Fully Organic Graphene Oxide-based Sensor with Integrated Pump

for Sodium Detection

Jingfeng Huang

1,2,3

, James Harvey

1,2,3

, Hu Chen

1,2,3

, Steve Faulkner

3

, James King

3

Myra A. Nimmo

2,3

and Alfred Tok I. Y.

1,2

1

School of Materials Science and Engineering, Nanyang Technological University,

50 Nanyang Avenue, Singapore, 637553, Singapore

2

Institute for Sports Research, Nanyang Technological University, 50 Nanyang Avenue, Singapore, 639798, Singapore

3

School of Sport, Exercise and Health Sciences, Loughborough University,

Ashby Road, Loughborough, Leicestershire, LE11 3TU, U.K.

Keywords: Graphene Oxide, Real-time, Sweat, Organic Sensor, Sodium Sensor, Biosensor, Field Effect Transistor.

Abstract: Sweat is produced by the body nat.urally during physical activity and this fluid can be analysed in real-time

to reflect the body’s hydration and electrolyte status. This paper reports a new type of organic disposable

sensor pump that integrates sweat collection and sodium (Na

+

) ion sensing into cotton threads. This

integration allows the sensor platform to be small, portable and wearable; thus allowing potential advantage

to interface with the human body during field exercises enabling the provision of real-time data for

immediate intervention. The sensor uses a sodium-selective Ion Selective Electrode (ISE) modified

graphene oxide transducer intertwined with a thread pump. In this paper, we present the characterisation,

synthesis and sensing data of this sensor.

1 INTRODUCTION

During exercise, sweating can lead to the loss of

electrolytes such as sodium and potassium (Baker et

al., 2009). With increasing sweat rate, only Na

+

and

Cl

-

(from extracellular compartments)

concentrations in sweat tend to increase while Ca

2+

(from intracellular space) decreases; K

+

and Mg

2+

(from intracellular space) remain unchanged

(Costill, 1977). Electrolyte loss through urine during

exercise is small because of decreased urine

formation and increased renal Na

+

reabsorption.

Deficits of 5% to 7% of the body’s Na

+

and Cl

-

ions

can be lost through sweat in comparison to less than

1.2% loss for K

+

and Mg

2+

. (Costill, 1977).

Measurement of sodium and potassium ions in sweat

can be used to predict changes in serum (Baker et

al., 2009). Thus sodium levels in sweat can be also

used to predict exercise-associated hyponatremia.

Therefore, sodium measurement in sweat is

important and essential. In this paper, we present the

characterisation, synthesis and sensing data of a

novel disposable, organic, low-cost, graphene-based

and pump-integrated sodium sensor suitable for real-

time sensing of sweat sodium concentration in field

conditions.

2 RESULTS AND DISCUSSION

2.1 Idea of Fully Organic Sodium

Sensor

From a list of currently available sodium portable

sensors (Table 1), there is a niche to develop a

disposable and low-cost sodium sensor suitable for

real-time sensing in field conditions.

There is a demand for such a sensor platform in

the fast-growing biosensor market which is

projected to reach US$12 billion by 2015 propelled

by the growing population and health issues (GIA,

2012).

Increasingly graphene is the transducer material

of choice because of its ability to detect single

molecule binding events (Schedin et al., 2007). This

is due to its exceptional low-noise electronic

material property. Graphene, being a 2-dimensional

material with high surface area to volume ratio, is

also very sensitive to small perturbations on its

surface and these perturbations change its electrical

83

Huang J., Harvey J., Chen H., Faulkner S., King J., A. Nimmo M. and Tok I. Y. A..

Fully Organic Graphene Oxide-based Sensor with Integrated Pump for Sodium Detection.

DOI: 10.5220/0004636200830088

In Proceedings of the International Congress on Sports Science Research and Technology Support (icSPORTS-2013), pages 83-88

ISBN: 978-989-8565-79-2

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

Table 1: Comparison of practical and portable sodium sensors.

Na

+

Sensors Minimum

Sample

Volume

Useful

Range

Precision Size Disadvantage

Wescor brand –Sweat

Check Conductivity

Meter (to be used with

Macroduct system)

8μl 0-150mM

2% from

75-110mM

10x20x16 cm;

1kg

-Non-real time

-Not suitable for field testing

Wescor brand –

Neonatal Sweat

Analysis system

Needed but

not indicated

3-200mM

<1% from

25-150mM

19x13x5 cm;

0.5kg

-Not suitable for field test

Centre for sensor web

technologies – Wearable

sodium sensor

(Schazmann et al.,

2010)

Needed but

not indicated

0mM-

100mM

3% RSD in

lab testing

Not stated

-Requires special plastic molds

- Requirement to store electrode

in special liquids when not in use

-Not disposable, bacteria growth

observed

BIOTEX—Biosensing

Textiles for Personalised

Healthcare Management

(Coyle et al., 2010)

Needed but

not indicated

Not stated Not stated Not stated

-Requirement to store electrode in

special liquids when not in use.

-Not real-time as contact between

fabric and electrode is poor

resistivity drastically (Huang et al., 2013b).

Briefly, graphene is a single atom thick film

made up of carbon atoms connected in a sp

2

hybridized network. It has novel properties such as

size tunable band gap and high carrier mobility.

Graphene has already demonstrated that it is able to

detect single gas molecules (Schedin et al., 2007).

Graphene can be obtained via several methods,

including chemical vapour deposition (Huang et al.,

2013c), mechanical exfoliation (Novoselov et al.,

2004) and chemical methods (Larisika et al., 2012).

However, the chemical method has several

advantages: low-cost, scalability and aqueous

processability. Using graphene from the chemical

route can lower the cost of sensors down to less than

£1 per chip. Graphene produced via the chemical

route contains several oxygen groups even after

reduction and is thus sometimes termed reduced

graphene oxide or reduced aqueous graphene

(Huang et al., 2013d). In later discussions, we term

the product as reduced graphene oxide (RGO).

RGO-based bio-sensors have also been reported to

be able to detect single bacteria (Mohanty and Berry,

2008), cell-activities (He et al., 2010) and label-free

DNA (Ohno et al., 2009). The graphene transducer

can be used in an optical, amperometrical or

acoustical sensor setup.

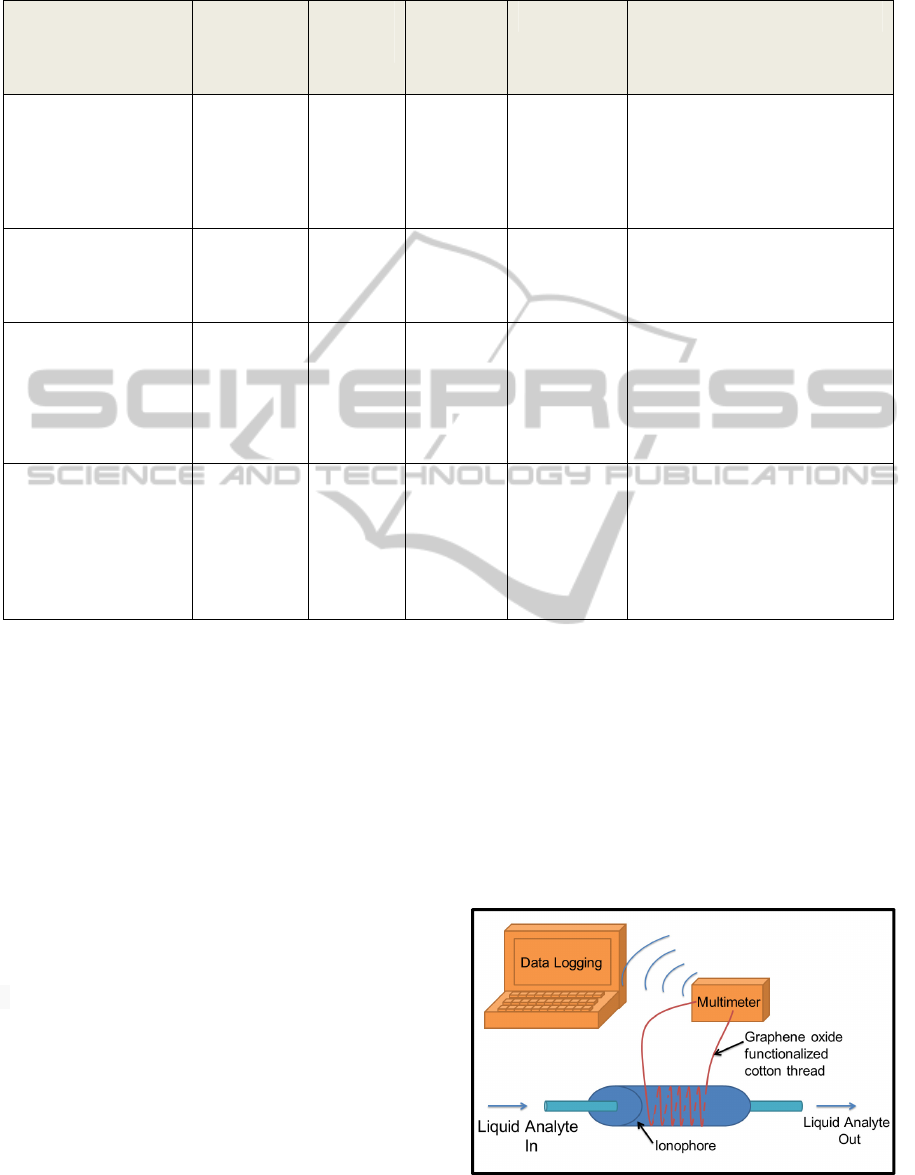

This paper uses the amperometric field effect

transistor detection setup (Figure 1) as it can

eliminate the need for expensive, bulky, highly-

specialised equipment in diagnostic screening tests.

For selectivity, any receptors (e.g. sodium

ionophore) can be attached to the amperometric

graphene transducer to enable detection of a large

variety of biological molecules with biomedical

significance in real time.

Figure 1: Schematic of amperometric field effect transistor

(FET) biosensor setup.

icSPORTS2013-InternationalCongressonSportsScienceResearchandTechnologySupport

84

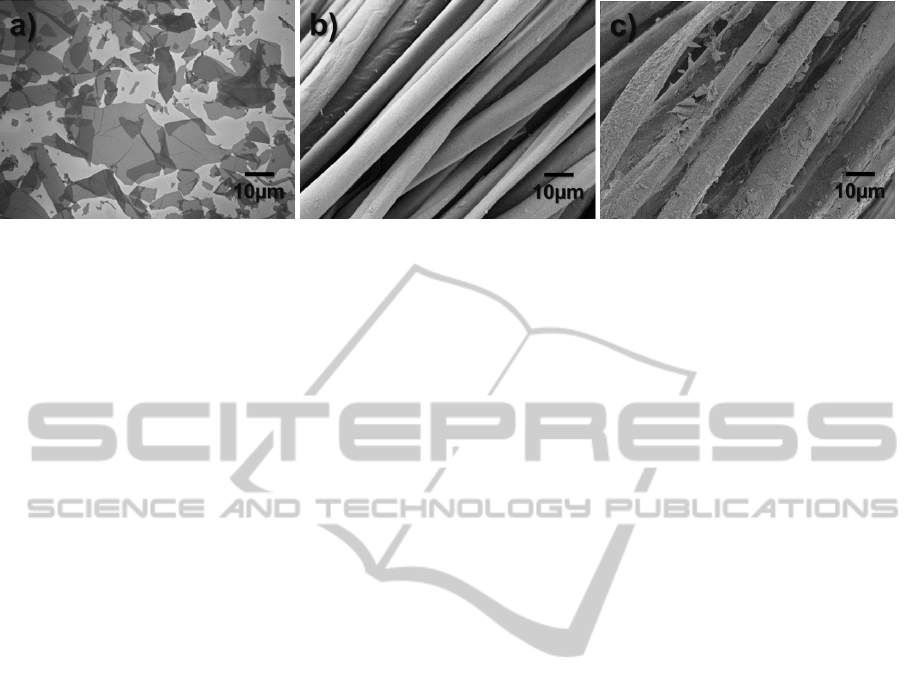

Figure 2: Field emission scanning electron microscopy images of (a) graphene oxide flakes on silicon dioxide wafer (b)

cotton thread after plasma treatment (c) graphene oxide on cotton thread taken under similar magnification.

2.2 Integrating Sweat Collection

Methods for the collection of sweat include whole

body washdown (WBW) believed to be the most

accurate and reliable with analysis undertaken later.

However this method is limited to cycling and

requires a controlled laboratory setting.

Alternatively, regional skin collection is relatively

simple, practical for field studies and is able to

accurately and reliably predict WBW sodium

concentrations (Patterson et al., 2000). Regional skin

collection methods with occlusive coverings have

been reported to result in falsely high electrolyte

readings because of electrolyte leeching from the

stratum corneum of the skin (Weschler, 2008).

However, if the skin can be kept dry by a sweat

wicking material, it could be possible to obtain

reliable estimates of local sweat electrolyte

concentrations. A wicking sensor can thus prevent

reabsorption of Na

+

back into the body. It will then

be possible to measure the true Na

+

excretion. After

these considerations, we designed a novel RGO-

based, amperometric sensor platform with an

integrated pump which can be used for real-time

sensitive detection of sodium ions.

2.3 Fabrication and Characterisations

Special large Graphene Oxide (GO) flakes, a

precursor to RGO, were prepared by modified

Hummer’s method from natural graphite flakes (3-

5mm). Briefly, 2g of graphite flakes were mixed

with H

2

SO

4

(12ml) and stirred for 5 hours at 80˚C.

The mixture was ultra-sonicated for 1 hour and

diluted with DI water (500ml). The suspension was

then filtered using 0.2μm filter to obtain dry pre-

oxidized graphite powders. To fully oxidize the

graphite, H

2

SO

4

(120ml) and KMnO

4

(15g) was

added to the powder and stirred for 2 hours before

diluting with 950ml of DI water slowly in ice-bath

and finally stopping the reaction using H

2

O

2

(20ml).

The upper portion of the solution was collected,

filtered and washed to remove remaining metal ions

and acid. This forms the stock GO solution

containing large GO flakes used in subsequent

experiment. To image the large GO flakes, GO

solution was drop-cast on silicon dioxide flat

substrate and scanning electron microcopy was used

(Figure 2a). Using this method, the average size of

the GO flakes are 700 μm

2

and this is 7 orders of

magnitude larger (Larisika et al., 2012) than existing

literatures. Larger GO flakes exhibit remarkable

lower sheet resistance, lower intra-flake resistance

and higher hole carrier mobility which could result

in a more sensitive sensor.

To prepare the cotton substrate for the RGO,

cotton threads were treated with oxygen (25%)

plasma. This treatment removes natural wax and

increases oxygen moieties on the surface of the

thread, making subsequent chemical

functionalization possible. After a 50 minute plasma

treatment, the structure of the cotton thread is still

intact (Figure 2b). Then (3-Aminopropyl)

triethoxysilane (2% v/v ethanol) was used to

functionalise the cotton surface to make it positively

charged. The functionalised thread was then

submerged in the GO stock solution for 30 minutes.

As the surface of GO is negatively charged, during

the incubation period, the GO will be

electrostatically attached onto the thread.

It had been reported that GO can also be coated

directly onto the cotton thread using a drip-and-dry

method (Shateri-Khalilabad and Yazdanshenas,

2013). However, attaching the graphene using the

electrostatic attraction method allows self-assembly

and termination, thus allowing controlled 1-2 layers

of GO to be adhered to the thread (Figure 2c). The

2-dimensional material characteristics of GO is

preserved with 1-2 layers of GO as the hole or

electrons carriers can only move along the planar

direction. Having more than two layers of GO will

allow the carriers to travel in parallel (3-

FullyOrganicGrapheneOxide-basedSensorwithIntegratedPumpforSodiumDetection

85

dimensional) and decreases the sensor’s sensitivity

to any perturbations from the ionophore.

After the attachment of GO to the thread, a

chemical reduction is needed to remove oxygen

moieties from the carbon backbone of GO and

restore its electrical conductivity. The thread is

placed in a sealed petri dish with 500μl of hydrazine

monohydrate and left overnight at 70˚C. The

hydrazine vapor produced will reduce the GO into

RGO. This RGO-lined cotton thread forms the RGO

transducer. The exposed RGO transducer is sensitive

to all molecules, such as H

2

O (humidity) and NO

2

(gas) molecules. Therefore a coat is needed to

protect the RGO transducer from the environment.

To achieve selectivity of sodium on the RGO

surface, a sodium ionophore cocktail was coated

onto the RGO transducer. Briefly, bis(1-butylpentyl)

adipate, sodium ionophore (71733) and poly(vinyl

chloride) high molecular weight, (Sigma-Aldrich, St

Louis, USA), were dissolved in tetrahydrofuran

solvent and then the ionophore cocktail was left

overnight to stabilise before coating on the RGO

transducer. The ionophore used is an electrically

neutral, lipophilic ion-complexing agent of small

relative molar mass. Two coatings of sodium

ionophore were applied to the RGO transducer to

ensure complete coverage.

The ionophore-covered RGO transducer was

then fixed across a polyethylene terephthalate (PET)

platform and attached to a multimeter (Agilent

U1273A and E3ABAG) via copper wire and clips.

Another plasma-treated thread was coiled around the

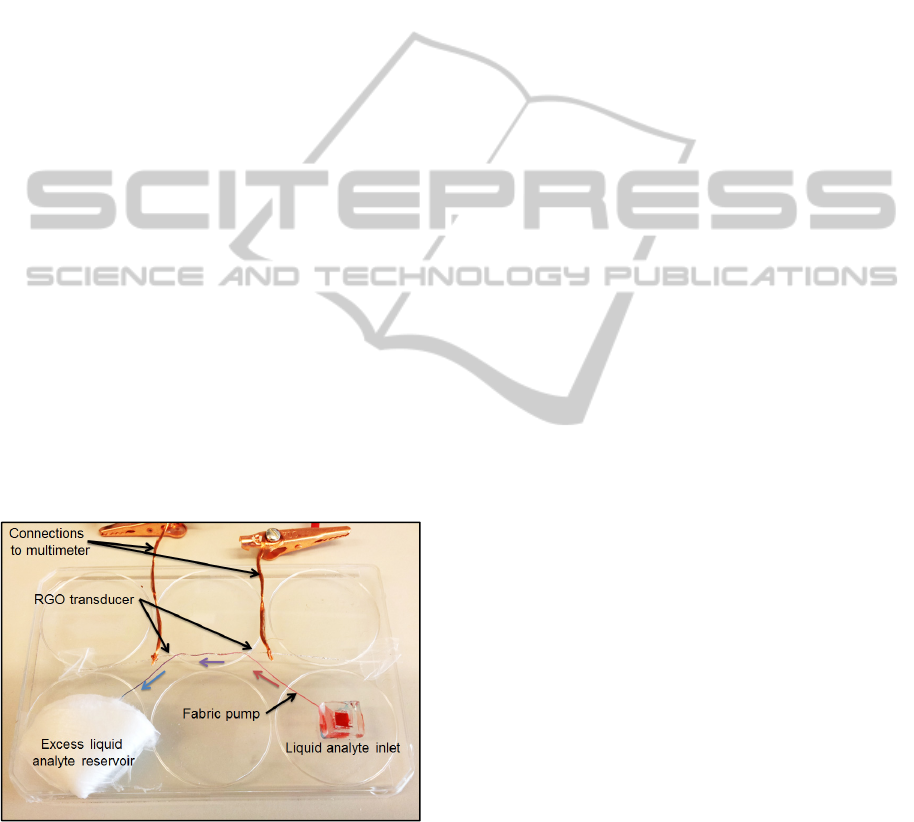

Figure 3: The graphene oxide based sensor with integrated

fabric pump. (For interpretation of the colored dyes on the

figure, kindly refer to the online version of this article).

RGO transducer. This allows the liquid analyte to

flow through it to reach the transducer (figure 3).

One of the thread ends is attached to a silicone

rubber liquid analyte inlet and the other to a cotton

wool excess liquid analyte reservoir. The large

collection reservoir allows constant flow of liquid

analyte through the thread. This thread acts as a

pump using capillary action and no external power

source is needed (Reches et al., 2010; Li et al.,

2009). After the sensing setup is completed, colored

dyes are used to detect the movement of liquid

analyte.

2.4 Pump Testing and Sodium Sensing

From Figure 3, it can be observed that the blue and

then red colored dyes travel cleanly along the fabric

pump. The wicking rate increases exponentially with

increasing plasma treatment time on the cotton

thread ca. 3mm/min, 10mm/min and 50mm/min

after 10, 30, 50 minutes of oxygen plasma treatment

respectively. In the experiments, 50 minutes of

plasma treatment on all cotton thread was used.

Then the colored dyes were replaced with sodium

analyte for sensing data collection.

To test the sodium detection window of the

sensor, different concentrations of sodium chloride

solution were added to fill the analyte inlet and

allowed to flow through the thread pump. The liquid

analyte travels via capillary action along the thread

pump towards the ionophore-coated transducer. The

ionophores selectively extract sodium ions into the

hydrophobic membrane phase and transport these

ions across the barrier by carrier translocation. The

ions carried across the ionophore will then cause

perturbations on the RGO surface and change the

electrical resistivity. This change in electrical

property can be detected by a multimeter and the

data is then sent to a data-logger. A sensing window

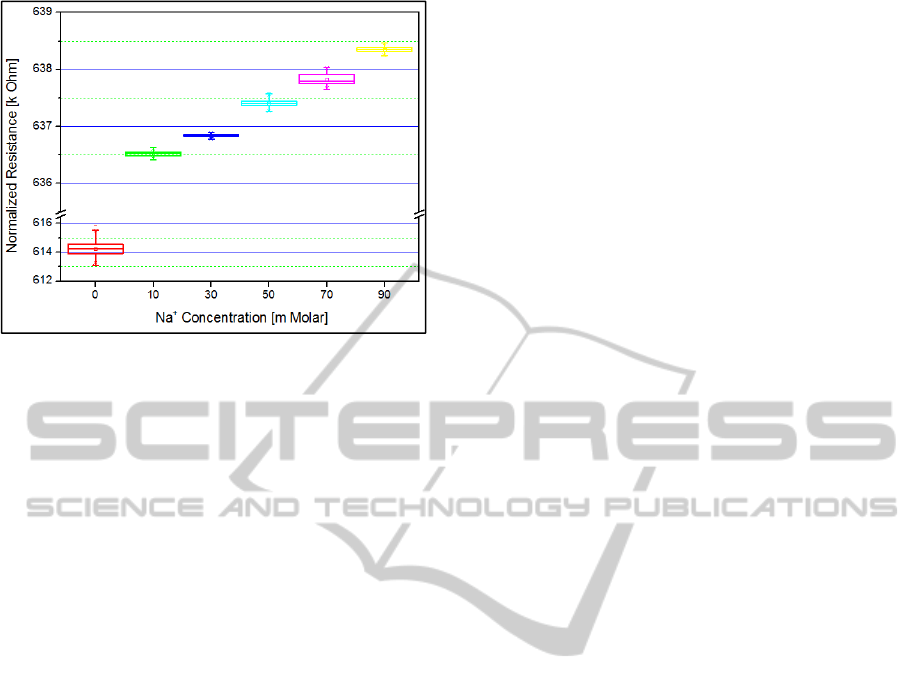

is thus obtained and presented in Figure 4.

As the fabricated RGO transducer is a p-type

semiconductor (Huang et al., 2013a), when positive

sodium ions travel through the ionophore onto the

surface, it induces a positive gating effect (Huang et

al., 2013b) and increases the RGO’s electrical

resistance. The electrical resistance changes

according to the change in the concentrate on of

sodium chloride.

As the concentration of the sodium chloride

increased from 0mM to 90mM, the electrical

resistance through the RGO transducer increased

from 615.2 to 638.5kΩ correspondingly. A 90mM

sodium ion concentration contributed a 3.9%

increase in electrical resistance across the RGO

transducer.

Patterson et al (Patterson et al., 2000) reported

whole-body sweat Na

+

concentrations of 24.1±15.0

mM (mean ± SD). Na

+

levels at specific regions

icSPORTS2013-InternationalCongressonSportsScienceResearchandTechnologySupport

86

Figure 4: Normalized electrical resistance output vs.

sodium ion concentration input.

(such as the forearm, chest and scapula) were

consistently higher (mean Na+ concentration at each

site: 42.2±25.8, 47.6±25.7 and 42.2±24.8 mM

respectively). Therefore, our sensor operates within

the typical physiological range. As can be seen from

the large standard deviations for sweat Na

+

levels,

sweat composition can vary widely between

individuals. Our sensor is therefore of interest in the

field of exercise science: real-time monitoring of

sweat Na

+

losses allows for the development of

athlete-specific rehydration strategies.

In theory, the lower detection window of the

reported transducer is only limited to the sodium

ionophore applied and electronic amplification

equipment used, as graphene had already been

shown to detect 1 single molecular binding events

(Schedin et al., 2007). As a comparison, a single liter

of 10mM of sodium chloride solution contains

6.023x10

26

number of sodium ions. With such high

sensitivity, this RGO-based sensor can also be

modified with antibodies or other ionophores to

detect other specific ions or biomolecules of interest

to the community. The presented sodium sensor

could potentially be used to diagnose dehydration in

the ageing population and used in the study of the

biology of sweat in older people. Future work on the

disposable and low-cost real-time fully-organic

sensor platform would include optimizing the

fabrication technique for mass-production and

sensing for other ions or proteins.

3 CONCLUSIONS

During exercise, one of the body’s major ionic

deficits of concern is Na

+

. Measurements of sodium

ions in sweat had been reported previously to predict

changes in serum. In this paper, we have shown the

fabrication, characterisation and physiologically-

relevant sodium-ions detection limits of a novel

RGO-based sensor with an integrated pump that is

fully organic, low-cost and disposable. As the sensor

is small, light and wearable, it has enormous

potential to be integrated onto the human body

during field training to obtain real-time data for

immediate intervention.

ACKNOWLEDGEMENTS

The research was supported by the National Institute

for Health Research (NIHR) Diet, Lifestyle &

Physical Activity Biomedical Research Unit based at

University Hospitals of Leicester and Loughborough

University. The views expressed are those of the

authors and not necessarily those of the NHS, the

NIHR or the Department of Health. The research

was also funded by the Institute for Sports Research

(ISR) of Nanyang Technological University (NTU).

REFERENCES

Baker, L. B., Stofan, J. R., Hamilton, A. A. & Horswill, C.

A., 2009. Comparison of regional patch collection vs.

whole body washdown for measuring sweat sodium

and potassium loss during exercise. Journal of Applied

Physiology, 107, 887-895.

Costill, D. L., 1977. Sweating: Its Composition and

Effects in Body Fluids. Annals of the New York

Academy of Sciences, 301, 160-174.

Coyle, S., King-Tong, L., Moyna, N., O'gorman, D.,

Diamond, D., Di Francesco, F., Costanzo, D., Salvo,

P., Trivella, M. G., De Rossi, D. E., Taccini, N.,

Paradiso, R., Porchet, J. A., Ridolfi, A., Luprano, J.,

Chuzel, C., Lanier, T., Revol-Cavalier, F.,

Schoumacker, S., Mourier, V., Chartier, I., Convert,

R., De-Moncuit, H. & Bini, C., 2010. Biosensing

Textiles for Personalised Healthcare Management.

Information Technology in Biomedicine, IEEE

Transactions on, 14, 364-370.

Gia, 2012. Biosensors in Medical Diagnostics. Global

strategic business report. CA.

He, Q., Sudibya, H. G., Yin, Z., Wu, S., Li, H., Boey, F.,

Huang, W., Chen, P. & Zhang, H., 2010. Centimeter-

Long and Large-Scale Micropatterns of Reduced

Graphene Oxide Films: Fabrication and Sensing

Applications. ACS Nano, 4, 3201-3208.

Huang, J., Harvey, J., Chen, H., Fam, W. H. D., Nimmo,

M. A. & Tok, I. Y. A., 2013a. Growth of Graphene

Oxide Using Ethanol CVD. Procedia Engineering.

Huang, J., Harvey, J., Fam, W. H. D., Nimmo, M. A. &

FullyOrganicGrapheneOxide-basedSensorwithIntegratedPumpforSodiumDetection

87

Tok, I. Y. A., 2013b. Novel Biosensor for Interleukin-

6 Detection. Procedia Engineering.

Huang, J., Larisika, M., Fam, W. H. D., He, Q., Nimmo,

M. A., Nowak, C. & Tok, A. I. Y., 2013c. The

extended growth of graphene oxide flakes using

ethanol CVD. Nanoscale, 5, 2945-2951.

Huang, J., Larisika, M., Nowak, C. & Tok, I. Y. A.,

2013d. New Methods in Aqueous Graphene (Graphene

Oxide) Synthesis for Biosensor Devices.

Larisika, M., Huang, J., Tok, A., Knoll, W. & Nowak, C.,

2012. An improved synthesis route to graphene for

molecular sensor applications. Materials Chemistry

and Physics, 136, 304-308.

Li, X., Tian, J. & Shen, W., 2009. Thread as a Versatile

Material for Low-Cost Microfluidic Diagnostics. ACS

Applied Materials & Interfaces, 2, 1-6.

Mohanty, N. & Berry, V., 2008. Graphene-Based Single-

Bacterium Resolution Biodevice and DNA Transistor:

Interfacing Graphene Derivatives with Nanoscale and

Microscale Biocomponents. Nano Letters, 8, 4469-

4476.

Novoselov, K. S., Geim, A. K., Morozov, S. V., Jiang, D.,

Zhang, Y., Dubonos, S. V., Grigorieva, I. V. & Firsov,

A. A., 2004. Electric Field Effect in Atomically Thin

Carbon Films. Science, 306, 666-669.

Ohno, Y., Maehashi, K., Yamashiro, Y. & Matsumoto, K.,

2009. Electrolyte-Gated Graphene Field-Effect

Transistors for Detecting pH and Protein Adsorption.

Nano Letters, 9, 3318-3322.

Patterson, M. J., Galloway, S. D. R. & Nimmo, M. A.,

2000. Variations in Regional Sweat Composition in

Normal Human Males. Experimental Physiology, 85,

869-875.

Reches, M., Mirica, K. A., Dasgupta, R., Dickey, M. D.,

Butte, M. J. & Whitesides, G. M., 2010. Thread as a

Matrix for Biomedical Assays. ACS Applied Materials

& Interfaces, 2, 1722-1728.

Schazmann, B., Morris, D., Slater, C., Beirne, S., Fay, C.,

Reuveny, R., Moyna, N. & Diamond, D., 2010. A

wearable electrochemical sensor for the real-time

measurement of sweat sodium concentration.

Analytical Methods, 2, 342-348.

Schedin, F., Geim, A. K., Morozov, S. V., Hill, E. W.,

Blake, P., Katsnelson, M. I. & Novoselov, K. S., 2007.

Detection of individual gas molecules adsorbed on

graphene. Nat Mater, 6, 652-655.

Shateri-Khalilabad, M. & Yazdanshenas, M. E., 2013.

Fabricating electroconductive cotton textiles using

graphene. Carbohydrate Polymers, 96, 190-195.

Weschler, L. B., 2008. Sweat electrolyte concentrations

obtained from within occlusive coverings are falsely

high because sweat itself leaches skin electrolytes.

Journal of Applied Physiology, 105, 1376-1377.

icSPORTS2013-InternationalCongressonSportsScienceResearchandTechnologySupport

88