Compressor Design for a 30fs-300J 10PW Ti:sapphire Laser

Divided-compressor with an Object-Image-Grating Self-tiling Tiled Grating

Zhaoyang Li

1

, Tao Wang

1

, Guang Xu

2

and Yaping Dai

1

1

Shanghai institute of laser plasma, No. 1129 chenjiashan Road, Jiading, Shanghai, China

2

Shanghai institute of optics and fine mechanics, No. 390 qinghe Road, Jiading, Shanghai, China

Keywords: 10PW Laser, Chirped-Pulse Amplification, Grating Compressor, Tiled Grating, Dispersion, Self-Phase

Modulation.

Abstract: A 30fs-300J Ti:sapphire laser need an optimized compressor to compress the 8ns/90nm deep chirped long

pulse to 30fs. We proposed a compressor design, which reduces the grating number, grating size, vacuum

compression chamber cubage, and system complexity by using a divided-compressor structure and an

object-image-grating self-tiling method.

1 INTRODUCTION

Femtosecond 10 petawatt (PW) lasers are being

planned and constructed recently in the worldwide.

A 30fs-300J 10PW laser based on Ti:sapphire is

right now under plan in China. This system will use

the well-known chirped-pulse amplification (CPA)

technique to support its output capability (Mourou,

1988).

The primary design of the system linear chirped

ratio is around 8ns/90nm. Therefore, the pulse

compression process will be challenged by several

problems, including large-size gratings, long

compression distance, and huge vacuum

compression chamber (Kramer, 2013). In this paper,

we attempt to give a basic compressor design to

solve the above problems.

2 COMPRESSOR STRUCTURE

The primary parameter of the positive chirped pulse

after the amplification chain is given by Tab.1. And

the compressor should compress the 400J, 8ns

chirped pulse to less than 30fs.

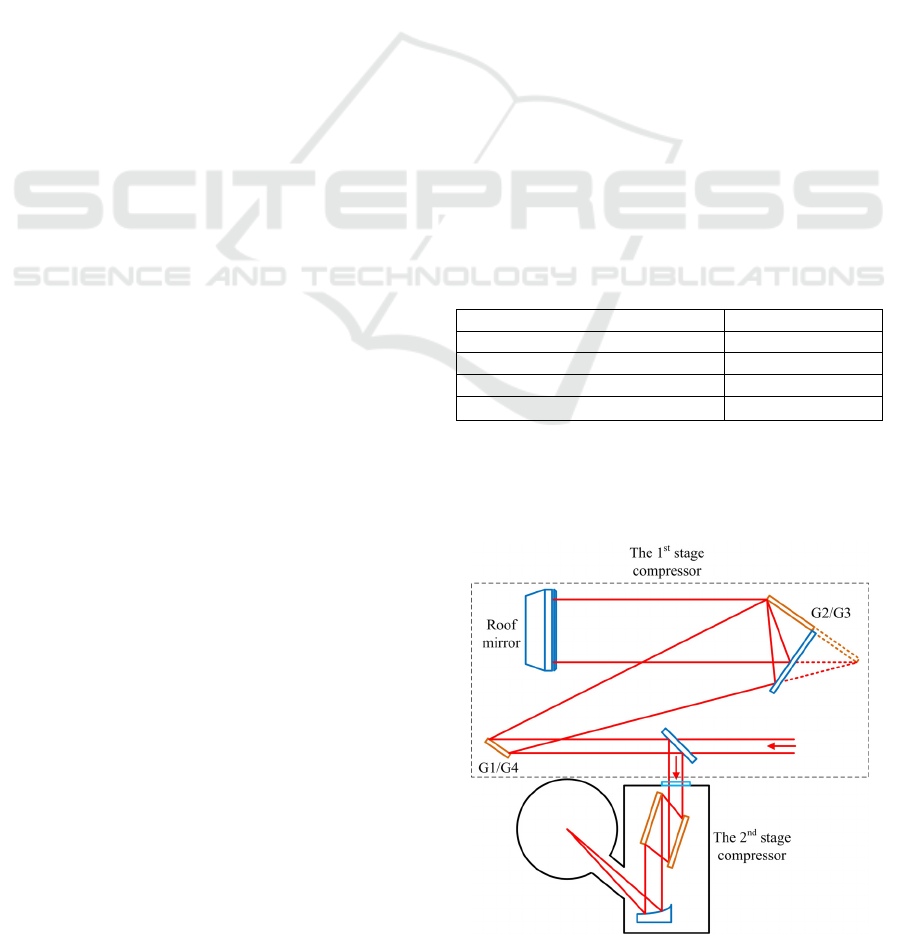

In order to reduce the vacuum chamber, as

shown in Fig.1, the treacy compressor (Treacy, 1969)

will be divided into two compressors: a double-pass

and a single-pass grating pairs are used as the 1

st

stage and the 2

nd

stage compressors, which are

located in air and a vacuum chamber, respectively.

Table 1: Beam parameter after the amplification chain.

Centre wavelength 800nm

FWHM 90nm

Single pulse energy 400J

Duration 8ns

Beam diameter

Φ150mm

The compression pulse from the 1

st

stage compressor

is delivered via a fused silica window into the

vacuum chamber and is further compressed by the

2

nd

stage compressor.

Figure 1: Divided-compressor design.

The thickness of the fused silica window is

191

Li Z., Wang T., Xu G. and Dai Y..

Compressor Design for a 30fs-300J 10PW Ti:sapphire Laser - Divided-compressor with an Object-Image-Grating Self-tiling Tiled Grating.

DOI: 10.5220/0004679701910195

In Proceedings of 2nd International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2014), pages 191-195

ISBN: 978-989-758-008-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

designed as 20mm to balance the air pressure and

the nonlinear effect. The compressed duration of the

1

st

stage compressor is a key paramter, which need

to be shorter enough to reduce the 2

nd

stage

compressor, as well as the vacumm chamber, but

longer enough to avoid the pulse distortion, fused

silica damage, air ionization, and so on. Generally,

the requirement of the pulse temporal and spatial

distortion by self-phase modulation (B integral) and

self-focusing is higher than that of the others.

Therefore, the B integral should be as small as

possible, and the beam breakup distance must be

much longer than the window thickness. The beam

breakup distance can be given by

2

z

G

nkI

(1)

where G is a coefficient from 3 to 10 depended on

different cnditions. Here we choose 3 to leave the

largest margin.

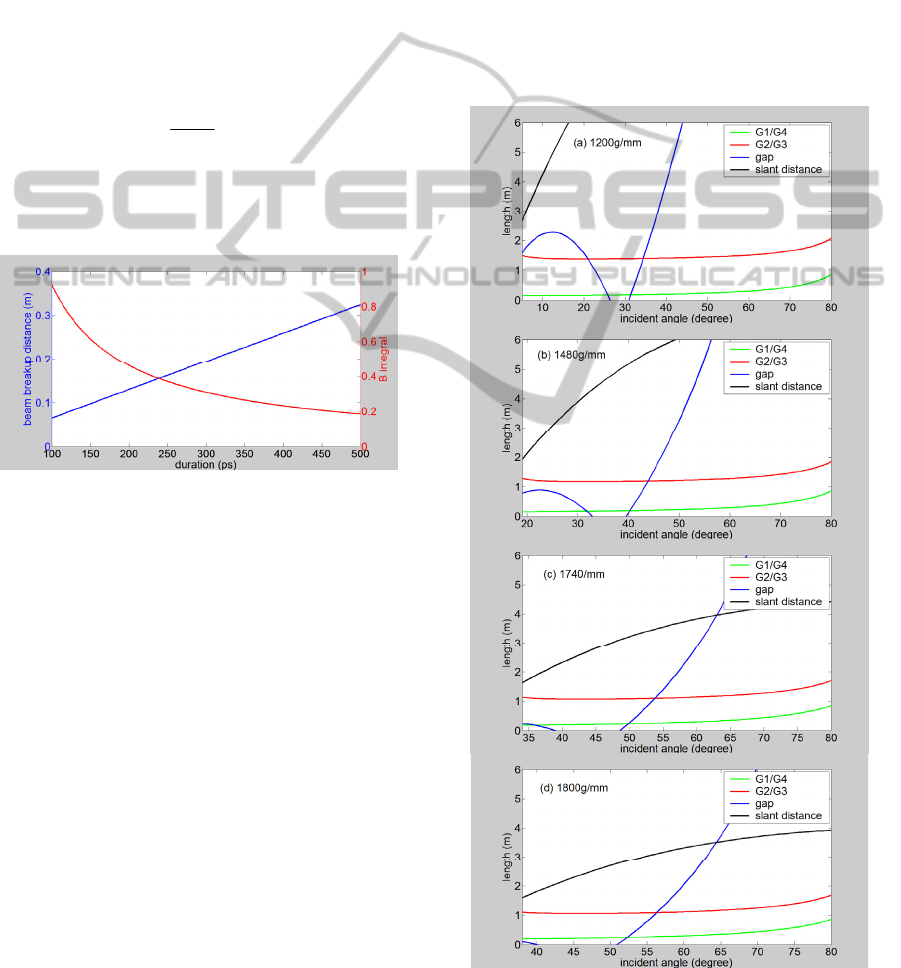

Figure 2: B integral and beam breakup distance versus

duration.

The evolution of B integral and beam breakup

distance for pulse duration is given by Fig. 2, and

the 300ps is chosen. Accordingly, the B integral is

0.3, and the beam breakup distance is 0.2m. The

intensity is 6GW/cm

2

which is below the 10GW/cm

2

threshold of air ionization, and the fluence is

1.84J/cm

2

that is below the 20J/cm

2

threshod of

fused silica damage for a 300ps pulse (Stuart, 1995).

3 PARAMETER OPTIMIZATION

3.1 The 1

St

Stage Compressor

Beside of the output parameters of a laser beam from

the amplification chain, there are many other

parameters determine the geometry of a treacy

compressor, such as unclipping spectrum range,

part-clipping spectrum range, grating groove density,

grating size, slant distance of grating pair, beam

incident angle, and so on. The grating groove

density and the incident angle are two basic

parameters which influence the other ones, and in

this section we will calculate parameters of the 1

st

stage compressor by choosing a suitable grating

groove density and an optimized incident angle.

The unclipping spectrum range of our design is

set as 90nm around the centre wavelength to allow

the FWHM passing without clipping. The design of

a treacy compressor must satisfy some limitation

conditions:

Grating equation;

Grating-beam overlap;

Sufficient wide spectrum window.

Figure 3: Grating size, gap and slant distance for 1200,

1480, 1740 and 1800 g/mm versus incident angle.

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

192

This design is based on the broad bandwidth 800nm

dielectric grating due to high damage threshold and

wide spectral range (Martz, 2009) and (Wang, 2010),

therefore types of available groove density include

1200g/mm, 1480g/mm, 1740g/mm and 1800g/mm.

Fig.3 shows the evolution of beam-grating gap,

grating size (a tradition single-pass 4-grating

compressor with the 1

st

, 2

nd

, 3

rd

, and 4

th

grating G1,

G2, G3, and G4. G1&G4 and G2&G3 have some

sizes, respectively.), and grating pair slant distance

for various amounts of incident angle with different

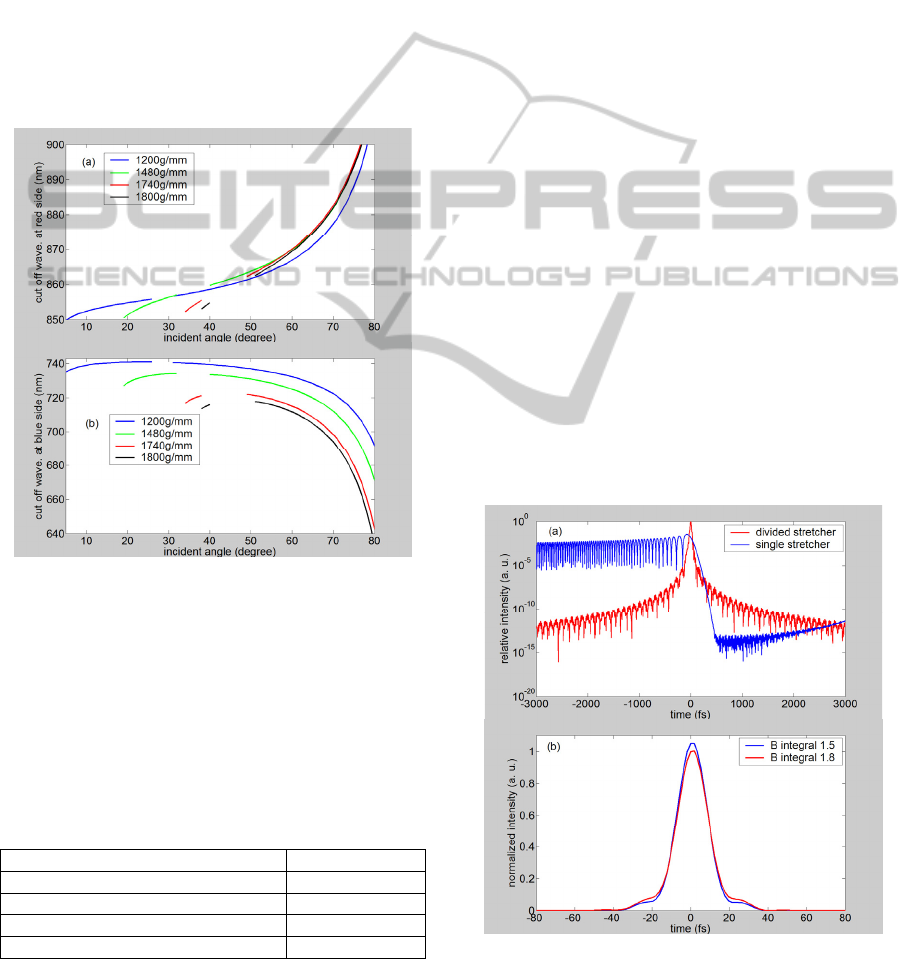

grating groove densities. And Fig.4 gives the

evolution of cut off wavelength of the part-clipping

spectrum range for various values of incident angle

with four types of grating groove density.

Figure 4: Cut off wavelength of the part-clipping spectrum

range for 1200, 1480, 1740 and 1800 g/mm versus

incident angle.

Our chosen principles of grating groove density

and incident angle include: relatively large beam-

grating gap, short length of grating and slant

distance, and wide range of part-clipping spectrum

range. And the optimized parameters are given by

Tab.2.

Table 2: Optimized 1

st

stage compressor parameter.

Grating density (g/mm) 1740

Incident angle (degree) 52

Grating size (m) 1.10

Slant distance (m) 3.37

Wavelength range (nm) 721-864

According to Martz’s work, the high diffraction

efficiency spectrum window of the broad bandwidth

dielectric grating is relative to the incident angle,

and the 52 degree incident angle could meet the

requirement of 721-864nm spectrum window.

To avoid the first grating damage where a short

pulse is achieved, a large incident angle is preferred.

The fluence with the optimized 52 degree incident

angle is 1.13J/cm

2

(below the 1.76J/cm

2

damage

threshold for a 120ps pulse reported by Martz).

3.2 The 2

nd

Stage Compressor

The 2

nd

stage compressor needs to dechirp the rest

chirp, and a 30fs short pulse will be obtained after it.

Hence, it is very easy to cause a grating damage. In

femtosecond regime, the damage threshold of the

broad bandwidth dielectric grating (0.18J/cm

2

for a

120fs pulse reported by Martz) is lower than that of

the gold coated grating (0.6J/cm

2

). Thus, Horiba

Jobin Yvon’s gold coated gratings are used in the

design of the 2

nd

stage compressor. The 0.6J/cm

2

damage threshold determines the smallest incident

angle is 71 degree. A 74 degree incident angle is

chosen to make the fluence 0.5J/cm

2

. Because of the

small spatial chirp, a single-pass parallel grating pair

is designed as the 2

nd

stage compressor. And the

other parameters are 1740g/mm grating groove

density, 0.336m slant distance, 0.544m grating size,

0.37m grating-beam gap, and 95-1078nm spectrum

range.

3.3 Dispersion and B Integral

Figure 5: (a) Compression pulse with and without 3

rd

dispersion compensation. (b) Compression pulse with and

without extra 0.3 B integral.

CompressorDesignfora30fs-300J10PWTi:sapphireLaser-Divided-compressorwithanObject-Image-Grating

Self-tilingTiledGrating

193

The non-equivalent incident angles of the 1

st

and 2

nd

stage compressors will lead to a big amount of

uncompensated 3

rd

dispersion, and the nonlinearity

effect within the fused silica window would

introduce self-phase modulation (B integral), hence

these two factors will distort the compression pulse

temporal profile.

Fig. 5 (a) shows the compression pulses with a

single-stretcher and with a divided-stretcher,

respectively. The incident angle and the grating

groove density of the single-stretcher are equivalent

to those of the 1

st

stage compressor. The 2

nd

dispersion of the single-stretcher-divided-

compressor system could be compensated, but the

3

rd

dispersion cannot be eliminated completely. In

this way, a divided-stretcher is designed to match the

divided-compressor to compensate both the 2

nd

, 3

rd

,

and 4

th

order dispersion. The incident angle, the

grating groove density, and the chirped ratio of the

divided-stretcher and those of the divided-

compressor are matched exactly. Moreover, the

divided-stretcher has another advantage: the smaller-

stretcher can be precisely adjusted to match the 2

nd

order dispersion of the whole system without

changing the larger-stretcher and the divided-

compressor.

Besides, we could also adjust the incident angle

of the single-stretcher to compensate both the 2

nd

and the 3

rd

but the 4

th

order dispersion within the

single-stretcher-divided-compressor system.

The control purpose of the B integral within the

amplification chain is 1.5. Fig. 5(b) shows the

compression pulse with a 1.8 B integral added the

influence of the fused silica window, and this

distortion is acceptable.

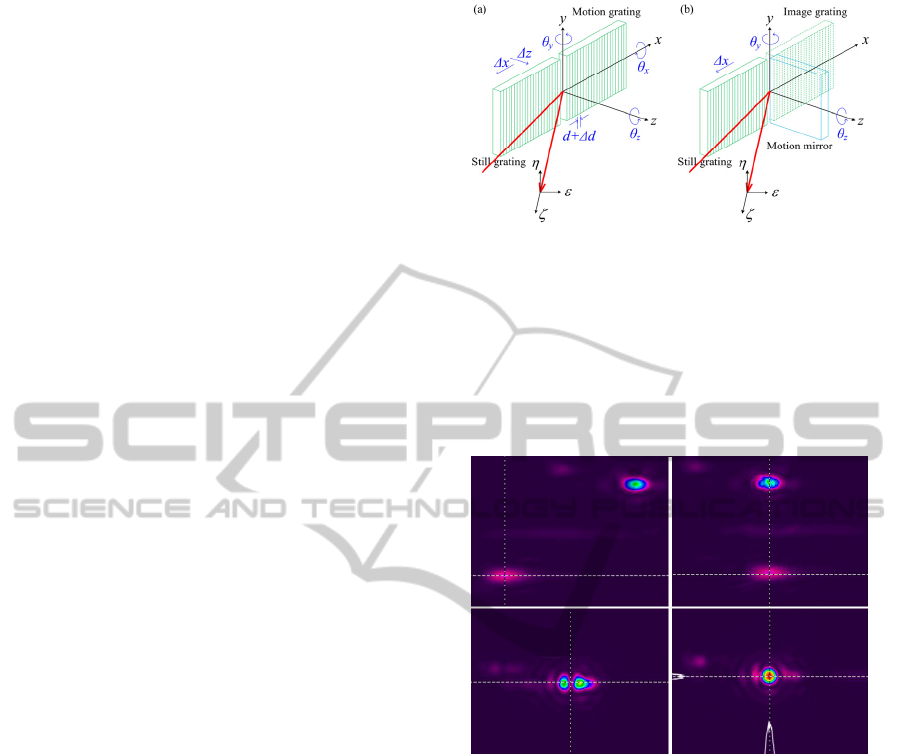

4 TILED GRATING

The requirement size of the second grating in the 1

st

stage compressor is 1.1m. However, the largest size

of the available grating is 0.56m. Therefore, the

object-image-grating self-tiling method is used to

double the effective grating size to 1.1m, and the

size of the corresponding mirror is 0.8m (Li, 2010).

The object-image-grating self-tiling method is a

very easy way to enlarge the effective grating size,

as shown in Fig.6, which reduce the number of tiling

errors within a tiled grating from 6 to only 3.

Besides, the tiling condition monitoring of the

proposed compressor design, as shown in Fig.1, is

very convenient, which can be achieved only by

observing the distribution of the main beam focal

spot. Unlike the traditional grating tiling, no

Figure 6: Degrees of freedom within (a) a tradition grating

tiling and (b) an object-image-grating self-tiling.

additional monitoring lasers are needed in a

compressor with only one tiled grating. And a

similar demonstration experiment is shown in Fig.7,

we just need 3 steps to achieve an ideal object-

image-grating self-tiling tiled grating by adjusting

y,

z, and

x (illustrated by Fig.6) one by one.

Figure 7: Steps to achieve the ideal tiling condition.

5 CONCLUSIONS

A divided-compressor is designed for a 30fs-300J

10PW Ti:sapphire laser to compress the 8ns/90nm

deep chirped laser pulse. This design could satisfy

the 30fs-300J compression requirement. The number

and the size of gratings, the cubage of the vacuum

compression chamber, and the complexity of the

system are reduced.

ACKNOWLEDGEMENTS

This work was supported by the National Natural

Science Foundation of China under project

11304296.

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

194

REFERENCES

P. Maine, D. Strickland, P. Bado, M. Pessot, and G.

Mourou, 1988. Generation of ultrahigh peak power

pulses by chirped pulse amplification. IEEE Journal of

Quantum Electronics vol. 24, pp 398.

D. Kramer, J. Novák, and B. Rus, 2013. Hybrid

compressor design for a 10PW laser. EPJ Web of

Conferences 48, 00010.

E. B. Treacy, 1969. Optical pulse compression with

diffraction gratings. IEEE Journal of Quantum

Electronics vol. QE-5, pp 454.

B. C. Stuart, M. D. Feit, A. M. Rubenchik, B. W. Shore,

and M. D. Perry, 1995. Laser-induced damage in

dielectrics with nanosecond to subpicosecond pulses.

Physical Review Letters vol. 74, pp 2248.

D. H. Martz, H. T. Nguyen, D. Patel, J. A. Britten, D.

Alessi1, E. Krous, Y. Wang, M. A. Larotonda, J.

George, B. Knollenberg, B. M. Luther, J. J. Rocca and

C. S. Menoni, 2009. Large area high efficiency broad

bandwidth 800nm dielectric gratings for high energy

laser pulse compression. Optics Express vol. 17, pp

23809.

J. Wang, Y. Jin, J. Ma, T. Sun, and X. Jing, 2010. Design

and analysis of broadband high-efficiency pulse

compression gratings. Applied Optics vol. 49, pp 2969.

Z. Li, G. Xu, T. Wang, and Y. Dai, 2010. Object-image-

grating self-tiling to achieve and maintain stable, near-

ideal tiled grating conditions. Optics Letters vol. 35,

pp 2206.

CompressorDesignfora30fs-300J10PWTi:sapphireLaser-Divided-compressorwithanObject-Image-Grating

Self-tilingTiledGrating

195