Pilot Study for the Evaluation of Thermal Properties and Moisture

Management on Ski Boots

Matteo Moncalero

1,3

, Martino Colonna

1

, Alessandro Pezzoli

2,3

and Marco Nicotra

1

1

DICAM – Alma Mater Studiorum, Università di Bologna, Via Terracini 28, 40131, Bologna, Italy

2

DIATI, Politecnico di Torino, C.so Duca degli Abruzzi 24, 10128, Torino, Italy

3

MeteoSport, Sport Psychology Research Unit, Motor Science Research Centre, School of Motor and Sport Sciences,

University of Turin, P.zza Bernini 12, Torino, Italy

Keywords: Ski Boots, Thermal Comfort, Temperature Sensing, Humidity Sensing, Sport Equipment, Equipment

Design.

Abstract: Winter sports are often performed in severe environmental conditions and this could represent a limit in

terms of comfort and therefore performance. Since alpine skiing has the biggest number of practitioners

among the winter sports and because the feeling of cold in the feet is one of the most common problem, a

testing method has been developed to perform outdoor tests on ski boots in order to evaluate the thermal

comfort for different liner materials. The tests, performed on both male and female skiers wearing the same

shell with different liners simultaneously (one on the left foot and one on the right foot), showed that a

significant difference in terms of comfort using different liners in the same environmental conditions is

present. Specific tests have been made to ensure that such differences between the two feet were not due to

physiological difference between left to right feet; for this reason, data has been recorded using the same

shell and liner for both feet, obtaining negligible differences between the two. Moreover, the collected data

can be used to optimize the target of use of the ski boot and liner, choosing the best materials to achieve

specific behaviour in terms of heating, breathability and moisture management.

1 INTRODUCTION

Footwear thermal insulation is one of the most

important factors for protection against cold. Since

hands and feet have a large surface area compared to

their volume and a small muscle mass, they both

tend to be much more sensitive to cold exposure

compared to other parts of the human body

(Kuklane, 2009). If it is true that the entire body’s

thermal insulation affects the local thermal condition

and that the local insulation has an effect on the total

thermal comfort (Afanasieva, 1972), the feeling of

cold discomfort into the feet will dominate in spite

of proper clothing on the rest of the body (Kuklane,

2009). The feet are comfortable when the skin

temperature is about 33°C and the relative humidity

next to the skin is about 60% (Oakley, 1984);

(Kuklane, 2009). The cold feeling of feet starts at

toe’s temperatures around 25°C, while discomfort

from cold is noted at temperatures under 20-21°C

(Enander et al., 1979); (Goldman and Kampmann,

2007); (Kuklane, 2009). A further decrease of the

foot temperature below 20°C is associated with a

strong perception of cold (Luczak, 1991); (Goldman

and Kampmann, 2007); (Kuklane, 2009).

Moisture is the most important variable that

affects footwear thermal insulation and thus foot

comfort (Kuklane, 2009). Nevertheless, it is

important to note that no specific human receptor

exists for the sensation of humidity (Bertaux et al.,

2010). Footwear should be chosen to keep external

moisture from entering and to allow internal

moisture to leave the footwear (Kuklane, 2009).

The importance of developing new studies on

thermal comfort in sport equipment arises from the

need to investigate which are the interactions

between men, equipment and environment. All men

activities can be strongly influenced by the climate

and sport activities are not exceptions.

It is well known how the garments, in sport

activities with stressful weather conditions, can

affect sport performances (Pezzoli et al., 2010; 2011;

2012). The possibility to study directly on the person

the benefits of a particular garment represents a new

171

Moncalero M., Colonna M., Pezzoli A. and Nicotra M..

Pilot Study for the Evaluation of Thermal Properties and Moisture Management on Ski Boots.

DOI: 10.5220/0004644401710179

In Proceedings of the International Congress on Sports Science Research and Technology Support (EESP-2013), pages 171-179

ISBN: 978-989-8565-79-2

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

frontier in applied research in sport, allowing to

determine whether and how it is possible to improve

the performance in different climatic conditions.

Winter sports are performed in the coldest and

harshest external conditions of all sports and the

effect of the external environment in terms of cold is

therefore more consistent with respect to summer

sports. Alpine skiing has the biggest number of

practitioners among the winter sports. Long

exposure times to cold temperature are often the

norm since the best conditions are present at

temperatures below 0°C.

The best thermal feature that a user can expect

from a ski boot is to keep him warm and dry, to

enjoy a sport day in the outdoors or to perform well

in a race. With the right amount of insulation it is

possible to keep the feet into the range of comfort

and to avoid frostbite; moreover, the heat generated

is better trapped in boots with higher insulation

(Kuklane, 2009). The insulation properties of shoes

and boots are directly proportional to the amount of

air trapped inside the fabric and between the foot

and the shoe, but when this space is filled by

moisture, the insulation loses its effectiveness. The

use of thicker socks could increase the overall

insulation but if the thickness it too high, it could

subtract space to the foot inside the boot, creating

problems to the blood circulation.

Another critical element among the

characteristics of a boot is its ability to expel

moisture from the inside to the outside; this feature

is usually called breathability. A different way to

expel moisture is called “pumping effect” and it

takes place during walking. In ordinary shoes the

pumping effect can remove about 40% of humidity

(Gran, 1957); (Kuklane, 2009). On the contrary, for

ski boots these considerations are not applicable. In

fact, it has been well demonstrated that in cold

conditions (sub-zero temperatures), the evaporation

due to the pumping effect and evaporation in general

are usually less than 5% (Kuklane and Holmér,

1998); (Kuklane et al., 1999; 2000); (Rintamäki and

Hassi, 1989). Moreover, ski boot shells are made of

impermeable plastics such as polyurethane,

polyolefin and polyamide. Impermeable materials do

not allow moisture from the outside to enter and wet

the insulation layers but, at the same time, almost all

the moisture generated during the sport activity

condenses inside the boot. Finally, the physical

activity, especially during sport performance can

affect the amount of moisture and this can strongly

influence foot temperatures. Some of the latest

studies have demonstrated that a foot can sweat

about 30 g/h and in some cases even up to 50 g/h

(Taylor et al., 2006); (Fogarty et al., 2007);

(Kuklane, 2009).

Therefore, the properties of the inner boot (in

terms of insulation and moisture management)

become dramatically important.

For all the reasons reported above it is clear the

need of a method for testing and evaluating the

thermal comfort on ski boots with different liners.

A pilot study was carried out on a reduced

number of testers with the intent to obtain

preliminary qualitative and quantitative data to use

for the construction a complete measurement

protocol. Since the method proposed in this paper

can collect data directly from outdoor conditions

during real skiing activity, it represents an

innovative approach in terms of materials

development, which has been instead previously

based on climatic chamber simulations (Havenith et

al., 2008); (Wang et al., 2012).

2 MATERIALS AND METHODS

Tests have been performed by placing small wireless

sensors (Maxim-Dallas, Hygrochron) to record

temperature and relative humidity inside the liner

and between the liner and the shell (inside the foot-

board placed between the liner and the external

plastic shell).

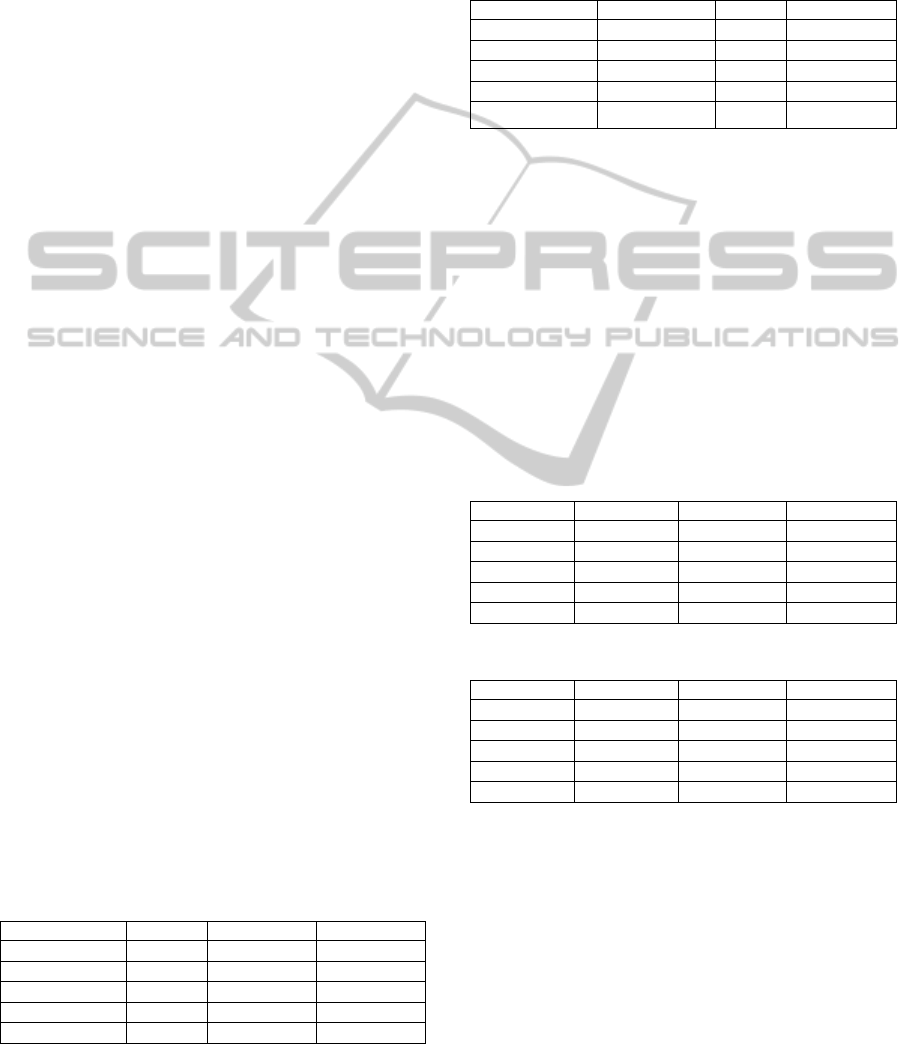

Figure 1: Sensor shape and size [mm].

The sensor dimensions (Figure 1) allow the

possibility to position them in the place where the

most cold is expected (front part of the boot),

without interfering with the skiing action or causing

pressures to skier’s feet. Proper slots have been

obtained by removing small amounts of material

from the sole and the foot-board. For both positions,

the most sensitive part of the sensor has been

directed towards the foot (sole) and toward the

liner’s sole (foot-board). The slots have been

externally insulated in order to avoid an increased

entrance of cold from the slots.

The relative humidity resolution of the sensor is

0,6% while the temperature resolution is 0,5 °C

icSPORTS2013-InternationalCongressonSportsScienceResearchandTechnologySupport

172

working with a sampling bit-rate of 8-Bit

(recommended for battery saving, especially in cold

environment). The data collection was carried out

through a software designed for the sensors by the

manufacturer, correction for humidity and

temperature is handled automatically using the

software (typical accuracy is ± 0,5 °C and ± 5 % for

relative humidity with software correction). Sensor

sampling rate was set to 30 seconds, since this low

frequency data acquisition has been considered

sufficient to describe the phenomena; the average

values are calculated among the data recorded

during the ski session (lift sessions included), values

are rounded to the first decimal place.

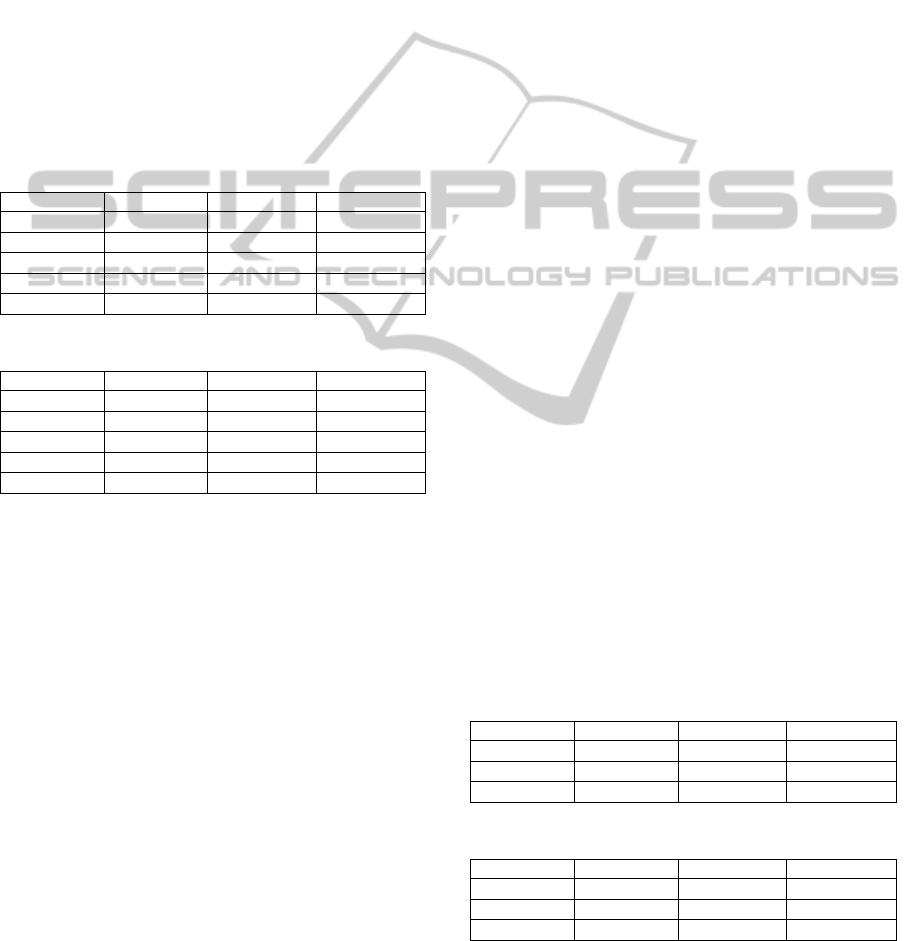

Each boot was equipped with two sensors: one

placed on the liner sole (Figure 2) and one on the

foot-board (Figure 3). All sensors have been placed

in the toe area, considering this as the most critical

part. Indeed, it is reported in the literature that the

temperature in the toes is lower than that in the

whole foot in cold conditions (Kuklane, 2009). On

the contrary, in comfort conditions (above 25°C), is

easy to have similar temperature levels in toes and

the rest of the feet (Kuklane, 2009). Wearing

appropriate footwear to protect from the cold, during

strong cold sensations, the toe’s skin temperature is

about 5°C lower than the mean foot skin temperature

(Kuklane, 2009).

Figure 2: Sensor placed on the liner sole (SOLE).

Figure 3: Sensor placed on the Foot-board (F-B).

A portable weather station (Skywatch, GEOS 11)

has been used in order to validate the results and

measure the environmental conditions during the

test. The weather station was used to measure the

wind speed, air temperature, air relative humidity,

altitude and pressure.

An additional on-board sensor (Maxim-Dallas)

was used to measure air temperature and relative

humidity outside the ski boots for all the duration of

the test. The sensor has been installed outside the

skier’s jacket and, comparing its output with the data

from the weather station, it has been verified that the

body heating did not affected its records.

Each test session has been performed by

comparing simultaneously two types of liners, built

with different materials and technology. One liner

tested is a traditional liner (Figure 4), made of a mix

of preformed ethylene vinyl acetate (EVA) and

others foams with the upper layer made of

polyethylene (PE) or polyvinyl chloride (PVC) and

with the lower sole made of PVC; the other liner

tested is a liner fully made of a mix of different

density closed cell EVA foam (Figure 5).

Figure 4: Traditional liner.

Figure 5: Liner made of closed cell EVA foam.

For women tests four different liners have been

tested:

Traditional with PVC upper layer and PVC

bottom sole.

Traditional with PE upper layer and PVC bottom

sole.

Traditional with PE upper layer and PVC bottom

sole with extra insulation at the tip.

Full EVA closed cell liner.

Tests have been carried out on the slopes, using both

chairlifts (open) and gondolas (closed) simulating a

PilotStudyfortheEvaluationofThermalPropertiesandMoistureManagementonSkiBoots

173

standard ski sessions. Data has been recorded in

continuous from 2 to 4 hours for each session

depending on the weather conditions; mean values in

the following tables have been calculated on an

average time of 2 hours. All testers have been

interviewed on their perceptions and sensations

about the ergonomic and thermal comfort during the

tests and at the end of each session. All test have

been performed in the Italian Alps: male tests took

place in Limone Piemonte (Top: 2085 m; Bottom:

1043 m), female tests took place in Val Gardena

(Top: 2453; Bottom: 1200 m).

Four testers have been used:

TESTER 1 (T1), male, 29 years old, 70 kg,

expert skier, (Session S1 – S2)

TESTER 2 (T2), male, 32 years old, 80 kg,

expert skier (Session S3)

TESTER 3 (T3), male, 29 yeas old, 85 kg,

professional skier (Session S4 – S5)

TESTER 4 (T4), female, 26 years old, 55 kg,

professional skier (Session S6 – S7 – S8 – S9).

All testers have used socks that they routinely use

during their alpine skiing. All socks used are made

of synthetic fibres.

3 RESULTS AND DISCUSSION

3.1 Male Tests

All tests have been performed in winter conditions,

in five different sessions.

In the following tables are reported the results

obtained for temperature and humidity, measured

with the on-board sensor on the skier jacket

(AMBIENT), in the foot-board (F-B) and at the sole

level (SOLE).

The first test has been performed to measure feet

temperature and relative humidity with the same

boot setup on both feet (Session 1, Tester 1,

traditional liner with PVC upper layer and PVC

bottom sole for each ski boot) in order to assess the

difference between left and right foot and the

reproducibility of the method.

Table 1: Session 1, TEMPERATURE [°C].

MIN MAX AVERAGE

AMBIENT 1,0 13,1 5,2

F‐BPVCsx 7,0 8,0 7,4

F‐BPVCdx 7,1 8,6 7,5

SOLEPVCsx 14,1 15,6 14,5

SOLEPVCdx 13,1 14,1 13,5

The same average foot-board temperature has

been recorded and the sole temperature difference

between the feet was 1 °C (Table 1). The humidity

values recorded on the foot-board were almost

coincident, while only in the sole it is possible to

notice a slight difference (Table 2; 2,2 %).

Table 2: Session 1, RELATIVE HUMIDITY [%].

MIN MAX AVERAGE

AMBIENT 46,6 91,1 64,6

F‐BPVCsx 51,9 56,2 53,9

F‐BPVCdx 52,2 55,7 53,8

SOLEPVCsx 96,0 101,2 99,4

SOLEPVCdx 92,5 100,9 97,2

These results show that, even if there could be a

difference in terms of temperature and relative

humidity between the two feet due to physiological

or mechanical causes (e.g. different buckles

clamping), these differences are negligible compared

to those due to the liner performance, which will be

shown in the following.

Graphs that report the temperature and humidity

measurements from S1 are shown in Appendix.

The results obtained for temperature and

humidity in the second session (S2), which has been

a mild winter day (Table 3) are reported in Table 3

and 4.

Table 3: Session 2, TEMPERATURE [°C].

MIN MAX AVERAGE

AMBIENT ‐3,5 11,1 1,9

F‐BPVC 4,1 14,1 6,4

F‐BEVA 5,1 15,6 9,6

SOLEPVC 10,6 28,2 14,5

SOLEEVA 13,1 29,6 21,2

Table 4: Session 2, RELATIVE HUMIDITY [%].

MIN MAX AVERAGE

AMBIENT 43,9 97,5 67,3

F‐BPVC 50,9 61,9 58,7

F‐BEVA 55,1 62,5 58,4

SOLEPVC 86,5 102,3 97,9

SOLEEVA 81,2 112,7 101,5

The testing session day has been characterised by

an average temperature which stayed above 0 °C

(1,9 °C) with a maximum temperature of 11,1°C

(Table 3). In this case there is a substantial

difference between the temperatures recorded in the

two soles (Table 3). The difference recorded

between the two liners (average, 6,7 °C) is well

above the difference measured in the first session

using the same ski-boot and liner set-up for both feet

(average, 1 °C) and therefore it is possible to state

that there is a clear difference in thermal insulation

icSPORTS2013-InternationalCongressonSportsScienceResearchandTechnologySupport

174

between the two liners in these skiing conditions.

The EVA liner, maintaining the average foot

temperature above the critical temperature of 20 °C,

has been able to offer a greater thermal comfort, in

agreement with what was found at the end of the

session interviewing the tester about his feelings.

Indeed, T1 reported a higher thermal comfort with

the EVA liners and a similar ergonomic comfort

with both liners.

The average values for the relative humidity

inside the liner (Table 4) in both cases have been

close or above the saturation limit.

In Table 5 and 6 are reported the results obtained

for temperature and humidity in the third session

(S3), which has been a much more colder winter day

with respect to S2.

Table 5: Session 3, TEMPERATURE [°C].

MIN MAX AVERAGE

AMBIENT ‐7,5 2,6 ‐4,6

F‐BPVC 3,1 11,6 7,5

F‐BEVA 10,5 14,6 12,4

SOLEPVC 10,1 25,6 17,3

SOLEEVA 23,1 29,6 26,9

Table 6: Session 3, RELATIVE HUMIDITY [%].

MIN MAX AVERAGE

AMBIENT 35,9 65,9 52,5

F‐BPVC 42,3 53,7 50,5

F‐BEVA 42,2 54,9 48,3

SOLEPVC 96,3 106,9 103,2

SOLEEVA 74,3 107,8 96,6

The whole test was conducted with an average

temperature which has been constantly below 0 °C.

As for S2 (Table 3), it is interesting to notice that

inside the liner, next to the toe (sole temperature),

the PVC liner has had an average temperature which

stayed in the discomfort range (Table 5; 17,3 °C),

while the EVA one offered enough comfort (Table

5; 26,9 °C), especially when compared to the

extreme cold conditions recorded.

Also the foot-board in the system equipped with

the EVA liner showed higher temperature values.

However, the temperature difference in the foot-

boards (with the two different liners) is lower if

compared to the difference of the temperature

measured in the sole for the same couple of liners.

For this reason, as expected, the sensor positioned in

the sole can show more significant differences in

terms of insulation behaviour for different liners

with respect to that positioned in the foot-board. The

sensor positioned in the foot-board should give

instead good information on the insulation behaviour

of the shell, if tests with different type of plastic

shells are performed. Indeed, the temperature in the

foot-board was always comprised between the

external temperature and the sole temperature,

indicating that the shell has a real thermal insulation.

Moreover, the thermal fluctuation between the

maximum and the minimum temperature record is

always less intense in the foot-board with respect to

the sole and to the external temperature, again

indicating an insulating behaviour of the shell.

The average relative humidity (Table 6) of the

EVA liner stayed below 100% while the PVC one

passed the saturation limit (103,2 %), indicating that

the foot was wet.

The tester reported a higher thermal comfort with

the EVA system despite a higher ergonomic comfort

with the PVC liner.

The results confirmed the tendency of the EVA

liner to be warmer compared to the PVC one.

Maximum difference between the two, during

session 1 and session 2, can be calculated from

Table 5 (9,6 °C) and from Table 3 (6.7 °C)

indicating that the external conditions have an effect

on the temperature difference between the two liners

and in particular that in very cold environments

(below -10°C) the difference between the liners will

be larger.

In Table 7 and 8 are reported the results obtained

for temperature and humidity in the fourth session,

which is the first of two sessions (S4 - S5) carried

out with tester 3. These tests have been performed in

order to maintain the same tester and to perform two

different skiing activities (free-skiing and slalom

racing).

In tables 7 and 8 are reported the results obtained

for temperature and humidity, measured with the on-

board sensor (AMBIENT) and at the sole level

(SOLE) for the comparison between PVC liner and

full EVA one during a free skiing session with no

gates.

Table 7: Session 4, TEMPERATURE [°C].

MIN MAX AVERAGE

AMBIENT 5,0 10,0 7,6

SOLEPVC 13,5 16,0 14,9

SOLEEVA 14,5 17,1 15,9

Table 8: Session 4, RELATIVE HUMIDITY [%].

MIN MAX AVERAGE

AMBIENT 27,6 48,0 36,7

SOLEPVC 93,5 100,5 97,2

SOLEEVA 91,1 99,6 95,2

In Table 9 and 10 are reported the results

obtained for temperature and humidity in the fifth

PilotStudyfortheEvaluationofThermalPropertiesandMoistureManagementonSkiBoots

175

session, which is the second (S5) carried out with

T3, this time in a slalom racing skiing activity.

Table 9: Session 5, TEMPERATURE [°C].

MIN MAX AVERAGE

AMBIENT 5,6 12,2 8,2

SOLEPVC 20,6 27,6 23,4

SOLEEVA 24,6 28,1 25,8

Table 10: Session 5, RELATIVE HUMIDITY [%].

MIN MAX AVERAGE

AMBIENT 26,5 39,8 33,5

SOLEPVC 99,1 103,8 101,6

SOLEEVA 94,5 99,9 97,6

Both sessions of tests have been carried out in

similar conditions of temperature (Table 7 and Table

9) and humidity (Table 8 and Table 10). In both

cases the EVA liner has recorded higher sole

temperature values compared to the PVC one; but

during S4 both average temperatures (PVC and

EVA) have been very low (Table 7) while in session

5 they have been both closer to the comfort area

(Table 9).

This difference can be ascribed to the different

physical effort made by T3 between the two

sessions. Indeed, S4 has been a free skiing session

while S5 has been characterized by a racing ski

slalom session using gates that requires more effort

with respect to a free skiing activity.

The higher physical effort in S5 is also

responsible of the higher humidity values (Table 10)

compared to S4 (Table 8). Therefore, it is clear the

effect of the type of skiing performed and for this

reason it is not possible to make comparison

between different sessions unless a controlled skiing

is performed (same terrain, same length of the run,

same skiing approach and speed). Nevertheless, the

use of two different skiing styles does not affect the

relative behaviour of the two liners: in both sessions

(S4 and S5) a similar trend was observed since in

both cases the full EVA liner was warmer compared

to the PVC liner (average difference 1°C in session 4

and 2,4 °C in session 5).

3.2 Female Tests

All four sessions have been performed in winter,

using four types of liners. Similarly to what has been

done for men tests, for each session, the trend of

environmental parameters for the entire duration of

the test has been recorded and analysed. The

following results have been recorded testing ski

boots with a professional skier, female, 26 years old

(T4).

In the following tables are reported the results

obtained for temperature and humidity, measured

with the on-board temperature (AMBIENT), and at

sole level (SOLE).

Table 11, Table 12 (

PE vs. PE + tip extra insulation)

Table 13, Table 14 (

PVC vs. PE + tip extra

insulation

)

Table 15, Table 16 (

PVC vs. full EVA)

Table 17, Table 18 (

PE vs. full EVA)

Table 11: Session 6 - PE vs. PE + tip insulation

TEMPERATURE [°C].

MIN MAX AVERAGE

AMBIENT ‐5,5 12,6 1,7

SOLEPE 17,6 28,1 20,7

SOLEPE+

tipextra

insulation

17,6 28,6 21,8

Table 12: Session 6 - PE vs. PE + tip insulation

RELATIVE HUMIDITY [%].

MIN MAX AVERAGE

AMBIENT 35,2 86,3 66,4

SOLEPE 94,1 113,3 103,5

SOLEPE +

tipextra

insulation

75,6 102,4 99,3

The average temperatures of the sole (Table 11)

show that, under the conditions in which S6 took

place, the extra insulation on the toe of the shoe

ensures a slightly improved thermal comfort.

Furthermore, the different type of material used for

the tip insulation seems to give the footwear a higher

breathability, due to the lower relative humidity,

especially with reference to the minimum and

maximum values (Table 12).

Table 13: Session 7 - PVC vs. PE + tip insulation

TEMPERATURE [°C].

MIN MAX AVERAGE

AMBIENT ‐4,0 ‐0,4‐2,7

SOLEPVC 13,6 17,6 15,3

SOLEPE +

tipextra

insulation

11,6 16,1 13,4

Table 14: Session 7 - PVC vs. PE + tip insulation

RELATIVE HUMIDITY [%].

MIN MAX AVERAGE

AMBIENT 77,8 103,7 95,8

SOLEPVC 100,1 102,9 101,2

SOLEPE +

tipextra

insulation

95,6 103,1 100,1

icSPORTS2013-InternationalCongressonSportsScienceResearchandTechnologySupport

176

A rather cold climate and short snow showers have

characterized this second test made by T4 (session

7). In these conditions the PVC liner was warmer

compared to the PE with extra insulation liner but

none of the two shoes tested has allowed the athlete

to maintain the temperature of the feet within the

comfort levels (Table 13; both < 20 °C). The relative

humidity was very high in both cases (Table 14).

Table 15: Session 8 - PVC vs. full EVA [°C].

MIN MAX AVERAGE

AMBIENT 0,5 11,5 4,7

SOLEPVC 17,6 29,6 22,9

SOLEEVA 17,6 30,6 22,5

Table 16: Session 8 - PVC vs. full EVA RELATIVE

HUMIDITY [%].

MIN MAX AVERAGE

AMBIENT 53,2 91,32 74,0

SOLEPVC 84,6 110,8 103,2

SOLEEVA 92,5 106,8 101,5

S8 has been carried out in a winter sunny day

with high average temperature (4,7 °C; Table 15);

moreover, the aspect of the slopes and the solar

radiation should have emphasized the feeling of

comfort. In fact, both liners behaved in a similar

manner, ensuring enough thermal comfort at the tip

of the foot (Table 15).

Table 17: Session 9 - PE vs. full EVA [°C].

MIN MAX AVERAGE

AMBIENT ‐2,5 9,6 1,2

SOLEPE 18,6 26,6 22,8

SOLEEVA 21,1 24,6 22,7

Table 18: Session 9 - PE vs. full EVA RELATIVE

HUMIDITY [%].

MIN MAX AVERAGE

AMBIENT 64,1 104,7 94,5

SOLEPE 95,5 104,7 101,0

SOLEEVA 88,5 100,5 95,7

S9 was performed with an average temperature

slightly above 0 °C (Table 17; 1,2 °C) and a really

high air humidity due to some snow showers (94,5

%). The analysis of the extreme values in table 17

shows that, despite a difference of 2,0 °C for the

maximum values (26,6 °C and 24,6 °C), the EVA

liner did not crossed the border between the comfort

and the feeling of cold; indeed, the minimum

temperature recorded in the PE liner is 2,5 °C lower

compared to the one in the EVA liner (18,6 °C and

21,1 °C; Table 17). For each liner comparison, the

tester’s sensation of comfort was in agreement with

the data collected by the sensors.

4 CONCLUSIONS

Using this innovative method, it has been possible to

measure the performance of the footwear in the real

conditions of use, providing detailed information on

the thermal comfort for different materials used.

From the perspective of interaction with the

human body, taking into account the environmental

conditions in which the tests were performed (being

those that generally characterize alpine skiing), the

EVA liner seems to have superior thermal

characteristics for both male and female testers.

As for the temperature, very high differences

were found between the different types of liner

(Table 5) and significant differences were revealed

with the selective use of insulating material in the

area of the tip of the foot (Table 11). These

differences, even if of the order of a few degrees,

can be decisive for the achievement of a sufficient

thermal comfort, for a safe sport practice and for the

attainment of high performance.

Though with minor differences, the behaviour of

the ski boots in moisture management is in line with

what expect from a shell completely impermeable to

air and water. The ability of the ski boot system to

manage the water vapour and its condensation inside

the boot represents an important research field for

further investigation in the immediate future.

The climate data collected by the weather

stations (fixed and portable) and from the additional

on-board sensors have been essential to correlate the

environmental parameters to the behaviour of

different materials used. In fact, the difference in

terms of average temperature inside the shoe

between EVA liners and traditional ones increases as

the ambient temperature decreases (Table 3, Table

5).

While the on-board sensors showed fluctuations

synchronous with the typical phases of stop/motion

due to the alternation between lift and skiing

sessions, the ski boot system seems to be not

affected by these alternations, showing no

fluctuation in phase with those mentioned above; for

this reason it can be argued that, under the

conditions in which the tests were conducted, lifts

sessions do not represent a particularly critical issue

in achieving thermal comfort, though it must be

taken into account that they represent quasi-static

sessions.

The data collected also show that higher

temperatures have been recorded for men testers

PilotStudyfortheEvaluationofThermalPropertiesandMoistureManagementonSkiBoots

177

with respect to those for women; this denotes a

greater difficulty in ensuring a good level of thermal

comfort for the female gender. For both male and

female, further research can be carried out on

subjects with different tolerance to cold.

The application of this method to a larger

number of testers in a more standardised manner

(i.e. using the same skiing exercise pattern, the same

duration of each session and the same socks),

coupled with a statistical analysis, can assure great

improvements in products optimization, for a better

sport experience and a higher performance.

ACKNOWLEDGEMENTS

The authors would like to thank Calzaturificio Dal

Bello S.r.l. (Casella d'Asolo – TV – Italy) for the

support and funding of the research project.

REFERENCES

Afanasieva R. F. (1972) Hygienic basis for designing cold

protective clothing (Doctoral thesis), Moscow.

Bertaux E., Derler S., Zeng X., Koehl L., Ventenat V.

(2010) Textile, Physiological, and Sensorial

Parameters in Sock Comfort. Textile Research Journal

Vol 80(17): 1803–1810 DOI: 10.1177/004051

7510369409.

Enander A., Ljungberg A-S., Holmér I., (1979) Effects of

work in cold stores on man. Scand J Work Environ

Health 5, 195–204. Ergonomics 34, 687–720.

Fogarty A. L., Barlett R., Ventenar V., Havenith G.,

(2007). Regional foot sweat rates during a 65-minute

uphill walk with a backpack. The 12th International

Conference on Environmental Ergonomics, Mekjavic

I. B., Kounalakis S. N., Taylor N. A. S., (Eds.), 283–4,

Biomed d.o.o., Ljubljana, Piran.

Gran G (1957) Investigations on shoe climate and foot

comfort. J Soc Leather Techn & Chem 43, 182–97.

Goldman R., Kampmann B., (2007) Handbook on

clothing. Biomedical Effects of Military Clothing and

Equipment Systems. 2

nd

Edition.

Havenith G., Richards M. G., Wang X., Brode P., Candas

V., den Hartog E., Holmer I., Kuklane K., Meinander

H., Nocker W., (2008) Apparent latent heat of

evaporation from clothing: attenuation and “heat pipe”

effects. J Appl Physiol 104(1): 142-149.

Kuklane K., Holmér I., (1998) Effect of sweating on insu-

lation of footwear. Int J Occup Saf Ergon 4, 123–36.

Kuklane K., Holmér I., Giesbrecht G., (1999) Change of

footwear insulation at various sweating rates. Appl

Human Sci 18, 161–8.

Kuklane K., Holmér I., Giesbrecht G., (2000) One week

sweating simulation test with a thermal foot model. In:

The Third International Meeting on Thermal Manikin

Testing, Nilsson H and Holmér I (Eds.), 106–13,

National Institute for Working Life, Stockholm.

Kuklane K., (2009) Protection of Feet in Cold Exposure.

Luczak H., (1991). Work under extreme conditions.

Oakley E. H. N., (1984) The design and function of mili-

tary footwear: a review following experiences in the

South Atlantic. Ergonomics 27, 631–7.

Pezzoli A., Baldacci A., Cama A., Faina M., Dalla Vedova

D., Besi M., Vercelli G., Boscolo A., Moncalero M.,

Cristofori E., Dalessandro M., (in press) Wind-wave

interactions in enclosed basins: the impact on the sport

of rowing. In: Physics of Sport. Ed. Ecole

Polytechnique de Paris. Paris.

Pezzoli A., Cristofori E., Gozzini B., Marchisio M.,

Padoan J., (2012) Analysis of the thermal comfort in

cycling athletes. Procedia Engineering, 34:433-438.

Pezzoli A., Moncalero M, Boscolo A, Cristofori E,

Giacometto F, Gastaldi S, Vercelli G (2010) The

meteo-hydrological analysis and the sport

performance: which are the connections? The case of

the XXI Winter Olympic Games, Vancouver 2010.

Journal of Sports Medicine and Physical Fitness,

50:19-20.

Rintamaaki H., Hassi J., (1989) Thermal physiology and

cold protection of feet with two types of rubber boots.

Arctic Rubber, Scandinavian Rubber Conference,

Tampere.

Taylor N. A. S., Galdwell J. N., Mekjvic I. B., (2006).The

sweating foot: local differences in sweat secretion

during exercise-induced hyperthermia. A viat Space

Environ Med 77, 1020–7.

The Thermal Environment Laboratory, Division of

Ergonomics and Aerosol Technology, Department of

Design Sciences, Faculty of Engineering, Lund

University, Box 118, SE-221 00 Lund, Sweden.

Wang F., del Ferraro S., Lin L. Y., Sotto Mayor T.,

Molinaro V., Ribeiro M., Gao C., Kuklane K., Holmer

I., (2012). Localised boundary air layer and clothing

evaporative resistances for individual body segments.

Ergonomics 55(7):799-812. doi: 10.1080/00140139.

2012.668948.

APPENDIX

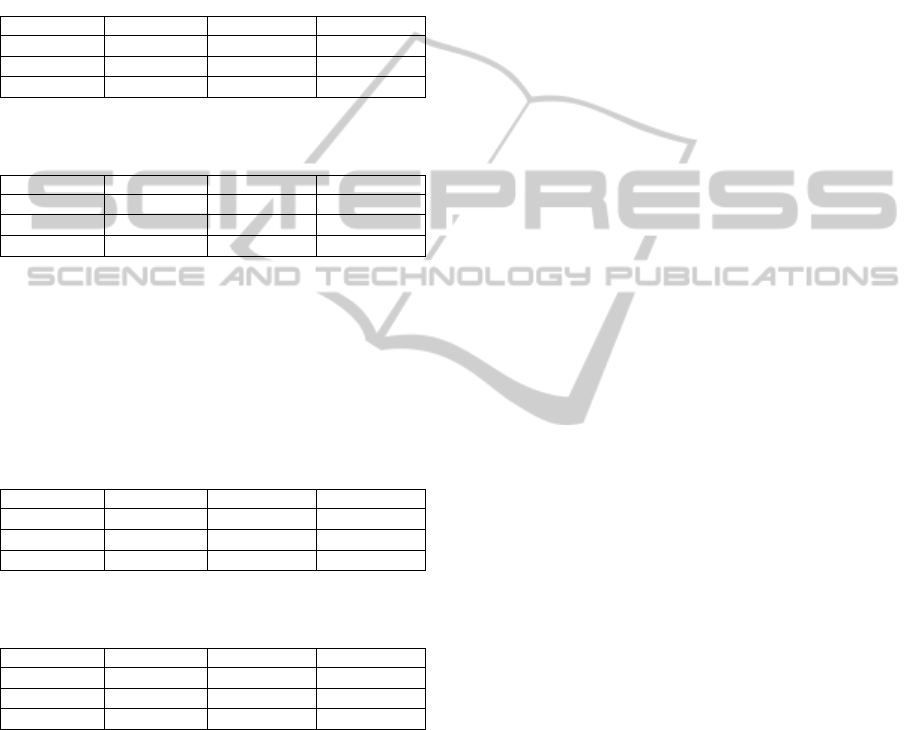

Graph 1: Session 1, F-B TEMPERATURE [°C].

icSPORTS2013-InternationalCongressonSportsScienceResearchandTechnologySupport

178

Graph 2: Session 1, F-B RELATIVE HUMIDITY [%].

Graph 3: Session 1, SOLE TEMPERATURE [°C].

Graph 4: Session 1, SOLE RELATIVE HUMIDITY [%].

PilotStudyfortheEvaluationofThermalPropertiesandMoistureManagementonSkiBoots

179