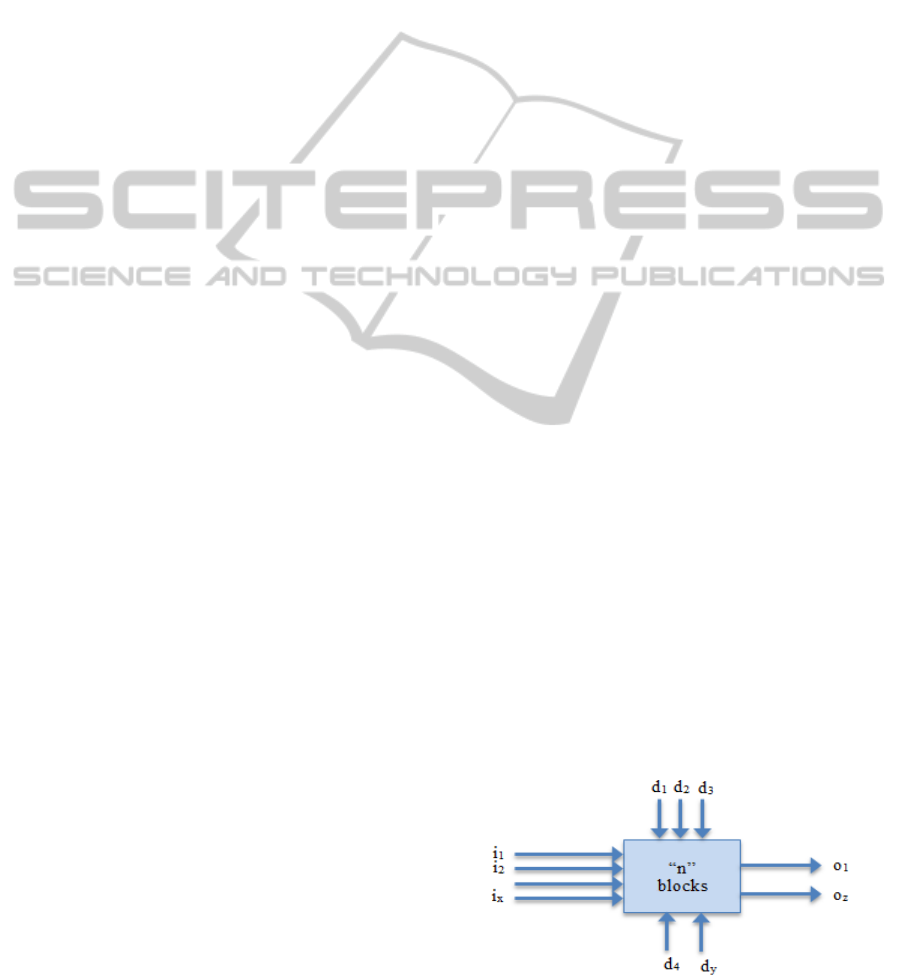

Figure 6: MBD based representation of a general system

with inputs, outputs and dependencies.

IncreasingEfficiencyofISO26262VerificationandValidationbyCombiningFaultInjectionandMutationTestingwith

ModelbasedDevelopment

255

As illustrated in Figure 6, a given system/function

generally have following common features (in

context of model based development): firstly it will

have x inputs (i

1,2…x

); it would have dependencies to

other y components/ functions (d

1,2…y

); it will have z

outputs (o

1,2…z

); and it will have a number of sub-

units/modules within it that implement the intended

functionality, let us assume that this part contains n

basic blocks in the modelling environment

corresponding to n statements for a hand written

code. To verify and validate the correct functionality

and ISO-26262 compliance of this generic function

using fault and mutation testing approach we can

follow the steps as:

a. Assign or define the technical safety

requirements (TSRs) corresponding to the

functional safety requirements (FSRs) for the

given system/function to its z outputs.

b. Use fault injection techniques to inject faults

which are similar to commonly occurring

defects and other possible fault conditions at

the x inputs of the function.

c. Fault scenarios that leads to violation of

TSRs/FSRs are identified, statistics are built on

what percentage of total faults lead to such

failures and fault propagation properties of

such cases are studied to build the fault

tolerance within the system for given fault

conditions.

d. Repeat steps (b) & (c) to test, correct and

validate the given system/function for its

dependencies on other functions/components.

e. Cause mutations to the n basic blocks of given

functional model and asses the detection

effectiveness of test suite/cases for possible

implementation bugs.

f. Examine the mutants which are not killed by

given set of test cases/suits for their effect on

FSRs. If a given mutation violates the FSRs

then a suitable test case is created to detect/kill

such mutants, i.e. detect such bugs in actual

code.

By following the above mentioned steps we not only

ensure that the given function holds the FSRs and

TSRs under faulty inputs, but we can also prevent

potential implementation defects and ensure that we

have test cases ready to catch such faults that can

potentially violate the FSRs/TSRs already at the

design (model) level.

It is also worthwhile to note here that steps (a) to (e)

can be easily automated using the currently available

testing methodologies, which makes the usability

and industrial viability much higher that testing

frameworks requiring high manual interventions.

Further to make this framework/approach more

effective in industrial practice we identify a number

of best practices that will have positive impact on

detecting defects early in the development process

and thus have effective V&V of ISO-26262:

a. The best practice is to build and maintain

models corresponding to each abstraction layer

of software architecture.

b. The next best practice is to specify and test

these models for FSRs and TSR at the

appropriate abstraction level.

c. Also identification of different types of

defects/faults and at what stage they could be

modelled/injected in the behavioural models

would ensure that models are tested for these

faults at the earliest - leading to models being

build that are robust right from the start instead

of adding fault tolerance properties in the later

stages of development.

5 CONCLUSIONS

The development of software in the automotive

domain has widely adopted the paradigm of model

based development to allow for easier integration of

functionality usually developed by multiple

suppliers. By the nature of the domain much of the

functionality developed and implemented in cars is

safety critical; the criticality that requires

observation of stringent quality assessment and

adherence to functional safety standards such as ISO

26262.

Development of behavioural models in MBD

offers significant opportunity to do functional testing

early in the development process. Fault injection and

mutation testing approach in combination can be

used to effectively verify and validate the functional

properties of a software system/function. The

approach also provides required statistics for the

argumentation of safety standards compliance. In

this paper the need for such validation and a

framework on how this could be achieved in practice

is discussed. The results are a roadmap for further

research and tool support to bring this approach into

wider industrial adoption.

By detecting defects early and being able to do

much of verification and validation of intended

functionality, robustness and compliance to safety

standards on the models – the quality and reliability

of software in automotive domain can be

significantly enhanced. Effective approaches and

tools support reduce the V&V costs and lead to

shorter development times.

ICSOFT2013-8thInternationalJointConferenceonSoftwareTechnologies

256

ACKNOWLEDGEMENTS

The work has been funded by Vinnova and Volvo

Cars jointly under the FFI programme (VISEE,

Project No: DIARIENR: 2011-04438).

REFERENCES

Andrews, J. H., Briand, L. C., Labiche, Y., 2005. Is

mutation an appropriate tool for testing experiments?

[software testing], in: Software Engineering, 2005.

ICSE 2005. Proceedings. 27th International

Conference On. pp. 402–411.

Boehm, B., Basili, V. R., 2001. Defect Reduction Top 10

List. Computer 135–137.

Brillout, A., He, N., Mazzucchi, M., Kroening, D.,

Purandare, M., Rümmer, P., Weissenbacher, G., 2010.

Mutation-based test case generation for simulink

models, in: Formal Methods for Components and

Objects. pp. 208–227.

Broy, M., 2006. Challenges in automotive software

engineering, in: Proceedings of the 28th International

Conference on Software Engineering. pp. 33–42.

Charette, R. N., 2009. This Car Runs on Code.

http://spectrum.ieee.org/green-tech/advanced-cars/this-

car-runs-on-code.

DeMillo, R. A., Lipton, R. J., Sayward, F.G., 1978. Hints

on test data selection: Help for the practicing

programmer. Computer 11, 34–41.

Fennel, H., Bunzel, S., Heinecke, H., Bielefeld, Jü, rgen,

Fü, rst, S., Schnelle, K.-P., Grote, W., Maldener, N.,

Weber, T., Wohlgemuth, F., others, 2006.

Achievements and exploitation of the AUTOSAR

development partnership. Convergence 2006, 10.

Hillenbrand, M., Heinz, M., Adler, N., Müller-Glaser,

K.D., Matheis, J., Reichmann, C., 2010. ISO/DIS

26262 in the context of electric and electronic

architecture modeling, in: Architecting Critical

Systems. Springer, pp. 179–192.

Hsueh, M. C., Tsai, T. K., Iyer, R. K., 1997. Fault

injection techniques and tools. Computer 30, 75–82.

ISO 26262 - 2011, 2011. Road vehicles -- Functional

safety -- Part 1-10.

Jia, Y., Harman, M., 2011. An analysis and survey of the

development of mutation testing. Softw. Eng. IEEE

Trans. 37, 649–678.

Jones, E. L., 2001. Integrating testing into the

curriculum—arsenic in small doses, in: ACM SIGCSE

Bulletin. pp. 337–341.

Joshi, A., Heimdahl, M. P. E., 2005. Model-based safety

analysis of simulink models using SCADE design

verifier.

Kakade, R., Murugesan, M., Perugu, B., Nair, M., 2010.

Model-Based Development of Automotive Electronic

Climate Control Software. Model. Found. Appl. 144–

155.

Megen, R., Meyerhoff, D. B., 1995. Costs and benefits of

early defect detection: experiences from developing

client server and host applications. Softw. Qual. J. 4,

247–256.

Mellegård, N., Staron, M., Tö, rner, F., 2012. A light-

weight defect classification scheme for embedded

automotive software and its initial evaluation.

Mellegård, N., Staron, M., Törner, F., 2013. A Light-

Weight Defect Classification Scheme for Embedded

Automotive Software Development.

Offutt, A. J., 1992. Investigations of the software testing

coupling effect. Acm Trans. Softw. Eng. Methodol.

Tosem 1, 5–20.

Plummer, A., 2006. Model-in-the-loop testing. Proc. Inst.

Mech. Eng. Part J. Syst. Control Eng. 220, 183–199.

Rana, R., Staron, M., Berger, C., Hansson, J., Nilsson, M.,

Törner, F., 2013. Improving Fault Injection in

Automotive Model Based Development using Fault

Bypass Modeling. Submitted To: 2nd Workshop on

Software-Based Methods for Robust Embedded

Systems, Informatik 2013, Koblenz, Germany.

Schätz, B., 2010. Certification of Embedded Software–

Impact of ISO DIS 26262 in the Automotive Domain,

in: Leveraging Applications of Formal Methods,

Verification, and Validation. Springer, pp. 3–3.

Svenningsson, R., Vinter, J., Eriksson, H., Törngren, M.,

2010. MODIFI: a MODel-implemented fault injection

tool. Comput. Saf. Reliab. Secur. 210–222.

Vinter, J., Bromander, L., Raistrick, P., Edler, H., n.d.

FISCADE - A Fault Injection Tool for SCADE

Models, in: Automotive Electronics, 2007 3rd

Institution of Engineering and Technology Conference

On. pp. 1–9.

Ziade, H., Ayoubi, R. A., Velazco, R., others, 2004. A

survey on fault injection techniques. Int Arab J Inf

Technol 1, 171–186.

IncreasingEfficiencyofISO26262VerificationandValidationbyCombiningFaultInjectionandMutationTestingwith

ModelbasedDevelopment

257