Geometrical Improvement of a Noninvasive Core Temperature

Thermometer based on Numeric Modeling and Experiment

Validation

Ming Huang

1

, Toshiyo Tamura

2

, Wenxi Chen

3

, Kei-ichiro Kitamura

4

,

Tetsu Nemoto

4

and Shigehiko Kanaya

5

1

Computational Systems Biology Lab, Graduate School of Information Science,

Nara Institute of Science and Technology, 8916-5 Takayamacho, 630-0192, Ikoma, Nara, Japan

2

Department of Biological Engineering, Osaka Electro-Communication University, 18-8 Hatcho,

572-8530, Neyagawa, Osaka, Japan

3

Biomedical Information Technology Lab, the University of Aizu, Tsuruga, Ikki-machi,

965-8580, Aizu-wakamatsu, Fukushima, Japan

4

Department of Laboratory Science, Kanazawa University, 920-0942, Kanazawa Ishikawa, Japan

5

Computational Systems Biology Lab, Graduate School of Information Science,

Nara Institute of Science and Technology, 8916-5 Takayamacho, 630-0192, Ikoma, Nara, Japan

Keywords: Noninvasive Measurement, Long-term Measurement, Core Temperature, Dual-Heat-Flux Method, Numeric

Modeling, Experiment.

Abstract: This paper describes the improvement of a transcutaneous core temperature thermometer by modifying the

configuration, in terms of height and radius, of the thermometer using the so-called dual-heat-flux (DHF)

method. The motivation of these modifications is to decrease the volume of the thermometer so as to reduce

the transverse heat flow inside, in other words, to preserve the underlying assumption of the DHF method

that heat flows from the inner part of human body through skin onto the thermometer longitudinally. The

modification’s effect is evaluated by both numeric modeling based on finite element method and

experiment. The results of simulations and experiments show that a lower-in-height and larger-in-radius

configuration will improve the accuracy of the thermometer. Prototypes of 22.0 mm radius can attain

satisfactory accuracy with error less than 0.5 C when heights are 8.0 mm or less..

1 INTRODUCTION

Core temperature is one of the vital signs of human

body and its noninvasive monitoring is valuable in

both clinical aspect and daily healthcare aspect. In

order to lower the probability of developing

complications after surgeries, the National Institute

for Health and Clinical Excellence (NICE) has

issued guidance to the NHS in England and Wales to

prevent hypothermia during perioperative period

(NICE, 2008). However, it is acknowledged that the

three standard measurement sites of pulmonary

artery, nasopharynx and distal esophagus are

difficult to access during the perioperative period. A

clinical trial applying a transcutaneous thermometer

adopting the so-called double-sensor (DS) method as

an alternative to the invasive core temperature

monitoring has been carried out (Kimberger et al.,

2009).

As one of the major endogenous biorhythms, the

rhythm of core temperature plays a major role at the

treating of sleep disorder as an important criterion of

the circadian phase, because that the core

temperature rhythm and the sleep/wake rhythm are

closely related (Bjoryatn and Pallesen, 2009). Such

kind of studies will benefit a lot from a reliable

technique that is able to monitor the core

temperature continuously (Baehr et al., 2000).

To meet the requirement of long-term and

noninvasive measurement needs, tradeoff among the

measurement accuracy, response time and safety

should be made. This characteristic excludes the

means such as tympanic infrared thermometer or

magnetic resonance temperature mapping. A

feasible choice is to use the skin-contacting

temperature sensors and thermal physical principles

to estimate the core temperature, which the existing

23

Huang M., Tamura T., Chen W., Kitamura K., Nemoto T. and Kanaya S..

Geometrical Improvement of a Noninvasive Core Temperature Thermometer based on Numeric Modeling and Experiment Validation.

DOI: 10.5220/0004790000230027

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2014), pages 23-27

ISBN: 978-989-758-013-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

zero-heat-flux (ZHF) method (Fox and Solman,

1971), DS method (Gunga et al., 2008) and the dual-

heat-flux (DHF) method (Kitamura et al., 2009) are

attributed to.

Of the three said methods , ZHF is greatly

limited by its adoption of heater. As for the other

two methods, we have to consider the blood

perfusion in the skin and subcutaneous tissue, which

makes the heat conductivity in the corresponding

tissues change greatly even for the same individual.

This problem is tactfully dodged by DHF method.

However, the underlying assumption of DHF

method that the heat flow from the inner body

through the skin and subcutaneous tissue onto the

thermometer longitudinally is somewhat diverging

from the practical situation. The thermometer is

conducting heat exchange with the ambient

environment through convection and radiation. The

effect of convection can be greatly moderated with

proper clothing during measurement whereas the

radiation can’t be ignored. The insulator, featured

with a relative higher emissivity, consists of the

peripheral boundary of the thermometer. Thus a

lower height and larger radius design may help to

suppress the transverse heat flow so as to improve

the accuracy.

In this study, we validated the geometrical

improvement through simulation, and the effect of

the geometrical modification by practical

experiments with our experimental system.

This paper can be divided into two parts. The

first part is to examine the effect of the geometrical

modification on a physiological significant

temperature range (36.0-38.0 °C) by a 3D modeling

based on finite element method (FEM). The second

part is to fabricate the thermometer’s prototypes

according to the simulation results, to construct the

experimental system and finally to validate the

effects of the geometrical improvement.

2 METHOD

2.1 The DHF Method

DHF method uses at least four temperature sensors

inlaid inside the DHF thermometer to calculate the

core temperature. Elucidation can be made based on

following formulas and Fig. 1.

There is temperature difference between the deep

body part and the skin surface. If we assume that the

inner boundary of skin is of the same temperature

with the deep body part, heat flow from inner part to

skin surface will arise and then stream into the

thermometer as shown in Figure 1. Considering that

heat flow from deep body part into the thermometer

is the same, two equations below can be acquired by

Fourier law.

/

/

,

(1)

and

/

/

,

(2)

where T

d

is the temperature of the inner boundary of

skin, i.e., the core temperature, while T

1

, T

2

is skin

temperature measured by cutaneous temperature

sensors inside the thermometer and T

3

, T

4

are the

temperature measured by the other two sensors. R

s

is

the heat resistance of the skin, R

1

and R

2

are the heat

resistance of the two heat path inside the

thermometer. According to (1), (2), T

d

then can be

expressed as

,

(3)

Where

/

and can be represented with the

ratio of length of the two concentric cylinders

constructing the thermometer.

2.2 3D Modeling based on FEM

In this paper, we only carried out the stationary

study of the 3D model, in other words, the whole

model was assumed to be at a heat equilibrium state.

It was used to mimicking the situation when the

reading of the thermometer becomes stable. We also

set the related thermophysical properties of each

component in the model to be isotropic.

Hence, the well-acknowledged mathematical

description of bioheat transfers: Pennes equation

could be simplified as (4), where

b

b

, c

b

, k, and q

m

are perfusion rate (m

3

/m

3

s), density (kg/m

3

) specific

heat (J/kg·C) of blood, thermal conductivity

(W/m·C), and rate of metabolic heat generation. T

is the local temperature and T

b

is the temperature of

blood. What is more, because we used this model to

simulate the situation when the thermometer was

applied to a rubber sheet that no extra heat generated

inside, the second and the third terms of the equation

could be eliminated.

0∙

.

(4)

The heat exchange between the

thermometer/tissues and the ambient environment

was described by radiation only because that the

effect of convection can be greatly mitigated by

proper clothing. Hence, the boundary condition of

the thermometer and the cutaneous surface is:

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

24

Table 1: Related thermophysical properties of the materials used in simulations.

Component

Conductivity

(W/m·C)

Density

(kg/m

3

)

Specific heat

(J/kg·C)

Emissivity

Skin 0.17 1100 3500 0.98

rubber 0.06 180 2010 0.95

aluminum 400

8700 385 0.05

∙

(5)

T

amb

and T

s

is the ambient temperature (°C) and

temperature on boundaries, respectively, is the

Stefan–Boltzmann constant, and is the emissivity

of material. FEM model was constructed and

analyzed by COMSOL Multiphysics software

(COMSOL Inc., Sweden). In this model, lower

boundary of skin was considered to be of the same

temperature as the core temperature, while the

peripheral boundary of the skin was assumed as heat

insulation. Details about this mathematical

description and the underlying deduction of the DHF

method can be found in (Huang and Chen, 2010)

and (Kitamura, et al., 2010).

In numeric study aspect, we constructed a series

of thermometer of 4 different heights ({h

1

, h

2

} =

{4.5, 3.0} {8.0, 5.0}, {15.0, 9.0}, {29.0, 17.0} mm)

and 4 different radii (

,

= {11.0, 5.5}, {22.0,

11.0}, {33.0, 16.5} {44.0, 22.0} mm}, thus a total of

16 combinations, that is 16 different configurations

were used. Cross-section view of the thermometer

and details of its configuration are illustrated in

Figure 1.

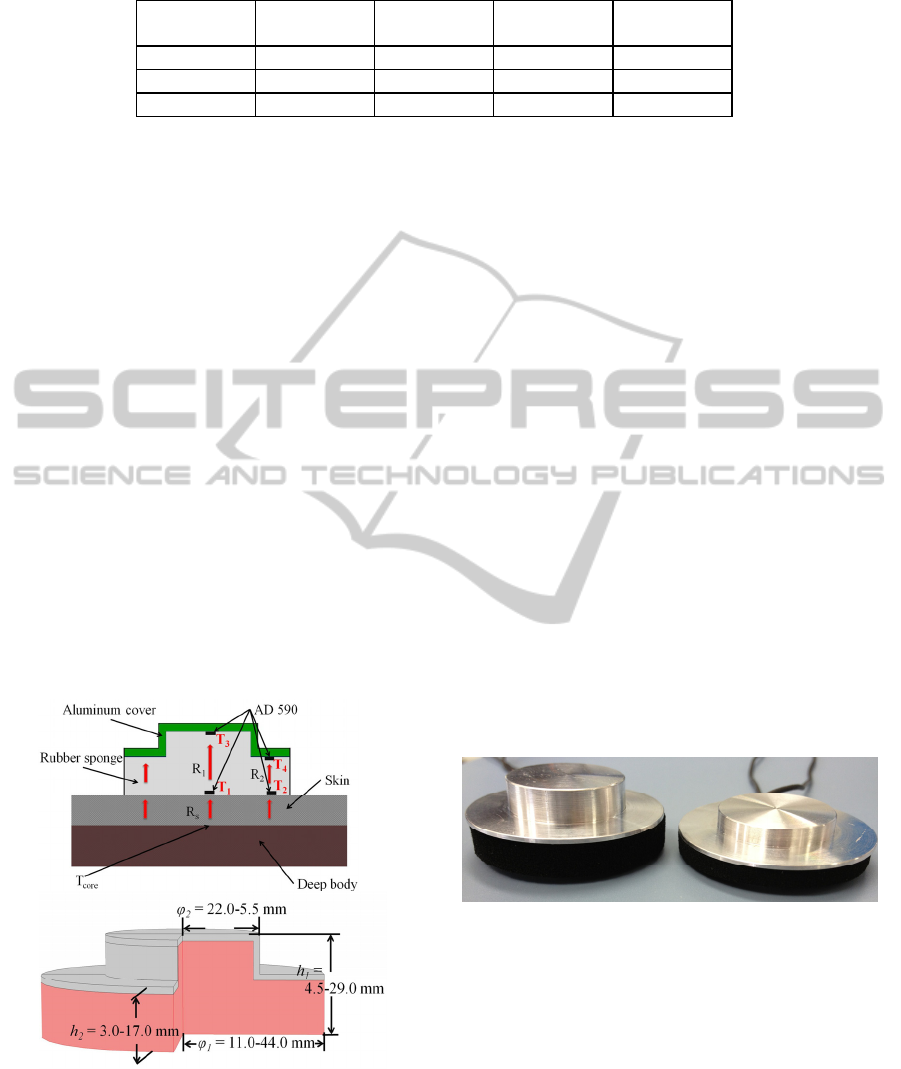

Figure 1: Upper: The illustration of the two-layer structure

and the arrangement of the four temperature sensors (AD

590, Analog, 2-pin style). It is supposed that the heat from

deep body part flows as the arrow’s indicating and no

transverse heat flow arises in the skin and the thermometer.

Lower: The cross-section view of the thermometer. The

thickness of the top aluminum cover is 1 mm.

With this model, we simulated the situation where

the thermometer is applied to skin surface when the

temperature at the bottom of skin (rubber sheet) is

36.0, 37.0 and 38.0 °C respectively, while the

ambient temperature is 28.0 °C.

2.3 Prototypes and Experimental

System

We fabricated a series of prototypes based on the

simulations results, whose heights are different

while radii are the same (22.0 mm). Because that

clumsy volume is a negative factor for the

universality for a transcutaneous thermometer, only

the height was changed. We would only consider

changing the radius of the thermometer if acceptable

accuracy can’t be obtained with present radius. In

this paper, we illustrate the results of two prototypes,

{8.0, 5.0} mm

and {15.0, 9.0} mm (Figure 2). The

higher one is of similar configuration with the initial

prototype proposed by Kitamura et al. while the

lower one is the thinnest one fabricated so far. It is

reported that a thicker geometry is a negative factor

for the accuracy (Huang et al., 2013). Hence, these

two kinds of prototype can show the improvement

based on height modification.

Figure 2: Front view of the two prototypes. Radii of the

two prototypes are 22.0 mm, while heights are {15.0, 9.0}

and {8.0, 5.0} mm, respectively.

The experimental system was constructed to

mimic the core temperature measurement carried out

on skin noninvasively, thereafter to acquire, store

and process the data of those experiments.

The body-mimicking module comprises of a

thermostatic water bath (± 0.1 °C systematic error)

stabilizing the temperature of water and a skin-

mimicking 10.0 mm neutral rubber sheet.

The data acquired by the 4 temperature sensors,

GeometricalImprovementofaNoninvasiveCoreTemperatureThermometerbasedonNumericModelingandExperiment

Validation

25

which were used to calculate the estimate of core

temperature, was streamed into PC for data

processing, visualizing and storage on LabVIEW

platform. The program of LabVIEW was organized

to suppress the measurement noise. As for the data

processing in the system, the DAQ sampled

temperature values from the 4 sensors, then a

median filter, which performs median filtering for

every 100 measurements for real-time data

acquisition, was adopted in LabVIEW platform (by

the function named PtByPt median filter) to acquire

measurements in real time with 1 Hz sampling rate

and write into a spreadsheet. This routine enables the

automatic and dynamic tracing of the thermal

physical evolution of the system.

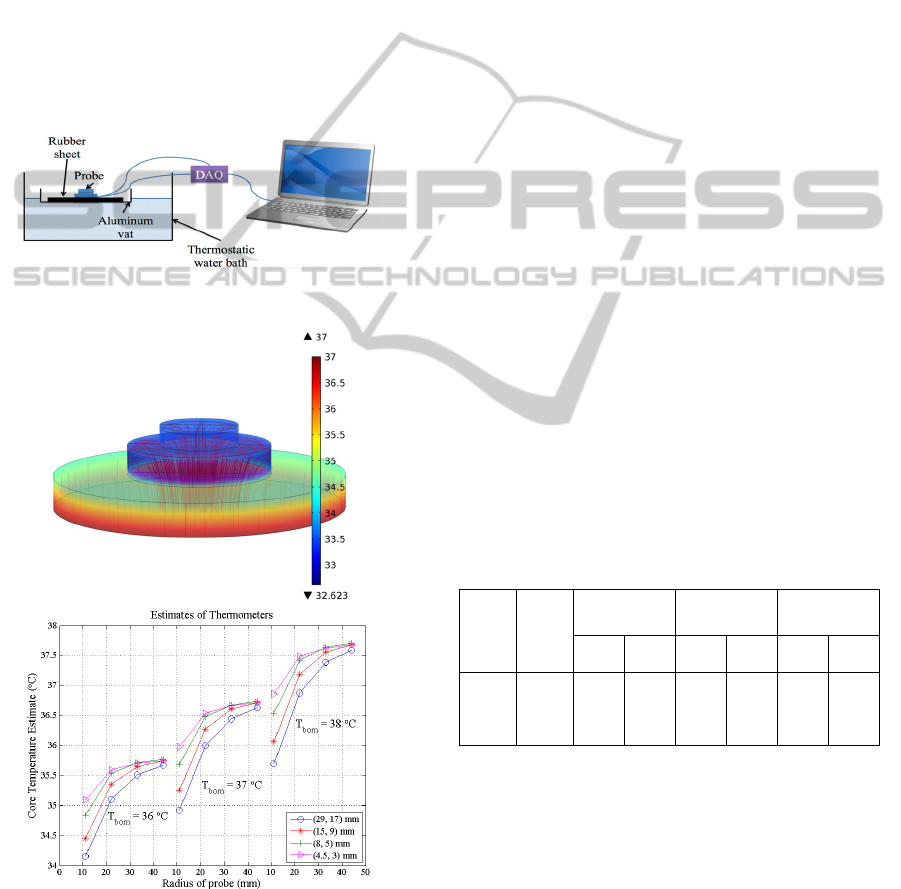

Figure 3: The schema of the experimental system.

Figure 4: Upper: An image of temperature distribution and

heat flow inside the prototype. Lower: Results of the

simulations. X-axis is the radius of the thermometer; Y-

axis is the estimates of thermometers.

With the said prototypes and experimental system,

we carried out experiments in a laboratory

environment, where the ambient temperature was

28.0 ± 0.5 °C. The prototypes went through tests 5

times for each condition that the bottom of the

rubber sheet was regulated at 36.0, 37.0 and 38.0 °C

respectively.

3 RESULTS

With the model of FEM, temperature distribution

and heat flow condition corresponding to specified

condition (upper figure in Figure 4) can be attained.

The results of the numerical study were summarized

into the lower figure in Figure 4. 3 clusters of curves

mark the estimates of each configuration under

different core temperature condition.

Each of the temperature situations shows similar

trend. We should also notice that the latitudinal

factor is more effective than the longitudinal factor

in terms of accuracy.

The results of the experiments are tabulated in

Table 1. In order to make an easier comparison, the

corresponding results of simulation are tabulated in

column 5 and 6. The measurements are stable under

the same environmental condition. Significant figure

is tenth here and standard deviation that marked as 0

represent highly stable experimental outcome.

However, additional digit is added to the Std

(standard deviation) for a better discrimination.

Table 2: Results of the experiments. Prot 1 denotes the

prototype of {15.0, 9.0} mm height, while Prot 2 the

prototype of {8.0, 5.0} mm height.

t

bom

(°C)

t

amb

(°C)

Mean (°C)

Simulation

result (°C)

Std (°C)

Prot

1

Prot

2

Prot

1

Prot

2

Prot

1

Prot

2

36.0 27.6 35.2 35.3 35.4 35.6 0.00 0.00

37.0 28.5 36.5 36.6 36.3 36.6 0.06 0.01

38.0 28.5 37.4 37.5 37.2 37.5 0.15 0.00

4 DISCUSSION

In the numeric study phase, mesh qualities and the

material values would affect the accuracy and

simulation result greatly. In this study, the quality of

mesh was guaranteed by the COMSOL Multiphysics

software and the related physical parameters were

extracted from the COMSOL material library.

However, these parameters may not match the real

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

26

materials used perfectly, thus these differences could

be considered as a reason for the deviation between

simulations and experiments.

From the results of the simulations, two

considerations on the thermometer’s configuration

should be given. One is that the height could not be

decreased arbitrarily to ultra-thin level, says 1 mm,

which will be very difficult to fabricate. Another one

is the radius. We intend to maintain the miniature

configuration and try to attain equal accuracy by

reducing the height only. That is the reason why the

radius of prototypes is kept unchanged.

The experiments were carried out under the

laboratory environment, where the ambient

temperature was regulated by central-air

conditioning at about 28.0 °C. However, during the

experiment, the ambient temperature couldn’t be

regulated at a constant value, which is the major

limitation of these experiments. This limitation can

also be considered as another reason for the

deviation between simulations and experiments.

However, the insight that DHF thermometer will

benefit from a thinner design can be obtained. To

obtain a more precise comparison, the experiment

should be operated inside a thermostatic room,

because that the performance of the thermometer is

prone to be affected by the ambient temperature

according to (Huang and Chen, 2010). What is more,

in view of this disadvantage, an important direction

of the next step of improvement should be the

mitigation of the effect brought about by the

environment.

The geometrical parameters that we adopted to

fabricate here are only a subset of the parameters

used in the simulations. The thicker one is of the

similar configuration as the initial prototype of DHF

method, while the thinner one is a product balancing

the implementability and accuracy. To further

elevate its accuracy, consideration except for the

geometrical parameters should also be given, e.g.,

the arrangement of a urethane sponge to cover the

thermometer. Of course, we could try to enlarge the

radius to get a more satisfactory performance if only

its size cause no obstruction to practical application.

5 CONCLUSIONS

We constructed 3D finite element models to carry

out an overall numeric study of the geometrical

parameters’ effect on the performance of the DHF

thermometer. According to the numeric results, we

designed and fabricated prototypes and an

experimental system. Results from both numeric and

experiment studies show that to lower the height and

enlarger the radius of the thermometer will improve

its performance. Thermometer of 22.0 mm radius

can acquire satisfactory accuracy with error less than

0.5 °C when height is 8.0 mm or less.

ACKNOWLEDGEMENTS

This study was supported by the Keihanna Science

City Healthcare Project of Ministry of Education

Culture, Sports, Science and Technology, Japan.

REFERENCES

Baehr, E. K., Revelle, W., and Eastman, C. I., 2000.

Individual differences in the phase and amplitude of

the human circadian temperature rhythm: with an

emphasis on morningness-eveningness, Journal of

sleep research, 9(2), pp. 117-27.

Bjoryatn, B., and Pallesen, S., 2009. A practical approach

to circadian rhythm sleep disorders, Sleep medicine

reviews, 13(1), pp. 47-60.

Fox, R. H., and Solman, A. J., 1971. A new technique for

monitoring the deep body temperature in man from the

intact skin surface, J Physiol, 212, pp. 8-10.

Gunga, H. C., Sandsund, M., Reinertsen, R. E., Sattler, F.,

and Koch, J., 2008. A non-invasive device to

continuously determine heat strain in humans, Journal

of Thermal Biology, 33(5), pp. 297-307.

Huang, M., and Chen, W., 2010. Theoretical simulation of

the dual-heat-flux method in deep body temperature

measurements, Proceeding of IEEE EMBC 2010, 2010,

pp. 561-64.

Huang, M., Chen, W., Kitamura, K., Nemoto, T., and

Tamura, T., 2013. Improvement of the Dual-heat-flux

Method for Deep Body Temperature Measurement

Based on a Finite Element Model, Proceeding of IEEE

EMBC 2013, 2013, pp. 1202-05.

Kimberger, O., Thell, R., Schuh, M., Koch, J., Sessler, D.

I., and Kurz, A., 2009. Accuracy and precision of a

novel non-invasive core thermometer,” British journal

of anaesthesia. British journal of anaesthesia. 103(2),

pp. 226-31.

Kitamura, K., Zhu, X., Chen, W., and Nemoto, T., 2010.

Development of a new method for the noninvasive

measurement of deep body temperature without a

heater, Medical Engineering & Physics, 32(1), pp. 1-6.

NICE, 2008. http://www.nice.org.uk/CG065.

GeometricalImprovementofaNoninvasiveCoreTemperatureThermometerbasedonNumericModelingandExperiment

Validation

27