Biomechanical Analysis of Orthodontic Appliances Through 3D

Computer Aided Engineering

Roberto Savignano

Department of Civil and Industrial Engineering, University of Pisa, Largo Lucio Lazzarino, n.1–56126 Pisa, Italy

1 STAGE OF THE RESEARCH

In the field of dental health care, misaligned teeth

can cause aesthetic and functional problems for the

patients. Different appliances have been developed

to correct malocclusions, first of all the classic fixed

wire appliance. In the last decades, however,

research in the orthodontic field has focused not

only on the effectiveness of the appliances on

correcting teeth position, but also on the fulfilment

of comfort issues during the treatment. For this

reason, many new orthodontic appliances have been

developed with the aim at being minimally invasive

for the patients. In particular, lingual brackets, which

are less visible than vestibular brackets and clear

removable aligners, made of transparent

thermoplastic material and then almost invisible,

raised a growing interest.

Treatments based on clear aligners are composed

of a set of thermoformed templates (Figure 1),

having different shapes, which are sequentially worn

by the patient (Kesling, 1943). Each aligner is

shaped a bit different than the real teeth position in

the mouth in order to force teeth to move in the

correct position. The shape of the last aligner

corresponds to the desired position of the teeth at the

end of the treatment. When the dentition have

reached the position imposed by the aligner, the

patient can wear the following aligner which

continues to move the teeth. A set of distinct

templates is usually required to achieve the final

desired outcome since each aligner can perform only

a limited rotation and/or translation. Usually, each

aligner needs about two weeks to completely exert

its specific function. When the dental technician

started to produce the first aligners, about 70 years

ago, they were made designing manually each of

them. The technician used a plaster cast of the

mouth and moved the teeth in the desired position

for the creation of the first aligner, then he had to

repeat the process until the last aligner of the

treatment. Nowadays through the increase of CAD

systems the design process has become faster and

has changed the market of these appliances. The

aligner's producers have changed from small local

laboratories to industries which can serve a large

amount of patient all over the world. (Beers, Choi,

and Pavlovskaia, 2003).

Figure 1: Example of a thermoplastic aligner.

The production process of these appliances is

composed of 3 distinct steps:

Creation of a digital model of the patient's

mouth

Design: The shape of each aligner is defined

by a technician through CAD software tools.

The technician designs the aligners starting

from the teeth position in the mouth obtained

by the digitalization process. Then following

doctor's prescription which indicates the

desired teeth position at the end of the

treatment with the aligners the technician

designs the aligners.

Aligner production.

Actually, the design is made mainly through

geometrical consideration about the teeth's crown

position almost neglecting the roots. This

simplification can bring to erroneous prediction

about the real treatment outcome. Roots can have

interferences between them during the treatment

causing an undesired final teeth position. Their

28

Savignano R..

Biomechanical Analysis of Orthodontic Appliances Through 3D Computer Aided Engineering.

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

shape also influences very much the way how the

teeth move into the alveolar region.

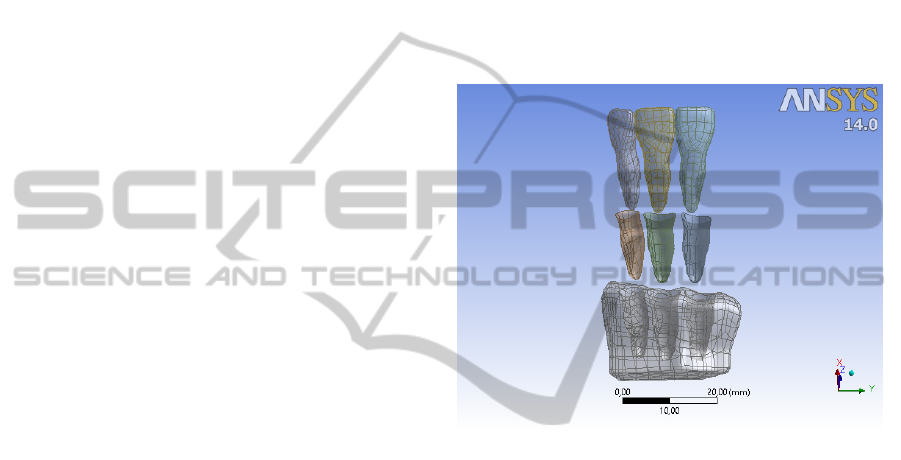

Figure 2: Virtual designed treatment. Initial teeth position

(upper), half-treatment (center), end of the treatment

(lower).

During the design phase, the technician can

suggest to the physician the application of

attachments, having particular shapes, onto some

teeth in order to facilitate the load transfer between

the aligner and the dentition. (Figure 3). A typical

attachment consists of dental composite material

which is polymerized onto the tooth surface.

Even if orthodontic treatments based on the use

of clear aligners are commonly used in clinical

practice there is no technical literature describing

how the loads are transferred from the thermoformed

aligner to the patient dentition. Since both design

and production processes involves many clinical and

technological skills (knowledge), the optimisation of

aligners features represents one of the most

challenging aspects of this kind of orthodontic

treatments. The design of customised and optimised

Figure 3: Attachments (orange) positioned on the two

upper canines teeth that have to be rotated.

templates would be of utmost importance to obtain

more effective treatment plans and accurate

prediction of the achievable results.

2 OUTLINE OF OBJECTIVES

The aim of the present research consists in the

development of a simulation model to be used in the

design of an orthodontic treatment by using

thermoformed aligners. Demanding problems are

given by the understanding on how each aligner

works on teeth, how load are transmitted from the

aligner to the teeth and what are the effects that can

be observed on the surrounding dental structures.

The objective of this research is to understand limits

and real effectiveness of clear aligners by using

FEM simulations.

Some of the characteristics which have to be

investigated and then optimised are:

Composite attachments shape and dimensions

with the aim at facilitating teeth movements;

Aligner thickness;

Aligner material properties;

Treatment strategies.

Production process

Model verification

3 RESEARCH PROBLEMS

Concerns encountered in the first part of the study

can be catalogued into three categories:

Creation of an accurate 3D patient mouth

model;

Estimation of the mechanical properties

characterising the involved dental structures;

Contact modelling between teeth and aligner;

BiomechanicalAnalysisofOrthodonticAppliancesThrough3DComputerAidedEngineering

29

3.1 Geometry Creation

The creation of a customised 3D digital mouth

model represents the starting point for each

simulation. This model should accurately reproduce

both bone and dental structures of the patient.

Recent developments in digital imaging techniques

have allowed a wide spread of three-dimensional

methodologies based on capturing anatomical tissues

by different approaches, such as CBCT, three-

dimensional photography and surface scanning.

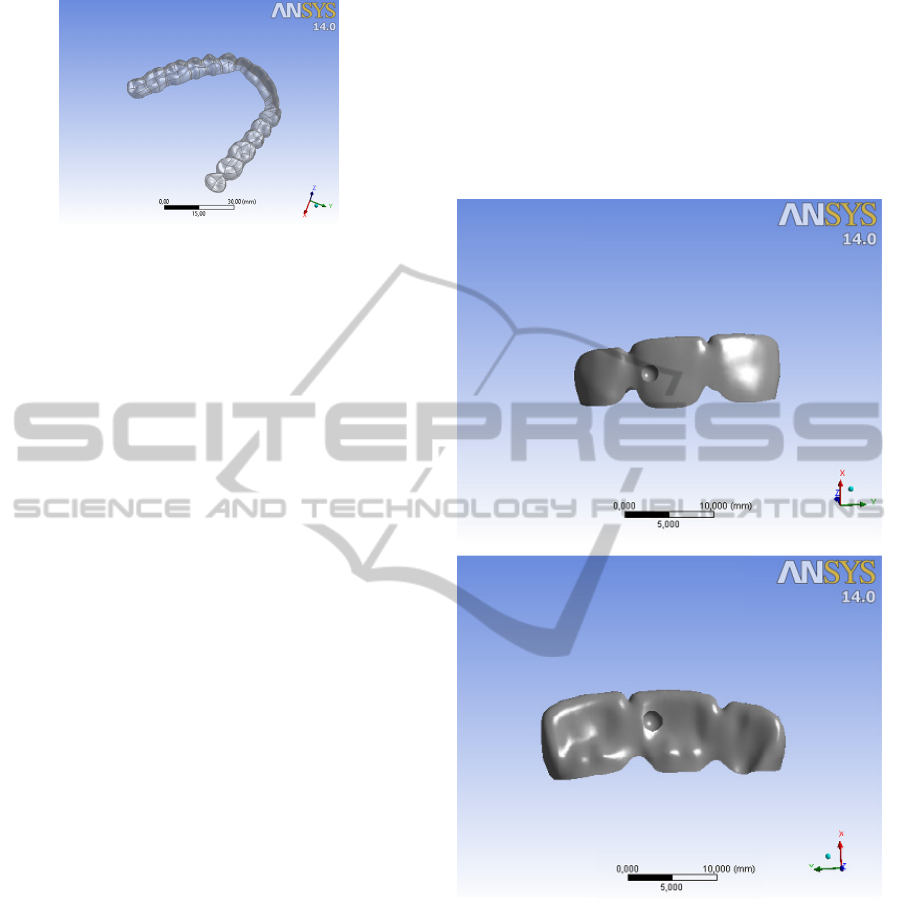

(Barone et al., 2013b). Figure 4 shows an example

of a patient model composed of maxillary bone and

teeth with their roots . Combining optical and

radiographic technologies (CBCT,

Orthopantomography) allows the evaluation of roots

morphology that usually is not available while

designing an orthodontic treatment with clear

aligners.

Figure 4: Reconstructed geometry of maxillary bone and

teeth(left) and teeth with roots reproduction.

A further problem is related to the aligner

modelling. The aligner is supposed to have a

constant thickness of 0.7 mm originating from the

mean thickness of the thermoplastic material disk

(having 0.75 mm thickness) after the thermoforming

process (Ryokawa, Miyazaki, Fujishima, & Maki,

2006).

However, possible thickness variations may

occur after the thermoforming process and should be

taken into account. Discontinuities in the aligner

thickness could modify its mechanical behaviour

during the orthodontic treatment.

3.2 Material Properties

Material properties must be correctly assigned to

each component of the model. Scientific literature

has been used to identify teeth and bone properties

(i.e.: Young's modulus and Poisson's ratio).

Periodontal ligaments properties are rather

characterised by different values and theories which

vary from linear elastic models to multiphase models

through literature (Fill, Toogood, Major, and Carey,

2012). Also for the aligner and the attachments the

material properties have to be appropriately

assigned. About the aligner the properties changes

due to the production process must be taken into

account.

3.3 Tooth-aligner Interface

A complex problem is related to the contact

conditions between the aligner and the teeth. In

particular, the interface between aligner and tooth

must be modelled. When simulations concerning

fixed orthodontic wires have to be performed, loads

can be supposed as concentrated and transferred

through a single point of the tooth crown. In many

cases, the wire can be neglected since not

meaningful for the simulation results except when

the aim of the study is to investigate the stress

generated along the wire (Penedo, Elias, Pacheco,

and de Gouvêa, 2010). When a clear aligner is used,

the transferring interface is represented by the

overall tooth crown geometry and the load

distribution over the contact surfaces is unknown.

The aligner could be disregarded within the model in

order to have faster simulations. This could be

possible only if the load distribution would be

known. However, the exact formulation of this

distribution represents a difficult task due to the high

irregular and patient-specific shape of the dentition.

4 STATE OF THE ART

Several studies about orthodontic biomechanics have

been performed by considering the problem from

different point of views. In the last few years, some

researchers have reported results of orthodontic

FEM simulations, starting from single tooth models

(Penedo, Elias, Pacheco and de Gouvêa, 2010) to

more complex multi-teeth models (Field, et al.,

2009). However, the majority of the presented

models refer to fixed orthodontic appliances and

only few studies focused on the study of orthodontic

treatments through clear aligners by using FEM

models (Martorelli, Gerbino, Giudice and Ausiello,

2013). Some recent experimental studies have been

focused on the measurement of load and torques

applied by an aligner onto the dentition model using

electronic devices based on strain gauges which are

connected to a replicated teeth arch (Hahn, et al.,

2010). Other studies used a pressure measurement

film in order to evaluate the force transferred by the

aligner to the teeth. (Barbagallo, Shen, Jones, Swain,

Petocz and Darendeliler, 2008).

Useful studies have

BIOSTEC2014-DoctoralConsortium

30

been published about the material properties of some

different thermoformed aligners and can probably

help us in the research development (Kohda, Iijima,

Muguruma, Brantley, Ahluwalia, and Mizoguchi,

2013). Some studies are related to the material

properties before thermoforming while others

investigate the mechanical properties after

thermoforming and trying to replicate the real

working environment of the aligner (Ryokawa,

Miyazaki, Fujishima, and Maki, 2006).The

mechanical properties of the dental structures have

been well studied and the properties of tooth and

bone structures are almost the same in most of the

papers, but there is a different situation regarding the

periodontal ligament.

A lot of literature regards the periodontal

ligament mechanical properties. However, it is really

hard to investigate its in-vivo properties due to its

small dimensions (about 0.2 mm thickness). For this

reason, the majority of the available papers

investigated the mechanical properties of the

periodontal ligament through experimental analyses.

Typical values for the periodontal ligament

Young Modulus (E) vary from 0,059 MPa to 1750

Mpa (Fill et al., 2012). This great difference is due

to the different assumptions and the different

environments considered in each research. Some of

the experiments have been performed during

masticatory load simulation (Natali, Pavan and

Scarpa, 2004)while some others during orthodontic

simulation (Penedo, Elias, Pacheco, & de Gouvêa,

2010). Another reason of this results are the

biological differences between the subjects

considered in each research. All the assumption

made by researchers caused a great variability of the

properties estimated for the periodontal ligament.

5 METHODOLOGY

5.1 Geometry Creation

In the present study, dental data, captured by

independent imaging sensors, are fused to create

multi-body orthodontic models composed of teeth,

oral soft tissues and alveolar bone structures. The

methodology is based on integrating CBCT and

surface structured light scanning (Barone et al.,

2013a). An optical scanner is used to reconstruct

tooth crowns and soft tissues (visible surfaces)

through the digitalization of plaster casts. These data

are also used to guide the segmentation of internal

dental tissues (tooth roots) by processing CBCT data

sets. The 3D individual dental tissues obtained by

the optical scanner and the CBCT sensor are fused

within multi-body orthodontic models with

minimum user interaction. The final orthodontic

model is provided by the fusion of the multi-modal

data sets including the most accurate representation

for each tissue: i.e., tooth crowns and gingiva by

optical scanning and tooth roots and alveolar bone

by CBCT imaging. The created anatomical geometry

is converted into “Iges” models in order to be

imported within a Finite Element modeller software

(Ansys

14). The periodontal ligament has been

modelled as an uniform 0.2 mm thickness shell

between tooth and bone (Figure 5).

Figure 5: View of the model with three teeth with their

periodontal ligaments and underlying bone.

The aligners are always created by

thermoforming a disc of thermoplastic material on a

cast obtained by a rapid prototyping machine. The

disc thickness can vary depending on the producer,

but an often used thickness is 0.75 mm, so has been

decided to start the study using this value. To

simulate the aligner creation the teeth have been

combined and the resulting object has been cut

manually over the gingival margin to obtain a thin

object (0.7 mm) that wears well on teeth surfaces.

Assuming a constant thickness for the aligner is a

simplification that can bring to some errors in the

simulation results, so an alternative way can be to

create the model for the aligners using an optical

scanner to acquire the aligner geometry and then to

create the geometry readable by the finite element

modeller in order to have a more realistic model.

5.2 FEM Simulation

The bodies have been meshed dividing them into

solid and shell bodies. The teeth, bone and the

BiomechanicalAnalysisofOrthodonticAppliancesThrough3DComputerAidedEngineering

31

Figure 6: Model of the orthodontic aligner.

attachment have been modelled as solid bodies using

tetrahedrons. The periodontal ligaments and the

aligner have been modelled as shell bodies due to

their small thickness.

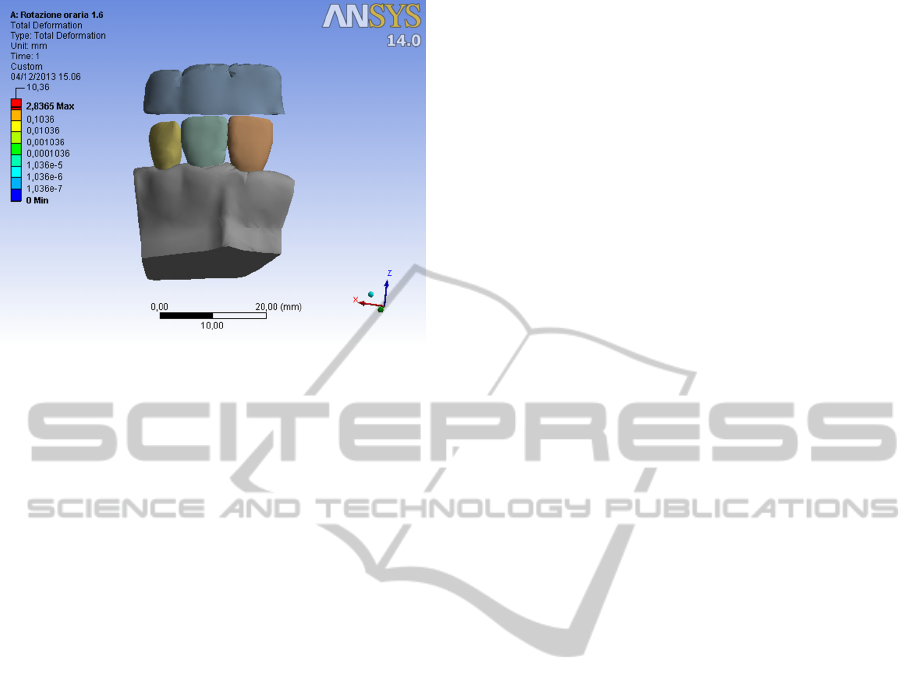

The simulation phase started with the creation of

a single tooth model, then the complexity has been

increased in order to obtain a more complete and

realistic simulation.

For the single tooth model has been used an

upper central incisor. The single tooth model has

been used only in the first time while trying to

replicate a well working model for orthodontic

simulation with brackets (Penedo, Elias, Pacheco, &

de Gouvêa, 2010). Couldn't be used the single tooth

model while simulating the treatment with the

removable aligner because is not possible to model

the mesial and distal extremity of the aligners.

Cutting the aligner at the mesial and distal side

brought to an erroneous result because the aligners

completely followed the tooth while not having any

grip point. Also closing the aligner on the mesial and

distal sides brought to the same problems, so has

been used this model to simulate a torque movement

and to "validate" the chosen model.

With three teeth the aligner has the right grip

point to generate forces on the teeth. The three teeth

model comprised the upper central incisor and the

two neighbours teeth. The first simulation was

related to a 2° clockwise rotation of the upper central

incisor. The simulation was performed using three

different appliances features. In the first case was

used a common clear aligner, in the second case has

been added a composite attachment on the tooth that

is commonly used to help this kind of tooth

movement. In the third case we used an aligner with

an introflection on the lingual surface and an

introflection on the vestibular surface that are

positioned in order to concentrate the force on the

tooth and are supposed to help achieving a better

result.

The idea for the next phases of the research is to

perform the simulation using a full dental arch to

have a more realistic situation and simulating

different shape and dimensions of the composite

attachments and different aligner thickness to find

the best configuration for the different teeth

movements. Then could be simulated a complete

treatment of a set of aligners that involves bone

remodelling evaluations (Qian, Fan, Liu and Zhang,

2008).

Figure 7: Introflection on vestibular and lingual surfaces.

5.2.1 Material Properties

Data have been then transferred to the finite element

modeller (Ansys

14). The structures of the mouth

have been distinguished in three different parts:

Bone;

Teeth;

Periodontal ligaments.

There is no distinction between Cancellous and

Cortical bone, because of the very higher stiffness of

the second one. For the same reason also the teeth

are not divided into: Dentin, Enamel, Pulp, but each

tooth is considered a homogeneous body .This

BIOSTEC2014-DoctoralConsortium

32

simplification has been made in previous studies

(Penedo, Elias, Pacheco and de Gouvêa, 2010) to

save computational time without losing many

information if the aim of the research it's not to

study the single part, but as in this case to evaluate

the effects of the treatment in a more macroscopic

way.

The material properties that have been used are:

Table 1: Material properties.

Young's Modulus

[MPa]

Poisson's

Ratio

Tooth 20000 0.3

Bone 13800 0.3

Periodontal

ligament

0.059 0.49

The most difficult choice regards the model to be

used to simulate the ligament properties since many

are the biomechanical models available in literature.

Some researchers assumed a viscoelastic model

for the periodontal ligament(Su, et al., 2013), which

seems to simulate well the time-dipendent properties

of the ligaments.

However in this phase of the research, the linear

elastic model has been used since the project is more

focused on the comparison of the results obtained by

using different properties of the appliances rather

than on the study of the behaviour of the ligament

itself. In a further stage of the research, different

assumptions regarding the periodontal ligament

model could be introduced in order to refine the

investigations.

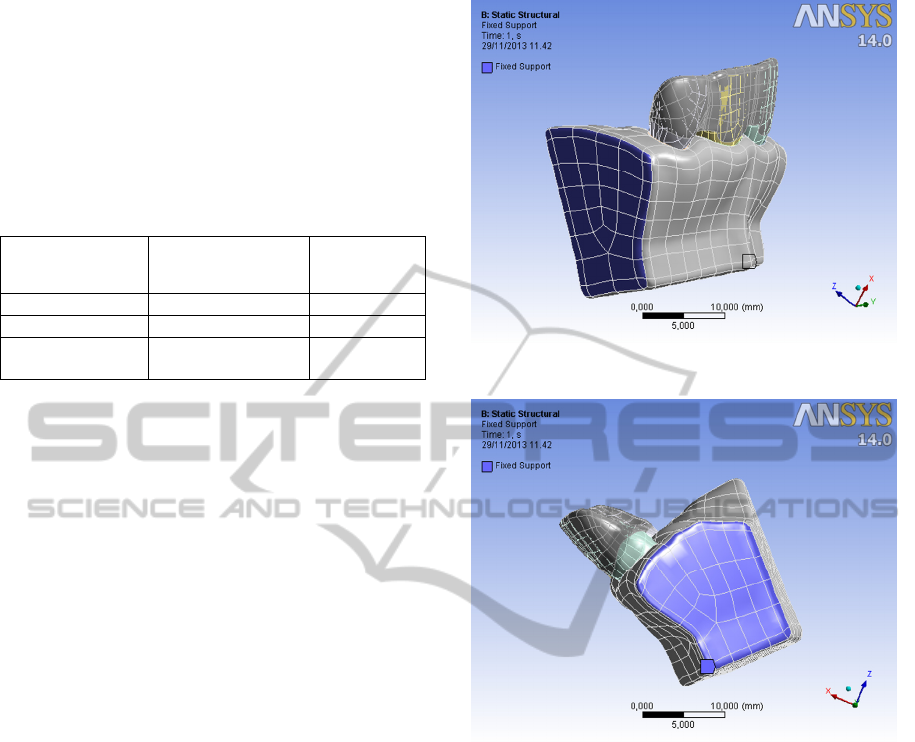

5.2.2 Boundary Conditions

The tooth and the ligament are joined by a bonded

contact which allows only small sliding movements

between joined nodes. The same connection has

been used to join bone and ligament. The mesial and

distal faces of the bone have been fixed to the

ground (Figures 8-9).

5.2.3 Creating Teeth-aligner Displacement

The created aligner is completely congruent with

teeth. For this reason, a difference between aligner

and dentition geometry has been generated in order

to simulate a real treatment condition. As a first

example, the treatment simulation during the

rotation of an upper central incisor has been

investigated. This has been done through the finite

element modeller by defining the tooth principal axis

and clockwise rotating the upper central left incisor

by 2° around its axis.

Figure 8: Distal view of the model.

Figure 9: Mesial view of the model.

5.2.4 Analysis Settings

Once the models are created, two are the possible

strategies to solve the problem. The first one consists

of positioning the aligner onto the dentition and let

the software to solve the contact problem in order to

obtain a stable condition. In a second strategy, the

aligner is positioned over the teeth (Figure 10) and

then it is slowly moved until it reaches the contact

condition with teeth. This second approach, which

needs more computing time, gives further

information about the use of the aligners in

orthodontic treatments. It is indeed possible to

analyse the wearing phase, which is characterised by

high and not negligible stresses. Moreover, the

evaluation of the stress distribution could allow the

prediction of possible aligner fractures.

BiomechanicalAnalysisofOrthodonticAppliancesThrough3DComputerAidedEngineering

33

Figure 10: Aligner over the teeth at the starting point of

the simulation.

5.3 Model Validation

After obtaining the desired results from the

simulations will be performed an experimental

validation comparing them with that obtained by

other techniques. Some ideas are:

5.3.1 Photoelasticity

Photoelasticity is a full-field technique which

directly provides the information of principal stress

difference and the orientation of principal stress

direction by fringe analysis of components made of

birifrangent materials. The thermoplastic material

which composes the aligner is transparent and is

characterized by having photoelastic properties. The

introduction of customized photoelastic analyses for

real components would greatly enhance the

detection of possible criticalities arising from a

challenging application such as the optimisation of

removable aligners.

5.3.2 Electronic Measurement Device

Some researchers have developed electronic

systems, based on strain gauges, able to measure

forces and moments during a simulation of an

orthodontic treatment. The comparison between the

FEM model with the measurements obtained by the

electronic device can give an idea about the

accuracy of the model. (Hahn et al., 2010)

5.3.3 Clinical Tests on Real Patients

The best way to validate the model would rely on

the comparison of the numerical results with those

obtained by clinical tests involving real orthodontic

treatments.

6 EXPECTED OUTCOME

The present research project is focused on the study

of how the orthodontic aligners work and on the

optimization of their design process. The appropriate

definition of parameters as shape, dimensions of

attachments, thickness and material of the aligner

would allow the definition of a more predictable

treatment. Moreover, shorter treatment times would

be characterized by less discomfort for the patient

and lower costs since performed by a lower number

of aligners.

The results obtained by this research could be

also used to extend the use of invisible aligners to

malocclusion problems which are presently treated

by different orthodontic appliances, and to improve

their production process.

REFERENCES

Barbagallo, L., Shen, G., Jones, A., Swain, M., Petocz, P.,

& Darendeliler, M. (2008). A novel pressure film

approach for determining the force imparted by clear

removable thermoplastic appliances. Annals of

Biomedical Engineering , 335-341.

Barone, S., Paoli, A., & Razionale, A. (2013b). Computer-

aided modelling of three-dimensional maxillofacial

tissues through multi-modal imaging. Proceedings of

the Institution of Mechanical Engineers, PArt H:

Journal of Engineering in Medicine , 227,89-104.

Barone, S., Paoli, A., & Razionale, A. (2013a). Creation of

3D Multi-Body Orthodontic Models by Using

Independent Imaging Sensors. Sensors , 13,2033-

2050.

Beers, A., Choi, W., & Pavlovskaia, E. (2003). Computer-

assisted treatment planning and analysis. Orthodontics

& craniofacial research , 117-125.

Field, C., Ichim, I., Swain, M., Chan, E., Darendeliler, M.,

Li, W., et al. (2009). Mechanical responses to

orthodontic loading: A 3-dimensional finite element

multi-tooth model. American Journal of Orthodontics

and Dentofacial Orthopedics , 174-181.

Fill, T. S., Toogood, R. W., Major, P. W., & Carey, J. P.

(2012). Analytically determined mechanical properties

of, and models for the. Journal of Biomechanics , 9-

16.

Hahn, W., Engelke, B., Jung, K., Dathe, H., Fialka-Fricke,

J., Kubein-Meesenburg, D., et al. (2010). Initial forces

and moments delivered by removable thermoplastic

appliances during rotation of an upper central incisor.

Angle Orthodontist , 80,2,239-246.

BIOSTEC2014-DoctoralConsortium

34

Kesling, H. (1943). The philosophy of the tooth

positioning appliance. American Journal of

Orthodontics and Oral Surgery , 297-304.

Kohda, N., Iijima, M., Muguruma, T., Brantley, W.,

Ahluwalia, K., & Mizoguchi, I. (2013). Effects of

mechanical properties of thermoplastic materials on

the initial force of thermoplastic appliances. Angle

Orthodontist , 476-483.

Martorelli, M., Gerbino, S., Giudice, M., & Ausiello, P.

(2013). A comparison between customized clear and

removable orthodontic appliances manufactured using

RP and CNC techniques. Dental Materials , e1-e10.

Natali, A., Pavan, P., & Scarpa, C. (2004). Numerical

analysis of tooth mobility: Formulation of a non-linear

constitutive law for the periodontal ligament. Dental

Materials , 623-629.

Penedo, N., Elias, C., Pacheco, M., & de Gouvêa, J.

(2010). 3D simulation of orthodontic tooth movement.

Dental Press Journal of Orthodontics , 98-108.

Qian, Y., Fan, Y., Liu, Z., & Zhang, M. (2008). Numerical

simulation of tooth movement in a therapy period.

Clinical Biomechanics , s48-s52.

Ryokawa, H., Miyazaki, Y., Fujishima, A., & Maki, K.

(2006). The mechanical properties of dental

thermoplastic materials in a simulated intraoral

environment. Orthodontic Waves , 64-72.

Su, M., Chang, H., Chiang, Y., Cheng, J., Fuh, L., Wang,

C., et al. (2013). Modeling viscoelastic behavior of

periodontal ligament with nonlinear finite element

analysis. Journal of Dental Sciences , 8,2,121-128.

BiomechanicalAnalysisofOrthodonticAppliancesThrough3DComputerAidedEngineering

35