Low Power Remote Neonatal Temperature Monitoring Device

Hiteshwar Rao

1

, Dhruv Saxena

1

, Saurabh Kumar

3

, Sagar G. V.

1

, Bharadwaj Amrutur

1,2

, Prem Mony

4

,

Prashanth Thankachan

4

, Kiruba Shankar

4

, Suman Rao

5

and Swarnarekha Bhat

5

1

Robert Bosch Center for Cyber Physical Systems, Indian Institute of Science, Bangalore, India

2

Department of Electronics and Communication Engineering, Indian Institute of Science, Bangalore, India

3

Department of Instrumentation and Applied Physics, Indian Institute of Science, Bangalore, India

4

Division of Epidemiology and Population Health, St. John’s Research Institute, Bangalore, India

5

Department of Neonatology, St. John’s Medical College Hospital, Bangalore, India

Keywords:

Neonatal Monitoring, Wearable Sensors, Telemedicine, Body Sensor Network, Temperature Measurement,

Temperature sensors, Skin Temperature, Noninvasive Wearable Wireless Monitoring System, Biomedical

Measurements.

Abstract:

In this paper we present the design of a wearable temperature sensing device for remote neonatal monitoring.

It is designed for continuous and real-time monitoring of the infants in remote rural areas, for the first few

weeks after their birth. It is capable of sensing the neonate’s skin temperature with 0.1

◦

C accuracy to detect

the early onset of hypothermia. The sensed data is transferred securely over bluetooth low energy radio to a

nearby gateway, which then relays the information to a central database for real time monitoring. The device

incorporates a medical grade thermistor which is directly interfaced to a microcontroller with an integrated

bluetooth low energy radio. Low power optimizations at both the circuit and software levels ensure sleep

currents of only 1uA, ensuring very long battery life. The device is packaged in a baby friendly, water proof

housing and is easily sterilizable and reusable.

1 INTRODUCTION

Neonatal Mortality Rate (NMR)(WHO et al., 2012) is

defined as number of newborn deaths (that is within

the first 28 days of life) per thousand births. The

global neonatal deaths today account for more than

40% of all child deaths before the age of five and is

estimated to be more than 8 million(Oestergaard and

Inoue, 2011). More than 95% of these deaths occur in

developing nations like regions of Africa and South

Asia. Reports(Global Health, 2010) have shown that

India has about 10 times higher NMR compared to the

western world. NMR in India was 31 as of 2011, a

33% decrease in NMR since 1990, yet taking into ac-

count its burgeoning population, approximately1 mil-

lion newborn died in 2010, nearly 30% of the global

neonatal deaths(WHO, 2012).

Recent research indicates that hypothermia is in-

creasingly considered as a major cause of neonatal

morbidity and mortality, especially in rural resource

constrained settings(Kumar et al., 2009)(Kumar et al.,

2008). Hypothermia for neonates is defined as an

aberrant thermal state of diminution of their body’s

temperature below 36.5

◦

C. Further decrease in body

temperature causes respiratory depression, acidosis,

decreases the cardiac output, decreases the platelet

function, increases the risk of infection and may

even lead to fatality without preemption(Macfarlane,

2006). WHO has classified hypothermia into follow-

ing three categories depending on the body tempera-

ture(WHO, 1993).

• Mild hypothermia: 36.0 to 36.4

◦

C

• Moderate hypothermia: 32.0 to 35.9

◦

C

• Severe hypothermia: < 32

◦

C

In newborns, hypothermia can be caused by loss of

body heat to surroundings through conduction, con-

vection, radiation or evaporation. Premature new-

borns are even more susceptible to these factors be-

cause of their low weight at the time of birth, they

have a large ‘surface area to weight ratio’ with min-

imal subcutaneous fat. They have poorly devel-

oped shivering, sweating and vasoconstriction mech-

anisms and they are unable to retain their body’s

heat(Macfarlane, 2006). Hypothermia has a wider

spread in the developing nations. In the rural context

28

Rao H., Saxena D., Kumar S., G. V. S., Amrutur B., Mony P., Thankachan P., Shankar K., Rao S. and Bhat S..

Low Power Remote Neonatal Temperature Monitoring Device.

DOI: 10.5220/0004798300280038

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2014), pages 28-38

ISBN: 978-989-758-013-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

thermal care of newborn is often overlooked and hy-

pothermia goes undetected. The most prevalent tech-

nique in rural settings on which caregivers rely is hu-

man touch, which is less sensitive and is not a reli-

able method. Commonly used mercury thermometers

are often fragile and require some degree of training.

Hence there is a need for an automated and robust

way of measuring the neonate’s temperature on a con-

tinuous basis, and be able to initiate intervention in a

prompt manner as required. This has been the main

motivation towards developing the temperature mon-

itoring device and system.

The ever increasing cost for state-of-the-art medi-

cal facilities like NICU(Neonatal Intensive Care Unit)

impedes the user from accessing it in rural areas. The

problem is exacerbated in rural parts as India’s popu-

lation is still largely rural, with limited or no access to

modern health care infrastructure. Mothers are often

discharged earlier and infants are taken home right af-

ter delivery. In some cases delivery is even carried out

at their residence without any medical professional or

facilities at their disposal. We would like to capitalise

the technical advancementsof 21st century to perform

remote neonatal healthcare monitoring in an econom-

ical manner.

In this paper, we propose a novel wearable

monitoring device, designed and developed for the

neonates in remote, rural and resource constraint set-

tings. Our objective is to develop an ultra low power

wireless skin temperature sensor, capable of monitor-

ing newborns’ body temperature unobtrusively and in

real time over a span of the first few days to weeks.

Sensed temperature data will be securely uploaded via

a gateway device to a centralised database. Analytics

on the temperature data will be run to determine the

intervention needed in case of temperature excursions

beyond normal levels. This system will be given to

new mothers to take home after delivery.

However this will require solutions to a number

of significant challenges like ultra low power sensing,

device integration and packaging, ultra low power

short haul communication and baby friendly design.

1.1 Requirements and Challenges

We conducted a user study in the NICU of St. John’s

Medical College Hospital in Bangalore, India. The

study involved understanding the current techniques

and equipment used in NICU to monitor the health

of the neonates. This led to understandings in how

the neonates are handled and how their vital parame-

ters such as body temperature are measured. It also

revealed concerns of the doctors regarding current

equipment and the feasibility of use of such equip-

ment in a remote rural setting. Issues like placement

of the sensor on the body, ability of the device to be

sterilised and other aspects which will be highlighted

in the coming sections, were dealt with through brain-

storming sessions and concept generation. Feedback

from the doctors/neonatologists was taken time and

again on the concepts generated which led to a more

concrete list of requirements.

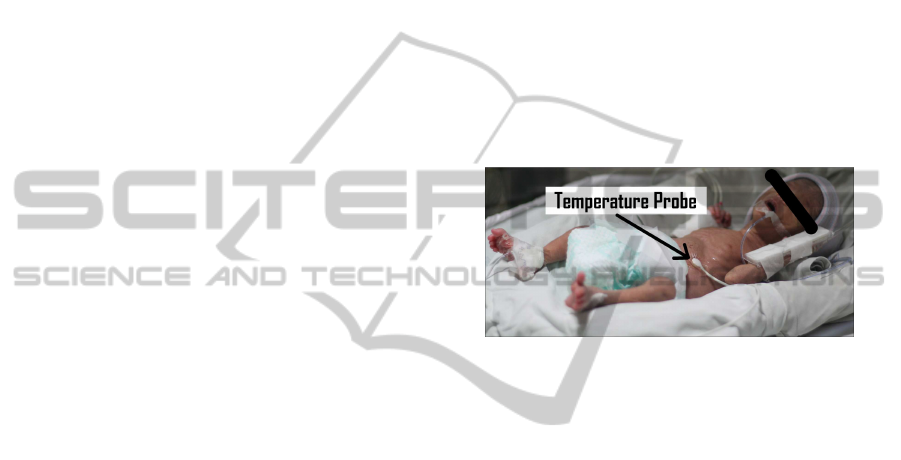

1.1.1 Safety

In an NICU setting neonates are kept under radi-

ant warmers to regulate their body temperature. To

achievethis, neonates’ body temperature is constantly

monitored by employing conventional temperature

probes, attached to their skin with adhesive tape as

shown in figure 1.

Figure 1: Neonate kept under radiant warmer in NICU at

St. John’s Medical College Hospital.

The skin of neonates is extremely delicate and

vulnerable to environmental stress. Research(Susan

et al., 2001) has shown that increase in microbial

growth under temperature probe can be harmful.

Medical tape causes irritation and when it is removed

it causes skin abrasion and damage(Rutter, 2000).

Risk of the damage of internal organs involved with

the tympanic and rectal temperature measurement

limits their use for continuous monitoring. Thus the

primary concern and requirement is their protection,

safety and non-invasive monitoring.

For continuous measurement of body temperature

the safest potential location for the sensor is over the

right upper quadrant of the abdomen just below the

rib-cage.

1.1.2 High Accuracy

For monitoring hypothermiaor hyperthermia,temper-

ature measurement accuracy should be same as that

of medical grade NICU temperature probes. Thus an

high accuracy of 0.1

◦

C should be achieved in a re-

mote rural setting.

1.1.3 Longer Battery Life

Once the device is installed and given to the user,

neonates should be continuously monitored for the

LowPowerRemoteNeonatalTemperatureMonitoringDevice

29

duration of first 2 to 3 weeks, with a sampling period

of once every 15 minutes. Battery should last long

enough without any need for charging or replacement.

This calls for an ultra low power design to meet the

requirement of longer battery life.

1.1.4 Robustness

The device needs to unobtrusively operate for several

days. During the operation in remote regions, manual

intervention for maintenance or repair is difficult to

provide. Hence the device should be robust enough to

cater to challenges like shock, vibration, and should

not get reset accidentally. It should be hermetically

sealed to protect the electronics from getting dam-

aged in case liquids seep in during sterilisation or due

to contact with body fluids (e.g sweat, urine, faeces,

etc.). Moreover, the device should be adjustable so

that it can used on neonates of different abdominal

girths, it should be aesthetically pleasant and should

be baby friendly.

Detailed description of the solution to these re-

quirements and challenges is provided in section 2.3

1.2 Related Works

In India, remote rural health monitoring is being en-

abled by many companies and government agencies.

For instance, in (Neurosynaptics, 2002), the com-

pany has developed a health kiosk and system called

ReMeDi, which is deployed at the primary health cen-

ter. The Kiosk allows a number of basic health tests

to be conducted, the results of which are communi-

cated over the cellular network to a central repository

which keeps track of patient health data. This system

is in use in a number of rural districts in Bihar and

parts of Karnataka. Many other similar systems are

being developed and deployed by various NGOs and

startups across India.

Studies indicate that monitoring certain basic pa-

rameters, like temperature, could help indicate im-

pending problems and hence with timely interven-

tion, perhaps the mortality can be reduced. In this re-

gard, an innovative product, for keeping babies warm,

has been developed by a startup called Embrace (Em-

brace, 2012).

In a related work, authors in(Chen et al., 2010)

describe some sensors and packaging which has been

developed for monitoring new borns. The sensors

are embedded in a smart jacket, with careful attention

paid to the baby friendliness of the design.

Another device(iThermometer, 2012) addresses a

similar application where temperature of body can

be measured and transmitted wirelessly to an android

platform based device.The device has a battery life of

only 48 hours and a relatively larger size as compared

to our design.

The authors in (Isetta et al., 2013), report an in-

ternet based health monitoring system for newborns.

The parents fill up an online form with some data

about their babies regularly. These include: Weight,

body temperature, sleeping patterns, skin color, feed-

ing etc. The remote nursing staff monitor these pa-

rameters and provide timely advice. The authors con-

ducted a clinical research study for the efficacy of this

system and found that it helped reduce the number of

visits to the hospital by a factor of 3 for the babies be-

ing monitored via this system, as compared to a con-

trol group, which did not use it. This study encour-

ages us to develop automated monitoring techniques

like in (Chen et al., 2010) which will be more reliable

and efficient than manually entering the data.

2 SYSTEM DESIGN

This section describes the design decisions involved

in developing the hardware platform and the proto-

type device

2.1 Wireless Communication

There are many low-power wireless technologies like

Bluetooth low-energy(BLE), Bluetooth classic, ANT,

ZigBee, Wi-Fi, Nike+, IrDA, and the near-field com-

munications (NFC) standards currently being em-

ployed in the field of healthcare.

For our application, the following critical key pa-

rameters drove the selection of the wireless interface:

ultra-low-power, low cost, small physical size, appli-

cation’s network topology requirements and security

of communication.

The authors in (Artem et al., 2013) do a power

consumption analysis of BLE, ZigBee and ANT sen-

sor nodes in a cyclic sleep scenario and find BLE to

be the most energy efficient. We believe that in the

next few years, millions of mobiles and computers

will support BLE, thus enabling BLE based sensors to

utilize these as gateways to the internet ((Alf Helge,

2010) and (Gomez et al., 2012)). We already see

commercial products with BLE like FitBit (Hawley E

et al., 2012), Pebble Watch and Hot Watch, and hence

it encourages us to leverage the advantages of em-

ploying BLE as the short-range wireless communica-

tion technology for connecting the sensor to the gate-

way.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

30

AES-128

Xtals

Status LEDs

3volt Coin Cell

Thermistor

Impedance Matching

Embedded Inverted F antenna 2.4 GHz

Analog

Front

End

Programming Interface

Balun Filter

8051 +

Bluetooth 4.0

12

Bit

ADC

CC2540

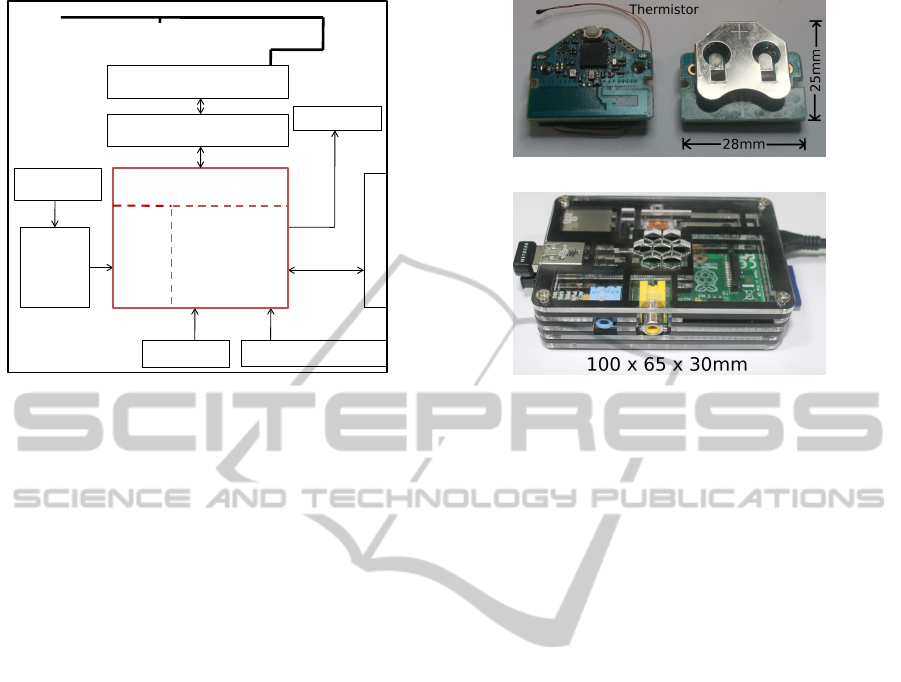

Figure 2: Block diagram of the temperature sensor.

2.2 Hardware Platform

2.2.1 Sensor Platform

A monolithic design of sensor platform is required to

minimize the form factor, facilitate ease of manufac-

turing and to reduce the overall cost of the product.

Hence a custom made platform has been developed

using a multilayer Printed Circuit Board. The assem-

bled sensor platform has a dimension of 28 mm x 25

mm x 8 mm.

The sensor hardware platform as shown in Fig-

ure 2a and consists of a Microcontroller(MCU) with

integrated Bluetooth 4.0(BLE) and a 12-bit ADC

(CC2540 from Texas Instruments), the NICU grade

temperature sensor with its analog front end circuit,

status LEDs, power supply and RF balun filter and an-

tenna for wireless communication over 2.4 GHz ISM

band. The microcontroller system has 256 KB pro-

grammable flash memory and 8-KB RAM and sup-

ports very low-power sleep modes, with sleep current

as low as only 0.4µA. There is built-in 128-bit hard-

ware AES support for secure communication.

Sensor hardware can be programmed wirelessly

and application programs can be downloaded on

MCU’s flash over the air via mobile or a gateway de-

vice. This feature enables us to dynamically control

the sensor platform without having to disassemble the

module and remove it from the package.

High precision MF51E NTC thermistors (Can-

therm, 2009) are used for extremely accurate temper-

ature measurements. These are especially designed

and calibrated for medical equipment. The extremely

small size of thermistor allows it to respond very

quickly to small variations in temperature.

(a) Top and bottom view of the sensor

(b) “Raspberry pi” as a gateway device

Figure 3: Hardware platforms.

The temperature profile running on sensor meets

the universal standard of body temperature profile de-

fined by Bluetooth SIG (Bluetooth, 2012). Hence our

sensor device can communicate to any authenticated

host independent of the gateway platform being used.

2.2.2 Antenna Selection and Performance

The antenna for the sensor device has to balance be-

tween small size and efficiency. High efficiency an-

tenna enables larger separation between the sensor de-

vice and the gateway - thus simplifying the usage sce-

nario. On the other hand, larger size impacts the over-

all device size which is not desirable for a wearable

device. A chip antenna offers a very small footprint

solution but leads to a compromise of some critical

parameters, such as:

• Reduced efficiency (or gain)

• Shorter range

• Smaller useful bandwidth

• More critical and difficult tuning

• Increased sensitivity to components and PCB

• Increased sensitivity to external factors

Detuning of chip antenna happens due to its proxim-

ity with ground plane, power source, plastic enclo-

sure and the condition whether it is worn by the user

or not. Our experiments with the chip antenna indi-

cated an effective range of only about 3 meters. To

overcome these issues, we have used an embedded

Inverted F-antenna (IFA). Performance and character-

istics of both the antennas are tabulated below.

The Inverted-F Antenna has higher efficiency,

longer range and a wider bandwidth than a chip an-

tenna, though larger in size. For our device, the coin

LowPowerRemoteNeonatalTemperatureMonitoringDevice

31

Table 1: Comparison of chip antenna and Inverted-F An-

tenna.

Parameters Chip antenna IFA

Range

†

(m) 3-5 10-12

Bandwidth

∗

(MHz) 100 300

Efficiency

∗

90% 50%

Reflection loss

∗

< 10% > 50%

Cost Low Nil

Size (mm) 8 x 6 25.7 x 7.5

†: Measured in closed indoor enviroment

∗: Obtained from dataheet(TI, 2008)

cell was another size limiting factor and hence we

found this to be a good choice which provides high

performance at a very low cost.

2.2.3 Low Power Analog Front End

Conventional thermistor interfacing techniques

(Boano et al., 2011) use a linearization circuitry

followed by a gain stage(G) and finally a ADC(A)

as shown in figure 4(b). We could eliminate most of

these components in our approach shown in figure

4(a), by using the high precision thermistor, a high

precision low tolerance low temperature coefficient

resistor R

1

and the high resolution 12 bit ADC in the

CC2540. Thanks to the well defined Temperature -

Resistance characteristics of the thermistor the non-

linearity can be taken care of by solving following

log-polynomial Steinhart-Hart equation in software.

1

T

= A+ Bln(R

Th

) +C(ln(R

Th

))

3

(1)

A, B, and C are the Steinhart-Hart coefficients

which are provided by the manufacturer (Cantherm,

2009). This non linearity correction can be done ei-

ther in the gateway or the sensor, thus incurring no

power penalty on the sensor device itself.

The minimum voltage resolution for the 12 bit

ADC operating at full range of 0−3V is 0.732mV. For

the use case in which the sensor module will be em-

ployed, the temperature range lies from 25

◦

C−40

◦

C.

The minimum accuracy requirement within this tem-

perature range is 0.1

◦

C which corresponds to a mini-

mum change of 2.743mV for the sensor module, well

above the LSB of the ADC and hence eliminates the

need for a separate gain stage.

As per the circuit shown in figure 4(a) analog volt-

age reference for 12 bit ADC (M = 12) is also sup-

plied from digital I/O. Therefore the voltage at the in-

put of ADC is given by

V

ADC

=

N

ADC

2

M

V

REF

=

R

Th

R

Th

+ R

1

V

REF

(2)

R

NTC

R

1

10k

R

Th

MCU

Digital I/O

AREF

12-bit ADC

GND

10k

±0.1%

V

ADC

V

REF

(a) new

R

Th

R

1

VCC

GND

G

R

2

R

3

A

GND

(b) conventional

Figure 4: Thermistor interfacing technique.

From above equation R

Th

can be calculated inde-

pendent of the voltage supplied by digital I/O.

R

Th

=

N

ADC

2

M

− N

ADC

R

1

(3)

For the change in R

Th

due to ±1 LSB variation of

ADC and tolerance of R

1

,

∆R

Th

=

R

TH

2

M

∆N

ADC

(2

M

− N

ADC

)N

ADC

+

(N

ADC

)∆R

1

(2

M

− N

ADC

)

(4)

The proposed approach uses a single resistor R

1

with a low temperature coefficient of ±10ppm/

◦

C and

a tolerance of 0.1%. For R

1

= 10KΩ, ∆R

1

is ±10Ω

due to tolerance and ±2Ω due to temperature change

of 20

◦

C. Therefore, total ∆R

1

≈ ± 11Ω. ∆R

Th

due the

change in ±1 LSB of ADC is calculated to be ±10Ω

at 25

◦

C and ±5Ω at 42

◦

C.

From equation 4 the total ∆R

Th

due to ±1 LSB

variation of ADC and tolerance of R

1

is found to be

±15Ω at 25

◦

C and ± 12Ω at 42

◦

C. This corresponds

to an error margin of ±0.03

◦

C at 25

◦

C and ±0.08

◦

C

at 42

◦

C. Error margin is within our accuracy require-

ment. The thermal noise from the resistors are negli-

gible.

The conventional approach suffers from increased

errors due to the number of resistors used because

each has its own temperature dependence and toler-

ance values. Another drawback of the earlier tech-

nique is that current is constantly consumed by the

wheat-stone bridge and the gain stage, irrespective

of the microcontroller being in sleep mode. In the

proposed design, since the sensor interface is pow-

ered from the micocontroller’sGPIO, the current con-

sumption can be significantly reduced by suitably pro-

gramming the GPIO output during the sleep mode.

This is illustrated in the measurements of both the

conventional and the proposed approach in table 2.

The use of well calibrated thermistor and a very

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

32

Figure 6: Prototyped temperature sensor with belts.

300µA

150µA

Sleep Active

New Circuit

Conventional

Figure 5: Current consumption during active and sleep

mode.

Table 2: Current consumption comparison.

Mode New circuit Conventional

Active mode 150µA 300µA

Sleep mode 0µA 300µA

low tolerance resistor eliminates the need for any

other calibrations saving the cost and effort.

2.2.4 Gateway Platform

The sensor communicates with the gateway and

the temperature data is stored on a centralized

database over a secured internet backbone provided

by GPRS/Wi-fi. We have developed the gateway us-

ing both a smartphone (Google Nexus 4) as well as a

low cost platform “Raspberry pi” as shown in figure

3(b). Raspberry pi has a 700MHz ARM core as an

application processor and 512 MB RAM. Dual USB

connectors are used for BLE and Wi-Fi dongles. A

Linux based operating system is booted on it to run

the application program. In the case of the smart-

phone an android application connects to the sensor

and relays the information to the server.

2.3 Prototype and Implementation

The prototype developed includes a casing which

houses the electronics and a belt which is used to fas-

ten the casing around the abdomen of the neonate.

Compared to monolithic design approach of (Chen

et al., 2010) by integrating sensors into textile, our

modular approach of designing a separate belt and

enclosure facilitates the sterilization, assembly, cost

reduction and easier interchangeabilityof the device.

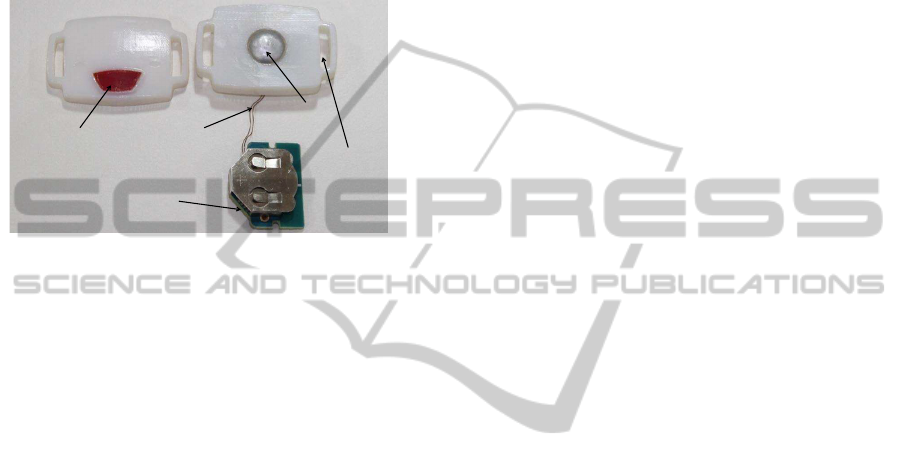

2.3.1 Temperature Sensing Interface

The thermistor has a dimension of 1.6mm x 4mm and

is required to be in thermal contact with the test sur-

face to measure its temperature. However due to the

requirements of the device to be robust and safe for

the neonate (without any sharp/pointy objects stick-

ing out of the device) the sensor was placed in contact

with a thermal interface which would touch the body

of the neonate on one side and house the sensor on the

other side as depicted in Figure 7.

Enclosure

Minimum

protrusion

Aluminum cup

Thermistor

Conductive

Adhesive

Figure 7: Vertical cross-section of the enclosure.

The interface consists of an aluminium cup made

by cold-working of an aluminium sheet. Aluminium

was chosen for its easy formability as well as abil-

ity to retain its shape once it is cold-worked. Alu-

minium also has a very high thermal conductivity

ranging from 200−250 W/m.K, which enables our

thermal interface design to attain thermal equilibrium

with the body of the patient in a short span of time.

The aluminium cold-worked cup is only 0.1mm thick

LowPowerRemoteNeonatalTemperatureMonitoringDevice

33

to minimize the heat loss. To ensure complete ther-

mal contact,the thermistor is glued on the inner side of

the aluminium cup with a highly thermally conductive

copper tape which ensures efficient and quick conduc-

tion of heat from the aluminium surface to the sensing

element. The cup is securely housed inside the casing

while ensuring that it protrudes slightly from the bot-

tom surface of the casing to enable reliable thermal

contact with the body of the patient.

Aluminum

Cup

Silicone

Membrane

Thermistor

Sensor platform

Belt Section

Figure 8: Disassembled prototype.

2.3.2 Power Switch

The device is designed to stay in deep sleep by de-

fault when not operational. To initiate connection es-

tablishment with a BLE gateway, we have provided a

power switch, which needs to be pressed and held for

5 seconds or more. However since the same switch

is also used to reset the device it is placed at a short

depth inside the casing to minimise the chance of ac-

cidental reset. A silicone membrane is flushed with

the top surface of the enclosure such that only if the

membrane is pressed to a depth of 3 mm or more

will the switch get activated. This requires concen-

trated force on the center of the membrane. Exper-

iments were conducted to check if any sort of acci-

dental pressing could lead to such a situation and it

was concluded that only intentional pressing could

achieve such a result. The silicone membrane also

ensures that the casing is water tight.

2.3.3 Enclosure

The enclosure is required to be water tight to pro-

tect the electronics from liquids used for sterilization

as well as from urine. Moreover the casing needs

to be made with minimum number of parts for ease

of production and low cost. The methods for mak-

ing the casing water tight are either to make a sim-

ple lip interface in the design where the top and bot-

tom parts can be pasted, or to go for a more compli-

cated design which involves either snap fits or screw

fittings and requires rubber gaskets to make the de-

vice water tight. The former method although cheaper

to manufacture has the disadvantage that the casing

can only be used one time. However since the de-

vice does not need battery replacement for several

months, the former method seems more feasible given

the fact that even an openable casing will be prone

to damage since it will move from patient to pa-

tient and might eventually be required to be replaced.

The custom designed enclosure as shown in the fig-

ure 6 is rapid-prototyped with the latest and higher

resolution 3-D printing technology (Stratasys, 2013).

The 3-D printed prototype was drop tested from a

height of 2 meters without any damage to the pro-

totype and enclosed circuitry. The actual production

model however would be even more robust due to

higher strength of commonly used injection molding

materials like Polypropylene or Acrylonitrile butadi-

ene styrene(ABS).

2.3.4 Belt Design

Respiration rate for newborns varies from 30−60

breaths per minute and during a respiration cycle the

abdomen region expands and contracts. An increase

in the height of the sternum of around 1/2 cm is con-

sidered as a normal expansion(Scavacini et al., 2007).

Hence the belt has to be designed with the require-

ments of being

• soft and elastic to accommodate the changes in

abdominal circumference during breathing

• able to accommodate different sizes of neonates

• washable for sterilization and reuse

All the above requirementswere met through a de-

sign where the belt is made out of a soft fabric. The

belt has a thin elastic band inside the fabric which can

be elongate upto 3 cms, hence it dynamically allows

for expansion of the belt during breathing. The belt

also has small loops in which fastening velcro can be

attached. The fastening velcro is placed at the ends of

the belt and when the belt folds on itself, the velcro

hooks come in contact with the loops thereby fasten-

ing the belt. This allows for accommodation of differ-

ent sizes of neonates. The fabric is completely wash-

able and the belt can be washed and dried for reuse.

Multiple belts can be assigned for a patient and these

belts can be replaced daily to maintain hygiene.

2.3.5 Baby Friendly Design

The industrial design of the device reflects the face

of a friendly abstract toy, where form follows func-

tion. All features of the face have functional rele-

vance. To keep the number of parts to a minimum,

light gates have been avoided by making the sections

under which the LEDs are housed thinner than the

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

34

Figure 9: Baby friendly enclosure.

overall casing. The thin sections allow light from the

LEDs to be seen well. These sections also give the

appearance of eyes for the face. The membrane for

the switch forms the mouth and the cavities through

which the belt passes give an appearance of ears. This

friendly face appearance of the design could help en-

force confidence in parents that the device is friendly

and is safe for their child. This design was arrived

at after multiple iterations and discussions with the

Neonatologists at SJRI. Initial prototypes were im-

proved through feedback from the Neonatology team

and features like exposed edges, sharp corners and

crevices as well as exposed buttons were removed

and the final design was presented which has been ac-

cepted by the Neonatology team.

3 EVALUATION

This section describes the evaluation method em-

ployed for testing our sensor platform. Experimental

results indicate that the device has the required accu-

racy. Later in the section power calculation is per-

formed to estimate the battery life.

3.1 Experimental Setup

As described in the section 2.3.1 temperature sensing

element is thermally interfaced with aluminium.To

determine the response time and accuracyof the pack-

aged module, experimental setup shown in the figure

10 is used.

A glass beaker filled with 300 ml of water is

placed on a hot plate. An accurate RTD based temper-

ature sensor is placed in the beaker. The temperature

of water is controlled by giving a closed loop feed-

back to hot plate’s heating element. The sensor device

is immersed in water bath along with a bare thermis-

tor. A precision digital thermometer is employed for

setting reference temperature. Packaged devices were

kept immersed in the water bath for 10 hours of con-

tinuous operation and the temperature measurements

Figure 10: Experimental setup.

were logged wirelessly. Temperature readings from

all the sensors were periodically sampled once every

two minutes.

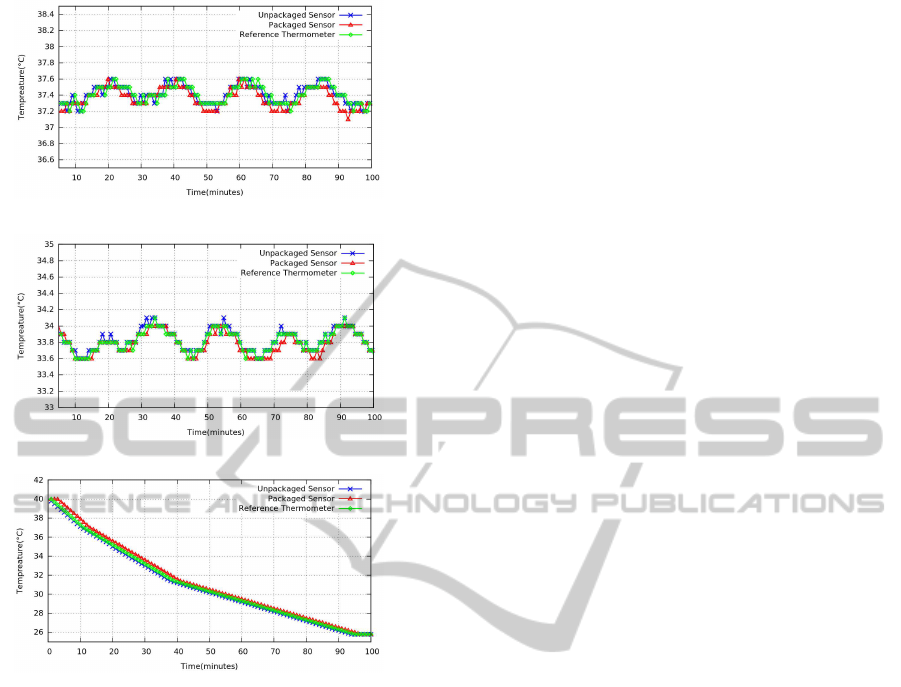

3.2 Results

3.2.1 Responsiveness

Figures 11(a) and 11(b) show the temperature mea-

surements during the experiment. A periodic oscilla-

tion of the temperature waveform was observed, indi-

cating the action of the servo control loop of the hot

plate. The period of the oscillations is approximately

40 minutes and is within ±0.3

◦

C of the temperature

configuration being used.

By definition, responsiveness is the time taken by

the system to respond to an event or a change, hence

these small changes in temperature provides an ideal

environment to determine the response time.

Table 3: Response time and sensivity comparison.

Parameter Bare Reference Packaged

Response < 4sec ≈ 3min ≈ 4min

The bare thermistor is fastest in responsiveness

followed by the reference thermometer and finally the

packaged device. The observed response times are

shown in table 3, indicating that the packaged sen-

sor would take approximately 3−4 minutes to attain

thermal equilibrium with the surroundings. In our ac-

tual application scenario, we are required to take con-

tinuous temperature readings once every 15 minutes,

hence the responsiveness is well within our require-

ment limits.

3.2.2 Accuracy

Using the same configuration for measuring the ac-

curacy, water was heated upto 40

◦

C and then was al-

lowed to cool down to room temperature. Figure 11

LowPowerRemoteNeonatalTemperatureMonitoringDevice

35

(a) Temp. measurements with hot plate at 37

◦

C

(b) Temp. measurements with hot plate at 34

◦

C

(c) Temperature measurements without hot plate

Figure 11: Responsiveness and accuracy measurement of

the sensor.

(c) shows the logged temperature reading. The vari-

ance (error bar) in the reading from the sensor device

is ±0.04

◦

C. By comparing the data obtained from

the sensor with a high precision digital thermometer

it was calculated that the error was within 0.1

◦

C for

the temperature range of 25

◦

C to 40

◦

C.

3.3 Power Consumption

The sensor device establishes a connection with the

near by gateway device through initial advertisement.

After a successful connection event, the sensor is con-

figured for periodic sleep and data transmission. Fig-

ure 12 and Table 4 shows the measured current and

energy consumed by the device during these modes of

operation. The profile in Figure 12(b) shows typical

power consumption over a sensing cycle. Sleep cur-

rent is measured using 6.5 digit 34411A Agilent mul-

timeter and transient current is measured using hall

effect current probe with TDS5104 Tektronix oscillo-

scope. The initial advertisement is the most energy

expensive - however this action is expected to happen

very rarely. The data transmission energy is also sig-

nificant compared to sleep energy and hence needs to

be minimised to ensure long battery life.

3.3.1 Battery Life Estimation

The sensor device is configured to send temperature

measurements once every 15 minutes. Thus there will

be 96 data transmission cycles in a day. The device

is powered by a 3V CR2032 coin cell of 225mAh

given capacity. Considering the derated capacity to

be 200mAh, the total energy it can deliveris estimated

to be 2160 Joules. Total energy consumed by the de-

vice during one full day of operation is estimated to

be 5.54 Joules which results in a battery lifetime of

388 days (about a year).

4 CONCLUSIONS

Continuous, automated monitoring of vital parame-

ters of neonates in remote rural areas has the potential

of saving many lives each year. The current meth-

ods are not reliable and the technological interven-

tion enabled by the proposed device can play a major

role in getting these vital parameters to the doctors

in real time. Critical requirements like reliability and

robustness of the device are met through a methodi-

cal design approach using state-of-the-art technology

like the integrated blue tooth low energy microcon-

troller, along with optimised sensor electronics and

software, to ensure good performance and battery life.

Human interface aspects have been incorporated into

the device to allow for a friendly yet robust device

which fulfils all the physical requirements for the de-

vice to be used comfortably on neonates in rural set-

tings while addressing maintenance and sterilisation

issues. The design also aims to connect emotionally

with the stakeholders like parents of the neonates and

health care providers to enforce confidence and a feel-

ing of security. The current design is modular and can

be extended beyond temperature measurement.

4.1 Future Research Needed

• From bench-to-bedside and then from bedside-to-

community to test the safety, accuracy, accept-

ability, efficacy, effectiveness, techno feasibility

of this device in humans

• Testing through the various phases of clinical tri-

als and other appropriate epidemiological study

designs

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

36

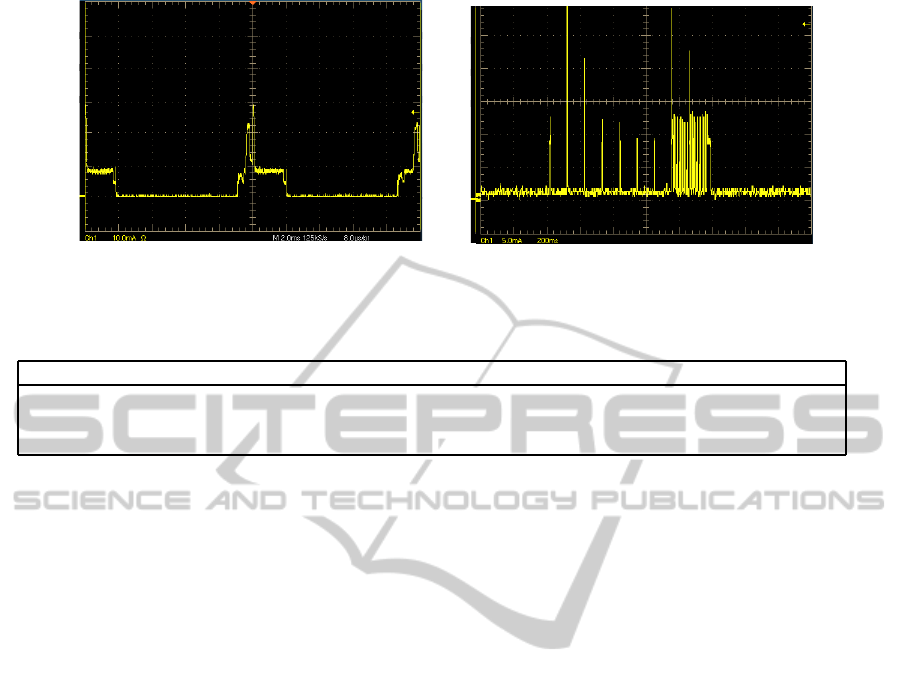

time (2msec/div)

current (10mA/div)

(a) initial one time advertisement mode

time (200msec/div)

current (5mA/div)

(b) periodic data transmission mode

Figure 12: Oscilloscope plot showing current measured using precision current probe for different modes of operation.

Table 4: Current consumption for different mode of operation.

Mode Peak current Average current On Time Energy from 3V @ 90%η

Sleep 1µA 1µA 899 sec 1.1 mJ

Data Transmission 30 mA 17 mA 1 sec 56.6 mJ

Initial Advertisement 30 mA 4.5 mA 180 sec 2700 mJ

• Testing within nationally and globally acceptable

ethical and legal frameworks for research on hu-

man participants

• Testing for potential scale-up on a large-scale

ACKNOWLEDGEMENTS

We acknowledge the Robert Bosch Center for Cyber

Physical Systems at the Indian Institute of Science for

funding support.

REFERENCES

Alf Helge, O. (2010). Bluetooth Low Energy: Wireless

Connectivity for Medical Monitoring. Journal of Di-

abetes Science and Technology, 4(2).

Artem, D., Steve, H., Stuart, T., and Joshua, S. (2013).

Power consumption analysis of Bluetooth Low En-

ergy, Zigbee, and ANT sensor nodes in cyclic sleep

scenario. IEEE International Wireless Symposium,

Beijing, China.

Bluetooth (2012). Health tempertute profile. https://

developer.bluetooth.org/TechnologyOverview/Pages/

HTP.aspx.

Boano, C., Lasagni, M., Romer, K., and Lange, T.

(2011). Accurate temperature measurements for

medical research using body sensor networks. In

Object/Component/Service-Oriented Real-Time Dis-

tributed Computing Workshops (ISORCW), 2011 14th

IEEE International Symposium on, pages 189–198.

Cantherm (2009). High precision ntc thermistors. http://

www.cantherm.com/products/thermistors/mf51e.html.

Chen, W., Dols, S., Oetomo, S. B., and Feijs, L. (2010).

Monitoring body temperature of newborn infants at

neonatal intensive care units using wearable sensors.

In Proceedings of the Fifth International Conference

on Body Area Networks, BodyNets ’10, pages 188–

194, New York, NY, USA. ACM.

Embrace (2012). A low cost infant warmer. http://

embraceglobal.org/.

Global Health (2010). Causes of neonatal and child mortal-

ity in india: a nationally representative mortality sur-

vey. The Lancet, 376(9755):1853 – 1860.

Gomez, C., Oller, J., and Paradells, J. (2012). Overview and

evaluation of bluetooth low energy: An emerging low-

power wireless technology. Sensors, 12(9):11734–

11753.

Hawley E, M.-D., Salvatore P, I., and Jonathan A, B. (2012).

Movement toward a novel activity monitoring device.

Sleep Breath, 16(3):913–917.

Isetta, V., Agustina, L., Lopez Bernal, E., Amat, M., Vila,

M., Valls, C., Navajas, D., and Farre, R. (2013). Cost-

Effectiveness of a New Internet-Based Monitoring

Tool for Neonatal Post-Discharge Home Care. Jour-

nel of Medical Internet Research, (15(2):e38).

iThermometer (2012). Bluetooth digital thermometer for

android devices. http://download.chinavasion.com/

download/CVXX-A140.pdf.

Kumar, V., Mohanty, S., and Kumar, A. (2008). Effect

of community-based behaviour change management

on neonatal mortality in shivgarh, uttar pradesh, in-

dia: a cluster-randomised controlled trial. The Lancet,

372(9644):1151 – 1162.

Kumar, V., Shearer, J. C., Kumar, A., and Darmstadt, G. L.

(2009). Neonatal hypothermia in low resource set-

tings: a review. Journal of Perinatology, 29:401–412.

Macfarlane, F. (2006). Paediatric anatomy, physiology and

the basics of paediatric anaesthesia.

Neurosynaptics (2002). http://www.neurosynaptic.com/.

LowPowerRemoteNeonatalTemperatureMonitoringDevice

37

Oestergaard, M. Z. and Inoue, M. e. a. (2011). Neonatal

mortality levels for 193 countries in 2009 with trends

since 1990: A systematic analysis of progress, projec-

tions, and priorities. PLoS Med, 8(8):e1001080.

Rutter, N. (2000). Clinical consequences of an immature

barrier. Seminars in Neonatology, 5(4):281 – 287.

Scavacini, A. S. A.-l., Miyoshi, M. H., Kopelman, B. I., and

Peres, C. A. d. A. A. (2007). Chest Expansion for As-

sessing Tidal Volume in Premature Newborn Infants

on Ventilators. Jornal de Pediatria, 83:329 – 334.

Stratasys (2013). High-quality, precise, multi-

material prototypes in a compact system.

http://www.stratasys.com/3d-printers/design-series/

precision/objet260-connex.

Susan, B., Debra, D., and Lori A, L. (2001). Neonatal Ther-

mal Care, Part II: Microbial Growth Under Tempera-

ture Probe Covers. Journal Neonatal Network: The

Journal of Neonatal Nursing, 20:19–23.

TI (2008). 2.4ghz inverted f- antenna. http://www.ti.com/

lit/an/swru120b/swru120b.pdf.

WHO (1993). Thermal Control of the Newborn: a Practical

Guide. Maternal and Safe Motherhood Programme.

WHO (2012). Newborn deaths decrease but account for

higher share of global child deaths.

WHO, UNICEF, and UN (2012). Levels and Trends in

Child Mortality Report.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

38