A New Integration Method for Mounting and in vivo

Handling of Sub-mm Flexible Cuff Electrode

Fábio Rodrigues

1,2

and Paulo Mendes

1

1

Centro Algoritmi, University of Minho, Guimarães, Portugal

2

DIMES/ECTM, Delft University of Technology, Delft, The Netherlands

Keywords: Neural Stimulation, Cuff Electrode, Mounting, Polyimide, PDMS.

Abstract: Electrical stimulation of peripheral nerves is commonly used in both research and clinical fields. Cuff

electrodes are one possible interface between nerves and the stimulation microsystem. Among cuff

electrodes, flexible, polyimide-based devices have been demonstrating good and consistent results for the

past 15 years. Regarding mounting and mechanical stability of flexible electrodes for in vivo trials,

improvements are still due. A new concept aiming at the integration of polyimide-based devices in an elastic

handling structure was developed. By taking advantage of PDMS elasticity and moulding, this new

integration method provides surgeons with the ability to move and to rotate the cuff minimizing nerve-

electrode contact and, consequently, nerve damages. A 9 parts stainless steel mould was designed and

fabricated to allow integration of polyimide electrode arrays together with the PDMS mounting structure

and a print circuit board. Furthermore, with the fabricated mould it is possible to achieve a final cylindrical

channel with diameter of 800 µm, as well as handling strips to open and close the cuff.

1 INTRODUCTION

Electrodes are a key component in neural

engineering applications, being used as both

actuators and sensors, i.e. to excite neural tissue by

electrical stimulation or to record bioelectrical

signals from it. Therefore, implantable electrodes

work as interfaces between neural prostheses and the

biological tissue. Among others, potential

applications of implantable electrodes for neural

electrical stimulation range from restoration of

walking (Gustafson et al., 2010) to vagal nerve

stimulation (e.g., epilepsy treatment or heart rate

control) (Connor et al, 2012)and bladder

management in incontinence (Rijkhoff et al, 1997).

Geometrical configuration and dimensions of

electrodes are strongly dependent on the size and

morphology of target nerves. For cylindrical shaped

nerves (e.g., sciatic nerve, vagus nerve) electrodes

made of flexible substrates are a good solution

because they can be wrapped around the nerve.

Usually, this is made by means of cuff electrodes

(Veraart et al, 1993). Cuff electrode diameters range

from hundreds of micrometers (Rodrigues et al,

2012) to few milimeters. During the last two

decades, improvements in the variety and in the

complexity of electrodes for neural stimulation have

provided new solutions in new applications fields

(e.g., vagus nerve stimulation in epislepsy treatment

(Englot et al., 2011, or the FINE electrode for

walking restoration (Schiefer et al., 2008). Many of

these clinical improvements were enabled through

the development of micromachining technologies.

Polyimide-based electrodes have been

demonstrating good and consistent results for the

past 15 years. Polyimides have become an important

and widespread used material for flexible electrodes

due to its good adhesion to metals, long lifetime and

low rate of water retention. Electrodes made of

polyimide usually consist of a thin-film

metallization sandwiched between two layers of

polymer. Thin, uniform layers of polymer are

achieved by means of pouring polyimide on the

substrate followed by spinning. Therefore, the total

thickness of a flexible, polyimide-based electrode is

lower than 30 μm and in vivo handling conditions

require a protective layer between the polyimide and

the biological surrounding tissues.

Biomedical microsystems must fulfil different

requirements for acute and chronic implantation.

When using cuff electrodes for electrical stimulation

of peripheral nerves, three of these requirements are:

265

Rodrigues F. and Mendes P..

A New Integration Method for Mounting and in vivo Handling of Sub-mm Flexible Cuff Electrode.

DOI: 10.5220/0004914602650270

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2014), pages 265-270

ISBN: 978-989-758-013-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

1) a reliable method for cuff opening and closing

(without damaging the nerve), 2) a mechanical, thus

electrical, stable microsystem and 3) to protect the

thin polyimide layers from potential damages when

in vivo. In the present work, we these three practical

challenges were addressed by designing and

fabricating an elastic mounting structure. The

fabricated mould with which it is possible to achieve

the embedment of flexible electrode, silicon chip

and the print circuit board (PCB) is presented. The

used silicone is PDMS, a very used material in

microfluidics and bio-MEMS applications, because

it is easy to mould and biocompatible.

2 MATERIALS AND METHODS

2.1 Mounting Structure Design and

Materials

Our goal is to build a system to allow integration of

a flexible cuff electrode in an elastic mounting

structure, thus providing surgeons and physicians

with a tool to rotate or/and to move the electrode

array along the nerve. The target nerve in our

research is the rat vagus nerve – a cylindrical shaped

nerve with a diameter of approximately 600 μm.

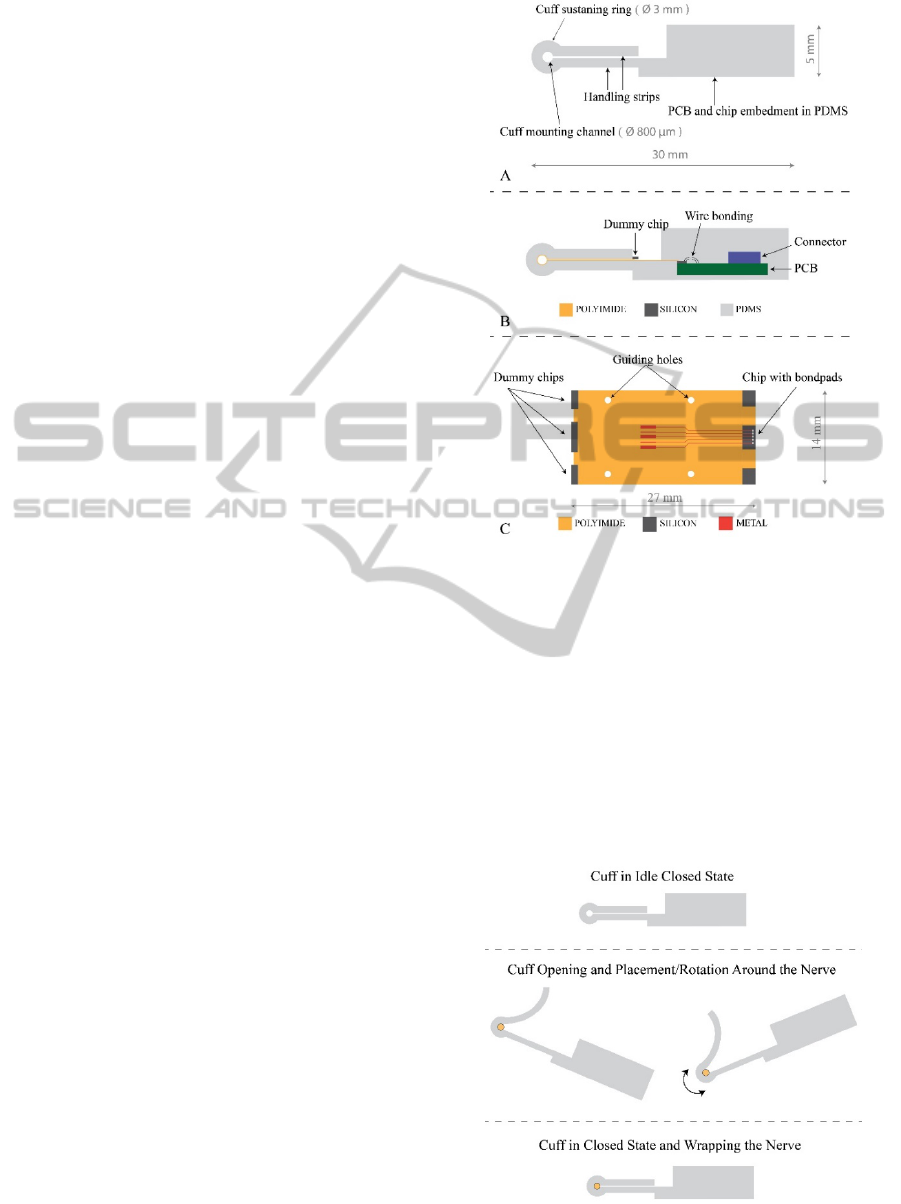

Fig. 1 shows a schematic of the proposed

mounting structure plus schematic of integrated

system and a 2-D view of the flexible electrode. In

order to have enough room for the nerve a central

channel with a diameter of 800 μm is designed – the

cuff mounting channel. A cuff sustaining ring is

designed with 3 mm in order to have a minimum

amount of elastic material around the flexible

polyimide. It keeps the cuff closed during

implantation but also allows an easy opening.

Handling strips allow positional adjustments during

in vivo experiments, as shown in fig. 2. Re-

positioning of electrode array around the nerve can

be done by using tweezers for cuff opening. As the

handling strips are released, cuff goes back to its

original closing position, taking advantage of PDMS

elasticity. Besides integration of polyimide

electrode, the mounting structure was also designed

to protect wire bonding (from chip to PCB), to

integrate PCB and a connector (fig. 1B). A good

alignment between the micro-fabricated electrode

and the mounting structure is crucial, as the

electrode array is designed to be wrapped around the

cuff mounting channel. To facilitate the alignment

between electrode and mounting structure, 4 guiding

holes (1.05 mm in diameter each) were included in

the polyimide layer (fig. 1C).

Figure 1: A. Cross section view of elastic mounting

structure. B. Schematic of integrated microsystem. C. Top

view of polyimide electrode array.

To fabricate the elastic mounting structure, a

mould consisting of 9 main parts was designed and

fabricated. Then, polydimethylsiloxane (PDMS,

Sylgard 184, Dow Corning) was poured and cured

inside the mould. Sylgard 184 consists of two parts:

elastomer and curing agent. These two parts were

mixed at 10:1 ratio (10 parts of elastomer - 1 part of

curing agent), very well mixed and degassed. For the

curing of PDMS, a short period of 30 min at 65 ºC

was used.

Figure 2: Operational states of the elastic mounting

structure.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

266

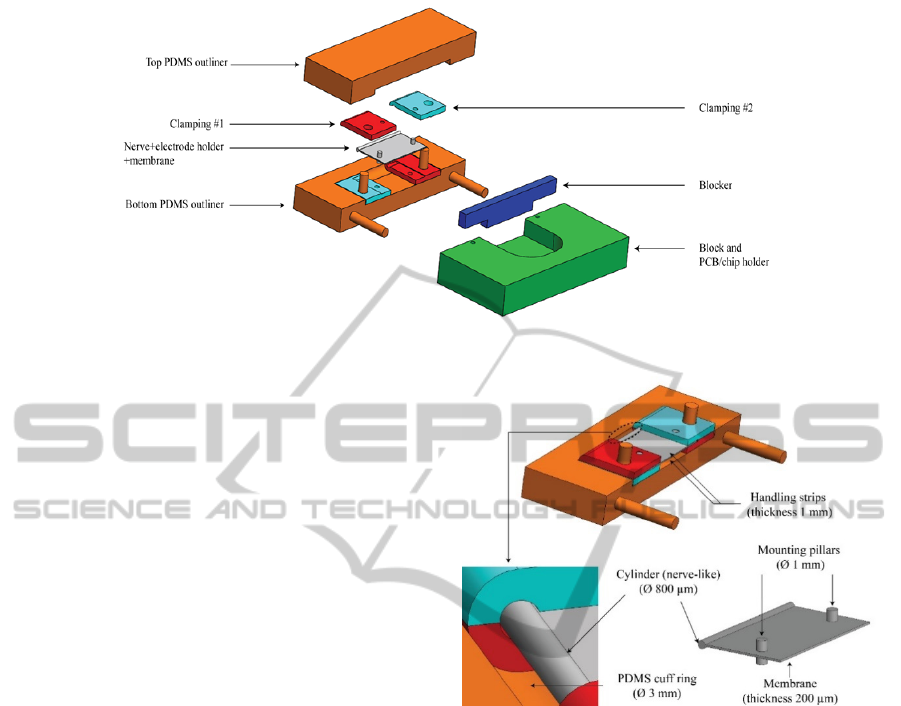

Figure 3: Exploded view of designed mould parts. Identification of each part by a label name.

2.2 Mould Design and Material

To realize the elastic mounting structure using

PDMS, a mould composed of 9 different parts was

designed using Solidworks 2013. Fig. 3 shows an

exploded view of the 9 parts of the mould. The

design was made in order to achieve the following

characteristics: 1) leak tight, 2) easy

assembly/disassembly and 3) straightforward

mounting of flexible electrode using the 4 guiding

holes. Due to PDMS viscosity in its uncured stage,

gaps higher than 20 µm between mating parts can

origin a leak. So then, tolerances were kept as high

as 10 µm. Few pillars were introduced to align

mould parts and 2 mounting pillars (1 mm in

diameter) were designed specifically for the

alignment of the flexible electrode, by using the 4

guiding holes. These 2 mounting pillars are the

smaller ones in the clamping parts (fig. 4).

Clamping parts fix the flexible electrode

wrapped around the ‘Nerve+electrode

holder+membrane’ part. This clamping mechanism

is responsible for alignment of flexible electrode in

the mounting structure.

Thickness of handling strips (1 mm) is given by

the thickness of clamping parts, as shown in fig. 4

and shaping of the cuff sustaining ring is given by

circular grooves in Top and Bottom PDMS outliner

parts. PDMS moulded by ‘Block and PCB/chip

holder’ part sustains the PCB and protects the chip

and the wire bonding area.

Stainless steel was chosen as material for the

moulding fabrication because of its high stiffness

(which reduces risks of breakage during cleaning)

and also because it is easy to clean by acetone and

isopropanol.

‘Nerve+electrode holder+membrane’ part is

composed by 2 independent parts: 1) a 200 µm sheet

Figure 4: Close-up of the clamping mechanism to mount

the flexible electrode.

of stainless steel with holes made by electrical

discharge machine (EDM): membrane and 2) a

cylinder with diameter of 800 µm coupled to the

membrane. These two parts are coupled together by

a longitudinal groove all along the cylinder, where

the membrane mates. This groove is also made by

EDM using a wire of 100 µm in diameter.

The mounting pillars are not solder to the

membrane. Also the grooves in the clamping parts

were made by EDM. All the other parts were made

by normal milling machines.

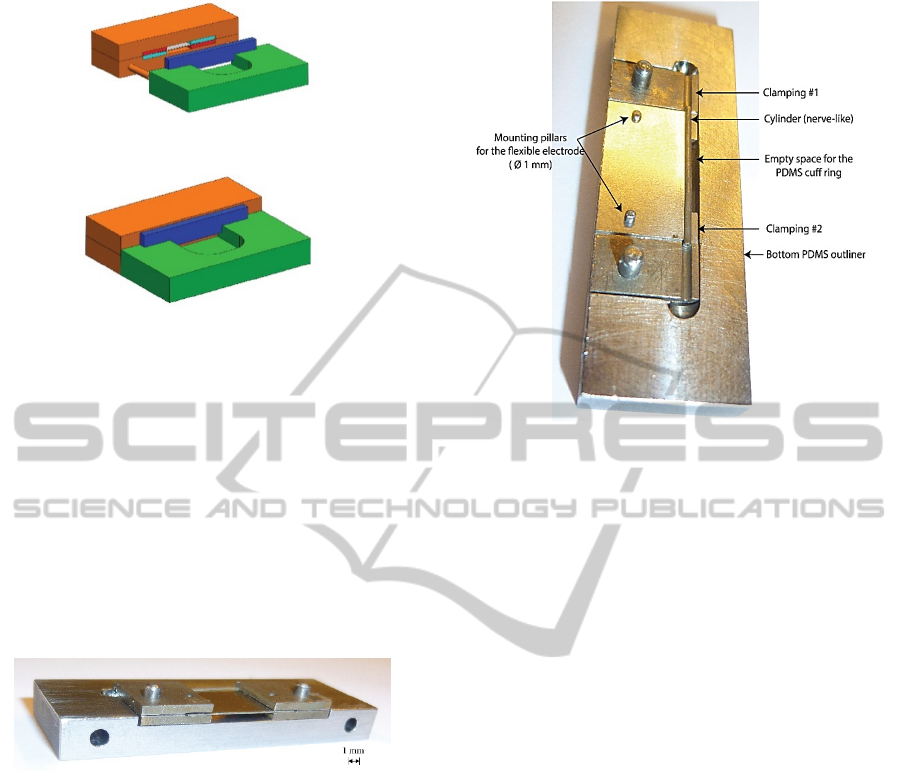

Fig. 5 depicts the final assembly of the mould.

All parts mate together. PDMS can be poured inside,

before adding the ‘Top PDMS outliner’ part, to

check for possible air bubbles. And it is also be

poured after mating all parts together, to make sure

that silicon, wire bonding and PCB are protected.

ANewIntegrationMethodforMountingandinvivoHandlingofSub-mmFlexibleCuffElectrode

267

Figure 5: Final assembly of mould.

3 RESULTS

Some of fabricated parts are shown in fig. 6 and

fig. 7. In fig. 6 it is emphasized the 200 µm thick

membrane sandwiched in between the 4 clamping

parts. Fitting pillars to mate different parts are also

visible as well as the simmetry of the entire mould,

which is import to achieve a stable and working

mounting structure. Also, low roughness of the

fabricated stainless steel parts is important to avoid

air bubbles inside PDMS.

Figure 6: Some of the fabricated parts. Membrane is 200

µm.

In fig. 7, ‘Bottom PDMS outliner’, 2 clamping

parts and the ‘Nerve+electrode holder+membrane’

part are shown. The cylinder of the former part is

well aligned with the grooves in the clamping parts.

Also the cylinder (nerve-like) is well aligned with

the grooves in the ‘Bottom PDMS outliner’, which

contributes for a good alignment of the flexible

electrode with PDMS cuff ring.

The 200 µm thick membrane could be very well

fitted in the mounting pillars, which also contributed

for a good alignment. In our first trials, PDMS was

poured before placing the ‘Nerve+electrode

holder+membrane’ which led to less air bubbles in

the final moulded mounting structure.

In fig. 8, the part ‘Nerve+electrode

holder+membrane’ is shown in detail. To prevent

damages (like bending) to the membrane it has to be

handled by tweezers. And also to prevent the stick

Figure 7: Alignment of cylinder (nerve-like) with the

clamping parts and with the groove for the PDMS cuff

ring.

and the membrane to detach from each other.

After few moulding iterations, we have not seen

any signs of reactions between the mould parts and

the PDMS. We also report that, acetone and

isopropanol are good cleaning agents for the

stainless steel parts after PDMS moulding. However,

if between moulding iterations cleaning is not well

done in all small features, some residues might

prejudice the next procedure.

3.1 Elastic Mounting Structure

In fig. 9 it presented one mounting structure after

being moulded and removed from the mould. It is in

the closed idle state, so the two handling strips are

closed and the cuff channel can be seen in the

bottom part of the figure. Total width is about the

diameter of a euro-cent coin, while the length is

slighty bigger.

In fig. 11, it is shown a cuff opening technique

by using a tweezer. It is possible to open the cuff

just by pulling the handling strip, so without using

high force. This is important to: 1) preserve, in a

future prototype, good adhesion between the flexible

polyimide electrode and the elastic mounting

structure and 2) cuff position around the nerve can

be adjusted without damaging the nerve.

Final moulded structure showed a good overal

mechanical stability and also a good opening and

closing procedures due to PDMS elasticity after

being cured.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

268

Figure 8: A. Close up view of the ‘Nerve+electrode holder+membrane’ part. B. Microscopic image of the slot made by

EDM to join membrane and stick together.

Figure 10: Left: Elastic mounting structure in its open state. Right: close up of the nerve (cuff) channel when the structure is

in its closed state.

Figure 9: Moulded mounting structure (without integrated

flexible electrode and PCB).

4 CONCLUSIONS AND FUTURE

WORK

A mould made of stainless steel was fabricated. The

presented mould is used to realize an elastic

structure which is a useful tool for implantation of a

cuff electrode around a nerve. Gometrical features of

the elastic structure were based on anatomical and

surgical constraints faced during in vivo tests in the

rat vagus nerve.

The integration of a flexible electrode in the

moulding step is under study. The final goal is to

achieve a fully embedded system for electrical

stimulation of the rat vagus nerve.

ANewIntegrationMethodforMountingandinvivoHandlingofSub-mmFlexibleCuffElectrode

269

ACKNOWLEDGEMENTS

This work was supported by the Portuguese

Foundation for Science and Technology

(SFRH/BD/62608/2009) and (PTDC/EEI-

TEL/2881/2012).

REFERENCES

Connor, D. E., Nixon, M., Nanda, A., & Guthikonda, B.

(2012). Vagal nerve stimulation for the treatment of

medically refractory epilepsy: a review of the current

literature. Neurosurgical focus, 32(3), E12.

doi:10.3171/2011.12.FOCUS11328.

Englot, D., Chang, E. & Auguste, K.. (2011). Vagus nerve

stimulation for epilepsy: a meta-analysis of efficacy

and predictors of response. Journal Neurosurgery,

115, 1248-1255.

Gustafson, K. J., Pinault, G. C. J., Neville, J. J., Jr, J. A.

D., Jean-claude, J., & Triolo, R. J. (2010). Fascicular

anatomy of human femoral nerve: implications for

neural prostheses using nerve cuff electrodes, 46(7),

973–984.

Rijkhoff, N., Hendrikx, L., van Kerrebroek, P., Debruyne,

F., & Wijkstra, H. (1997). Selective Detrusor

Activation by Electrical Stimulation of the Human

Sacral Nerve Roots. Artificial Organs, 21, 223–226.

Schiefer, M., Triolo, R., Tyler, D., (2008). A Model of

Selective Activation of the Femoral Nerve With a Flat

Interface Nerve Electrode for a Lower Extremity

Neuroprosthesis. IEEE Trans Neural Systems

Rehabilitation Eng., 16(2), 195-204.

doi:10.1109/TNSRE.2008.918425.

Rodrigues, F., Mimoun, B., Bartek, M., Dekker, R., &

Mendes, P. (2012). Flexible Multipolar Cuff

Microelectrode For FES Of Sacral Nerve Roots. In

Smart Machines – Neural Evolution. Banff, Canada:

IFESS .

Veraart, C., Grill, W. M., & Mortimer, J. T. (1993).

Selective control of muscle activation with a

multipolar nerve cuff electrode. IEEE transactions on

biomedical engineering, 40(7), 640–653.

doi:10.1109/10.237694.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

270