A Multi-objective Mixed-Integer Programming Model for a

Multi-Section Operating Theatre Facility Layout

Abdelahad Chraibi

1,2

, Said Kharraja

1

, Ibrahim H. Osman

3

and Omar Elbeqqali

2

1

University of Lyon, University of Saint-Etienne, Laboratory of Signal and Industrial Process Analysis (LASPI),

Roanne, France

2

University Sidi Mohamed Ben Abdellah, Faculty of Science Dhar El Mahraz,

Laboratory of Informatics Image Processing and Numerical Analysis (LIIAN), Fez, Morocco

3

Suliman S. Olayan’s School of Business, Business Information & Decision Systems, American University of Beirut,

Beirut, Lebanon

Keywords: Operating Theatre, Facility Layout Problem, Mixed Integer Programing, Multi-Section Layout, Multi-Goal

Formulation.

Abstract: The operating theater layout problem (OTLP) in a hospital aims to determine for a set of facilities their

positions and orientations on the floor-layout of departments in a hospital subject to a set of constraints on

distances, available areas, and non-overlapping facilities according to international medical standards and

specifications. The OTLP has two main objectives: a quantitative objective to minimize the

interdepartmental travel costs among facilities and a second qualitative objective to maximize the closeness

rating among facilities. In this paper, a mixed integer linear programming (MILP) model is proposed for

OTLP. The MILP model is validated on two illustrative cases to determine the positions as well as the

orientations of facilities in a two-dimensional space for a two-floor hospital using commercial optimization

software.

1 INTRODUCTION

The health care sector is one of the fastest growing

sectors in the world and in particular in France

where the current political, economic and social

conditions are the driving factors for hospitals to

streamline costs and improve quality of health care

services due to increased health care demands from

an aging population. As a consequence, hospitals are

conducting studies to establish better health

management tools to control the rapid increase in

health care cost as well as to improve the efficiency

of the health care system. In this regards, the

operating theater layout problem (OTLP) has a

significant impact on the cost efficiency

performance of any hospital and associated health

care services.

The OTLP consists of a set of n activities or

services to be placed on the floor-layout of

departments in a hospital. The positions and

orientations for each facility must be determined

subject to a set of constraints on distances, available

areas, and non-overlapping facilities according to

international medical standards and specifications,

(Tompkins et al., 2010).

The OT is one of the most critical and expensive

resources in hospitals (Guerriero and Guido 2011),

since 60–70% of all hospital admissions are due to

surgical interventions. They also account to more

than 40% of the total expenses of a hospital (Denton

et al. 2007). Such high expenses attracted the

attention of hospital management to look into

studying the efficiency of the operating theater.

The facility layout design of plants in

manufacturing systems aims to arrange in an

effective layout to minimize the material handling

costs. However, the design of OTLP in hospitals has

different objectives beyond classical manufacturing

requirements, it aims to find a layout design that

reduces operating expenses and the duration of the

health care process, enhances the quality of work

environment, increases the staff effectiveness,

improves patient and staff satisfaction and optimizes

the resources utilization.

In this paper, we will focus our research on the

OTLP in order to develop an optimal OT facility

layout respecting the standard guidelines and

specifications (Sehulster et al, 2003, AIA, FGI); to

196

Chraibi A., Kharraja S., H. Osman I. and Elbeqqali O..

A Multi-objective Mixed-Integer Programming Model for a Multi-Section Operating Theatre Facility Layout.

DOI: 10.5220/0004832401960204

In Proceedings of the 3rd International Conference on Operations Research and Enterprise Systems (ICORES-2014), pages 196-204

ISBN: 978-989-758-017-8

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

minimize the movement cost; making distinction

between patients, doctors, medical and non-medical

staff travel cost; (the movement cost is considered to

be proportional to travel frequency and distance

between activities); to maximize the desired

closeness among activities; and to develop a

decision making support system based on the above

mentioned specifications, international standards and

optimization methods.

Section II presents a state of the art literature

review. Section III introduces the problem statement

and our mathematical model and in Section IV our

computational results are presented. Finally, section

V contains conclusions and future research

perspectives.

2 LITERATURE REVIEW

The FLP can be classified in two categories

according to the problem according to the

arrangement of facilities: equal-area or un-equal area

layout problems. The un-equal area FLP category

can also be subdivided primarily into two more

groups based on the plan layout representations: a

discrete plan layout - the plant site is divided into

equal-area rectangular units, and each group of units

on the grid is assigned to a facility; and a continuous

plan layout- facilities can be placed anywhere within

the plan layout without any overlap among them.

The FLP aims to find an efficient non-overlapping

arrangement of n facilities in a given plant.

Generally, the material handling costs is used to

measure the efficiency of the facility layout.

Minimizing the total cost of material transportation

and maximizing the total closeness rating between

each two departments are the common objectives

used in FLP (Meller et al., 1996).

Three of the most popular modeling approaches

for the FLPs are the quadratic assignment

(Koopmans et al., 1957), the mixed-integer

programming (Montreuil, 1990), and integer linear

formulation and heuristics for the graph theoretical

approaches (Osman et al., 2002); (Osman et al.,

2003); (Osman, 2006); (Hassan and Hogg, 1987).

The Quadratic Assignment Problem (QAP) is a

special formulation for FLP. It assumes a fixed

known set of locations, equal areas for each facility

and one-to-one matching between facilities and

locations. In recent times, efforts are made to solve

QAP using heuristic procedures. Different types of

solutions were proposed in the literature to solve

QAP: an evolutionary search heuristic, Ramkumar et

al., (2007); simulated annealing method combined

with ant colony, Jingwei et al., (2012) and other

approaches including construction methods, limited

enumeration methods, tabu search, genetic

algorithms as well as their hybrids. For more details,

we refer to Commander (2003).

Montreuil (1990) extended the QAP formulation

to a mixed-integer programming (MIP)

formulation to minimize the material handling cost

within a plant. Generally the QAP is used for

discrete representation, while the MIP is used for the

continuous one. In Hathhorn et al., (2013), authors

presented a multi-goal approach to minimize both

the material handling and facility building costs and

proposed a lexicographic ordering technique to

handle the multiple objectives.

While the objective of MIP and QAP is to

minimize the material handling cost within a plant,

the objective of the graph-theoretic approach is to

maximize the weighted sum of desirable measures

among adjacent facilities (departments). In graph-

theoretic approaches, it is assumed that the closeness

ratings (desirable measures) between departments

are known. Each department is then represented by a

node in a graph and department adjacency

relationships are represented by an arc connecting

the two adjacent departments. The objective function

is to maximize the weight sum of adjacencies

between department pairs (Osman, 2006).

FLP has wide applications ranging from: an OT

to a whole hospital, an assembly line to the baggage

department in an airport, an existing warehouse to an

office. In OT, the facility layout design involves the

determination of how to design the physical layout

of OT of activities to provide the best support for

production of health care services. There is literature

on FLP in hospitals but a few in the OTFL design.

Motaghi et al., (2011) used heuristic techniques

(Diamond Algorithm) in Shafa hospital to optimize

the hospital layout. The application of the layout

improvement has increased the efficiency of the

hospital by 45%. Assem et al., (2012) applied the

FLP to the OTFL. They improved the design of OT

by generating a block layout based on a graph

theoretic method called SPIRAL which is a

qualitative approach to maximize the

interdepartmental adjacency of the graph layout.

Padgaonkar (2004) developed a multi-floor

facility layout for hospitals to minimize the moving

cost of four entities: patients, doctors, medical, and

non-medical staff. These entities have various

difficulties and cost factors, for which various

alternative layouts were developed and the best

strategy was selected. Barrett (2008) used a

modified systematic layout planning approach to

AMulti-objectiveMixed-IntegerProgrammingModelforaMulti-SectionOperatingTheatreFacilityLayout

197

assess the clinic’s space usage, operation levels, and

flow and activity patterns and identified a number of

opportunities for improvement. Feyzollahi et al.,

(2009) have designed a model for the location of

hospital service units and assessment of their

efficiency on the basis of QAP mathematical model.

Lin et al., (2013) proposed an approach for

designing and optimizing OTFL in hospitals. First, a

systematic layout planning (SLP) is applied to

design OTFL and they applied fuzzy constraint

theory to comprehensively evaluate the layout

schemes.

Given the advantage and disadvantage of various

reviewed approaches, MILP is deemed best for the

OTFL formulation. The MILP approach has been

widely used in the industrial domain, but it has never

been applied to OTFL to the best of our knowledge.

Hence, it is the basis for our motivation to explore

its applicability for OTFL context.

3 PROBLEM STATEMENT

Building a new facility for hospital is an expensive

process which requires a significant amount of

resources to complete. Further, once construction of

the facility is completed, it is very difficult to

restructure to correct bad design layout without

incurring additional cost and loss of revenue during

re-work process, especially in re-design of

healthcare facilities. Therefore, the design phase of a

healthcare project is of prime importance. The

placement of departments (activities in our case

study) or other units such as corridors or aisles in a

facility has to be carefully determined. Many of the

problems faced in the delivery of healthcare services

are directly related to poor building designs of the

interactions among services. Therefore, managers

and designers must adopt an integrated and

comprehensive approach to support the decision-

making process in building design (Tzortzopoulos et

al., 2008).

Finding an optimal OTFL to minimize the

various costs requires the following specification of

requirements: the number of sections, the land area

required by the facility, the number of corridors

within the facility, the length, width and orientation

of each activity, the activity and corridors

allocations to each section and placement of the

activities and corridor within each floor.

Given a set of activities, their areas and the

available space, the OTFL seeks to determine the

optimal placement of the set of activities within the

available space subject to non-overlapping activities

on the floor plan layout while optimizing the value

of the objective function. To find the optimal

placement, a multi-goal Mixed Integer Programming

model is proposed to solve the multi-section in the

OTFL The main objectives are minimizing the

traveling costs for the considered entities (doctors,

patients, medical and non-medical staff) and

maximizing the closeness ranking among activities

to accommodate health services within the optimally

layout of such activities.

The idea of this formulation came from the

multi-floor layout problem, using elevators to move

between the two floors. In this study, floors are

represented by adjacent sections. In addition to the

assumption used for a single floor layout in Chraibi

et al., (2013), we assume that the following for the

two-floor layout:

The maximum number of corridors and their

orientation are given. In the solution, corridors

are used to travel between two activities in the

same section, and to transit from one to the other

section.

The location of a corridor is a decision variable.

The corridors are aligned using a vertical

structure, i.e. they have the same x coordinates

on any section they service to insure the entrance

to the OT unit, crossing between section and the

exit from the OT unit.

No relationships of activities with the outside

world are allowed.

An activity cannot be split among multiple

sections (floors).

Transition between sections can only occur

through corridors.

The shape and area of the activities are given.

For each activity, the associated decision

variables are its location and its horizontal or

vertical orientation.

a. Definitions of Sets:

Let N= { a

i

; i=1,2,…,n } be the set of n

activities in a department,

Let K= { e

k

; k=1, …,4} be the set of k entity

types: doctor, patient, medical staff or non-

medical staff.

Let S= {

; s=1, 2,…,t } be the set of sections:

outer, restricted, Aseptic, disposal….

Let C= {

; c=1, 2,…,r } be the set of corridors:

clean, public, .

Let

be a set of a single element denoting the

section to which activity a

i

is belonging.

Let

be a set of single element denoting the

section to which corridor

is belonging.

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

198

b. Definition of Parameters:

α

i :

Length of activity ‘a

i

’

β

i :

Width of activity ‘a

i

’

l

c

, d

c

:

Dimensions of corridor

F

ijk

:

Number of trips between activity ‘a

i

’ to

activity ‘a

j

’ made by an entity type ‘e

k

’

φ

ijk

:

Moving difficulty between activity ‘a

i

’ to

activity ‘a

j

’ made by an entity type ‘e

k

’

σ

k

: Cost factor assigned to entity ‘e

k

’

x

max:

Maximum length of the department ;

y

max

: Maximum width of the department ;

R

ij

:

Desirable relationship value between

activity ‘a

i

’ to activity ‘a

j

’;

ρ

1

, ρ

2

: Weights for each sub-objective function.

,

,

X and Y boundary coordinates of sections

c. Definition of Decision Variables:

Ω

i

{

1 if length (α

i

) of activity a

i

is parallel to x_axis

(horizontal orientation)

0 otherwise

µ

ij

{

1 if ‘a

i

’ and ‘a

j

’ are fully adjacent

0 otherwise

V

ijc

{

1 if traffic between activities ‘a

i

’ and ‘a

j

’ travels

through corridor

0 otherwise

t

ij

{

1 if activity ‘a

i

’ and ‘a

j

’ are assigned to the same

section

0 otherwise

t

ic

{

1 if activity ‘a

i

’ and corridor

are assigned to the

same section

0 otherwise

v

is

{

1 if activity ‘a

i

’ is assigned to section

0 otherwise

v

cs

{

1 if corridor

is assigned to section

0 otherwise

{

1 if activity ‘a

i

’ is strictly to the right of activity

‘a

j

’

0 otherwise

{

1 if activity ‘a

i

’ is strictly above activity ‘a

j

’

0 otherwise

,

{

1 if activity ‘a

i

’ is strictly to the right (r) ( or left

(l) of corridor

)

0 otherwise

,

{

1 if activity ‘a

i

’ is strictly above (a) or below (b)

corridor

0 otherwise

x

i

,

y

i

:

x and y coordinates of the geometric center of gravity

activity ‘a

i

’

x

c

,y

c

:

coordinates of the geometrical center of corridor

l

i

:

x-length of activity ‘a

i

’ depending on whether α

i

or β

i

is parallel on x-axis

d

i

:

y-length of activity ‘a

i

’ depending on whether α

i

or β

i

is parallel on y-axis

:

x-distance between activity ‘a

i

’ and ‘a

j

’

:

y-distance between activity ‘a

i

’ and ‘a

j

’

d. Definition of Constraints:

Orientation constraints (activities and

corridors)

The values of the variables l

i

and d

i

depend on the

activity ‘a

i

’ orientation in the plane. When the

activities are placed, if the longer side is parallel to

the x-axis, then the activity orientation is horizontal,

otherwise it is vertical:

Ω

1Ω

∀

(1)

∀

(2)

Sections constraints

Constraints (3) ensure that each activity is assigned

to only one section. Constraints (4), (5), and (6) are

used to obtain the value of t

ij

. If two activities ‘a

i

’

and ‘a

j

’ are allocated to the same section (v

is

= v

js

),

then constraint (4) will have t

ij

=1, while constraints

(5) and (6) remain inactive. Else, if activities ‘a

i

’ and

‘a

j

’ are allocated to different sections, then

constraint (4) is inactive and constraints (5) and (6)

will ensure that t

ij

=0.

1 ∀

(3)

1

∀1,…,1;

1,…,;

∀

(4)

1

∀1,…,1;

1,…,;

∀

(5)

1

∀1,…,1;

1,…,;

∀

(6)

Corridors Constraints

Constraint (7) ensures that the routing of the flow

between two activities is through the corridors in the

case when they are not assigned to the same section.

1

∀1,…,1;

1,…,

(7)

The corridors must have common boundaries to

route flows between the two sections, and common

boundaries with the entrance or the exit of the

section to facilitate the communication with the

outside. So constraints (8) and (9) assure the

adjacency between corridors. Constraint (10) forces

the corridors to be vertically aligned to insure the

traveling between sections. Constraint (11) makes

sure that each corridor is assigned to only one

section.

AMulti-objectiveMixed-IntegerProgrammingModelforaMulti-SectionOperatingTheatreFacilityLayout

199

2

∀1,2 ∈

(8)

2

∀1,2 ∈

(9)

∀1,2 ∈

(10)

1 ∀

(11)

Activities Non-overlapping Constraints

When two activities ‘a

i

’ and ‘a

j

’ occupy the same

section, they should be separated in the x-direction

or the y-direction. These restrictions can be imposed

using Equations (12) and (13):

1

2

∀,

(12)

1

2

∀,

(13)

to guarantee the non-overlapping at least one of the

following inequalities must be active:

1

∀ 1,…,1;

1,…,

(14)

1

∀ 1,…,1;

1,…,

(15)

1

∀ 1,…,1;

1,…,

(16)

Bounding Constraints

Constraints (17) through (21) indicate that activities

have to be allocated within the appropriate section

space defined by the corners (0, 0) and (

,

),

while (22) through (24) insure the same bounding

for corridors.

2

∀,

(17)

2

∀,

(18)

2

∀,

(19)

2

∀,

(20)

2

∀,

(21)

2

∀,

(22)

2

∀,

(23)

2

∀,

(24)

Corridors & Activities Non-overlapping

Constraints

Constraints (25) to (29) provide the non-overlapping

between an activity ‘a

i

’ and a corridor

if they

occupy the same section, or to be in different

sections.

2

2

1

∀,

(25)

2

1

2

∀,

(26)

2

2

1

∀,

(27)

2

1

2

∀,

(28)

1

∀,

(29)

Distance Constraints

Distance between any two activities will be

calculated using constraints (30) to (35):

∀,

(30)

∀,

(31)

∀,

(32)

∀,

(33)

∀1,…,1;

1,…,

(34)

∀1,…,1;

1,…,

(35)

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

200

e. Objective Functions

The goal of the FLP is to provide the best placement

of the activities within the available space. This goal

is achieved using a composite of two objective

functions. The first one is denoted the quantitative

objective and the second one is denoted the

qualitative objective. Meller (1996) gives a literature

overview on the different types of objective

functions: quantitative, qualitative and weighted

combined objectives.

The quantitative objective of the FLP is to

minimize the material handling cost. It is

proportional to the rectilinear distance, travel

frequency, trip difficulty rating, and baseline travel

cost:

∗

(36)

While:

is the travel frequency attribute. It represents

the number of trips made from activity ‘a

i

’ to

activity ‘a

j

’ by an entity type ‘e

k

’.

is the trip difficulty rating. It represents the

difficulty of an entity ‘e

k

’ to move from activity ‘a

i

’

to activity ‘a

j

’. It is proportional to the required

resources and provided effort.

, is the baseline travel cost. It represents the cost

factor assigned to entity ‘e

k

’ which depends on the

human resources involved. Its assumed that

(The value of this parameter is detailed in

Chraibi et al., 2013).

The qualitative objective is to maximize the

subjective closeness rating by considering vital

factors such as international standards. Qualitative

factors are easily analyzed in a closeness rating

chart, which is essentially a grid that qualitatively

evaluates the desired

closeness between activities.

The used rates are relative to the strength of the

closeness: absolutely necessary (A), very important

(E), important (I), ordinary importance (O),

unimportant (U) and undesirable (X). These rates are

subjectively defined based on (Muther and Wheeler,

1962).

The qualitative objective function is expressed

by:

(37)

Where:

R

ij

: Relationship value that expresses the need for

proximity i.e. If two activities have a strong positive

relationship, they are considered adjacent, thus we

consider the rank A. The AEIOUX rates are

respectively considered equal to 16, 8, 4, 2, 0 and -2

(see Figure 1).

µ

ij

: Adjacency coefficient that expresses the

proximity of each two activities in the final layout:

Fully adjacent (µ

ij

=1): Two activities are fully

adjacent when they are facing each other directly.

Non-adjacent (µ

ij

=0): If the activities don’t share

any point or when they can’t be seen together in the

same area (septic/aseptic area).

The final objective function that we considered is a

weighted sum of the two objective functions shown

above:

∶

∗

(38)

To facilitate computation, we choose

0.5.

4 EXPERIMENTS

In this section, we validated the proposed

formulation using previously published two data

instances available in the literature (Chraibi et al.,

2013) on OTFL optimization. We used ILOG

CPLEX 12.2 software to solve the model using

Windows 7 platform, Intel5® Core ™ i5-2410M

CPU@ 2.30GHz and 6Go of RAM. For all

instances, the followings settings were used:

0.5,

80,

60,

40 and

20 are used.

The data instance are of dimension consisting of

eleven activities. The placements of these activities

in the appropriate sections are affected by OT

international standards in addition to physical

dimensions - a set of specific practices and

procedures performed under carefully controlled

conditions with the goal of minimizing

contamination by pathogens.

In this work, we only consider the restricted and

aseptic zone; the trip is assured by corridors that

make possible traveling between the four zones.

AMulti-objectiveMixed-IntegerProgrammingModelforaMulti-SectionOperatingTheatreFacilityLayout

201

Table 1: Instance 1 with eleven activities.

Nomination

Dimensions

Nomination

Orientation Optimal location

αi βi li di xi yi

Induction 1 8.6 4 Induction 1 8,6 4 15,3 15,6

Induction 2 8.6 5 Induction 2 8,6 5 15,3 26,5

OR1 8.6 7.2 OR1 8,6 7,2 4,3 17,3

OR2 7.6 6.4 OR2 7,6 6,4 15,3 20,8

OR3 8.6 7.2 OR3 8,6 7,2 4,3 24,5

OR4 7.6 6.4 OR3 7,6 6,4 4,3 31,3

Scrub room 3.4 8.6 Scrub room 8,6 3,8 15,3 31,3

PACU 13.4 8.6 PACU 8,6 13,6 4,3 6,8

Decontamination 4.6 8.6 Decontamination 8,6 4,6 15,3 11,3

Cleaning room 3.6 8.6 Cleaning room 8,6 3,6 15,3 2,8

Arsenal 4.4 8.6 Arsenal 8,6 4,4 15,3 6,8

Corridor 1 2.4 21 Corridor 1 2.4 21 9.8 24,1

Corridor 2 2.4 13.6 Corridor 2 2.4 13.6 9.8 6,8

(a) activities dimensions (b) Orientation and optimal location results

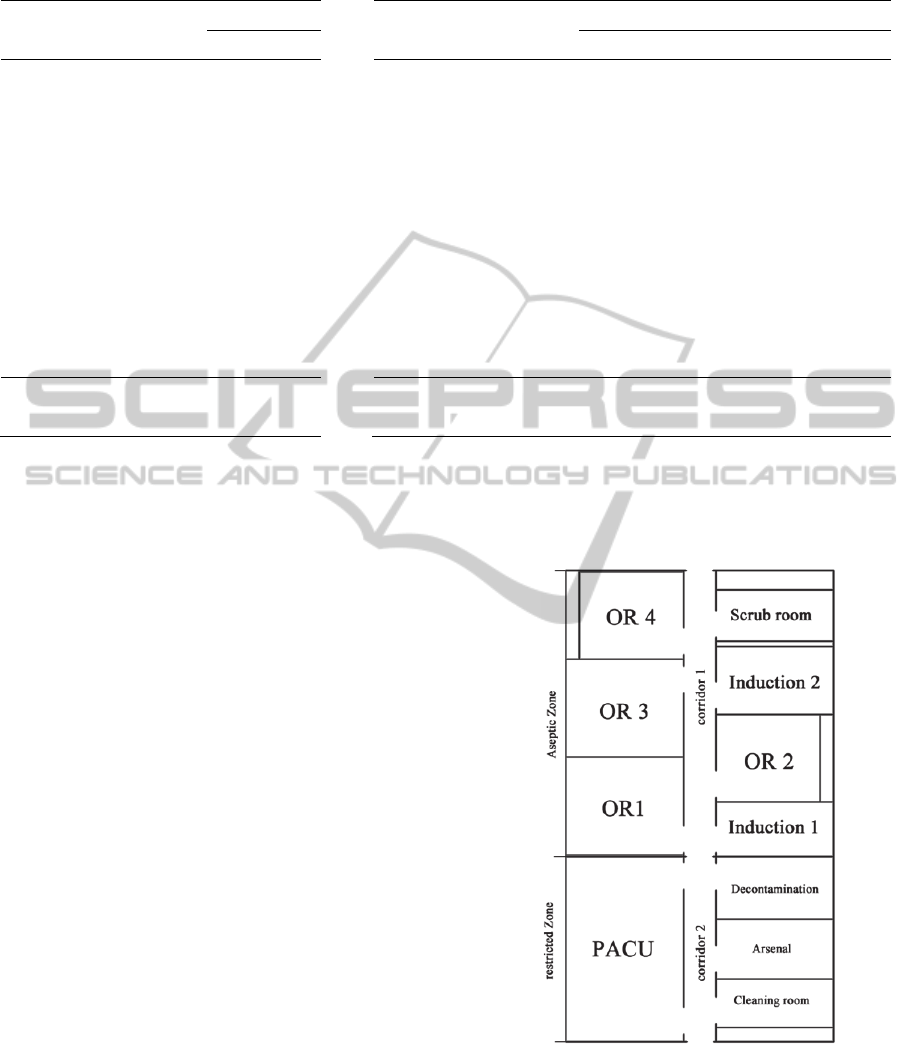

Instance 1: Large activities and more relationships

are considered. This example gives the optimal

layout with eleven activities. In contrary situation

to the first instance, the induction rooms are

considered to be independent activities where the

OR1 and OR2 share the induction room1 while the

OR3 and OR4 share the induction room2. The

scrub room is also shared by all the activities in the

aseptic section. Xmax and Ymax are fixed to 20

and 34.6, respectively (See Table1.a). Table 1.b

shows the optimal solution that was obtained after

23.06 sec. Figure 1 shows the optimal OT layout

for this configuration. Using the continuous

representation, we tested to solve the OT LP with

only the quantitative objective function. The

resulting layouts are more satisfactory than in

(Chraibi et al. 2013), both in term of quality, time

processing and the respect of entities flow.

In addition, the use of weighted criteria

function proved that the results were best in both

responding to our objectives and in computation

time. Several improvement works are planned such

as to use of heuristics for large sized OT.

5 CONCLUSIONS

In this paper, a new mixed integer linear

programing (MILP) model was introduced to find

the optimal solution to the Operating Theater

Layout Problem, which consists of laying medial

service activities on two-floor levels in two-

dimensional space.

Figure 1: Instance 1 optimal layout.

The MILP model was able to determine

simultaneously the position and the orientation of

each activity, the distribution of the set of activities

among floors, the location of corridors and lifts in

the final OT layout while minimizing the total

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

202

traveling cost and maximizing the desirable

closeness of activities to each other according to

international standards.

The proposed model was validated on two

typical instances from the literature. In our

numerical experiments, we observed that the

computation time increases as the number of

department increases until it reaches the maximal

number of facilities. The MILP model was able to

generate optimal solutions for thirteen activities

within seconds on a personal computer.

For future direction, the authors are

investigating other options such as (a) calculating

distances based on originating input and final

destination output point, (b) considering the

relationship between activities and the outside

environment, (c) applying the model to a larger

sized instances of OT layout (d) considering

activities with non-rectangular shape and (e) using

other heuristics and meta-heuristics to solve large

sized instances.

REFERENCES

AIA (American Institution of Architecture), Guidelines

for Design and Construction of Health Care

Facilities. http://www.aia.org.

Assem, M., Ouda, B., & Abdel Wahed, M., (2012).

Improving Operating Theatre Design Using

Facilities Layout Planning. Cairo International

Biomedical Engineering Conference (CIBEC),

Cairo, Egypt, December 20-21, 2012.

Barrett, A. (2008). Optimization of facility design and

workflow process at the phlebotomy clinic of

Toronto general hospital. Toronto: University of

Toronto

Chraibi, A., Kharraja, S., Osman, I.H., and Elbeqqali, O.

(2013). A mixed integer programming formulation

for solving Operating Theatre layout problem: a

multi-goal approach. Proceedings of IESM 2013,

Rabat, Morocco, October 27-30

th

.

Commander, C. W. (2003). A survey of the quadratic

assignment problem, with applications (Doctoral

dissertation, UNIVERSITY OF FLORIDA).

Denton, B., Viapiano, J., & Vogl, A. (2007).

Optimization of surgery sequencing and scheduling

decisions under uncertainty. Health Care

Management Science, 10 (1), 13–24.

Feyzollahi, M., Shokouhi, A., Modarres Yazdi, M., &

Tarokh, M. (2009). Designing a model for optimal

hospital unit layout. Pajoohandeh Journal, 14(4),

191–198.

FGI (Facility guideline institution), Guidelines for

Design and Construction of Health Care Facilities.

http://www.fgiguidelines.org.

Guerriero, F., & Guido, R. (2011). Operational research

in the management of the operating theatre: A

survey. Health Care Management Science,14, 89–

114.

Hassan, M., & Hogg, G. L. (1987). A review of graph

theory application to the facilities layout problem.

Omega, 15(4), 291-300.

Hathhorn, J., Sisikoglu, E., & Sir, M. Y. (2013). A

multi-objective mixed-integer programming model

for a multi-floor facility layout. International

Journal of Production Research, (ahead-of-print), 1-

17.

Jingwei, Z., Ting, R., Husheng, F., Jinlin, Z., & Ming, L.

(2012, May). Simulated annealing ant colony

algorithm for QAP. In Natural Computation (ICNC),

2012 Eighth International Conference on (pp. 789-

793). IEEE.

Koopmans, T. C., & Beckmann, M. (1957). Assignment

problems and the location of economic activities.

Econometrica: Journal of the Econometric Society,

53-76.

Lin, Q. L., Liu, H. C., Wang, D. J., & Liu, L (2013).

Integrating systematic layout planning with fuzzy

constraint theory to design and optimize the facility

layout for operating theatre in hospitals. Journal of

Intelligent Manufacturing, 1-9.

Maryam, H., Lei, W., Yuet, W., & Houshang, D. (2006,

May). Renovation of mercy family health center. In

Information Control Problems in Manufacturing

(Vol. 12, No. 1, pp. 665-670).

Meller, R. D., & Gau, K. Y. (1996). Facility layout

objective functions and robust layouts. International

journal of production research, 34(10), 2727-2742.

Montreuil, B., (1990), A modeling framework for

integrating layout design and flow network design,

Proceedings of the Material Handling Research

Colloquium, pp. 43-58.

Motaghi, M., Hamzenejad, A., & Riyahi, L. (2011).

Optimization of hospital layout through the

application of heuristic techniques (Diamond

Algorithm) in Shafa hospital. International Journal

of Management of Business Research, 1(3), 133–

138.

Osman, I.H., Al-Ayoubi, B., and Barake, M.A. (2003).

A greedy random adaptive search procedure for the

weighted maximal planar graph problem. Computers

and Industrial Engineering. Vol. 45, 635-651.

Osman, I.H. (2006). A tabu search procedure based on a

ranked-roulette diversification for the weighted

maximal planar graph problem. Computers and

Operations Research. Vol. 33: 2526-2546.

Osman, I.H., Hasan, M. and Abdullah, A. (2002). LP-

based meta-heuristics for the weighted maximal

planar graph problem. Journal of Operational

Research Society, Vol. 53, 10, 1142-1149.

Padgaonkar, A. S. (2004). Modeling and analysis of the

hospital facility layout problem. New Jersey: New

Jersey Institute of Technology.

Ramkumar, A. S., Ponnambalam, S. G., & Jawahar, N.

(2007, September). An evolutionary search heuristic

for solving QAP formulation in facility layout

AMulti-objectiveMixed-IntegerProgrammingModelforaMulti-SectionOperatingTheatreFacilityLayout

203

design. In Evolutionary Computation, 2007. CEC

2007. IEEE Congress on (pp. 4005-4011). IEEE.

Sehulster, L., Chinn, R. Y., Arduino, M. J., Carpenter, J.,

Donlan, R., Ashford, D. & Cleveland, J. (2003).

Guidelines for environmental infection control in

health-care facilities. Morbidity and Mortality

Weekly Report Recommendations and Reports RR,

52(10).

Tarkesh, H., Atighehchian, A., & Nookabadi, A. S.

(2009). Facility layout design using virtual multi-

agent system. Journal of Intelligent Manufacturing,

20, 347–357

Tompkins, J. A., White, J. A., Bozer, Y. A., and

Tanchoco, J. M. A., Facilities Planning, Wiley, New

York, New York, 4th edition (2010).

Tsai, R. D., Malstrom, E. M., & Kuo, W. (1993). Three

dimensional palletization of mixed box sizes. IIE

transactions, 25(4), 64-75.

Tzortzopoulos, P. et al. 2008. Design for Operational

Efficiency–Linking Building and Service Design in

Healthcare Environments. In: Proceedings:

ELAGEC-II Encuentro Latino-Americano De

Gestion Y Economia De La Construccion, Santiago,

Chile, January, 24–25.

Vos, L., Groothuis, S., & van Merode, G. G. (2007).

Evaluating hospital design from an operations

management perspective. Health care management

science, 10(4), 357-364.

Wahed, M. A., Ouda, B. K., & Elballouny, M. (2011).

Evaluation of an Operating Theater Design by a

Software Program (OTDA: Operating Theater

Design Analyzer). International Journal of Database

Management Systems, 3(3).

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

204