Smart Collaborative Processes Monitoring in Real-time Business

Environment

Applications of Internet of Things and Cloud-data Repository

Ahm Shamsuzzoha

1

, Sven Abels

2

, Simon Kuspert

2

and Petri Helo

1

1

Department of Production, University of Vaasa, PO Box 700, Vaasa, Finland

2

Ascora GmbH, Innovation & Product Development, Birkenallee 43, 27777 Ganderkesee, Germany

Keywords: Collaborative Business Network, Virtual Factory, Business Process Monitoring, Internet of Things, Cloud-

based Data Repository System, SMEs.

Abstract: In today’s business world there is a growing concern with business collaboration among companies,

especially small and medium enterprises (SMEs). The objective of forming and operating such collaborative

networks is to achieve market benefit through sharing resources, expertise and knowledge among the

networked partners. It is therefore necessary to track and trace each business process within such business

networks in a real-time environment in order to enhance their success level and reduce possible risks or

uncertainties. Keeping such an objective in mind, this research highlights the basic principles of business

process monitoring through smart technologies such as the Internet of Things (IoT) and cloud-based data

repository. Smart process monitoring through the combination of Internet of Things technology and cloud-

based data repository system is rarely discussed in the field of collaborative business. Within the scope of

this research, generic scenarios of both the IoT and cloud-based data storage are described with the

objective of implementing them in a collaborative business process monitoring domain. An implementation

example is highlighted in this paper, where IoT and cloud-based data storage are showcased in business

process monitoring and management. The overall research outcomes and future research directions are also

articulated in the conclusion section of this paper.

1 INTRODUCTION

An increasing level of market diversification and

customers’ complex needs are exerting extra

pressure on global manufacturing companies,

especially on small and medium enterprises (SMEs),

where there is a shortage of costly resources, expert

knowledge and innovative skills. To overcome such

constraints, SMEs are looking for an effective

collaboration environment where they can explore

their business opportunities through enhanced

capacities and capabilities. In such perspectives,

business collaboration among companies (SMEs) is

becoming of growing interest globally due to its

inherent benefits (Romero and Molina, 2010).

In order to execute successful business

collaboration, it is necessary to monitor and manage

business processes within a real-time environment.

This business process monitoring demands the

interoperability of existing technologies as used by

the individual partner companies. Within a business

network this interoperability process monitoring

contributes to process synchronization that ensures

reliability and safety (Smith, 2003). Synchronized

business processes within the VF environment

support monitoring and managing effectively and

efficiently. This real-time process monitoring would

be beneficial to the process owners in planning

ahead in case of process abnormality. This planning

process contributes substantially to avoiding or

minimizing the risk level.

Therefore, the objectives of this research are to

ascertain the obstacles to business process

monitoring, look for appropriate technologies and

tools which are available in the market or the need to

design and develop process monitoring from scratch,

and, in addition, to ensure a secured database design

that can store and retrieve the monitoring data across

a collaborative business network. These objectives

can be summarized into two specific research

themes: (i) to find out how sensor-based

556

Shamsuzzoha A., Abels S., Kuspert S. and Helo P..

Smart Collaborative Processes Monitoring in Real-time Business Environment - Applications of Internet of Things and Cloud-data Repository.

DOI: 10.5220/0004864805560563

In Proceedings of the 16th International Conference on Enterprise Information Systems (ICEIS-2014), pages 556-563

ISBN: 978-989-758-028-4

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

technologies and tools such as the Internet of Things

(IoT) can support collaborative business processes

monitoring, and (ii) to check how a cloud-based data

repository system can be implemented successfully

to store and retrieve data as used to monitor and

manage collaborative business processes.

2 RESEARCH MODEL

IoT is a topical issue nowadays in the technological

world, which can be successfully implemented to

achieve increased business control through its

sensor-based technologies in either wired, wireless

or hybrid systems. It is an integrated part of the

future Internet technology that can be defined as the

dynamic global network infrastructure with self-

configuring capabilities based on standard and

interoperable communication protocols that can be

used as an intelligent interface to business process

monitoring within a VF network.

In addition to the implementation of IoT there is

growing concern within the business community

with storing a maximum amount of VF process

monitored data securely, which can then be retrieved

according to need. This brings about the necessity to

harness a data storage facility which can easily be

accessed with minimum time and cost. Recently,

researchers have been focusing on the issue of

cloud-based data repository in the form of cloud

manufacturing, cloud computing, cloud-based

information systems and monitoring, etc., which can

easily fulfil the needs of different kinds of

manufacturing data storage and retrieval.

This research particularly emphasizes

investigating the possibilities of how an

implementation of IoT technology and cloud-based

data repository can be realized effectively to monitor

business processes thoroughly. Figure 1 displays the

proposed research model to monitor business

processes in a VF environment.

3 LITERATURE REVIEW

SMEs can achieve manufacturing agility and higher

competiveness through forming collaborative

business networks, where valuable resources,

knowledge and expertise can be shared for mutual

benefits (Rabelo, 2008). From the SME point of

view, business collaboration is an alternative to

traditional supply chain management, where

companies can enhance their value adding activities

and have better control within the business

domain (Walters and Rainbird, 2007).

Figure 1: The research model.

Business process monitoring can be viewed from the

contribution it makes in adding value to the potential

customer and the alignment and realization of the

strategic business objectives. Process improvement

as achieved through process monitoring will start by

obtaining better understanding of the customers and

their demand on the business. There is a lack of

automated support in process monitoring, which is

mostly an isolated set of activities separated from

the actual process execution. It is critical for

business network partners to monitor and manage

accompanied processes. Various sensor-based

technologies are applied to monitor individual

products or processes (Angeles, 2005; Krastela et

al., 2011; Miorandi et al., 2012), but only limited

research has been performed to monitor processes

within business networks. Most of the research work

in network process monitoring has been done mainly

to identify focused abnormalities in the partner’s

premises (such as machine breakdown, labour

unrest, production delay, etc.) and not necessarily to

obtain information on the processes as a whole

(Hallikas et al., 2004).

With increased awareness of business process

monitoring it needs to be approached holistically and

with the support of technology (Jeston and Nelis,

2008). Recently developed technologies such as the

Internet of Things and smart objects can successfully

contribute to process monitoring through their

inherent sensor-based approach (Bandyopadhyay

and Sen, 2011). Wireless sensor networks have been

a very promising development in business process

monitoring during the last few years, but there is a

distinct lack of real applications in collaborative

networks. This process monitoring is enhanced

through smart technologies such as RFID tags,

GPRS trackers, smart objects, IoT, etc (Kortuem et

al., 2010).This monitored data needs to be stored and

retrieved within a secured and encrypted database

such as a cloud-based data repository system. To

SmartCollaborativeProcessesMonitoringinReal-timeBusinessEnvironment-ApplicationsofInternetofThingsand

Cloud-dataRepository

557

enable process monitoring and management over the

cloud is a concept that companies are embracing,

and this service is growing in popularity among

different manufacturing companies that have yet to

transition IT operations over to the cloud (Lombardi

and Di Pierto, 2010). The process monitoring related

to network business operations is defined and stored

within the cloud storage. All the relevant

information associated with a process such as

process template, process model, process editor,

process design, etc., is stored and retrieved from the

cloud storage as necessary. This functionality from

the cloud storage provides extra benefits in terms of

managing the processes from the user side to the

data management side (Shamsuzzoha et al., 2013).

4 INTERNET OF THINGS:

CONCEPTS AND

IMPLEMENTATION

PERSPECTIVES

The application of IoT is mainly the result of a

global network interconnecting smart objects by

means of internet technologies (Kortuem et al.,

2010; Uckelmann et al., 2011). It envisions a future

in which digital and physical entities can be

interfaced through appropriate information and

communication technologies. In industry, where

there is a demand for smart environments it helps to

improve automation in industrial plants through the

automatic identification of objects with a massive

deployment of sensor-enabling technologies and

tools such as RFID tags, sensors/actuators, machine-

to-machine communications devices, etc., (Atzori et

al., 2010).Implementing RFID tags as a source of

smart objects enables the tracking objects and the

EPC (electronic product code) serves as a link to

data which can provide information about each

individual object through the Internet.

This automatic identification of objects can be

used extensively to improve data handling

capabilities for an individual product or batch

identification. Its implementation perspective may

fill the information gap between logistics and supply

chain networks through tracking and tracing objects

as they move along the supply chain. This tracking

includes both real-time position tracking of object-

flow monitoring to improve the workflow in supply

chains and the tracking of motion through choke

points, such as access to designated areas. It ensures

the foundation for product identification and

authentication, anti-counterfeiting and other supply

chain integrity. This product identification and

authentication supports the reduction of incidents

harmful to products (such as wrong

place/time/condition), comprehensive and current

product maintenance to meet the requirements of

security procedures, and avoiding theft or losses of

important products.

Figure 2: A holistic scenario of the Internet of Things

within the business domain.

A holistic scenario of the Internet of Things can be

presented as in Figure 2, where the concerns related

to its implementation are highlighted. From Figure

2, it is noticed that the IoT is needed to define itself

with its inherent security issue and benefits to the

business community. In the definition it is

highlighted that IoT enables distributed intelligence,

identification, data management and integration of

smart objects. In terms of its security concern, IoT

needs to comply with trust management, data

encryption and confidentiality, authentication,

protocols and rule engine. The benefits of IoT are

mainly focused on real-time business process

monitoring, supply chain visibility, promotion of

business collaboration and resource management.

5 CLOUD-BASED DATA

REPOSITORY: CONCEPTS

AND IMPLEMENTATION

PERSPECTIVES

A cloud-based data repository system is nowadays

an attractive element within a business domain. This

data repository system has a relation between cloud

computing and the Internet of Things by collecting

and storing data in the cloud. The tracking

information as received from the smart objects

allows for the combination of real-world object data

and IT-based process information. In this case, a

cloud-based data warehouse is created containing

Internet of Things

Security

Benefits

• Distributed intelligence

• Computing, communication,

identification

• Data management

• Smart objects integration

• Trust management

•Data encryption

•Data confidentiality

• Authentication

• Protocols and rules engine

• Real-time business process

monitoring

• Supply chain visibility

• Promotion of business

collaboration

• Resource management

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

558

current and former manufacturing process

information and it also provides cloud-based data

management and archiving solutions. This data

management system provides necessary support in

collaborative business through data analysis and

reporting in order to detect process failures, to

perform risk assessment and to identify space for

improvement. It also allows for business traceability

and continuity and provides competitive advantage

for manufacturing companies.

Figure 3: An architecture of cloud-based data storage

service.

A high-level architecture description of cloud-based

data storage service is illustrated in Figure 3. This

architecture consists of three different entities: cloud

user, cloud service provider and trusted third party

auditor (TTPA). The cloud customer employs the

cloud storage and computing resource facilities to

remotely store and process data, whereas the cloud

service provider, which has significant storage space

and computation resources, manages and operates a

cloud infrastructure of storage and computing

services. The TTPA is considered as a seller of a

cloud privacy service in collaboration with the cloud

service provider (Wang et al., 2010; Lin and

Squicciarini, 2010). From Figure 3, it is assumed

that a cloud customer has a large amount of data

files which he/she wants to store on a cloud server,

which is managed by a cloud service provider. For

this purpose, the user needs to register with TTPA

before receiving output data securely. The Internet is

the basic communication system for information

exchange between the cloud customer and the

computing cloud.

As outlined above, a lot of research has been

performed in the area of three core technologies: (i)

Virtual Factories and their application of

manufacturers and especially SMEs, (ii) The Internet

of Things and its impact on monitoring and

informing manufacturers about their goods, and (iii)

Cloud Storage for managing information in a

scalable and distributed manner. The following

section demonstrates a use case for combining these

approaches into a holistic information system.

6 IMPLEMENTATION OF IOT

AND CLOUD-DATA STORAGE

IN COLLABORATIVE

BUSINESS ENVIRONMENT: A

CASE EXAMPLE

The combination of both always-on connections and

cheap hardware provide a vital base for the Internet

of Things. In the FP7 EU ADVENTURE project

1

,

the consortium created a virtual factory environment

for collaborative business. ADVENTURE allows

different manufacturers to collaborate with the help

of an ICT platform (ADVENTURE, 2011). The

ultimate aim of this platform is to realize a “plug &

play factory” approach in order to support the

collaboration of partners in all phases. This plug-

and-play virtual factory helps companies to move

beyond existing operational limitations with

technologies and methodologies that can establish

and execute cross-organizational manufacturing

processes.

ADVENTURE plug-and-play factory offers real-

time process monitoring and makes process status

information available to the process owner. The

valuable information or data source is made

available through the IoT. The data sources required

for manufacturing processes, intermediate goods and

manufactured goods are often enriched with

identification, sensor and communication

technologies. Through well-defined interfaces, up-

to-date and real-time status information can be

transmitted from ‘smart objects’ such as RFID tags,

which are the formats of IoT. Accessing data from

smart object sensors may be performed in three

different ways in the ADVENTURE platform: (a)

Firstly, dashboard users interface, (b) Secondly

through a REST (Reliability Estimation System

Testbed) interface and (c) Finally, an Android app.

(a) VF process Monitoring through ADVENTURE

Dashboard

The dashboard system enables collaborating partners

to view their processes and to drill down into

______________________________

1

http://fp7-adventure.eu

SmartCollaborativeProcessesMonitoringinReal-timeBusinessEnvironment-ApplicationsofInternetofThingsand

Cloud-dataRepository

559

accessing IoT data from their processes. Figure 4

show an extract from the ADVENTURE dashboard.

The dashboard uses IoT approaches to allow each

partner to be informed about the overall

manufacturing process and the current state of the

collaboration.

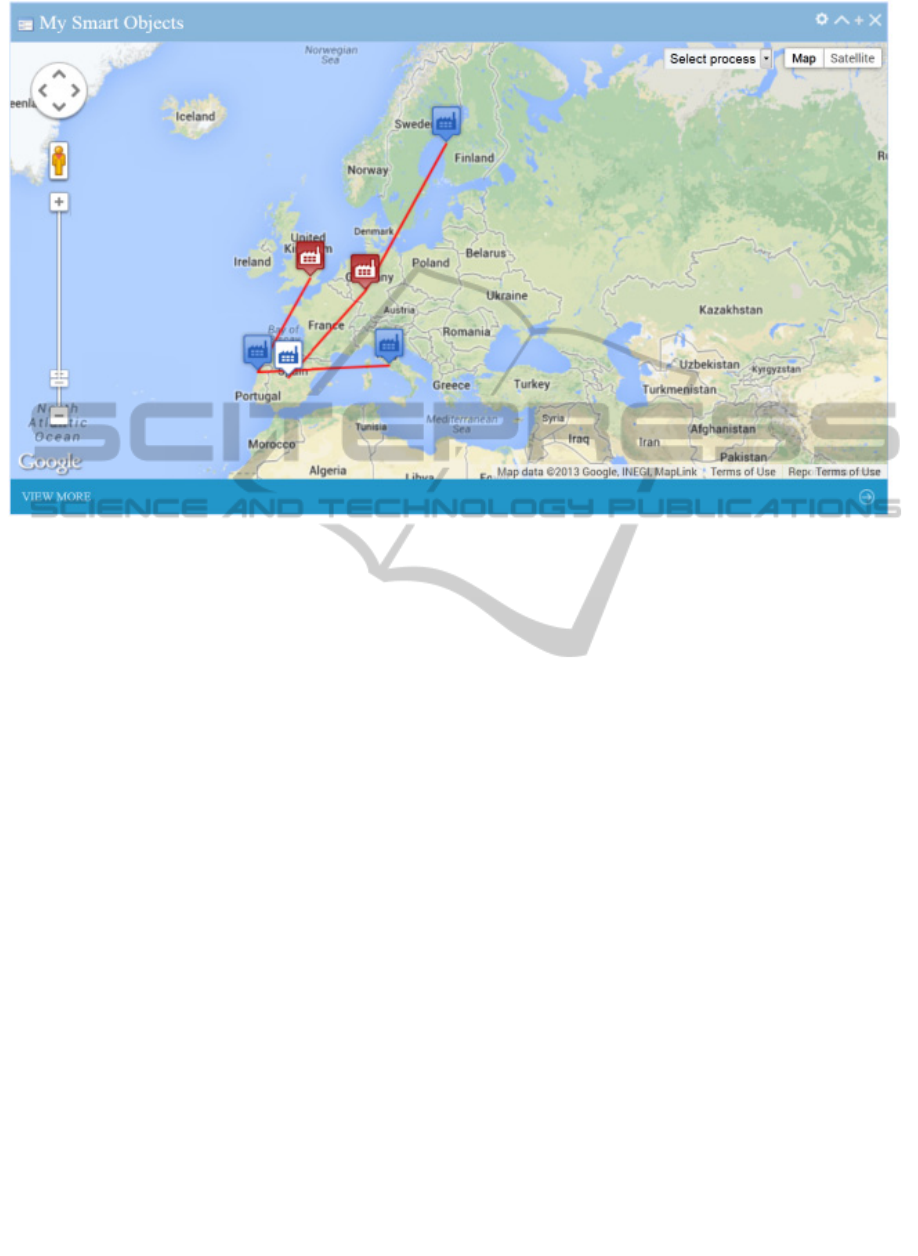

The ADVENTURE dashboard contains several

widgets or portlets based on the VF process needs.

Figure 5 displays a snap shot of ‘My Smart Object’

widget. This widget mainly provides the visibility

and status information of each of the smart objects

within the VF processes. Along with the status

information it also visualizes the location of the VF

partner’s smart objects and presents their status

through displaying different colours (e.g. red for

urgent, yellow for alert, green for normal). This

widget may also be used to monitor temperature,

CO

2

values and other relevant information received

from the smart sensors.

For example, collaborating partners may be

informed as to whether the temperature of a

transport exceeds a specific limit and receive an alert

whenever a specific threshold is passed.

(b) VF process Monitoring through REST Interface

Within the scope of this research, a REST interface

has been provided by the cloud storage component,

allowing external developers to access the data in a

programmatic way. In this REST engine, VF

operations are defined in the messages and offer a

unique address for every process instance. It also

offers the loose coupling of components, and each

object supports the defined (standard) operations.

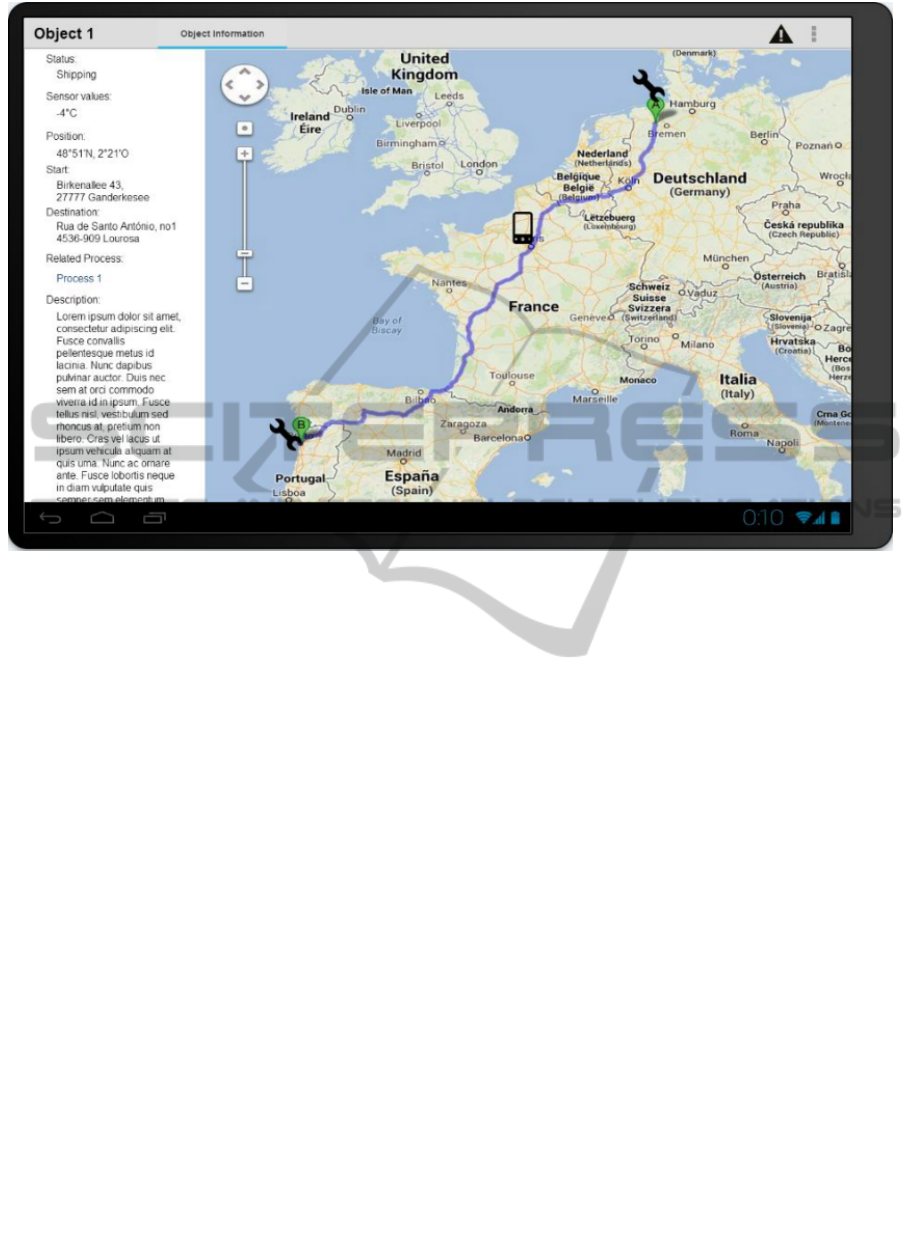

(c) VF process Monitoring through an Android App

An Android app designed and developed in this

research allows virtual factory partners to access

their sensor data as received from smart objects

using a mobile tablet device. This mobile app allows

manufacturers the possibility to check sensor data

even when in the production hall. Figure 6 displays

the screen design of the ADVENTURE Android

app.

Figure 4: The ADVENTURE Dashboard.

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

560

Figure 5: Snap shot of ‘My Smart Object’ widget.

7 DISCUSSIONS AND

CONCLUSIONS

There is a growing need to create and execute

business collaboration whatever the formats are

(Camarinha-Matos and Afsarmanesh, 2007;

Shamsuzzoha et al., 2013). The concept of virtual

factory, which is a kind of plug-and-play factory,

helps companies to move beyond their operational

limits. Using this concept, companies will be able to

manage cross-organizational manufacturing

processes as though they are being carried out within

a single company (Schulte et al., 2012). Currently,

manufacturers lack the appropriate real-time

information that would let them assess process

status. The main problem exists in such cases where

there is missing interoperability between business

partners’ IT systems as well as potential loss of

information due to prevailing data silos. Ultimately,

new methods and technologies are needed to connect

diverse technologies and aggregate the data from

them. In consequence, this research has

implemented state-of-the-art technology and tools to

execute collaborative business process monitoring in

a cross-organizational environment and it closes all

information gaps and integrates data seamlessly.

This research begins with high-level

collaborative business process monitoring with

special focus on the Internet of Things technology,

along with cloud-based data repository. Growing

interest in the IoT in the form of smart objects can

be successfully applied to business process

monitoring. These smart objects are mainly sensor-

enabled technology that is used to identify proposed

conditions and locations at the same time. These

process conditions and location characteristics

support real-time business process monitoring

successfully. This technology is demonstrated

through a mobile app, which works as a smart object

and is used in collaborative business process

monitoring. This mobile app was tested and

validated successfully to be implemented as an IoT

technology, applicable in smart process monitoring

and management within a collaborative business

environment.

Another concern in business process monitoring

is the need to store and retrieve process monitoring

data and information securely. One such business

objective, a cloud-based data repository system, is

also presented within the scope on this research. The

basic framework for cloud-based data storage along

with its implementation aspects is also discussed in

this paper. A generic model of cloud data storage is

formulated that supports the storage and retrieval of

data in collaboration business processes

successfully. This model also contributes to

SmartCollaborativeProcessesMonitoringinReal-timeBusinessEnvironment-ApplicationsofInternetofThingsand

Cloud-dataRepository

561

Figure 6: Android app view showing information about a process status.

providing benefits like availability (being able to

access data from anywhere), relatively low cost

(paying as a function of need) and on demand data

sharing among collaborative partners. In cloud-

storage systems, the data owner may represent either

an individual partner or all collaborative partners,

who rely on the cloud server for remote data storage

and maintenance and thus are relieved of the burden

of building and maintaining a local storage

infrastructure.

This research presented a case example where

the virtual factory’s business process monitoring is

highlighted. This monitoring process is

accomplished by the application of IoT technology

in the form of smart objects and sensors and is

visualized through the ADVENTURE dashboard,

REST interface and Android app. All the process

monitored data is stored within cloud-based data

storage, which was designed and developed within

the scope of this research. Different types of data

such as structured, semi-structured, binary and

semantic are stored in separate buckets of cloud-

storage in order to avoid data becoming mixed up

and maintaining data security and individuality.

This is on-going research, where the future

research activities are planned towards the

development of an open source Web-enabled

communication infrastructure that is accessed and

used by potential companies (mainly SMEs) to

monitor and manage their business processes within

a collaborative business environment. The research

results in the form of business process monitoring

are validated in one case company and will be

validated in another case company in the near

future.. In future work, the business process

monitoring data will be analysed and used as the

performance measures of KPIs (key performance

indicators) and the governance model o virtual

factory partners.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the co-

funding of the European Commission in NMP

priority of the Seventh RTD Framework Programme

(2007-13) for the ADVENTURE project (ADaptive

Virtual ENterprise ManufacTURing Environment),

Ref. 285220. The authors also acknowledge the

valuable collaboration provided by the project team

during the research work.

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

562

REFERENCES

ADVENTURE (Adaptive Virtual Enterprise

Manufacturing Environment) (2011), European RTD

project, Grant agreement no: 285220, Duration

01.9.2011-31.08.2014.

Angeles, R., 2005. RFID technologies: supply-chain

applications and implementation issues. Information

Systems Management, Vol. 22, No. 1, pp. 51-56.

Atzori, L., Iera, A. and Morabito, G., 2010. The Internet of

Things: a survey. Computer Networks, Vol. 54, No.

15, pp. 2787-2805.

Bandyopadhyay, D. and Sen, J., 2011. Internet of Things:

applications and challenges in technology and

standardization. Wireless Personal Communications,

Vol. 58, No. 1, pp. 49-69.

Camarinha-Matos, L.M. and Afsarmanesh, H., 2007. A

comprehensive modeling framework for CNOs.

Journal of Intelligent Manufacturing, Vol. 18, No. 5,

pp. 529-542.

Hallikas, J., Karvonen, I., Pulkkinen, U., Virolainen, V-M.

and Tuominen, M., 2004. Risk management processes

in supplier networks. International Journal of

Production Economics, Vol. 90, No. 1, pp. 47-58.

Jeston, J. and Nelis, J., 2008. Business Process

Management: Practical Guidelines to Successful

Implementations, Butterworth-Heinemann is an

imprint of Elsevier Ltd, Burlington, USA.

Kortuem, G., Kawsar, F., Sundramoorthy, V. and Fitton,

D., 2010. Smart objects as building blocks for the

internet of things. IEEE Internet Computing, Vol. 14,

No. 1, pp. 44-51.

Krasteva, Y., Portilla, De la Torre, J.E. and Riesgo, T.,

2011. Embedded runtime reconfigurable nodes for

wireless sensor networks applications. IEEE Sensors

Journal, Vol. 11, No. 9, pp. 1800–1810.

Lin, D. and Squicciarini, A., 2010. Data protection models

for service provisioning in the cloud. SACMAT’10,

Pittsburgh, Pennsylvania, USA.

Lombardi, F. and Di Pierto, R., 2010. Transparent security

for cloud. SAC’10, March 22-26, 2010, Sierre,

Switzerland.

Miorandi, D., Sicari, S., De Pellegrini, F. and Chlamtac, I.,

2012. Internet of things: vision, applications and

research challenges. Ad Hoc Networks, Vol. 10, No.

7, pp. 1497-1516.

Rabelo, R.J., 2008. Advanced collaborative business ICT

infrastructure. In Camarinha-Matos, L.M.,

Afsarmanesh, H. and Ollus, M. (Eds.), Methods and

Tools for Collaborative Networked Organizations,

Springer Science+Business Media, LLC, New York,

pp. 337-370.

Romero, D. and Molina, A., 2010. Virtual organization

breeding environments toolkit: reference model,

management framework and instantiation

methodology. Production Planning & Control, Vol.

21, No. 2, pp. 181-217.

Schulte, S., Schuller, D., Steinmetz, R. and Abels, S.,

2012. Plug-and-play virtual factories. IEEE Internet

Computing, Vol. 16, No. 5, pp. 78-82.

Shamsuzzoha, A., Abels, S. and Helo, P., 2013. Adaptive

virtual enterprise process management: Perspective of

cloud-based data storage. Proceedings of the 15

th

International Conference on Enterprise Information

Systems (ICEIS 2013), July 4

th

- 7

th

, Angers Loire

Valley, France, pp. 88-94.

Smith, R.V., 2003. Industry Cluster Analysis: Inspiring a

common strategy for community development.

Available at: www.cpwdc.org, 2003. Accessed on

24.08.2013.

Uckelmann, D., Harrison, M. and Michahelles, F., 2011.

Architecting the Internet of Things, Springer-Verlag

Berlin Heidelberg.

Walters, D. and Rainbird, M., 2007. Cooperative

innovation: A value chain approach. Journal of

Enterprise Information Management, Vol. 20, No. 5,

pp. 595 – 607.

Wang, C., Wang, Q., Ren, K. and Lou, W., 2010. Privacy-

preserving public auditing for data storage security in

cloud computing. Proceedings of 2010 IEEE

INFOCOM, 14-19 March, 2010, San Diego, USA, pp.

1-9.

SmartCollaborativeProcessesMonitoringinReal-timeBusinessEnvironment-ApplicationsofInternetofThingsand

Cloud-dataRepository

563