Mechanically Flexiable Biosensor for Detection

of Photoplethysography

Kian Davoudi,

Moein Shayeganyan, Kouhyar Tavakolian and Bozena Kamisnka

Simon Fraser University, 8888 University Drive, Burnabyr, Canada

Keywords: Photoplethysmography, Heart Rate, Inkjet Printing, Polymer Metallization, Flexible Sensor.

Abstract: Acute cardiovascular failure could be detected by continuous monitoring of electrocardiogram (ECG).

While electrode allocation on skin challenges quality of electrocardiograph, beat-to-beat heart rate obtained

from photoplethysmography (PPG) could be used to indicate cardiovascular activity as an alternative to

heart rate from ECG. In this paper we proposed a mechanically flexible PPG sensor integrated on thin layer

of polymer. Mean and standard deviation of beat-to-beat heart rate was obtained from a flexible PPG sensor

and compared to the beat-to-beat heart rate obtained from a commercial ECG and PPG devices. The

standard deviation of beat-to-beat heart rate from ECG and PPG intervals were analysed by the Bland and

Altman analysis. The corresponding 95% limits of agreement were estimated as 0.034 to -0.01 for PPG

flexible sensor compared to ECG and as 0.0081 to 0.0037 for PPG flexible sensor compared to PPG

commercial device. The good correlation between the measurement results demonstrated capability of our

proposed mechanical flexible PPG sensor to be used as practical alternative to ECG for heart rate variability

(HRV) analysis.

1 INTRODUCTION

Increasing cost of healthcare and accelerated aging

of society incite hospitals and other medical

caregivers to look for solutions that are inexpensive,

yet maintain proper quality of care. The prospects of

efficient remote health and activity monitoring using

biosensors have recently gained a lot of interest and

stimulate research in the area of wearable

electronics. Technological advances in sensors,

wireless communication and integrated circuits have

brought about small, inexpensive wearable

physiological monitors. These devices are usually

capable of sensing one or more vital signs, e.g. heart

rate, body temperature and blood pressure, then

communicating the acquired data to a local or

remote processing and interpretation centre.

The conventional wet adhesive Ag/AgCI

Electrocardiography (ECG) electrodes are used

almost universally in clinical applications. They

provide an excellent signal but are cumbersome and

irritating for mobile users. The chief advantage of

the standard clinical wet electrodes is their strong

adhesion to skin. However, their main issue is long-

term use problematic for a patient comfort (Chi,

2010). Adhesive wet electrodes stay fixed to

specific, clinical standard locations on the body.

These standard electrodes not only adhere well to a

body, but also are robust, inexpensive and simple.

As an alternative, dry and noncontact electrodes

without gel have been introduced to address the

comfort issues with the adhesive electrodes. These

electrodes offer few advantages for patients with

extremely sensitive skin burn units (Griffith, 1979)

and neonatal care (Bouwstra, 2009). However the

dry electrodes are much more difficult to secure

against the skin and they have yet to achieve the

acceptance for medical use. They also add cost and

complexity in active electrode circuitry. For these

technologies to be useful mechanical solutions must

be devised to place the dry electrodes in the proper

position or an alternative application must be found.

Photoplethysmography (PPG) is a non-invasive

method based on the reflection of light from

peripheral tissue. PPG waveform contains valuable

physiological information, such as respiration and

heart rate.

Pressure disturbance induced by the PPG probes

placed on a forehead affects quality of a PPG

waveform, and leads to the inability to measure heart

rate. In addition, due to rounded and optically

inhomogeneous surface properties of the skeleton of

159

Davoudi K., Shayeganyan M., Tavakolian K. and Kamisnka B..

Mechanically Flexiable Biosensor for Detection of Photoplethysography.

DOI: 10.5220/0004806401590164

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2014), pages 159-164

ISBN: 978-989-758-013-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

forehead, alternation in forehead PPG sensors

changes distribution of the light scattered to tissue;

hence, introduces noise in backscattered light

reaching PPG sensors (Dresher 2006).

In this paper we proposed a mechanically

flexible PPG sensor integrated on plastic substrate.

The advantages of our proposed flexible PPG sensor

can be summarized as follows:

a. It monitors heart rate without interfering

user’s daily routine for prolonged period of

time.

b. It minimizes the pressure disturbance

induced by the placement of a PPG sensor.

c. It requires inexpensive integration

methodology and less complex electronic

circuitry.

The objective of this paper is to assess feasibility

of integrating a PPG sensor on plastic (polymer) for

continuous monitoring of heart rate. We have

developed an algorithm to extract intervals between

successful cardiac cycles from five healthy subjects.

The data have been recorded from the proposed

flexible PPG sensor in parallel to the ECG and PPG

from commercial pulse oximetry and ECG devices.

HRV analyses has been conducted in time frequency

domain on the PPG waveform acquired from

flexible sensor in addition to the ECG and PPG from

the commercial devices.

2 METHODOLOGY

2.1 Principal of Operation

PPG assessment is available through the commercial

pulse oximetry devices. The estimation of pulse

oximetry requires use of two wavelengths, red and

infrared (IR) (~640nm, ~940 nm respectively). Red

Light Emitting Diode (LED) is being used for

estimation of oxygenated hemoglobin and IR LED is

being used for estimation of deoxygenated

hemoglobin.

The conventional PPG sensors are available in

two models. In the first model, light emitter is

located opposite side of photoreceptor. In this case,

the emitted light passes through skin tissue and a

photoreceptor on the other side of tissue detects

portion of the light passed through. This type of PPG

sensor requires a mechanical clip to secure location

of photodiode, for example on a finger and ear. In

the seconds model, LED and photo detector are

placed side by side on top of a tissue. In this case,

the photo detector observes the reflected light in the

same planar surface as the LED and sensor is

attached using a tap against the skin (Dresher R.

2006). Our sensor follows principles of the second

model.

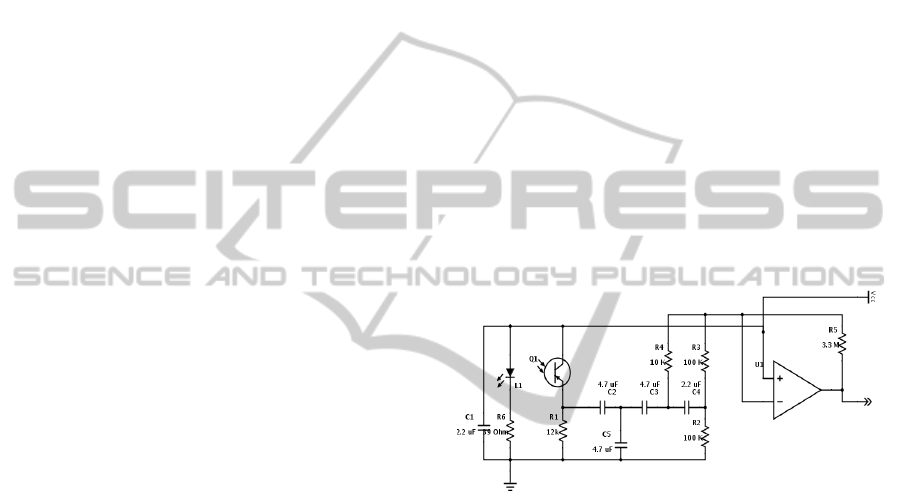

2.2 Design of a PPG Circuit

Since a PPG waveform can be obtained from one

LED, we have avoided the excessive use of LEDs

for our application, and LED (Kings light 530 nm)

has been chosen as the primary source of light. To

detect the reflected light, a photodiode (APDS-9008)

was utilized. To amplify the output waveform of the

photodiode, an operational amplifier (MCP6001)

was used. In addition, passive components with

small foot-print (0603Metric) were chosen for

filtering the high frequency noise from light sensor.

We have developed an electric circuit to obtain a

PPG waveform from the APSD-9008 photodiode.

As demonstrated in Figure 1, an electronic circuit

consists of five sections: light, photodiode, high pass

filter and active amplification. The circuit has been

designed and simulated using Eagle software.

Figure 1: The schematic of a PPG circuit obtained with the

Cad soft Eagle 6.5.

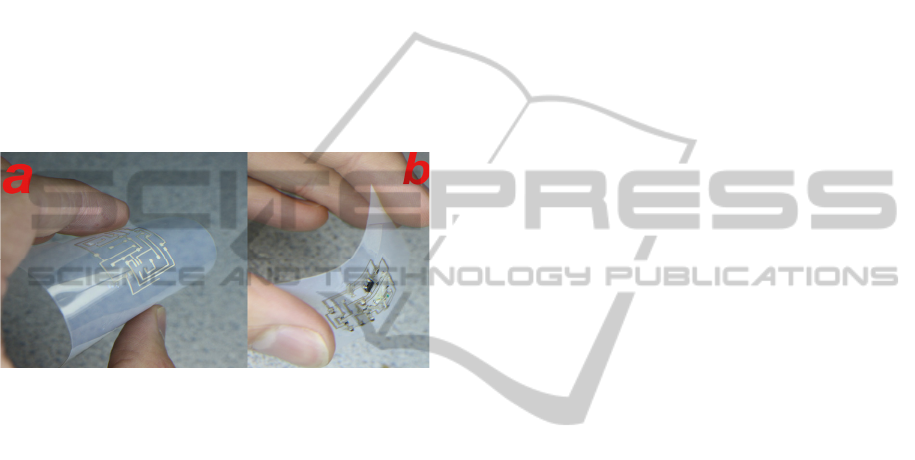

2.3 Fabrication Process

For fabrication of PCB sketch on flexible materials,

two components were used; polymer (IJ-220,

Novacentrix) and conductive silver ink (JS-25HV,

Novacentrix). Diamatix inkjet printing technology

(Fujifilm, DMP-2831) was used to fabricate the PCB

sketch on a polymer.

To print JS-B25HV silver ink on IJ-220 PET

substrate (figure 2.a), the jetting waveform was

adjusted to single size drops, and 6 nuzzles were

used during printing process. Because the JS-

B25HV is a water-based ink, each sample was also

cured for 60 minutes at 100°

c

in an oven. The

following setting were adjusted on Diamatix to

pattern conductive lines on IJ-220:

Resolution of drops = 20 um

Temperature of Surface of the plate = 42°

c

Temperature of cartridge = 28°

c

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

160

As demonstrated in figure 2.b electronic components

of the PPG circuit were manually attached on the

flexible substrate using silver epoxy (8331, MG

Chemicals). Curing time of the silver epoxy was

reported 20 minutes by manufacture. However

during testing and evaluation phase, we noted a high

frequency noise in the PPG signal that was

introduced by the silver epoxy. Hence, PCB layers

were cured for 24 hours at room temperature where

consequently the noise was disappeared.

Figure 2 illustrates the flexible characteristic of

our mechanical sensor after integration of electrical

components on the IJ-220. The flexibility and

simplicity are the main advantages of our sensor in

providing comfort for prolong usage on skin and

within accessory or special clothing.

Figure 2: A: demonstration of the PPG sketch fabricated

on IJ-220. B: Integration of electrical component of the

PPG circuit on metalized layer of polymer.

Figure 2.b exhibits the location of the LED and

the photodiode on our flexible mechanical PPG

sensor. Clearly, transmitter and receiver are located

on a same planar surface, and reflection mode is the

operation principle. In this design, all pressure

induced by the attachment of a sensor to the skin is

endured by the backside of the sensor. Hence, the

minimal disturbance is interfered into the photo

diode. This fact establishes the second main

advantage of our proposed PPG sensor, which is

minimizing the pressure disturbance included in the

available commercial PPG sensors such as Nonin

8600 pulse oximetry.

2.4 Experimental Setup

Five healthy subjects were voluntarily chosen to

install our fabricated sensor, Nonin 8600, and

Biopac ECG100c on them. The selected subjects

were non-smokers, aged between 22-32, males, and

without any known physiological diseases. They

were asked to sit on a chair and breathed at normal

pace.

The PPG and ECG signals were obtained from two

sensors: flexible PPG sensor and Nonin 8600. The

ECG was also obtained from Biopac ECG100C.

Two PPG sensors were located side by side on a

forehead of each subject, and the Biopac electrodes

were attached to the chest. One minute of the PPG

and ECG signals was recorded by NI 9205 NI DAQ

at 1kHz sampling rate and stored on a personal

computer.

3 SIGNAL PROCESSING

The changes in a PPG waveform arise from the

variation in path-length between source and detector

(Schäfer 2012). The typical waveform of a PPG

cycle can be divided into two parts: the anacrotic

phase and the catacrotic phase. Anacrotic phase is

the rising part of the pulse due to systole, which

happens shortly after QRS complex in ECG.

Catacrotic phase corresponds to the cardiac diastole

and often contains a secondary peak so called

dicrotic north, an effect diminishing with aging and

increasing arterial stiffness (Allen 2007).

In this study, we have developed an algorithm to

identify anacrotic pitch of the PPG waveform. An

interval between anacrotic peaks was identified as a

full cardiac cycle, and time difference between pair

of cardiac cycle was measured as beat-to-beat heart

rate. We have used this automated algorithm to

detect beat-to-beat heart rate from the PPG

waveform obtained by the flexible and the

commercial PPG sensors. The initial PPG waveform

from both sensors and ECG was fragmented into

different frames. Initial constants such as maximum

and minimum expected peak to valley values,

maximum window size, and maximum or minimum

window change were set. The algorithm actively

allocated a variable sized window to each frame. A

peak detector was used to measure the peaks, valleys

and the associated time index values, within each

window frame. The size of the window was then

varied based on initial window size, interval

between the peaks and pulse width to frame ratio.

The peaks, valleys and their time index of each

window were padded in to a vector. Hence, the beat-

to-beat heart rate was obtained by differentiating

consecutive time index values. The initial ECG

waveform was also fragmented into different frames.

Since QRS height is larger than anacrotic pitch in

PPG waveform, the initial constants were adjusted

differently than in PPG. The rest of the algorithm

remained the same as in the case of PPG. Hence, the

MechanicallyFlexiableBiosensorforDetectionofPhotoplethysography

161

peaks of R wave of ECG were automatically

obtained.

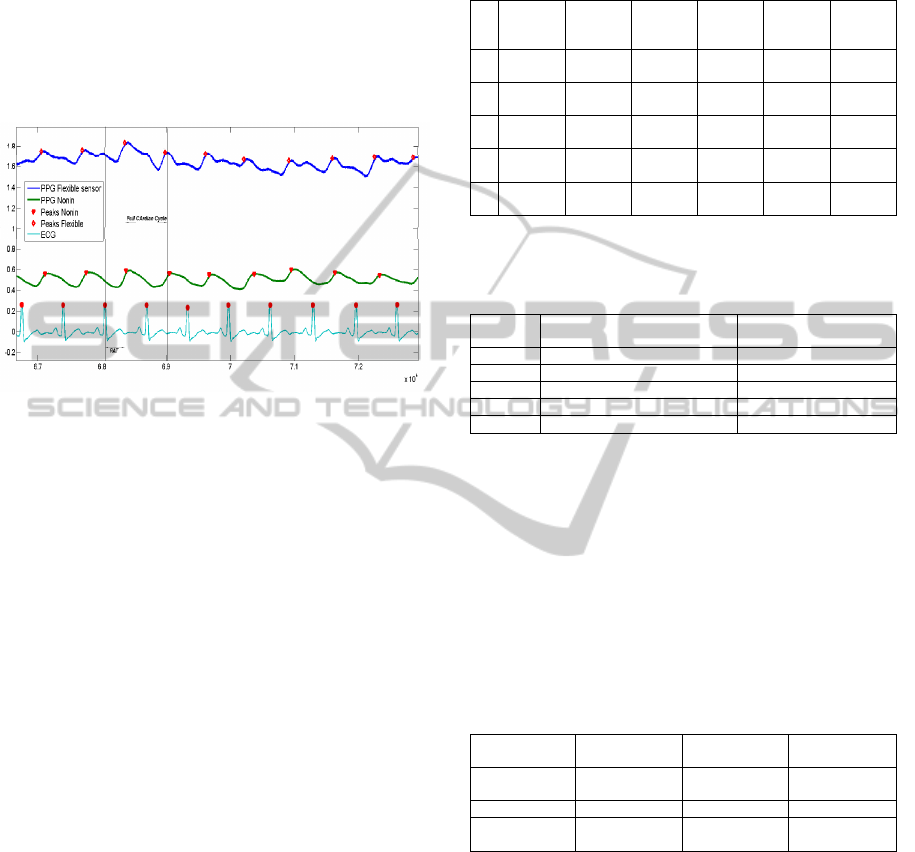

As demonstrated in Figure 3, while in the

commercial pulse oximeter devices, a high-pass

filter is applied to remove the respiration component

of the PPG signal by the manufacturer of device

(Karnel, 2013), the AC component of the signal

corresponding to the respiration induced intensity

variation was contained in our study (Nilsson, 2003).

Figure 3: Demonstration of PPG waveform by flexible and

commercial PPG sensor and ECG waveform.

In the Figure 3 the PPG waveform obtained by

flexible PPG sensor demonstrates variation in base

line of the PPG waveform, which corresponds to the

respiration component of a PPG signal. The red dots

correspond to the occurrence of anacrotic pitch in

PPG waveform. The PPG obtained from the

commercial pulse oximeter was high-passed filtered

by the manufacturer. The red dots correspond to the

anacrotic pitch were detected by the automated

algorithm as described in section 3. This algorithm

was also applied to the ECG waveform and the red

dots on ECG waveform correspond to the

occurrence of each successful cardiac cycle

extracted automatically.

4 RESULTS

According to Table 1, the mean and standard

deviation of beat-to-beat heart rate were calculated

from the PPG obtained by the flexible sensor, the

PPG obtained by the commercial pulse oximetry and

the ECG for each participant. In Table 2 the

difference between the means of heart rate from two

PPG sensors were compared to the ECG. This

comparison was fulfilled by estimating the mean

square error (MSE) for means of PPG from the

flexible sensor and the means of ECG, in parallel to

the means of PPG from the commercial device to

means of the ECG.

Table 1: Mean and standard deviation of beat-to-beat heart

rate from five subjects.

Mean

ECG

SD

ECG

Mean

PPG

Nonin

SD

PPG

Nonin

Mean

PPG

flex

SD

PPG

flex

#

1

0.0925

9

0.0065

5

0.0925

4

0.0099

8

0.0926

8

0.0082

6

#

2

0.0865

6

0.0075

6

0.0868

49

0.0144

0.0888

1

0.0149

0

#

3

0.0876

3

0.0765

6

0.0877

54

0.0080

6

0.0879

4

0.0105

4

#

4

0.0865

8

0.0073

5

0.0863

7

0.0065

4

0.0924

4

0.0243

7

#

5

0.0931

8

0.0077

7

0.0939

1

0.0069

0

0.1059

9

0.0366

2

Table 2: Mean square error of means of beat-to-beat heart

rate from PPG flexible to ECG and PPG commercial

device to ECG.

Subjects MSE PPG commercial to ECG

MSE PPG flexible to

ECG

#1 13*10

-10

4.4*10

-9

#2 4*10

-8

2.5*10

-6

#3 7.1*10

-9

4.9*10

-8

#4 2.23*10

-8

1.7*10

-5

#5 2.679*10

-7

8.2*10

-5

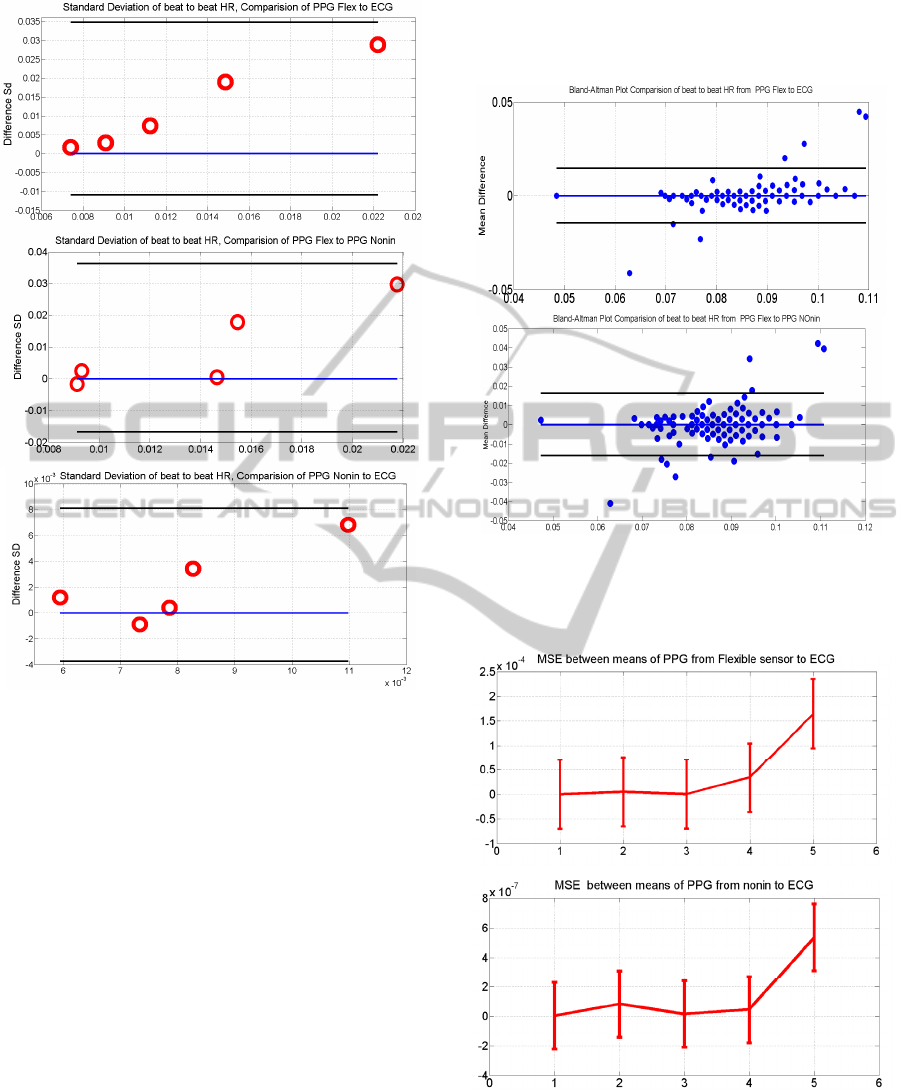

Furthermore, as demonstrated in Table 3 and

Figure 4, the degree of agreement between the PPG

from the flexible sensor to PPG from the

commercial oximeter and ECG was assessed using

Bland and Altman analysis. This analysis indicated

the mean of Standard Deviation (SD) ratio and

corresponding 95% limits of agreement, 0.034 to -

0.010 for PPG flexible compared to ECG and 0.0081

to 0.0037 for PPG flexible to PPG commercial.

Table 3: Bland and Altman analysis of SD of beat-to-beat

heart rate.

PPG Flex to

PPG nonin

PPG Flex to

ECG

PPG Nonin to

ECG

95% upper

limit

0.03632 0.03482 0.008131

Mean 0 0 0

95% lower

limit

-0.01679 -0.01089 -0.003736

Degree of similarity between bit-to-bit heart rates

obtained from flexible PPG devices was compared

to the heat rates obtained from commercial PPG

device and ECG, as demonstrated in figure 5. This

analysis demonstrates strong similarity between two

PPG signals.

Figure 6 presents the MSE between two sets of

measurements for all 5 subjects. The first

measurement is MSE between the mean of the heart

rate recorded by the commercial available pulse

oximetry and the one of Biopac ECG, as the

benchmark. The second measurement is MSE

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

162

Figure 4: Bland and Altman analysis, comparison of SD of

beat-to-beat heart rate from PPG flexible to ECG, PPG

flexible to commercial PPG and PPG from commercial

device to ECG.

between the mean of the heart rate estimated by our

flexible PPG sensor, and the one of the Biopac ECG.

In this figure, the horizontal line indicates the MSE

for each subject, and the vertical lines reveal the

MSE standard deviation between all subjects.

Evidently, a consistency can be noticed between

the two error bars. That is, the MSE of the 5th

subject is greatest in two sets of measurements, and

the best estimation in both sets belongs to subject

number 1. This consistency validates the heart rate

variability measured by our fabricated flexible PPG

sensor. In addition, the very small MSE between the

heart rate means between the flexible PPG sensor

and the Biopac ECG establishes the high accuracy of

our fabricated sensor. Even though this MSE is

higher than the one between the commercial PPG

and the Biopac ECG, but our sensor benefits from a

lower cost and less complexity. Also, this higher

error can be inferred to the lower accurate laboratory

facilities available in academics compared the

enhanced high accuracy fabrication facilities in

industry.

Figure 5: Bland and Altman analysis between heart rate

obtained from PPG flexible to PPG commercial and ECG

as well as PPG from commercial device to ECG for

subject number 3.

Figure 6: MSE between means flexible PPG sensor of

heart rate from five subjects to ECG, in parallel to MSE

between means of heart rate from commercial PPG to

ECG.

MechanicallyFlexiableBiosensorforDetectionofPhotoplethysography

163

5 CONCLUSIONS

The proposed flexible PPG sensor has been studied

as an alternative solution to the commercial PPG

sensor and the ECG device for continuous

monitoring of heart rate. Standard deviation and

mean of intervals between cardiac cycles were

analysed. Accuracy of this sensor and the algorithm

were analysed by Bland and Altman analysis. The

MSE between the mean values of beat-to-beat heart

rates from flexible PPG sensor and those of Biopac

ECG was compared to those between the

commercial PPG and Biopac ECG. The results

confirm feasibility of obtaining heart rate from the

flexible PPG sensor for analysis of heart rate

variability.

ACKNOWLEDGEMENTS

The author wishes to thank Dr. Kouhyar Tavakolyan

for his valuable guidance.

REFERENCES

Chi, Y. M., Jung, T. P., & Cauwenberghs, G. (2010). Dry-

contact and noncontact biopotential electrodes:

methodological review. Biomedical Engineering,

IEEE Reviews in, 3, 106-119.Smith, J., 1998. The

book, The publishing company. London, 2

nd

edition.

Griffith, M. E., Portnoy, W. M., Stotts, L. J., & Day, J. L.

(1979). Improved capacitive electrocardiogram

electrodes for burn applications. Medical and

Biological Engineering and Computing, 17(5), 641-

646.

Bouwstra, S., Feijs, L., Chen, W., & Oetomo, S. B. (2009,

June). Smart jacket design for neonatal monitoring

with wearable sensors. In Wearable and Implantable

Body Sensor Networks, 2009. BSN 2009. Sixth

International Workshop on (pp. 162-167). IEEE.

Dresher, R. (2006). Wearable forehead pulse oximetry:

Minimization of motion and pressure artifacts

(Doctoral dissertation, Worcester Polytechnic

Institute).

Schäfer, A., & Vagedes, J. (2012). How accurate is pulse

rate variability as an estimate of heart rate variability?:

A review on studies comparing

photoplethysmographic technology with an

electrocardiogram. International Journal of

Cardiology.

Allen, J. (2007). Photoplethysmography and its

application in clinical physiological measurement.

Physiological measurement, 28(3), R1.

Karlen, W.; Raman, S.; Ansermino, J. M.; Dvvccont, G.

A. (July 2013), "Multiparameter Respiratory Rate

Estimation From the Photoplethysmogram,"

Biomedical Engineering, IEEE Transactions on,

vol.60, no.7, pp.1946, 1953.

Nilsson, L., Johansson, A., & Kalman, S. (2003).

Macrocirculation is not the sole determinant of

respiratory induced variations in the reflection mode

photoplethysmographic signal. Physiological

measurement, 24(4), 925.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

164