Pressure Sensor for Gastrointestinal Intraluminal Measuring

L. R. Silva, P. J. Sousa, L. M. Goncalves and G. Minas

Centro Algoritimi, University of Minho, Campus de Azurem 4800-058 Guimaraes, Portugal

Keywords: Pressure Sensor, Intraluminal Pressure, GI Disorders, Strain Gauges.

Abstract: This paper reports an innovative technique to measure intraluminal pressure in the gastrointestinal tract

(GI), which is typically performed through an exam called oesophageal manometry. This type of

measurement is performed with a catheter, comprising several pressure sensors along it, and gives important

information for the diagnosis of motility and peristalsis disorders in the GI tract. The presented work

explores the use of PDMS polymer (Polydimethylsiloxane) as the support material for the pressure sensors.

These PDMS layers are placed in the pressure measurements sites of the catheter. The presented work also

explores different materials for the metal strain gauges that act as the pressure sensors. Due to the

microfabrication techniques, the presented pressure sensors allow on-chip integration (with other

microsensors for GI diagnosis), and its pressure measurements will add essential diagnostic information, not

only for the GI motility and peristalsis disorders, but also in the early cancer detection. The initial

mechanical tests showed promising results for the intended application. After optimization of the fabrication

process, different experiments are scheduled for simulating the pressure signals that would occur in vivo

conditions. In summary this method will permit high integration and good sensitivity measurement, while

maintaining low fabrication costs.

1 INTRODUCTION

An oesophageal manometry provides crucial

information for the diagnosis of motility and

peristalsis disorders, such as diffuse esophageal

spasm or nutcracker esophagus, and typically

assesses the motor function of three main structures:

Upper Esophageal Sphincter (UES); esophageal

body; and Lower Esophageal Sphincter (LES)

(ASGE, 2012, AGA, 2005). The pressures typically

associated with this exam are in the range of

7-200 mmHg (Holloway, 2006). The manometry

equipment is composed by a catheter and several

pressure sensors along it (Murray et al., 2003). A

manometry exam can be classified accordingly to

the number of sensors that are employed:

conventional (4 to 8 sensors) and high resolution

manometry (20 to 36 sensors) (Kahrilas et al., 2008).

The high resolution exam has been gaining ground

in the last few years due to the higher spatial

resolution within the oesophageal lumen, which

enables to completely define the intraluminal

pressure profile (Kahrilas et al., 2008).

The pressure sensors are typically based on two

methods: water perfused and solid state sensors

(Bodger and Trudgill, 2006). The solid state ones

permit to downsize the sensor area (areas sensible to

pressure as low as 1 mm

2

), which is preferable for

high resolution systems (ASGE, 2012).

This paper reports an innovative technique to

measure the intraluminal pressure in the

gastrointestinal tract (GI) using the concept of

oesophageal manometry. The developed system

explores the use of PDMS polymer

(Polydimethylsiloxane) as the support material for

deposited metal strain gauges that serve as the

pressure sensors. In order to create pressure sensitive

regions in PDMS, one or four diaphragms (four for

intrasphincteric measurements due to asymmetric

pressure profiles) per measurement site will be

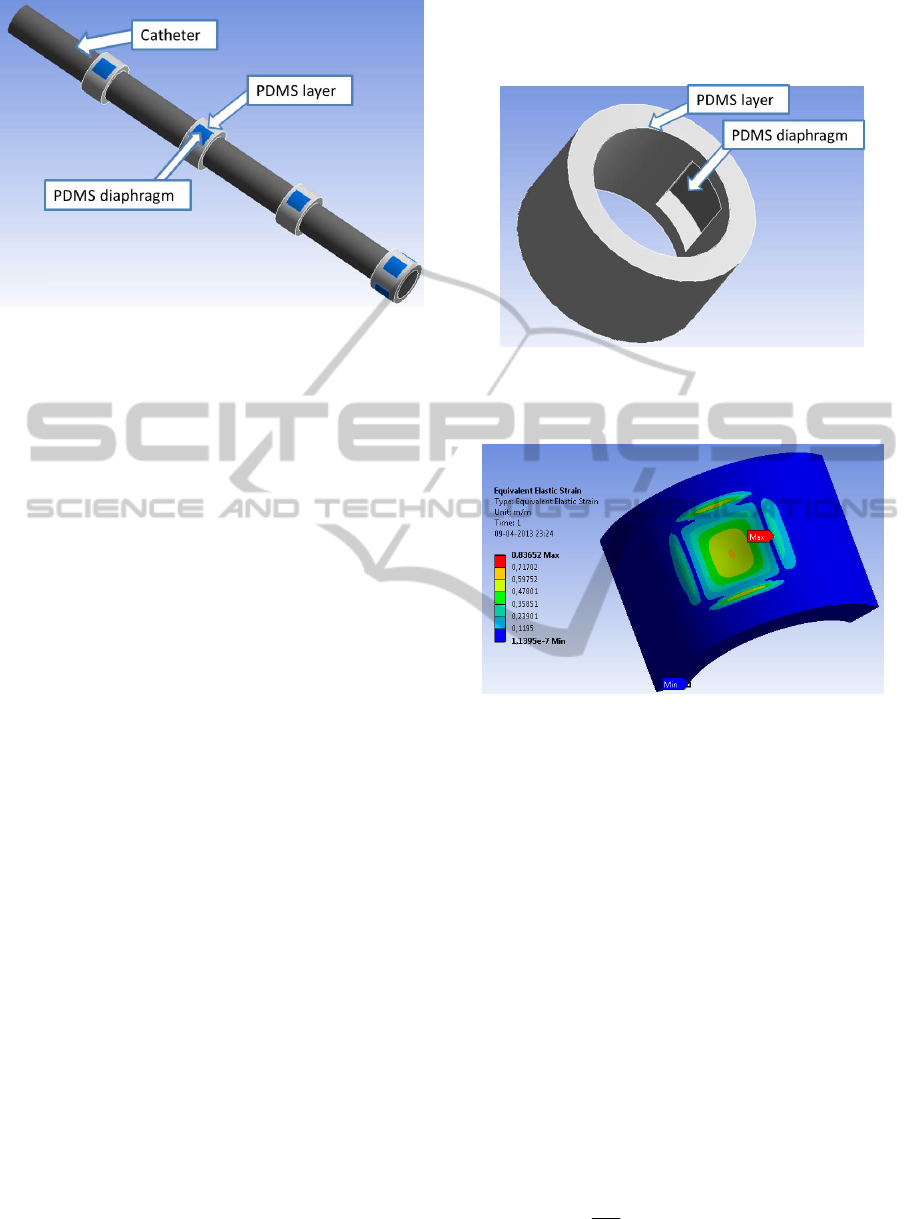

micromachined in the PDMS layers (Figure 1). An

external layer of PDMS is also required to isolate the

sensor from the organism.

The strain gauges are then distributed in these

diaphragm’s regions, where the elastic strain is

higher, thereby improving the measurements’

sensitivity. An external intraluminal pressure will act

in these diaphragms, thereby deforming the

deposited strain gauges, leading to a change of the

gauges’ electrical resistance, which directly relates

with the applied pressure.

200

R. Silva L., J. Sousa P., M. Goncalves L. and Minas G..

Pressure Sensor for Gastrointestinal Intraluminal Measuring.

DOI: 10.5220/0004901102000206

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2014), pages 200-206

ISBN: 978-989-758-013-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

Figure 1: Catheter and the respective PDMS layers along

it (diaphragms are highlighted). At the tip, four

diaphragms are machined for intrasphincteric

measurements.

2 PROPOSED SYSTEM

2.1 Catheter

A regular circular catheter with a diameter between

2.7 and 4 mm is typically used for intra-oesophageal

pressure measurements. This catheter should be

flexible and can be made of different polymeric

materials, as polyvinyl chloride or silicone (ASGE,

2012). In the proposed system, a PDMS layer is

placed externally to the catheter, in the pressure

sensitive areas (Figure 1). The PDMS polymer was

chosen due to its bio-compatibility and resistance to

pH down to 2, which are required features for GI

applications (Cao, 2013). Additionally, PDMS is a

material with low cost, high flexibility and

compatible with micro-electronic mechanical

systems (MEMS).

The various diaphragms are presented in

Figure 1. These regions are the pressure sensitive

sites that will enable the pressure measurements.

These diaphragms (Figure 2) enable a greater

flection of the structure in response to exterior

pressures. Figure 3 shows the strain on a PDMS

layer, which has a central diaphragm (simulated in

ANSYS software). In this simulation, both the

bottom and side surfaces of the structure were

defined as fixed supports. A 110 mmHg pressure

signal was then applied perpendicularly to the

exterior surface. As it can be seen, the diaphragm

strain (i.e. the central area) is several orders of

magnitude greater than the one in the surrounding

area. Furthermore, the highest strain was in the

borders of the diaphragm and in its centre.

Therefore, the pressure sensors should be placed in

these areas of interest, which significantly increases

the pressure measurement sensitivity.

Figure 2: Representative section of the catheter with a

diaphragm machined in the structure (centre of the

structure).

Figure 3: Elastic strain distribution along the diaphragm

and surrounding structure for a 110 mmHg pressure signal

(simulated using ANSYS software).

2.2 Pressure Sensors

As the name suggests, a pressure sensor is capable

of converting a mechanical deformation caused by

an external load into an electrical signal

(Elwenspoek, 2001). In this work, metal strain

gauges, deposited in PDMS, are used as pressure

sensors. This gauge is deposited through lithography

processes which are explained in detail in section 3.

A strain gauge consists of a flexible backing

which supports a metallic foil pattern. This type of

sensor is based on electrical resistance changes.

Whenever a force is applied to this sensor, a

deformation is developed in the metal pattern which

in turn leads to a change of the strain gauge

electrical resistance (Elwenspoek, 2001). This

change is given by the following expression:

(1 2 )

dR

R

(1)

PressureSensorforGastrointestinalIntraluminalMeasuring

201

where υ is the Poisson’s ratio of the material and ε is

the mechanical deformation of the material.

The resistance change is quantified using the

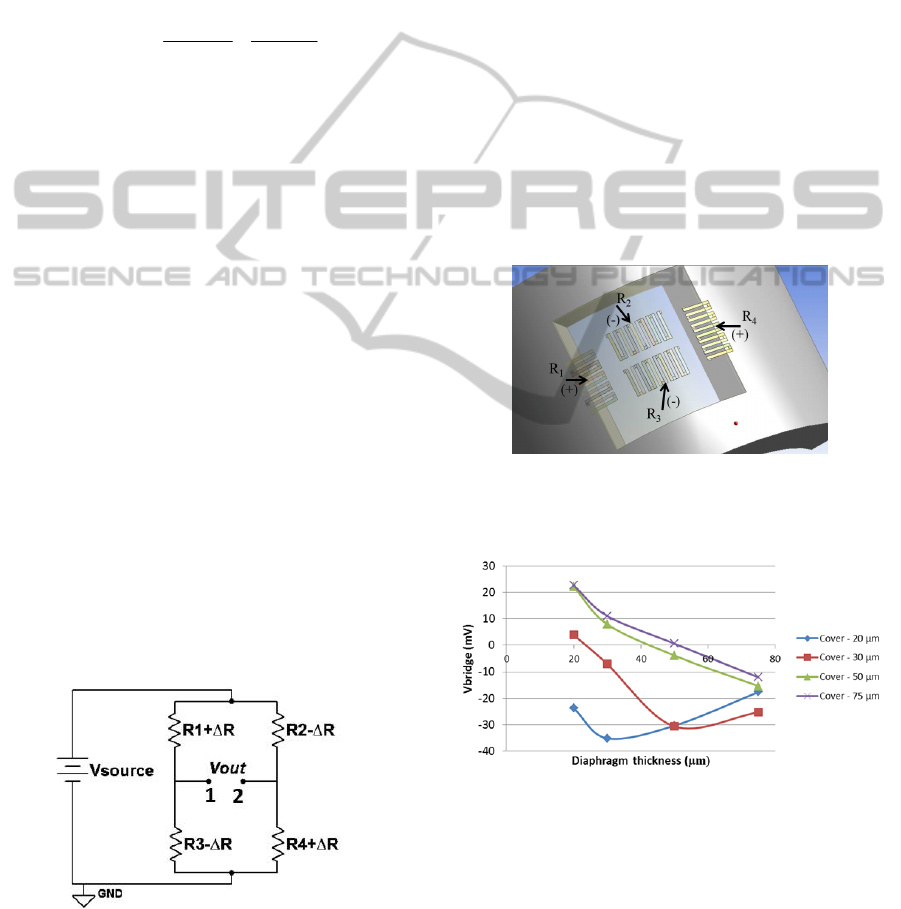

well-established Wheatstone bridge circuit (Figure

4), which converts the resistance change in an output

voltage proportional to this variation. The output

voltage is given by the combination of the electrical

resistances R1, R2, R3 and R4 that constitute the

fully active Wheatstone bridge which results in

(Elwenspoek, 2001):

R

R

R

R

R

R

VV

sourceout

13

3

24

4

(2)

Given the elastic strain distribution obtained in

Figure 3, the strain gauges should be placed in the

central region and in the borders of the diaphragm,

in such a way that the same pressure signal will

generate opposite variations on the resistance of

each pair of resistances (R

1

/R

4

and R

2

/R

3

). The strain

gauges final layout along the diaphragm is illustrated

in Figure 5. For example, in response to a pressure

signal, these strain gauges will either increase (R1

and R3) or decrease (R2 and R4) their resistance and

vice versa. By placing the resistances this way a

fully active bridge is ensured, which will result in a

higher value of V

OUT

(see equation (2)), i.e. a higher

output voltage of the Wheatstone bridge.

Furthermore, by placing the four resistances as close

as possible, undesirable changes of some

parameters, such as temperature, are almost

negligible, once all resistances will be subjected to

the same variations, cancelling each other out. These

resistors are then connected as presented in Figure 4.

Different materials, particularly Al (Aluminium) and

Au (Gold) are being study to act as the active

element of the pressure sensor. Important parameters

of the deposition process are being optimized, at this

stage, to ensure the best adhesion to PDMS.

Figure 4: Wheatstone bridge (fully active).

2.3 Encapsulation

An external PDMS layer is necessary to isolate the

strain gauges metal from the intraluminal medium.

Consequently, this layer will result in a reduction of

the measurement’s sensitivity. A numerical study,

through ANSYS, was done in order to optimize the

thickness of both this external layer and the

diaphragm. Figure 6 shows the theoretical electrical

signal output that results in response to the same

pressure signal for different thicknesses of both the

external PDMS layer (cover) and the diaphragm.

The inversion of the signal polarity is due to the

ratio between the thickness of the cover layer and

the thickness of the diaphragm.

As it can be seen, the highest sensitivities are

achieved with lower cover thicknesses and the best

result was obtained for a diaphragm’s and cover’s

thickness of 30 and 20 µm, respectively. These

values will serve as guideline for the fabrication

steps.

Figure 5: Strain gauges placement in the diaphragm

(ANSYS) (diaphragm is transparent for better

comprehension).

Figure 6: Voltage output of the Wheatstone bridge

according to the thickness of the diaphragm and the

PDMS cover layer, for Aluminium strain gauges (200 nm

thickness) and a pressure signal of 225 mmHg.

3 FABRICATION

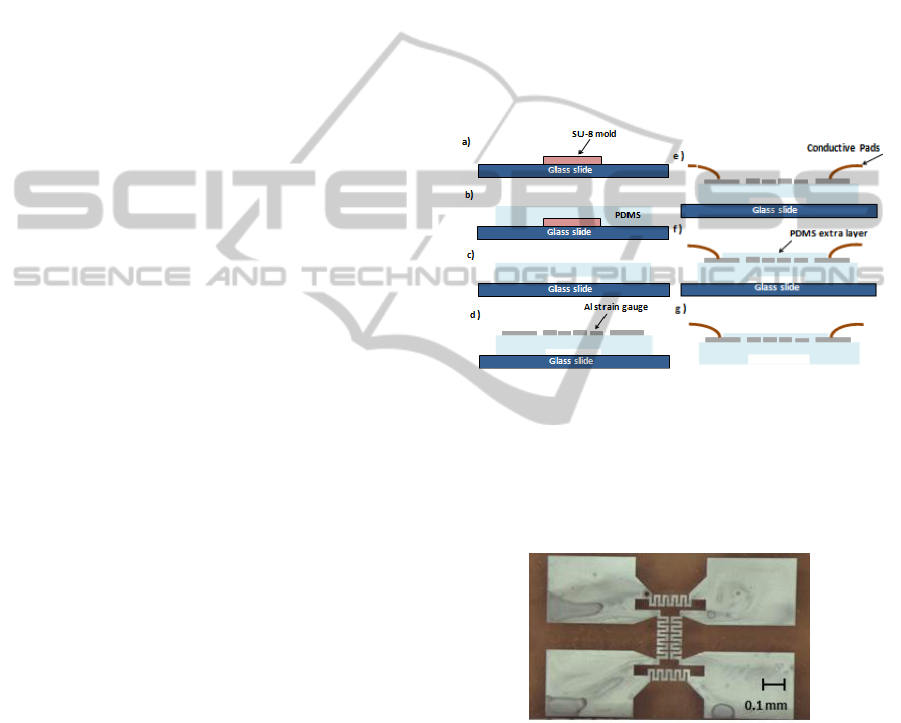

The fabrication steps of the diaphragm structure and

its embedded strain gauges are described in Figure 7.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

202

The diaphragm on the PDMS structure is fabricated

using a SU-8 mold (height of 50 µm). The PDMS

pre-polymer is mixed in the ratio of 10:1

(base/curing agent) and subsequent degassed in a

vacuum desiccator in order to prevent bubble

formation in the mold material (due to incorporated

gas and crosslinking reaction by-products).

The PDMS is then deposited by spin coating

over the mold at 500 rpm in order to obtain a PDMS

50 µm thick film. After this step, it is cured in a hot

plate at a temperature of 85°C for a period of two

hours. Subsequently the PDMS structure that

contains the diaphragm is detached from the mold,

with the help of a scalpel, that cuts the area around

the patterned zone and it is placed over a glass slide.

Then, a metallic thin film is deposited onto the

PDMS to create the strain gauges. This film is

deposited by Physical Vapor Deposition (E-beam)

and patterned by standard photolithography. In this

process the positive photoresist AZ4562 is deposited

by spin coating at 6000 rpm for 20 seconds and

cured in a hot plate at 100°C for 10 minutes. After

this period the samples are left to cool for 10

minutes and, then, exposed to UV light with the

MaskAligner equipment. In order to accomplish this

process it is necessary to use the mask that contains

the micro features to be transferred and exposed

using the Soft Contact mode during 0.85 minutes.

Then, the photoresist developer is used to remove

the zones exposed to the UV light remaining only

over the metallic zones that were protected. This

removing process uses a solution that contains the

AZ351-B developer diluted in distilled water (4:1)

and a mixer to perform the photoresist development.

After 10 minutes developing it is cleaned with

distilled water and dried with a nitrogen flow.

With the previous steps successfully carried out,

it is necessary to perform the etch of the metallic

deposited films. For the aluminium etching a

recipient that contains an Al etch solution is used.

Next, it is visualized when all the non-protected

areas have been removed. The samples are then

removed, cleaned with IPA and dried with a nitrogen

flow. Other etchants can be used for other metals. In

the case of Gold, a Gold etch TFA can be used. To

finish the patterning of the metallic film it is

necessary to remove the photoresist that has been

used to protect the zones of interest. For that, a

solution of AZ100 is used during 15 minutes. The

structure is then cleaned with distilled water. An

example of the final structure obtained is presented

in Figure 8. In order to maintain the electric contact

from the strain gauges to the exterior, wires are then

attached to the conductive pads with silver

conductive paint. Finally, the external PDMS layer

(30 µm) is spun (800 rpm) onto the metal to cover

the sensors. Although the manufacturing process just

described has been successfully used, several

challenges must be overcome. First, it is necessary

to improve the adhesion between the metal film and

the surface of PDMS, which could be done with

chromium adhesion layers or plasma surface

treatment of PDMS prior to deposition.

Another problem is the presence of microcracks

that can appear due to the pressure and temperature

conditions involved in the deposition process. As

such, an optimization of the process or the metal of

choice is currently being carried out. The best results

at this stage were obtained for aluminium and gold.

Figure 7: Schematic representation of the fabrication

process of the strain gauges. a) SU-8 mold; b) pouring the

PDMS pre-polymer on the SU-8 mold and curing; c)

detaching the structure in PDMS and putting on a glass

slide; d) deposition and patterning the metallic film; e)

outer electrical contacts; f) covering the sensors with a

second layer of PDMS; g) separating the sensor.

Figure 8: Aluminium strain gauges embedded in PDMS.

4 READOUT SYSTEM

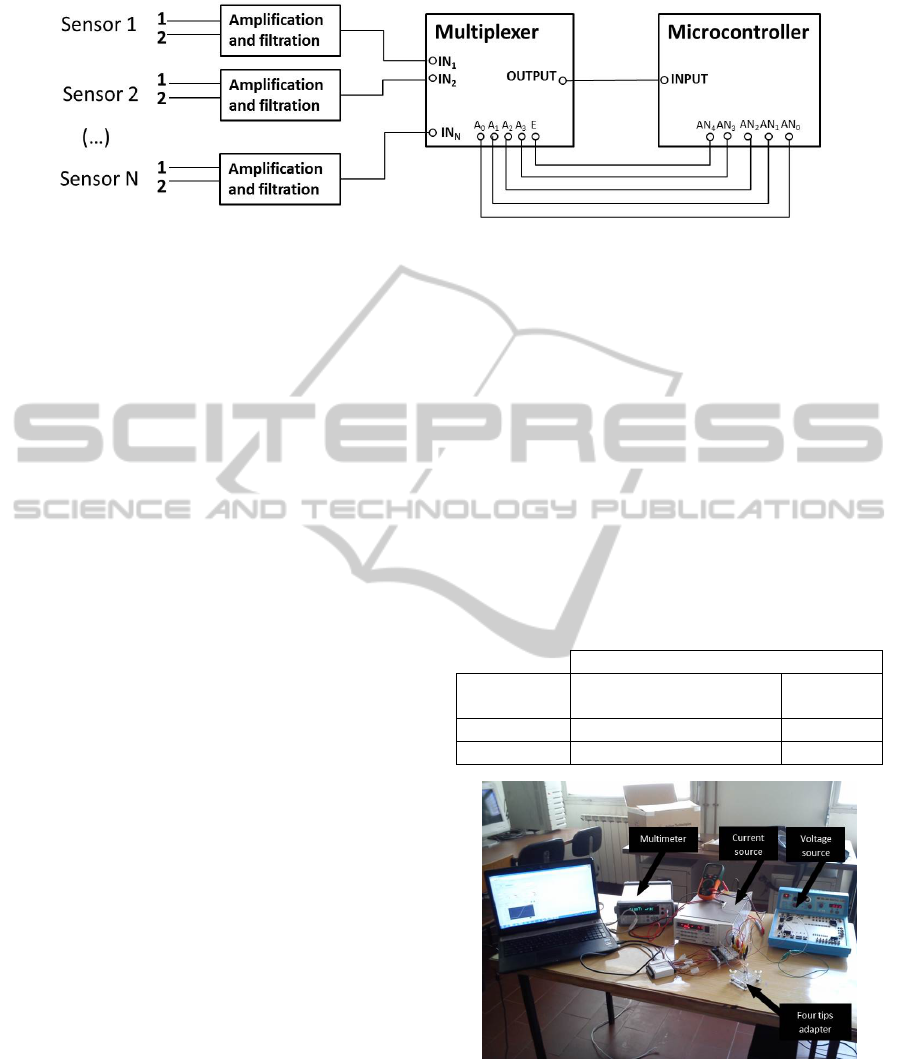

The final readout system can be seen in Figure 9. As

previously stated, a Wheatstone bridge is typically

used for strain gauge pressure measurements and

this case is no exception. Nevertheless, additional

components are required, so as to amplify the

resultant signal, which is of very low amplitude. The

signal is also filtered in order to reduce the high

PressureSensorforGastrointestinalIntraluminalMeasuring

203

Figure 9: Different blocks that constitute the readout system and their connections. The sensors can be seen in Figure 4.

frequency noise signal and the power supply signal

(~50 Hz) that could overlap the signal of interest.

In addition, a multiplexer is used enabling a

sequential reading of the pressure sensors. The

addressing of the multiplexer channels (which

determines what sensor signal to read) as well as the

reading and commutation frequencies between

channels are defined through a microcontroller

(PIC32MX795F512L). The microcontroller’s

programming is carried out by MPLAB IDE.

Finally, the signal is acquired and converted to

digital to be presented in a computer through a user

friendly interface that is being developed with the

software Qt Creator.

5 EXPERIMENTAL RESULTS

5.1 Resistivity Measurement

As reported in section 3 various materials are in

study for being used as the strain gauge’s active

element. Two of these, more precisely, gold and

aluminium, were already deposited with proven

methodology. At this stage a resistivity measurement

was carried out based on the Van der Pauw method.

This method enables the resistivity measurement of

a material, regardless of its form, considering that

the test sample is approximately two-dimensional

(i.e. width much larger than the thickness).

In that method, four electrical contacts are set in

the different corners of the sample. An electric

current is then applied between two contacts and the

resulting voltage is measured in the other two.

Altogether eight separate measurements are

conducted so as to ensure a greater precision.

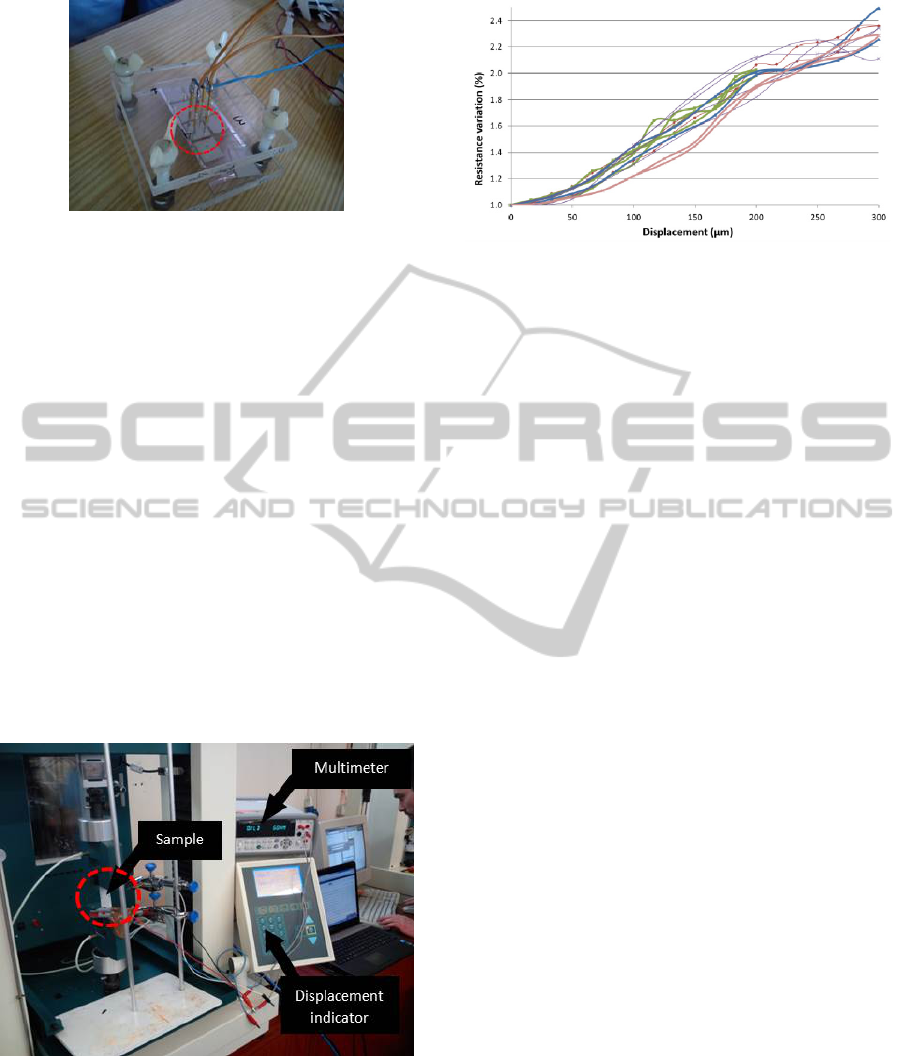

The experimental setup required for this test

includes a current source, a voltage source and a

multimeter with a four tips adapter (Figure 10). A

computer software then controls and varies the

applied current in all the four points (Figure 11) and

sets parameters such as: error margin; number of

readings; and film thickness for a correct calculation

of the resistivity.

As shown in Table 1, the obtained results for the

resistivity are dissimilar to the theoretical values

expected for gold and aluminium bulk films. This

was expected, since bulk material is typical a single

crystal structure, and thin-films are polycrystalline,

with much smaller crystal sizes, with many interface

regions. In addition, the deposition process doesn’t

guarantee a homogenous or free of cracks film, due

to PDMS substrate. For these reasons higher

resistivity values are expected. However, these

values are acceptable for the desired application.

Table 1: Theoretical and measured (mean value) resistivity

for aluminium and gold.

Resistivit

y

(nΩ/m)

Metal Theoretical (BYU,

1994)

Measure

d

Aluminiu

m

28.2 335±20

Gold 24.4 110±10

Figure 10: Experimental setup for the resistivity

measurements (including a multimeter, current and

voltage sources and a four tips adapter).

5.2 Mechanical Tension Test

At this stage mechanical extension tests were done.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

204

Figure 11: Four tips adapter.

Therefore, an experimental setup, shown in Figure

12, was used. The metallic film deposited in PDMS

is then attached to two clamps which are responsible

for the extension of the sample (PDMS/metal) in a

controlled manner (by the displacement indicator

seen in Figure 12). Simultaneously, the resistance of

the film is recorded in order to associate the

resistance change with the sample stretching. The

main purpose of this experiment was to verify if the

metallic film recovers its original resistance between

cycles of extension, which is required for this

application.

Figure 13 shows 6 distinct cycles of consecutive

extension and recovery for gold films (6 x 2 cm with

a thickness of 100 nm) in a 1 mm thick PDMS layer.

As it can be seen, for an extension of 300 µm, the

maximum resistance change was approximately

2.4 % of its initial value. Furthermore, the films

recovered their initial resistance value in the

recovery cycle as seen in the graph.

Figure 12: Experimental setup for the mechanical tests.

6 CONCLUSIONS

This paper relates to an innovative technique for

measuring the intraluminal pressure in the

Figure 13: Displacement versus resistance change for gold

films deposited in PDMS.

gastrointestinal tract (GI). A multiple sensor

approach is proposed, which is based in strain

gauges. The strain gauges are supported by a PDMS

layer, which guarantees a small sensitive area,

enabling a higher integration, while maintaining low

overall cost. At this stage the deposition process for

the strain gauges is being optimized. However, the

initial mechanical tests with gold show promising

results for the application intended. After this

optimization step, different experiments are

scheduled with the final geometry for the strain

gauges and adequate manometry equipment so as to

simulate the pressure signals that would occur in in

vivo conditions.

ACKNOWLEDGEMENTS

This work is funded by FEDER funds through the

"Eixo I do Programa Operacional Fatores de

Competitividade (POFC) QREN, project reference

COMPETE: FCOMP-01-0124-FEDER-020241, and

by FCT- Fundação para a Ciência e a Tecnologia,

project reference PTDC/EBB-EBI/120334/2010.

REFERENCES

AGA, 2005. Technical Review on the Clinical Use of

Esophageal Manometry. Gastroenterology, Volume

128, p. 209–224.

ASGE, 2012. Esophageal function testing - Report on

Emerging Technology. Gastrointestinal Endoscopy,

76(2).

Bodger, K. & Trudgill, N., 2006. Guidelines for

oesophageal manometry and pH monitoring. BSG

Guidelines in Gastroenterology.

BYU (Brigham Young University), 1994. Department of

Electrical & Computer Engineering. Available at:

http://www.cleanroom.byu.edu [February 2013].

PressureSensorforGastrointestinalIntraluminalMeasuring

205

Cao, W., 2013. Fabrication and modeling of stretchable

conductors for traumatic brain injury research.

Princeton.

Elwenspoek, M., 2001. Mechanical microsensors.

Londres: Springer.

Holloway, R. H., 2006. Esophageal manometry. GI

Motility online: Oral cavity, pharynx and esophagus.

Kahrilas, P. J., Ghosh, S. K. & Pandolfino, J. E., 2008.

Challenging the Limits of Esophageal Manometry.

Gastroenterology, Volume 134, pp. 16-18.

Murray, J. A., Clouse, R. E. & Conklin, J. L., 2003.

Components of the standard oesophageal manometry.

Neurogastroenterol. Motil., Volume 15, p. 591–606.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

206