IPFViewer

A Visual Analysis System for Hierarchical Ensemble Data

Matthias Thurau, Christoph Buck and Wolfram Luther

Computer and Cognitive Sciences (INKO), University of Duisburg-Essen, Duisburg, Germany

Keywords:

Small Multiples, Coordinated Multiple Views, Ensemble Data, Trend Analysis.

Abstract:

Analyzing ensemble data is very challenging due to the complexity of the task. In this paper, we describe

IPFViewer, a visual analysis system for ensemble data, that is hierarchical, multidimensional and multimodal.

The exemplary data set comes from a steel production facility and comprises data about their melting charges,

samples and defects. Our system differs from existing ones in that it encourages the usage of side-by-side

visualization of ensemble members. Besides trend analysis, outlier detection and visual exploration, side-by-

side visualization of detailed ensemble members enables rapid checking for repeatability of single ensemble

member analysis results. IPFViewer supports the following data interaction methods: Hierarchical sorting and

filtering, reference data selection, automatic percentile selection and ensemble member aggregation, while the

focus for visualization is on small multiples of multiple views.

1 INTRODUCTION

Nowadays, the complexity and quantity of data sets

are increasing rapidly. Often, data collection capa-

bility exceeds the ability to analyze and visualize the

data. An ensemble data set is a multirun or multi-

value data set. In other words, it is a collection of

data sets. While all data sets use the same data struc-

ture, each of them has different values. Our system

was developed for a real-world steel production facil-

ity. As in many other industrial processes, the out-

come of the process can be influenced by hundreds of

input parameters to create product variations in accor-

dance with customer wishes. Additionally, the out-

come is influenced by natural fluctuations during the

execution of the process. To analyze how these input

parameters and fluctuations influence the process out-

come, thousands of measurements monitor both the

process and the outcome. Results of interest include

the most and least significant influential variables and

the exact influence each exerts. This may lead to a

better understanding of the production process and,

thus, to its potential improvement.

Our proposed solution can be adapted to ensem-

ble data sets from various production processes with

variations and uncertainties in their outcomes. Fur-

thermore, our system will analyze data from simula-

tions in which a model is simulated several times, of-

ten with different input parameters, resulting in multi-

ple outcomes. However, for most simulation data sets,

the dimension of time is not supported by our system

as our data set is not computer-simulated and thus can

only analyze one measured outcome.

Our novel approach to analyzing such data sets is

as follows. The hierarchical ensemble data set is a tree

of complex nodes, each one an ensemble member. All

nodes at a given level of the tree are visualized side-

by-side. Each and every node is represented by a mul-

tiple view system to deal with the high number of di-

mensions and modalities of a node. In other words,

we use small multiples of multiple views. Through

user-generated and reusable multiple-view layouts,

users can balance the various requirements on a lay-

out for differential tasks. We present interaction tech-

niques such as

• Hierarchical sorting and filtering

• User-defined reference data selection

• Automatic percentile selection

• Ensemble member aggregation

2 RELATED WORK

The visual analysis of ensemble data sets is relatively

new (Wilson and Potter, 2009). Wilson et al. pub-

lished a general overview of the challenges of ensem-

ble data sets. While most ensemble data sets are de-

259

Thurau M., Buck C. and Luther W..

IPFViewer - A Visual Analysis System for Hierarchical Ensemble Data.

DOI: 10.5220/0004668202590266

In Proceedings of the 5th International Conference on Information Visualization Theory and Applications (IVAPP-2014), pages 259-266

ISBN: 978-989-758-005-5

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

rived from simulations, as in climate research (Nocke

et al., 2007) or automobile engineering (Matkovic

et al., 2005), our data is from a real-world production

facility containing a single outcome measurement per

production run.

Many visualization systems work with coordi-

nated multiple views (CMV) so that a great number

of publications are available (Roberts, 2007). How-

ever, we did not find any system that reuses a user-

generated multiple-view layout to visualize multiple

complex data items simultaneously in a scrollable

area. Typically, the multiple-view layout stays in

place, while users change the data it shows.

Small multiples (Tufte, 1990) visualize multiple

data items, such as ensemble members, side by side

through (typically) a single visual per item. We be-

lieve that ensemble data sets can benefit from reusing

a CMV layout multiple times in the style of small

multiples.

Systems analyzing ensemble data mostly focus

on simulated and thus time-varying data (Wilson

and Potter, 2009). Examples of such systems are

Ensemble-Vis (Potter et al., 2009) or SimEnvVis

(Nocke et al., 2007). Typically the focus is on views

of the complete ensemble data set. Variations in

the ensemble members are visualized by techniques

familiar from uncertainty visualization (Pang et al.,

1996). Small multiples are used to visualize different

time steps. The trend and plume charts in Ensemble-

Vis are comparable to our overview visualizations,

where a single data dimension is shown in compar-

ison to reference data (the other ensemble members).

However, our system is superior to available systems

in that it can conduct visual searches for interest-

ing ensemble members and trend analysis of non-

aggregated and partly aggregated ensemble members.

Also our multiple-view layouts are more flexible and

user-generated.

3 BACKGROUND AND DATA SET

Steel making is a very complex process consisting of

various stages. At each stage, the production param-

eters can vary to fulfill the wishes of differing cus-

tomers. There are thousands of grades of steel, each

having specialized properties relating to corrosion,

heat resistance, deformability, welding quality, costs

and so forth. To fulfill these differing requirements,

variations occur in the production process. There may

be variations in the process flow, whether intention-

allysuch as varying the number of production steps

in order to reduce costs, which would normally affect

the purity of the steelor unintentionallythrough mal-

functions. Also, there are variations in the process pa-

rameters, like different melting temperatures, differ-

ent material ingredients and the different timings and

durations of each production step. Additionally, the

process is subject to various natural fluctuations that

have an impact on the outcome. While the smelting

furnace should be heated to a certain temperature, it

may fluctuate by several degrees and may thus affect

the outcome. We define the process input parameters

as the combination of all the desired process input pa-

rameters and variations and also the mostly undesired

natural process fluctuations, because all these param-

eters affect the outcome.

The outcome is measured in the form of a mul-

timodal and multidimensional data set for a sample

of the finished steel slab. The steel-making facil-

ity is digitizing scientific volume data about defects

found in the steel. These defects can be impurities in

the form of nonmetallic inclusions, argon bubbles or

cracks. The volume data is analyzed in a preprocess to

create shape descriptors, which can be analyzed much

faster than the original volume data. Hence, we define

our ensemble data set as

• multidimensional (multiple process parameters,

process measurements, volume data sets, shape

descriptors of defects, statistical summaries)

• multimodal (volume data, steel surface pictures,

spectral data, statistics)

• hierarchical (three levels: melting charges, sam-

ples and defects)

Our tree has three hierarchical levels. On the first

level, there are the melting charges. For each melting

charge, thousands of input parameters are available.

On the second level, each melting charge has multiple

samples connected with it; thus, it is a family of sam-

ples. Each sample has a set of analysis results, such

as overall cleanliness or average defect size. On the

last hierarchical level, there are thousands of defects,

each having shape descriptors and a volume data set.

4 OBJECTIVES

The analysis of our ensemble data set reflects several

goals:

• identify the significance of various input parame-

ters on the output (sensitivity analysis)

• analyze those changes in detail (trend analysis),

• find relationships between different output vari-

ables

• analyze the range of outcomes (uncertainty)

• and find anomalies and outliers within the samples

for quality control purposes

IVAPP2014-InternationalConferenceonInformationVisualizationTheoryandApplications

260

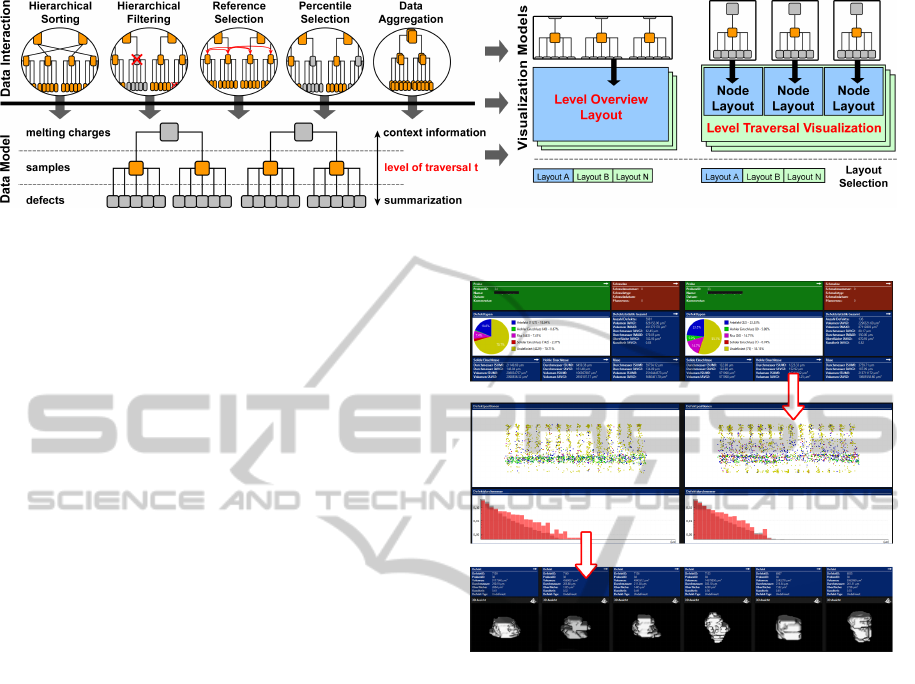

Figure 1: This screenshot shows the level of traversal set to samples. On the left, several graphs analyzing trends in various ag-

gregated values are shown. On the right, the samples of the current data tree are visualized in depth. Each sample is presented

in multiple views consisting of various visualization types and data from different hierarchical levels (context+details).

Some of the phenomena under observation in our spe-

cific data set are listed below. They can be analyzed

with our system.

• Defects floating in the liquid steel may have an

ascending force, like that of bubbles in sparkling

water. As a result, since the outermost layer of

the steel slab solidifies first when it meets a lower

ambient temperature, defects should be trapped in

the so-called inclusion band, which is located in

the surface of the slab. The larger a defect is,

the greater its ascending force and therefore the

higher its position in the inclusion band.

• Other properties that may influence the position

of defects are sphericity (form descriptor), type of

defect, and properties inherited from the melting

charge, such as material ingredients or the dura-

tion of the oxygen blowing process.

• With certain types of defects, the defects size may

correlate with its sphericity, again like bubbles in

sparkling water. The bigger the defect is, the more

nearly spherical it will be.

• A more complex relation may be the melting tem-

perature in combination with the defects position.

Because initial temperature determines how long

steel remains molten, the degree of influence the

defect’s size on its position may vary.

Figure 2: An overview showing aggregated nodes, while

small multiples showing more detailed data.

5 SYSTEM DESCRIPTION

The first idea is to have small multiples as well as an

overview as shown in fig. 2. On the right side, there

is a typical small multiple visualization. Each of the

so-called multiples is a histogram. This indicates that

there is already some kind of hierarchical data. There

are n nodes, each having multiple data points attached

to it. The overview to the left does not show the nodes

as a complex visualization, instead, the child data for

each node are aggregated to a single value, which then

can be plotted. Each data point in the plot is one (ag-

gregated) node.

Both visualizations have advantages and disad-

vantages. The overview is good, when there is a

meaningful method of aggregation. Therefore, in-

stead of showing multiple histograms, a graph show-

ing only average values can be beneficial as users can

interpret that very quickly. The disadvantage, how-

ever. is the loss of information. The original data,

shown as histograms, reveal more information, which

may also be interesting. While most ensemble visual-

ization systems focus on such aggregated overviews,

we want to offer an alternative and focus on the more

detailed multiples.

In summary, when there is a level of traversal t,

which is the level of interest in the tree, then the small

multiple visualization show each multiple tn in a sep-

arate visualization by using child data from level t+n.

In contrast, the overview visualization shows all mul-

tiples tn in a single visualization. Each data point is

an aggregation of all the children of tn.

The described example showed a one-dimensional

data set. This could have been the defect sizes for

all samples in the histograms and the average defect

size in the overview. However, in our real-world data

IPFViewer-AVisualAnalysisSystemforHierarchicalEnsembleData

261

Figure 3: The system architecture has a data tree in the center, the main data model. Several data interactions are available for

manipulating that tree. The resulting tree is visualized by two distinct visualizations.

set, we have many more data dimensions, modalities

and hierarchies. Using multiple views is a popular

way to handle such complexities. Therefore, we en-

hanced our system to use multiple-view systems for

the overview visualization and the small multiples as

shown in fig. 1. On the left, multiple aggregated di-

mensions are shown in the level overview and on the

right, there are the small multiples, each of which

is a multiple-view system. As these multiples are

no longer necessarily small, we call the visualization

level traversal visualization. A more detailed descrip-

tion of the visualizations will follow in subsection 5.2.

5.1 Interaction Techniques

Fig. 3 shows the complete system. It reveals that there

is a single data model. This means that the nodes in

the overview and the level traversal visualization are

in the same order. Moreover, filtering nodes will af-

fect both visualizations. The following sections will

explain the interaction techniques in greater detail.

5.1.1 Navigating and Searching

Using visuals, such as histograms, to search can be

highly beneficial because humans can interpret them

much more quickly than they can lists of values.

The visual search is comparable to modern image

browsers, where files are mapped to a grid of pictures

to support the user in finding an image of interest. Our

system does the exact same thing with visuals of en-

semble data.

There are two ways to traverse the tree of a hier-

archical ensemble data set. A traditional file browser

traverses from the top of the tree to the bottom by se-

lecting a node on each level. This can be done in our

system: All melting charges are presented in a grid

in a scrollable area (fig. 4, top). Summarized statis-

tical data from each sample related to that melting is

displayed. After a melting charge has been selected,

the samples that are the children of the selection are

shown (fig. 4, middle). After selecting a sample,

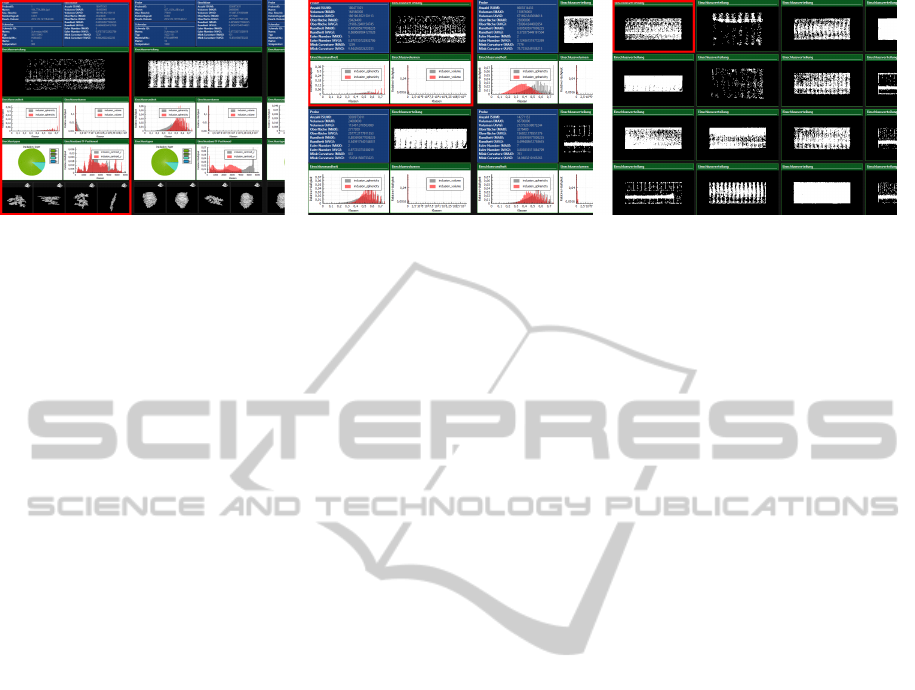

Figure 4: A multi-level navigation from meltings to samples

and then to defects.

all its defects can be browsed (fig. 4, bottom). This

is a typical multi-level navigation (Streit and Schulz,

2009).

Another way to search nodes of interest is to use a

level traversal, that is, to traverse the tree from side to

side. This may be beneficial when the user is search-

ing for a specific characteristic in a level, for exam-

ple, a specific distribution of defects. In this case, the

parent node is not of interest and thus the navigation

process does not start on the top level but on the level

of interest.

5.1.2 Hierarchical Filtering

To limit the number of visible nodes, filters can be ap-

plied. First, an attribute is selected from a list of avail-

able attributes. Here, attributes from all hierarchical

levels are offered. Filtering out parent nodes in a tree

will also filter out their children. Additionally, an ag-

gregation method is used when an attribute has been

chosen from a level that is lower than the current level

of traversal. In this case, multiple values would exist

for the specified attribute (one for every child node),

IVAPP2014-InternationalConferenceonInformationVisualizationTheoryandApplications

262

and therefore it has to be coupled with an aggregation

method such as sum, count, avg, min, max or median.

Statistical methods utilizing more than one attribute

can also be used, such as correlation, variance, co-

variance, regression etc. Aggregation is carried out

using SQL implementation. Additional aggregation

methods can be added directly into SQL. Once the

attribute selection has been defined to gain a single

value, an operator and a value for a comparison can be

set. It is also possible to create filters based on basic

existential quantifications like ”there is at least one”

or ”there are none” and to use multiple filters. One

example of this is the filtering of samples that have an

average defect diameter smaller than 50 of µm.

5.1.3 Hierarchical Sorting

Additionally, the nodes can be sorted. Here again,

attributes from higher levels or the current level of

traversal can be used, as can aggregated values from

lower levels. Reordering the nodes on any level of

a tree will, of course, also reorder their children on

lower levels. The main purpose of sorting the nodes

on the screen is to enable trend analysis, as shown in

fig. 5.

5.1.4 Reference Visualization

Figure 5: Several samples presented by histograms to allow

trend analysis. The red bars visualize the distribution of the

defects sphericity in the sample, and the grey bars visualize

the same data dimension from reference data.

Often, the significance of data is only visible in

comparison with other data. This is especially true

for ensemble data sets. What is the best way to clas-

sify the results of the current visible ensemble mem-

ber? This may be very difficult and at best visible to

a domain expert. To ease the classification, ensemble

data sets are commonly compared to reference data

(Kehrer and Hauser, 2013). The histograms in fig. 5

reflect the sphericity (shape descriptor) of the defects

for some samples. While the classification of the data

for one sample (the red bars) is not self-explanatory, it

is easy when the sample is compared to the reference

data (the grey bars). A more expressive alternative is

box plots (Mcgill et al., 1978). They display not only

the average [delete as a reference], but also the min-

imum, maximum and mean as well as further quar-

tile information. Thus, users can also see how far the

sample data lies outside of an uncertainty boundary.

5.1.5 Reference Selection

The interesting question is what to define as refer-

ence data. Within our ensemble data set from the

steel production facility, there are hundreds of differ-

ent grades of steel. For each the amount, distribution

and size of defects vary a great deal per definition.

On the other hand, only samples that have roughly the

same melting temperature are comparable as that pro-

cess parameter influences the defects so much. Ob-

viously, finding the right reference data is something

that needs to be flexible and may vary from applica-

tion to application and even from investigation to in-

vestigation.

Within our system, users define the reference data

by simply defining a list of attributes that have to

be equal. Thus, for the level traversal visualization,

where each sample is shown in a gallery, an attribute

name for the reference data may be the steel grade.

Our system will automatically fill the reference data

for each sample, so that only data from the same grade

as the individual sample is shown. When the attribute

is not categorical but numerical, an interval size or tol-

erance can be defined additionally; for example, the

user might stipulate that, besides adding only samples

with the same steel grade to the reference data, those

samples also have to have the same melting tempera-

ture, plus/minus 100 degrees.

5.1.6 Percentile Selection and Aggregation

Human perception is limited. Thus, one objection

to our system might be that the many millions of

nodes exceed the human users ability to analyze them.

While the perceptual overload regarding the visual-

izations of a single node can be solved by adopting the

multiple-view layout, there are two solutions avail-

able for dealing with the large number of nodes in

data space.

First, the number of nodes can be limited so that

only certain percentiles are visible. This can help in

the case of trend analysis. While including the com-

plete gallery of nodes may result in the visualization

of only small, nearly imperceptible changes from one

node to the next, presenting only a sampling of the

nodes (percentiles) may lead to the visualization of

more considerable changes. However, it is possible

that outliers might be included in the sample, render-

ing accurate trend analysis more difficult.

IPFViewer-AVisualAnalysisSystemforHierarchicalEnsembleData

263

Second, multiple nodes can be aggregated. While

this method is more secure against outliers, it can be

very slow when many millions of nodes have to be

aggregated and are visible at the same time. How-

ever, it can be done when the nodes have already been

filtered to a smaller number or when the number of

percentiles is high; for instance, aggregating tens of

nodes performs well and is more secure regarding out-

liers because it makes checking the area neighboring

percentiles less important. There is still a lot of work

ahead regarding data aggregation. While we imple-

mented aggregation of multiple nodes for histograms,

scatter plots and statistical summaries, we are still

working on aggregation methods for images and vol-

ume data.

5.2 Visualization

After describing the data interaction capabilities, the

description of the visualizations follows. It is com-

mon to visualize different hierarchical levels side by

side to support analysis (Kehrer et al., 2011)(Guo

et al., 2011). The level overview serves as an

overview of the selected level of traversal, while the

level traversal visualization shows detailed data of

level t+n about each node. There are various visual-

ization techniques that try to deal with the data com-

plexities that occur. There exists a great overview of

how to deal with multifaceted scientific data (Kehrer

and Hauser, 2013). We decided to use coordinated

multiple views as they are very flexible and can play

a variety of roles. Flexibility is very important as

there exists no one layout that is optimal for every

task (Wilson and Potter, 2009). This is not only true

for general multidimensional data sets, but also for the

range of tasks with which our system can assist.

To support users, our system can save user-

generated multiple-view layouts. Once a layout has

proven useful, it can be assigned a name and saved so

that it can be reused at a later time. While browsing

the nodes, changing the layouts is always possible by

clicking on the list of layout names at the top of the

visuals. While this is also possible in other systems,

like Microsoft Visual Studio

1

or Eclipse

2

, it is not yet

common in information visualization systems. One

reason for that may be the number of heterogeneous

data sets. A layout can only be reused for the same

data set or other data sets using the same data struc-

ture. Since the latter is the case for ensemble data

sets, quick access to predefined layouts is very bene-

ficial as it saves a lot of time that would otherwise be

spent re-creating layouts.

1

http://www.microsoft.com/visualstudio/

2

http://www.eclipse.org/

The user can choose from a range of visualization

options, including histogram, graph, pie chart, scat-

ter plot, text area, image and volume rendering. Two

resources of particular note in this regard are State

of the Art: Coordinated and Multiple Views in Ex-

ploratory Visualization (Roberts, 2007) and Guide-

lines for Using Multiple Views in Information Visual-

ization (Wang Baldonado et al., 2000). Because the

layouts are flexible and user generated, we do not

want to present specific layouts. Instead, we want to

describe the diverse requirements for the three tasks

our system supports: single node analysis, checking

for repeatability and trend analysis.

5.2.1 Single Node Analysis

Fig. 6 (left) shows a typical layout for analyzing one

individual node. The emphasis is on only one node;

neighboring nodes are not important. Thus, a lot of

screen space is used to visualize various aspects of

the hierarchical and multidimensional node in various

views. Multiple views are needed because the knowl-

edge about what data is interesting is not yet avail-

able. Context information, mostly textual, from par-

ents is shown, as are aggregated data and statistical

visuals about children. Also, simple data mining of

interesting nodes can be conducted to show anoma-

lies; for example, one might chose to visualize the

volume data of the largest defect or longest crack be-

cause they represent the greatest deterioration in steel

quality. This can be expressed with functions like

min, max, median, percentile etc. The use cases for

this layout role are

• generating a general hypothesis, which can be ap-

proved using neighboring nodes

• finding relationships between data dimensions,

like the influence of the defect volumes on the de-

fect positions

• finding anomalies and outliers that need further

investigation

• control of the current node, such as comparing the

outcome to a reference outcome

• and rapid assessment of the significance of indi-

vidual nodes, which is invaluable in cases such as

navigation of production outcomes

5.2.2 Checking for Repeatability

This functionality is often used right after the analy-

sis of a single node as described above. The result of

the initial analysis can be compared to other nodes. Is

the relationship between two variables or views also

visible in other ensemble members? The layouts can

IVAPP2014-InternationalConferenceonInformationVisualizationTheoryandApplications

264

Figure 6: Three different layout examples created for single node analysis, checking for repeatability and trend analysis.

be smaller and represent only that aspect of the data

that needs to be proven for repeatability, as shown in

fig. 6 (middle). In comparison to trend analysis, the

attention lies not on the differences between multi-

ple nodes, but on individual nodes examined one at

a time. Thus, multiple views are arranged to sup-

port each other. Filtering and sorting nodes is of great

importance in order to analyze whether the observed

result from one node is likely to be present in other

nodes, for example, it may depend on the steel grade

or the melting temperature.

5.2.3 Trend Analysis

Differences between nodes can be analyzed for trend

analysis. Here, the focus is not just on whether a given

characteristic can be found multiple times, but on the

degree to which that characteristic changes depending

on input parameters. Therefore, the nodes are sorted

according to those parameters and the data character-

istic of interest visualized. Various sort attributes can

be tested to find relationships and trends. Often, this

is done with single repeated visuals (small multiples).

However, using multiple views per node reveals

another dimension of relationships. When one data

dimension influences another data dimension in a sin-

gle node, the range of that influence may in turn be

influenced by some input parameter. For instance, the

position of a defect can be influenced by its size be-

cause larger defects rise faster while the steel is liquid.

However, because the initial temperature determines

the duration of the liquidity state, the degree of that

influence may vary.

6 IMPLEMENTATION

The system is implemented in C++ with the help of

OpenGL, Qt and vtk. The volume data is stored in

HDF5 files, while the rest of the data is stored in

a PostgreSQL database. The layout definitions are

saved as XML and contain visualization properties

(sizes, colors, etc.) and the names of SQL tables,

columns and aggregate functions to use. The system

data model queries the SQL table of interest (level

of traversal) and then adds those results (row defini-

tions) to the queries coming from the layouts. The vi-

sualizations are rendered through a render-to-texture

function, so that scrolling leads to a simple redraw of

a texture instead of a repaint of traditional windows.

View Frustum Culling enables the system to handle

multiple millions of nodes side by side. The system is

also extensible to more than three hierachical levels.

7 USER FEEDBACK

We collected feedback from the staff of the steel pro-

duction facility and also from information visualiza-

tion experts. Reactions were positive. Comparable

visualization systems focus on the creation of visual-

izations. Thus, once users create a visualization, they

switch between ensemble members manually to up-

date the data shown, for instance, selecting the en-

semble members in a text-based table view. With our

system, every layout change is seen directly for multi-

ple ensemble members. When a visualization appears

uninteresting, users can check other ensemble mem-

bers very quickly to verify this impression. This is

done either by scrolling or by setting up the layout in

such a way that multiple ensemble members can be

seen simultaneously.

The staff of the steel production facility had origi-

nally worked with static data reports, which had to be

opened one at a time. With our system, they were able

to create a node layout that provided the same infor-

mation as their previous reports. They can now search

much faster for specific characteristics and outliers in

the reports through sorted and filtered side-by-side vi-

sualizations, which also include up-to-date reference

data. While there are still disagreements over which is

the best layout to use, there is general agreement that

our system is useful and the staff were quick to adopt

it. Regarding choice of layout, since different groups

IPFViewer-AVisualAnalysisSystemforHierarchicalEnsembleData

265

have different expectations about content and visual-

izations, they defined different user groups, each with

their own set of layouts.

Regarding the more complex use cases, we plan

to conduct a user evaluation in future. While small

multiples in general have proven to be effective in

many situations (Archambault et al., 2011), it is un-

known how well they cooperate with multiple views.

Through small multiples of multiple views, users can

examine more complex relationships. For instance,

when a multiple view layout of one node reveals a

relationship between two data dimensions, how can

users perceive trends between multiple nodes within

that relationship? How does the influence of a de-

fects size on its position change as the temperature

of the melting charge increases? The influence may

be higher at higher melting temperatures. We plan

to publish a systematic expert and user evaluation to

study the strengths and weaknesses of our approach

in detail.

8 CONCLUSIONS AND FUTURE

WORK

In this paper, we have presented IPFViewer, a sys-

tem for visual analysis of hierarchical ensemble data.

Through the combination of small multiples with

multiple views and combining multiple hierarchical

levels, users can create multiple aggregated and non-

aggregated visualizations. Since layouts are user gen-

erated, the system is very flexible and can support

various analysis tasks. While we presented some ex-

amples to show the usefulness of our approach, the

full potential remains to be proven in a comprehen-

sive user evaluation. Newly developed high-density

displays and display grids are an especially useful ad-

dition to our system. The number of ensemble mem-

bers and the views themselves can be scaled to fit the

visible screen area. In future work, we will extend the

capabilities in areas of uncertainty visualization and

data aggregation.

REFERENCES

Archambault, D., Purchase, H., and Pinaud, B. (2011). An-

imation, small multiples, and the effect of mental map

preservation in dynamic graphs. IEEE Transactions

on Visualization and Computer Graphics, 17(4):539–

552.

Guo, H., Wang, Z., Yu, B., Zhao, H., and Yuan, X. (2011).

Tripvista: Triple perspective visual trajectory analyt-

ics and its application on microscopic traffic data at a

road intersection. In Pacific Visualization Symposium

(PacificVis), 2011 IEEE, pages 163–170.

Kehrer, J. and Hauser, H. (2013). Visualization and visual

analysis of multifaceted scientific data: A survey. Vi-

sualization and Computer Graphics, IEEE Transac-

tions on, 19(3):495–513.

Kehrer, J., Muigg, P., Doleisch, H., and Hauser, H. (2011).

Interactive visual analysis of heterogeneous scientific

data across an interface. IEEE Transactions on Visu-

alization and Computer Graphics, 17(7):934–946.

Matkovic, K., Jelovic, M., Juric, J., Konyha, Z., and Gra-

canin, D. (2005). Interactive visual analysis end

exploration of injection systems simulations. In

C. T. Silva, E. Gr

¨

oller, H. R., editor, IEEE Visualiza-

tion 2005, pages 391–398. IEEE.

Mcgill, R., Tukey, J. W., and Larsen, W. A. (1978).

Variations of box plots. The American Statistician,

32(1):12–16.

Nocke, T., Flechsig, M., and Bohm, U. (2007). Visual ex-

ploration and evaluation of climate-related simulation

data. In Simulation Conference, 2007 Winter, pages

703–711.

Pang, A. T., Wittenbrink, C. M., and Lodh, S. K. (1996).

Approaches to uncertainty visualization. The Visual

Computer, 13:370–390.

Potter, K., Wilson, A., Bremer, P.-T., Williams, D., Dou-

triaux, C., Pascucci, V., and Johnson, C. (2009).

Ensemble-vis: A framework for the statistical visu-

alization of ensemble data. In Data Mining Work-

shops, 2009. ICDMW ’09. IEEE International Con-

ference on, pages 233–240.

Roberts, J. (2007). State of the art: Coordinated multi-

ple views in exploratory visualization. In Coordi-

nated and Multiple Views in Exploratory Visualiza-

tion, 2007. CMV ’07. Fifth International Conference

on, pages 61–71.

Streit, M. and Schulz, H.-J. (2009). Towards multi-user

multi-level interaction. Collaborative Visualization on

Interactive Surfaces-CoVIS’09, page 5.

Tufte, E. (1990). Envisioning information. Graphics Press,

Cheshire, CT, USA.

Wang Baldonado, M. Q., Woodruff, A., and Kuchinsky, A.

(2000). Guidelines for using multiple views in infor-

mation visualization. In Proceedings of the working

conference on Advanced visual interfaces, AVI ’00,

pages 110–119, New York, NY, USA. ACM.

Wilson, A. T. and Potter, K. C. (2009). Toward visual anal-

ysis of ensemble data sets. In Proceedings of the 2009

Workshop on Ultrascale Visualization, UltraVis ’09,

pages 48–53, New York, NY, USA. ACM.

IVAPP2014-InternationalConferenceonInformationVisualizationTheoryandApplications

266