Portable OCT and its Industrial Application

Simple OCT for Industrial Use and Basic Health Care

Tatsuo Shiina

Graduate School of Advanced Integration Science, Chiba University,1-33 Yayoi-cho, Inage-ku, Chiba, Japan

Keywords: OCT (Optical Coherence Tomography), Industry, Health Care, Dentistry, Skin.

Abstract: Portable OCT; Optical Coherence Tomography has been developed for industrial use. This portable OCT is

time-domain type and it is evolved independently from the medical OCT in terms of product cost, system

size, flexibility, and its concept. To realize the unique concept, the new scanning mechanism was devised,

which is consisted of a rotating corner-reflector and a fixed mirror. Its scanning rate is not so high

(<200scan/s), while its measurement range can be enlarged easily. The Spectra-domain OCTs such as

Fourier-domain and Swept-source OCTs needs signal processing to obtain the information in the depth

direction. Their resolution depends on the scanning range and the sampling-rate. The time-domain OCT has

the feature that the resolution only depends on the spectrum width of the incident beam in isolation from the

measurement range. The depth information can be derived from the measured data easily and directly. The

system structure of the portable OCT is elastic in viewpoints of design of the optical prove and the

measurement range, and it is applied in various fields to date. Industrial use, educational aim, and basic

health care are its applications. In this report, the concept and the technical feature of the portable OCT are

mentioned. The concrete applications are introduced to represent the flexibility of the portable OCT, too.

1 INTRODUCTION

The optical sensors has been utilized for a long time

to measure and to diagnose the condition and the

appropriate structures of industrial materials. Here,

the optical sensors are interferometer, optical

displacement meter, moire inspection, stereoscopy,

holography, and so on. Especially, after the

innovation of laser, these devices and methods have

an advantage of high resolution in comparison with

the other sensing methods such as ultrasonic or

electrical measuring methods. The interior

monitoring of targets or materials is no less

important than the external form. The interior

structure measurement is fundamental. Clack,

bubble and uneven concentration can be visualized

by the interior monitoring of the optical sensors.

OCT, optical coherence tomography, is a low

coherence interferometer. (Huang 1991; Schmitt,

1999) The principle of measurement is the same

with white light interferometer. The white light

interferometer, however, mainly measures the

external form and displacement of the sample, while

OCT obtains the cross-sectional image. OCT

progressed in ophthalmology field. Its development

is started in the 2000s. Its technology and product’s

value are sufficiently matured.(Jiao, 2005; Rosa,

2007))

This ophthalmologic OCT, however, cannot

dominate to the industrial applications up to now.

The industrial OCT has large needs. (Goode, 2009;

Merken, 2011; Song, 2012; Wurm, 2007) Though it

is too expensive to install into industrial fields, it is

not only the reason to prevent its prevalence. The

ophthalmologic target, that is human eye, has the

typical size and features, and the manufacturer can

fix the specification of ophthalmologic OCT. In

other words, the system specification of

ophthalmologic OCT is optimized due to the human

eye. By this consideration, the high speed and the

high resolution are current trends of the

ophthalmologic OCT development. In the industrial

fields, there are various kinds of targets. Its size,

material, structure and measurement point are

different individually. The optical probe, which

throws the incident beam to the target, should be

changed due to the target, too. There are many

restrictions to adapt the ophthalmologic OCT to the

industrial fields. It will be better that the system is

simple, compact, robust and low cost. To apply the

83

Shiina T..

Portable OCT and its Industrial Application - Simple OCT for Industrial Use and Basic Health Care.

DOI: 10.5220/0004712200830090

In Proceedings of 2nd International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2014), pages 83-90

ISBN: 978-989-758-008-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

OCT technology to the industrial use, the system

should have flexibility to the various kinds of

targets. Its approach was started from the different

viewpoint with the development of the

ophthalmologic OCT.

The authors fixed such a concept of the industrial

OCT by 2000, and its portable one was developed in

2009. The system has a unique feature to meet the

industrial needs. The targets of an early date of the

industrial OCT are interior monitoring of industrial

materials, that is, glass, plastic, polymeric films. In a

half-decade, the targets spread not only in industrial

fields, but also expands to plant/food fields and basic

health care fields. In this report, the concept of the

portable OCT is explained and its actual applications

are introduced.

2 CONCEPT

The current OCT has some variations for the interior

diagnosis. Spectral domain OCTs including Fourier

domain OCT and swept source OCT is a technical

method to abandon the scanning in the depth

direction. They become high-speed and high-

resolution. These methods, however, fix their

measurement range and resolution due to the

characteristics of the light source, and it is hard to

change them for the targets. The high-resolution

needs the optical probe to be solid. The flexibility of

the measurement will be lower. The ophthalmologic

OCT is specialized for the human eye, while the

flexibility of the system configuration and the

measurement will be essential for the industrial

application, in which the targets will change its size

and specification.

The portable OCT for industrial use should cover

the various kinds of targets. It is different viewpoint

from the ophthalmologic OCT. The system is

desirable to change the following terms due to the

target.

Measurement range

Working distance of the optical probe

Scanning speed and repetition rate

Measurement range should be enlarged or be shorten

due to the target. The working distance of the optical

probe is better to have redundancy to expand or to

shorten it owing to the measurement target, too. The

scanning speed will be changed by the observation

method whether it is fixed-point measurement or

cross-sectional imaging. The former gives the

information of length (depth), while the latter is an

imager. The targets of industrial application are from

transparent materials such as glass, plastic and

polymeric film to scattering or absorbing materials

such as paper, paint, semi-conductor material and

biological tissue. The sensitivity of OCT

measurement will be sometimes too high, and the

strong reflection from the target may lower or

influence dynamic range of a detector. The

sensitivity should be changed due to the target, too.

The background optical noise, which does not

contribute to the interference, is also reflected by the

target surface. It should be removed.

At the viewpoint of redundancy, compactness

and low cost, we have developed the time-domain

type OCT (TD-OCT). Its resolution of the

measurement is uniquely decided by the spectrum

width of the low-coherent light source. The

measurement range and the working distance can be

fixed without relying on the resolution. As the

measurement data directly reflects the interior

structure, it makes the ensuring judgment easy.

3 PORTABLE OCT SCANNER

TD-OCT needs the mechanical scanning to move the

interference point in the depth direction. Typical

TD-OCT utilizes the piezoelectric transducer to

generate beat frequency of the interferogram. The

scan in the depth direction is conducted by another

scanning stage. This method is hard to speed up with

stable scanning. The stability of scanning depends

on the stage accuracy. In consequence, the long-path

scanning stage has the solid platform to keep the

accuracy. For the industrial use, the measurement

sample is often hard to fix its position precisely. It is

also difficult to shorten the distance between the

sample and the measurement probe. As a result, the

industrial OCT should have the flexibility in the

working distance and the measurement range

designs. The probe design and the scanning speed

should be optimized for each target.

The repetitive scanning motion should be stable,

too. In this study, the long optical path scanning

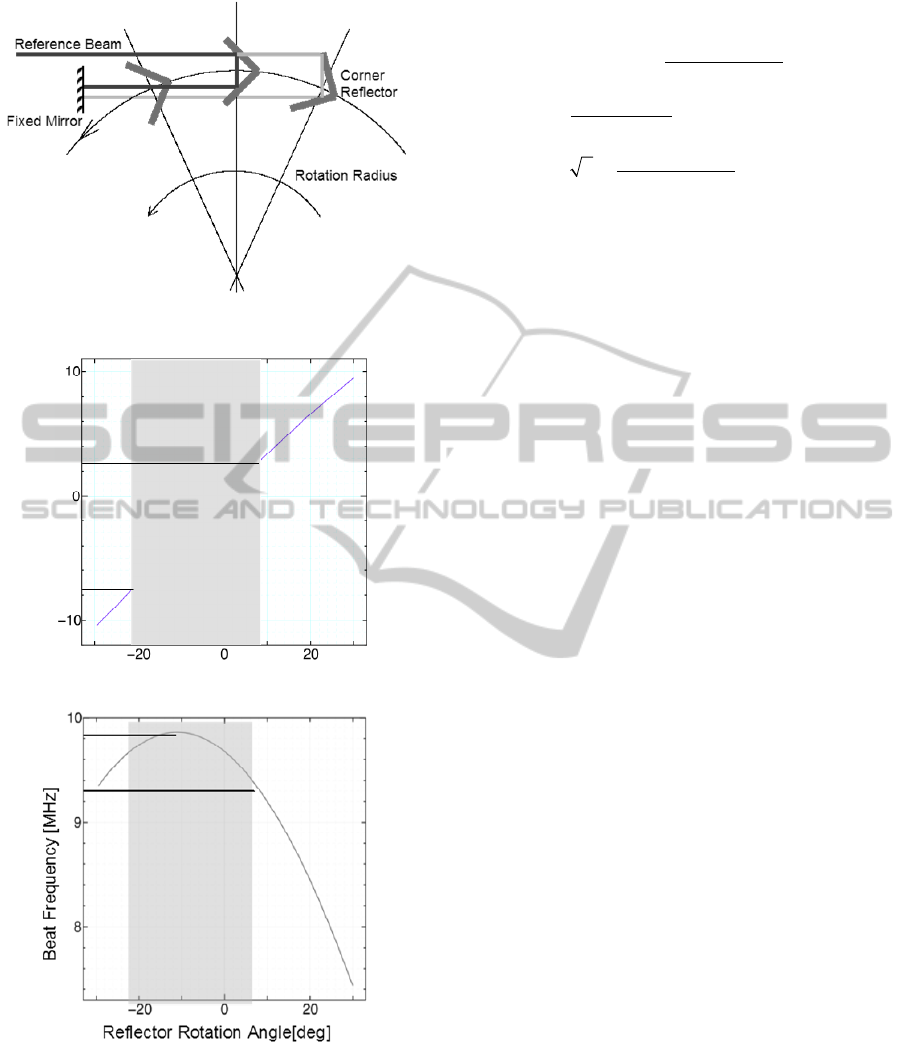

mechanism was developed as shown in Fig. 1. It

consists of a rotating corner reflector and a fixed

mirror. The scanning range depends on the rotation

radius of the reflector. The scanning speed

(repetition rate) is variable due to the rotation speed

of the reflector. The optical path length is derived by

the following equations.(Shiina, 2003)

Calculation examples of the optical path change

and the beat frequency of the interferogram are

shown in Fig. 2. The rotating radius and speed of the

reflector are 10mm and 50rps (= 3000rpm),

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

84

Figure 1: Long path scanning algorism.

(a) Optical path difference

(b) Beat frequency shift

Figure 2: Optical characteristics of scanning algorism.

respectively. The gray area in each graph indicates

the optical path difference of 10mm. The rotating

corner reflector generates the quasi-linear motion.

The divergence from the linear motion is 1-3%

within the rotation angle of +/-20 degrees. The

(1)

interferogram changes its frequency about 1MHz

within the above rotation range.

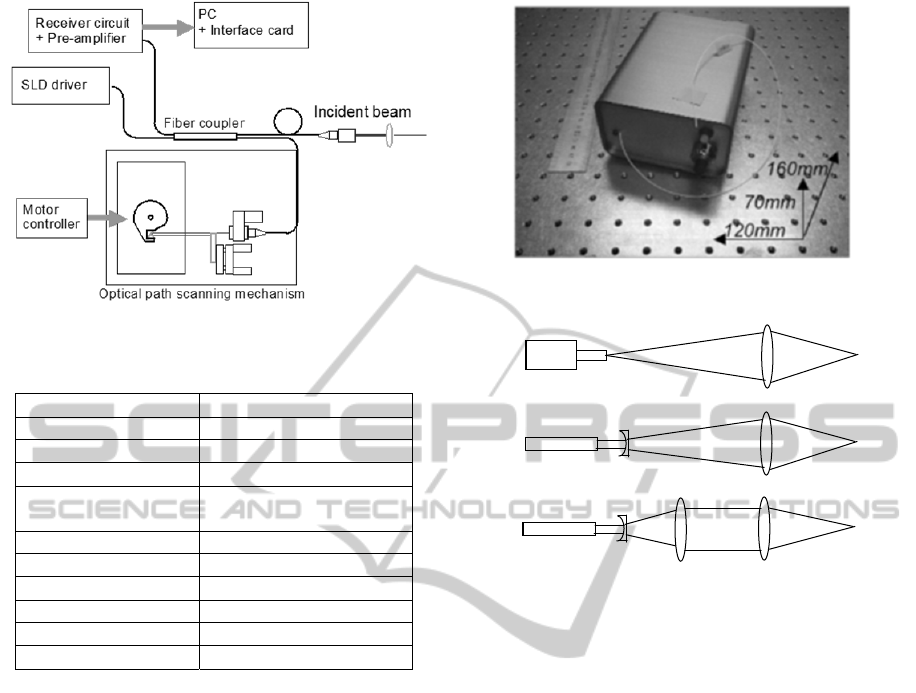

The portable OCT scanner is composed of SLD

light source module, optical fiber unit, motor unit for

optical path change and detector circuit as shown in

Fig. 3. The SLD light source is with a fiber optical

pigtail, witch is specially fabricated by Anristu Co.

Ltd. Its power is 3mW [max]. Its wavelength is

0.8m or 1.3m and its spectrum width is <60nm.

The resolution of TD-OCT is defined with the

spectrum width of the light source, and it became 6-

8m for the portable OCT. This SLD light source

does not have a cooler. A radiator can be stable

when the output of the optical power is refrained. A

radiator cooling fun is used for long time operation

when the output closes to the maximum (a few

milliwatt). The fiber assembly is specially

developed, too. It consists of a 2x2 fiber coupler and

two collimators, for fundamental structure. Optical

probe and reference ports have collimators. The

optical probe has the other lens optics due to the

target or optical arrangement. The detector circuit

catches the interference signal with a detector. It

outputs the interferogram signal and its envelope

signal through an electrical filter and an amplifier.

The digitized signals are gathered in PC via an

oscilloscope or an A/D interface card. The example

of the concrete setup is summarized in Table 1. The

scanning range is about 12mm when a reflector

rotates at the radius of 10mm. The scanning speed is

25scan/s. Position accuracy is <1m. The

divergence from the linear motion is able to correct

by using the equation (1). Figure 4 shows the

snapshot of the portable OCT scanner. Its size is

120mm x 70mm x 160mm. It can drive with a DC

power supply or a battery.

The wavelength, measurement range, and

scanning speed are fixed due to the target, while the

optical probe should be also designed individually.

The optical probe arranges the working distance

between the probe edge and the target. It receives

the backscattering light from the target with the

adequate numerical aperture (N.A.). It is designed

from 0 (parallel beam) to 0.3 due to the target. The

plate-like target is measured with narrow

Reflector Rotation Angle[deg.]

Optical Path Difference[mm]

Path _ Di f f er ence

2l

1

l

2

(1 sin 2

)

l

1

(r s)sin

(1 r )(1 cos

)

tan(

/4

)

l

2

l

3

cos(

/4

)

l

3

2s

(1 r )(1 cos

)

sin(

/4

)

PortableOCTanditsIndustrialApplication-SimpleOCTforIndustrialUseandBasicHealthCare

85

Figure 3: Portable OCT scanner.

Table 1: Portable OCT scanner.

SLD light module Anritsu Co. LTD

Powe

r

3mW [max]

Wavelen

g

th 1.3

m

Spectral width 61.2n

m

Fiber module

Tatsuta Electric wire &

cable Co., LTD

Scannin

g

Mechanism Maxon DC Servo moto

r

Rotation 25 scan/s (1500rpm)

Rotation Radius 10m

m

Resolution 7

m

Position accurac

y

<1

m

Scanning Range 12m

m

N.A., while the high-scattered target such as a

biological tissue is observed with wide N.A. The

spot size of the incident beam becomes 0.5mm

(N.A.=0) and 5m (N.A.=0.3). The measurement

data will be obtained by the combination between

the measurement range due to the reflector and the

depth of field on the optical probe. The design of the

optical probe has several assemblies of lenses as

shown in Fig.5. The differences among them comes

from ease of optical arraignment, simpleness, and

probe size.

4 APPLICATIONS

4.1 Industrial Use

The portable OCT can be installed into a factory as

an embedded equipment of production line. The

targets are the interior monitoring such as clack or

air bubble detection of plastic products, uneven

fluctuation of material or paint, and precision

evaluation of casting. For the industrial use, the

cross-sectional image is not always essential. The

Figure 4: Portable OCT scanner.

Figure 5: Optical probe assembly.

fixed-point measurement and its multi-channel

measurement will accommodate the demands of

industrial use.

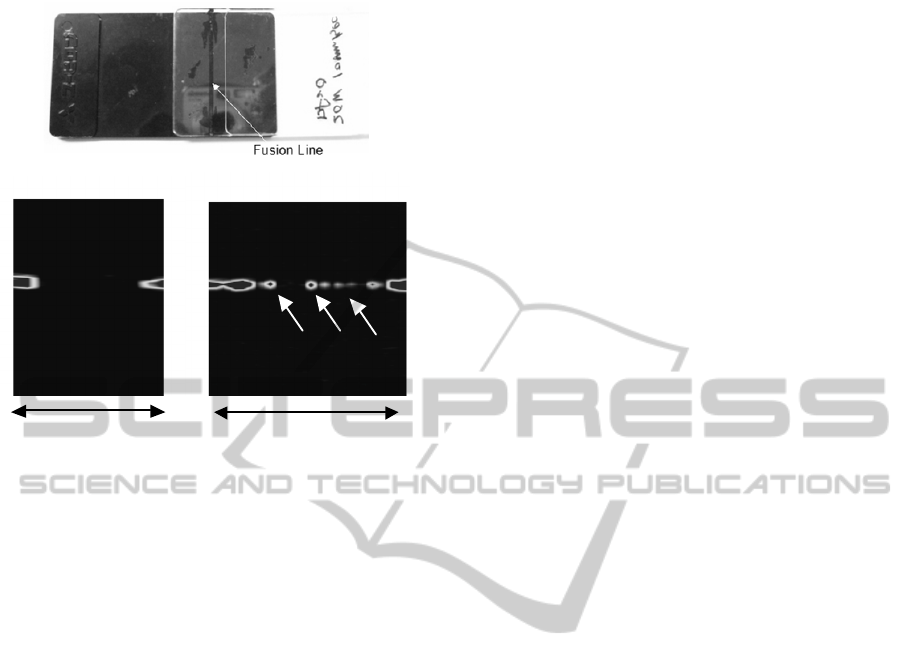

Figure 6 shows one of the measurement result,

which is the evaluation of laser fusion on the plastic

plates. (Shiina 2009) The cross sectional image is

obtained by moving the probe in perpendicular

direction against the optical axis (depth direction).

When the laser fusion is conducted perfectly, the

boundary surface between the upper and bottom

plastic plates is disappeared (left image). Then the

scanner does not receive any signal from the fusion

part. The gradations of the reflected interferogram

intensities are observed in the edges of the fusion

part (circle mark in left image). It is dependent on

the spot profile of the laser fusion. On the other

hand, when the fusion is incomplete, the scanner

receives the reflected interferogram signals from the

boundary surface (right image). The obtained OCT

image clearly shows the difference.

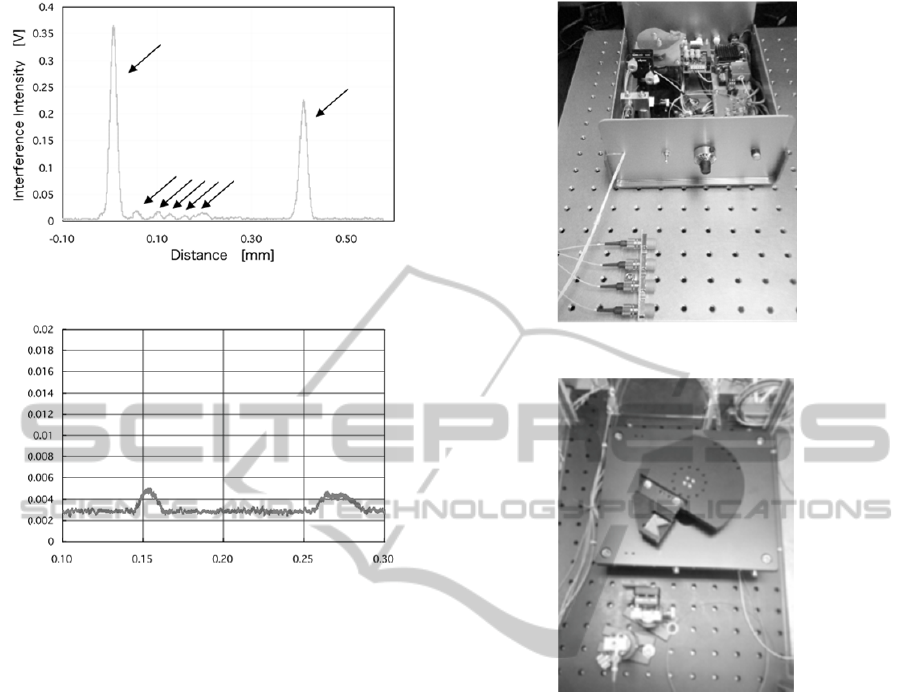

Figure 7 shows the measurement result of a

transparent laminated tube (mayonnaise tube). 6-7

layers thin films are layered. Because the differences

between the refractive indices are small, the

interference intensities inside the tube were small.

The layer structure is clearly distinguished. The

thickness of each layer is different from point to

FC Connector

Fiver Collimator

Fiver Collimator

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

86

Figure 6: Evaluation of laser fusion on plastic plates.

point of the laminate tube. The individual difference

among products can become a target of portable

OCT, too.

There is a great demand for thickness

measurements of glass, polymeric film, plastic, and

so on. Thickness fluctuation, precision and layer

structures are targets of industrial OCT measure-

ment. Tablet coating (wafer) of medicine was

observed as shown in Fig.8. The merit of portable

OCT is not only direct measurement of the tablet on

a factory line, but also follow-up measurement

through a package because the measurement range is

enough wide. There is no need of the precise

positioning of the target. The wavelength of portable

OCT is near infrared light (0.8 – 1.6 m), and the

influence of color is little. The industrial materials

have wide variety of size (thickness). The portable

OCT can adjust its measurement range to the target

size easily. The flexibility of the portable OCT is

suitable for the industrial use.

The portable OCT is expanded to add the new

function for the industrial demands. In a factory, a

certain procedure will separate on plural lines with

the same routine. In such case, the portable OCT can

separate the optical probe up to the number of the

lines. To make it realize, the optical switch is

installed into a portable OCT. The optical switch

produced by LEONI Co Ltd. was so small that it

could be installed into the case of a portable OCT.

The optical switch changes its channel at every

reflector rotation. When all of the plural probes have

the optical fibers with same lengths, each channel

will conduct the same measurement on plural lines.

When the probes have the different lengths, each

probe has a different task in a line.

The large targets such as combination lens,

crystal block, and liquid tank needs long

measurement range, while the traditional optical

sensor uses a long linear stage to scan the long

range. Such a sensor becomes large, heavy and high

cost. The portable OCT can expand the

measurement range by enlarging the radius of the

rotating reflector. The radius of 60mm, which is the

same size with a compact disc, has the measurement

range of more than 100mm. When the 3 x 3 fiber

coupler can add the reference port and these two

reference ports have different lengths, the

measurement range can enlarge twice as long as a

single reference port.(PCT 2010)

4.2 Basic Health Care

Medical OCTs including ophthalmology, internal

medicine, dentistry and dermatology are productive

applications.(Colston 1998, Leung 2011, Shimada

2012, Todea 2010) The ophthalmologic OCT is

success case to install it into a hospital. On contrary,

the other medical fields are in study phase. The main

impediment is a cost. The introduction of such a

OCT system needs space, cost and a specialist. The

portable OCT started to apply such fields, while it is

not the same direction as medical OCTs. The basic

health care is our purpose.

The portable OCT for dentistry is specialized its

optical probe, which is a stick-like body of the

diameter of 10mm with one-directional auto-stage.

N.A. was controlled to 0.14. The depth of field

becomes 5mm. The caries check is demonstrated

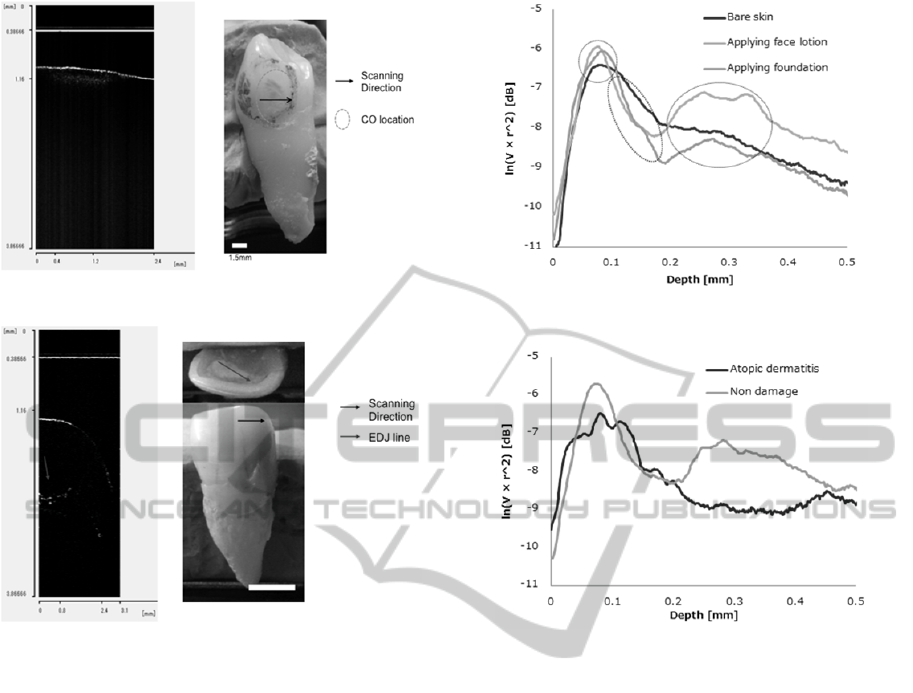

with this portable OCT as shown in Fig.11. The

caries occurs just under the surface of teeth. The

caries of CO could be easily monitored its depth and

area, while the optical probe does not reach to the

intricate position of a teeth at the adequate angle.

Another measurement of dentistry is the boundary

layer detection. The boundary layer between enamel

and dentin is called EDJ (Enamel-Dentin Junction)

and its recognition is important for artificial tooth

and implant placement. The depth of EDJ is about 2

– 3 mm. The portable OCT can visualize it with a

long measurement range as shown in Fig.12.

The human tissue such as skin is a scattering

material for the visible to infrared light. The

propagation depth to obtain the interference signal is

about 0.7 mm for medical OCT. The cross-sectional

image is often reported by medical OCT in

6mm

2.4mm

Complete Fusion

Incom p lete Fusion

Upper plate Upper plate

Lower plate Lower plate

OCT target (Laser-fused plastic plate)

PortableOCTanditsIndustrialApplication-SimpleOCTforIndustrialUseandBasicHealthCare

87

Figure 7: Transparent laminated tube (Mayonnaise tube).

Figure 8: Tablet coating (Thickness measurement).

viewpoint of dermatology.( Koenig 2012, Korde

2007, Mogensen 2009) On another front, the

application for skin measurement is unique for the

portable OCT. The basic health care and cosmetic

perspective are main targets for the portable OCT.

As the portable OCT can be compact and low cost, it

is easy to install it into a cosmetics counter and a

medical interview scene. To adapt the portable OCT

to the skin measurement, the optical probe had high

N.A. of 0.3. The depth of the field becomes about

1mm. The accumulation of about 1,000 times was

conducted for the stable evaluation. The

measurement depth became about 0.5 – 0.6 mm.

Figure 13 shows that the effect of cosmetics for

skin care is visualized by the portable OCT. The

interference intensity was corrected by multiplying

the square of distance. The vertical axis was

represented by log-scale. The normal skin of arm

has two peaks, of which the first is epidermal layer

and the second is dermal layer. The normal thickness

of the epidermal layer is about 0.2 mm. The patient

of Fig.13 had a dry skin. The second layer was not

clear. After the cosmetic care by applying a

foundation and a lotion to the skin, the second peak

from the dermal layer becomes clear. The water

retentivity of the lotion is more effective than that of

Figure 9: Multi-channel probes on a portable OCT.

Figure 10: Long-path scanning reflector on a portable

OCT.

the foundation.

The atopic dermatitis causes the severe damage

on the skin structure. Its damage is not only

exclusive to the epidermal layer, but it also rumbles

into the dermal layer. Figure 14 represents such

damage of the atomic dermatitis. The second peak of

the dermal layer was spoiled. It is clear as compared

with the normal skin. The epidermal layer was

subject to influence, too. It may be no need to be

visualized such skin conditions with a cross-

sectional image. The fixed-point observation such a

stethoscope is useful for a medical interview scene.

The other application is in ophthalmologic field.

Here, the direction of the portable OCT is the basic

health care, too. The fitting of the contact lens and

the combination of the optical power between the

naked eye and the contact lens are the targets for the

portable OCT. Off course, the traditional

ophthalmologic OCT is possible to evaluate such

targets. The current sophisticated OCT, however,

has a firm and big optical probe. To measure the

Distance [mm]

Interference Intensity [V]

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

88

Figure 11: Caries monitoring.

Figure 12: EDJ monitoring.

optical power, the eye should be unblocked to focus

an image. The portable OCT has the flexibility to

design the optical probe because the design of the

optical probe is separated from the resolution factor

and it is designed to unblock the eye.

The some applications mentioned above are now

in clinical practice. To install the portable OCT into

the clinical use as basic health care or cosmetics, the

usability will be pursued. It is because the users will

be not professionals. From this perspective, the

simple structure of the device and the direct

manifestation of the observed information are

important on medical care, especially basic health

care. The portable OCT can be operated with a

buttery. It is useful on rural clinics and developing

countries.

5 CONCLUSIONS

The portable OCT is time-domain type OCT. It is

not latest technology in comparison with the

ophthalmologic OCT. Especially its scanning speed

is much slower than the current ophthalmologic

Figure 13: Skin measurement through cosmetics.

Figure 14: Atopic dermatitis measurement.

OCT. The high scanning speed of the

ophthalmologic OCT, however, is for the real time

observation of the three-dimension or four-

dimension. The high speed signal processing is also

needed to calculate the huge memorized data. The

portable OCT is simple to analyze the obtained data

because the obtained interferogram directly

represents the condition of the interior structure of

the target. The scanning speed is not so high, but it is

enough for most of the industrial applications.

Instead the portable OCT has a feature of wide

flexibility for the designs of the optical probe and

the measurement range. It is adequate for the variety

of the industrial targets.

The applications of the portable OCT for medical

use are the direction to the basic health care and

cosmetics. At viewpoint of the simple operation,

small apparatus and low cost, the portable OCT will

be easily installed into such fields. The cross-

sectional image of teeth is useful to check the caries

and EDJ, while the skin condition can be evaluated

by the fixed-point observations. Easy to use

approach and direct representation of the desired

information are important for the medical interview

scene and formulation of cosmetics.

PortableOCTanditsIndustrialApplication-SimpleOCTforIndustrialUseandBasicHealthCare

89

Up to now, the wide variety of targets were

evaluated by the portable OCT. Their directions are

summarized in Table 2. It shows the targets’

directions with some categories. Now plural

Japanese companies produce the commercial

products of the portable OCT. They are evolved as

built-in system, stand-alone apparatus, and custom-

made device.

Table 2: OCT applications of industrial use.

Industrial use

Displacement, Thickness, Reflective index,

Solution concentration, Crack check, Volume

change, Time response, Vibration, …

Plant and Food processing

Plant Factory, Growth monitoring, Food

processing, Freshness check, Seal check, …

Basic health care and Cosmetics

Ophthalmology, Internal medicine, Visceral

Examination, Dentistry, Dermatology, Cosmetics,

…

REFERENCES

Colston B. W., Evertt Jr, M. J., Silva L. B. D., Otis L. L.,

Stroeve P., and Nathel H., 1998, “Imaging of Hard-

and Soft-Tissue Structure in the Oral Cavity by

Optical Coherence Tomography”, Appl. Opt., 37,

3582-3585.

Goode B. G., 2009, “OCT aims for industrial application,”

Laser Focus World, 45, 41–45.

Grulkowski I., Gora M., Szkulmowski M., Gorczynska I.,

Szlag D., Marcos S., Kowalczyk A, Wojtkowski M.,

2009, “Anterior segment imaging with Spectral OCT

system using a high-speed CMOS camera”, Optics

Express, 17, 4842-4858.

Huang D., Swanson E. A., Lin C. P., Schuman J. S.,

Stinson W. G., Chang W., Hee M. R., Flotte T.,

Gregory K., Puliafito C. A., Fujimoto J. G., 1991,

“Optical coherence tomography”, Science, 254, 1178-

1181.

Jiao S., Knighton R., Huang X., Gregori G., and Puliafito

C., 2005, “Simultaneous acquisition of sectional and

fundus ophthalmic images with spectral-domain

optical cohrence tomography”, Opt. Exp., 13, 444-452.

Koenig K., 2012, “Hybrid Multiphoton Multimodal

Tomography of in vivo human skin”, IntraVital, 1, 11-

26.

Korde V. R., Bonnema G. T., Xu W., Krishnamurthy C.,

Moore J. R., Saboda K., Slayton L. D., Salasche S.J.,

Warneke J. A., Alberts D. S., Barton J. K., 2007,

“Using Optical Coherence Tomography to Evaluate

Skin Sun Damage and Precancer”, Lasers in Surgery

and Medicine, 39, 687-695.

Leung C. K. S., Weinreb R. N., 2011, “Anterior chamber

angle imaging with optical coherence tomography”,

Eye (Lond), 25, 261-267.

Merken P., Vandersmissen R., Yurtsever G., 2011,

“Optical Coherence Tomography: OCT supports

Industrial Nondestructive Depth Analysis”, 47, 2-8.

Mogensen M. and Thrane L., 2009, “OCT imaging of skin

cancer and other dermatological disease”,

Biophotonics, 2, 442-451.

PCT/JP2010/070844.

Rosa C. C., Rogers J., Pedro J., Rosen R., and Podoleanu

A., 2007, “Multiscan time-domain optical coherence

tomography for retina imaging”, Appl. Opt., 46, 1795-

1808.

Schmitt J. M., 1999, “Optical coherence tomography

(OCT): A Review”, IEEE J. Quantum Electron., 5,

1205-1215.

Shiina T., Moritani Y., Ito M., and Okamura Y., 2003,

”Long optical path scanning mechanism for optical

coherence tomography”, Appl. Opt., 42, 3795-3799.

Shiina T., Satoshi M., and Honda T., 2009, “Factory Built-

in Type Simplified OCT System for Industrial

Application”, IEEJ Trans. EIS, 129, pp.1276-1281

(written in Japanese).

Shimada Y., Sadr A., Nazari A., Nakagawa H., Otsuki M.,

Tagami J., Sumi Y., 2012, “3D evaluation of

composite resin restoration at practical training using

swept-source optical coherence tomography (SS-

OCT)”, Dental Material Journals, 31, 409-417.

Song G., Harding K., 2012, “OCT for Industrial

Applications”, SPIE Proceedings, 8563, -

Steiner R., Kunzi-rapp K., and Scharffetter-Kochanek K.,

2003, “Optical Coherence Tomography: Clinical

Applications in Dermatology”, Med. Laser Appl., 18,

2459-259.

Todea C., Negrutiu M. L., Balabuc C., Sinescu C., Topala

F. I., Marcauteanu C., Canjau S., Semez G., Podoleanu

A. G. 2010, “Optical Coherence Tomography

Applications in Dentistry”, TMJ, 60, 5-17.

Wurm M., Wiesauer K., Nagel K., Pircher M., Götzinger

E., Hitzenberger C. K., Stifter D., 2007, “Spectral-

Domain Optical Coherence Tomography: A Novel and

Fast Tool for NDT”, IVth NDT in progress, 225-232.

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

90