An Improved Electrolytic Pump for Potential Drug Delivery

Applications

Ying Yi

1

, Ulrich Buttner

1

, Armando Arpys Arevalo Carreno

1

and Ian G. Foulds

2

1

Department of Electrical Engineering, King Abdullah University of Science and Technology (KAUST),

Thuwal, Saudi Arabia

2

Department of Electrical Engineering, University of British Columbia (UBC), Kelowna, Canada

Keywords: Electrolytic Pump, Platinum Mesh, Pumping Rate, Recombination Rate.

Abstract: This work presents a novel prototype of an electrolytic pump that uses a platinum (Pt) coated-nickel mesh in

the pumping chamber for increasing the recombination rate electrolysis products. The Pt coated-nickel mesh

that acts as a catalytic reforming element is able to significantly reduce the pulsed pumping period of the

pump, resulting in a more controllable system. Our presented electrolytic pump can provide the cyclical

actuation required for a solid drug in reservoir delivery system and shows potential application in the field

of drug delivery.

1 INTRODUCTION

The combination of microelectromechanical systems

(MEMS) with biochemical applications has attracted

growing interests, especially in the field of drug

delivery systems. MEMS fabrication technology

applied in drug delivery systems can provide a high

efficiency and accurately delivered dose and more

friendly operation (Nisar et al., 2008). MEMS based

drug delivery devices in general consisted of a

micro-pump, micro-fluid channels, micro-sensor and

another necessary units. As an essential component

of drug delivery devices, the micro-pump performs

the function of transferring the drug from the

reservoir to body tissue or blood vessel safely and

reliably. According to the different actuation

mechanism, micro-pumps can be divided into two

categories, namely mechanical micro-pumps and

non-mechanical micro-pumps.

In a mechanical micro-pump, actuators are

required to perform a pumping function. The

working mechanisms of mechanical micro-pumps

that show a potential application associated with

drug delivery systems are namely electrostatic

(Teymoori et al., 2005), piezoelectric (Junwu et al.,

2005), thermo-pneumatic (Hwang et al., 2005) and

shape memory alloy (SMA) (Guo et al., 2004).

Though mechanical micro-pumps provide a large

actuation, they require higher applied voltage and

consume more power causing large heat dissipation.

In contrast to mechanical pumps, non-mechanical

pumps do not need any reciprocating mechanical

component, the working principle of this kind

micro-pump is generally based on the conversion of

non-mechanical energy to kinetic momentum.

Moreover, non-mechanical micro-pumps usually

have neither moving parts nor complicated valves so

that the corresponding geometry design and

fabrication process are relatively simple. The

popular actuators that can be applied in non-

mechanical micro-pumps include osmotic-type (Su

et al., 2004) and electrochemical (Li et al., 2008 &

2010; Sheybani et al., 2012) categories. Osmotic-

type pump does not require any external power, but

its pumping force is extremely small and not

controllable. Therefore, osmotic pump is a suitable

option for those drug delivery applications of long-

term use with extremely low dosing requirements.

In contrast to those micro-pumps with the

traditional mechanisms, the electrolytic bubble

actuator has attracted a growing interest, particularly

in the field of drug delivery systems due to its easy

setup, low power consumption, miniaturized size,

simple operation, accurate delivery control and

adequate actuation force. In previously reported

electrolytic pumps for drug delivery (Li et al., 2008

& 2010), a liquid drug reservoir (LDR) approach has

been operated for high efficiencies, but requires

control of extremely small fluid volumes and

fabrication of complicated bellows. Recently, a solid

295

Yi Y., Buttner U., Arpys Carreno A. and G. Foulds I..

An Improved Electrolytic Pump for Potential Drug Delivery Applications.

DOI: 10.5220/0004943702950298

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2014), pages 295-298

ISBN: 978-989-758-013-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

drug in reservoir (SDR) approach was proposed

using magnetic actuation (Pirmoradi et al., 2011) to

pump fluid in and out of a reservoir that is filled

with a low solubility drug in solid form. This allows

for long term use because the reservoir can refill and

dissolve the next dose. This kind of micro-pump

shows a simplified structure but requires a strongly

aligned orientation and operates within short range.

Our proposed drug delivery system adopts the

simple structure of an SDR system and the

flexibility of an electrolytic pump system for

releasing the consistent drug. Moreover, improving

on our previous work (Yi et al., 2013), we further

introduce a platinum (Pt) coated nickel mesh into the

pumping chamber to achieve a higher recombination

rate, thereby reducing the pumping cycle time.

The rest of this paper is organized as follows;

Section 2 illustrates the prototype of the electrolytic

pump. Experimental setup and measurements are

evaluated in section 3. Conclusion is given in section

4.

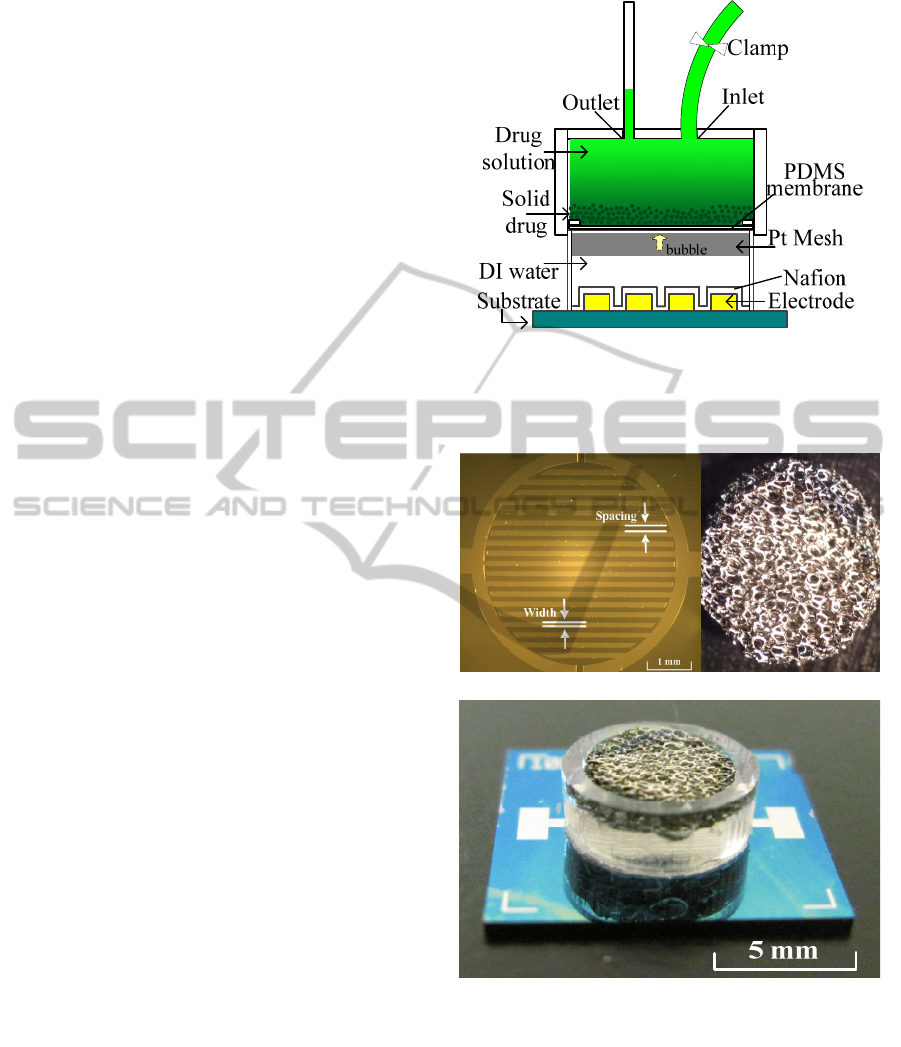

2 PUMP PROTOTYPE

This section illustrates a prototype of a drug delivery

system where the cyclical actuation is performed

using an electrolytic pump. Figure 1 illustrates a

cross sectional view of our initial prototype system.

For easy prototype testing, a cannula is replaced

by an inlet and outlet tube which can be

mechanically clamped. The major components of

our proposed electrolytic pump include: a flat PDMS

membrane, Pt electrode base and a Pt coated mesh.

The Pt electrode array was fabricated by a sputtering

technique and then patterned on a silicon wafer. The

corresponding design is shown in Figure 2 (a). The

dimensional parameters are 100 µm in width with

100µm spacing and a 400 nm height. Pt electrodes

are immersed in a deionized (DI) water filled

pumping chamber before assembling the other

components. Platinum was sputtered onto the

surface of a nickel mesh, forming a platinum coated

nickel mesh. Because the direction of sputtering is

vertical, the horizontal aspect of the nickel mesh was

not covered by platinum. When the Pt mesh was

immersed into the DI water, both platinum and

nickel were exposed to the electrolyte. The

corresponding micrograph of Pt mesh was shown in

Figure 2 (b). Figure 2 (c) illustrates the prototype of

pumping chamber. Nafion was coated onto the

platinum electrode to get a faster electrolysis-based

bubble generation rate (Sheybani et al., 2012). The

pumping chamber is separated from the drug

Figure 1: A cross-section view of the electrolytic pump

with major system components.

(a) (b)

(c)

(a) (b)

(c)

Figure 2: a) Micrograph of 400nm thick Pt electrode

layout showing element width and spacing of both 100μm.

b) Micro-scope of Pt-coated nickel mesh. c) Photograph of

pumping chamber with Pt mesh and Nafion coated

electrode.

reservoir by a PDMS membrane to avoid

electrochemical interaction with drug fluids. When

voltage is applied to the electrodes, electrolysis

reactions occur resulting in hydrogen (H

2

) and

oxygen (O

2

) bubble generation, the gas expansion

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

296

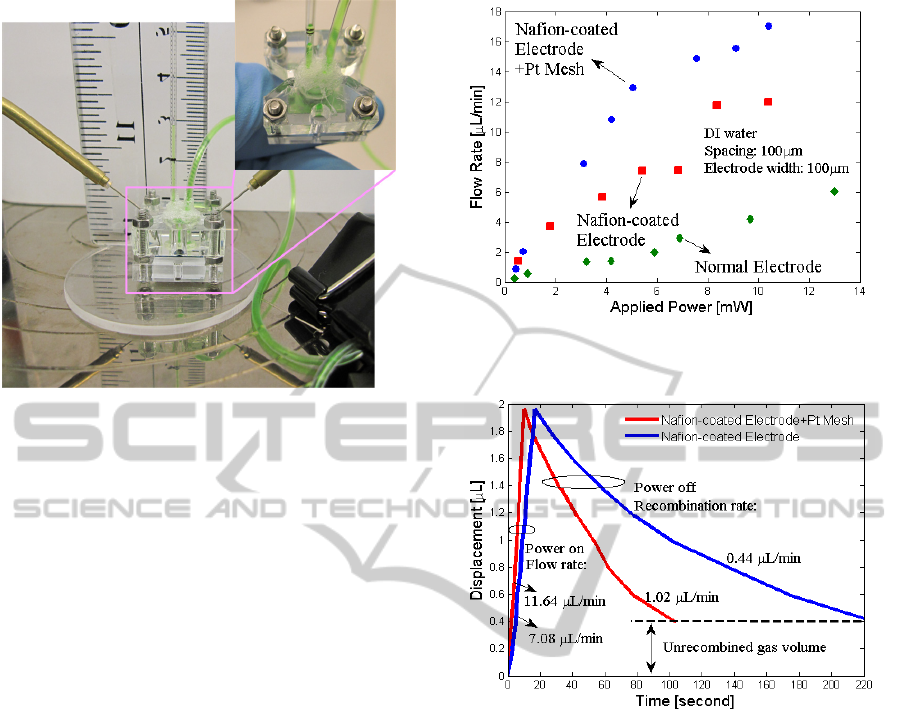

Figure 3: Photograph of the experimental setup and figure

of electrolytic pump.

pushes the membrane upwards to in turn push

dissolved drug solution out the cannula. Power is

applied until the desired volume of fluid is delivered,

after which the power is turned off and the pressure

in the electrolytic reservoir begins decreasing due to

the recombination of H

2

and O

2

. They rate of the

recombination is improved via the catalytic

properties of Pt, so that the membrane moves

downward drawing fresh fluids into the drug

reservoir to dissolve more of the remaining solid

drug. Power is turned on and off to the pump

periodically, so that the dissolved drug can be

delivered using this cyclical actuation.

3 EXPERIMENTAL RESULTS

Our proposed electrolytic pump was assembled and

measured using the test fixture as shown in Figure 3.

For easy prototype testing inlet tube is mechanically

clamped in order to accurately calculate the bubble

generation rate and recombination rate. The size of

the holder is 2 cm : 2cm : 2 cm (length : width :

height). In prospective drug delivery applications,

the pump could be permanently bonded allowing the

size of the structure to be significantly reduced. Two

probes are used to apply DC voltage to the

electrodes. A digital camera is placed in front of the

setup to record the displacement rate of the pump. In

the experiment, Nafion was uniformly spin-coated

onto electrodes because it is capable of preventing

bubble occlusion on the surface of the Pt electrode

and improving diffusion of gases away from the

catalyst surface (Maruyama et al., 1998).

Figure 4: Electrolytic pump flow rate vs. applied power

for with Pt-coated mesh and without Pt mesh.

Figure 5: Gas recombination rate comparisons for

electrolytic pumps with and without Pt mesh. Power of 4.6

mW was applied until the membrane achieved a maximum

displacement and then turned off.

Optimum electrode dimensions (Li et al., 2010) and

Nafion coating (Sheybani et al., 2012) had been

previously analyzed for achieving a higher pumping

efficiency, as shown in Figure 4. Based on the same

experimental conditions and electrodes, we added a

Pt mesh as shown in Figure 2 (b), and obtained a

higher flow rate than previous works (see Figure 4)

as well as a faster recombination rate (see Figure 5),

because Pt mesh increases the contact area between

the catalyst and electrolyte, improving catalytic

reactions.

Because the concentration of drug dose can be

kept stable during each delivery (Yi et al., 2013), a

faster bubble generation rate and recombination rate

that reduce each period of pumping allow delivering

a consistent and high drug volume within a short

pumping duration. Most importantly the Pt mesh

used in the electrolytic pump requires less power

AnImprovedElectrolyticPumpforPotentialDrugDeliveryApplications

297

(several mW) to achieve the same flow rate level

compared to the original electrolytic pump, which

makes the integration of wireless power transfer

techniques (Yi et al., 2013) and drug delivery

systems feasible.

4 CONCLUSIONS

This work presents a prototype electrolytic pump

that uses a Pt coated-nickel mesh in the pumping

chamber to improve the cycling time of an

electrolytic pump intended for a drug delivery

system. Using our catalytic reforming element, the

cyclical actuation of the drug delivery system

improved both in terms of the time of the

pump/recombination cycle, as well as the applied

power requirement, resulting in a faster and more

efficient drug delivery system.

REFERENCES

Nisar, A., Afzulpurkar, N., Mahaisavariya, B., &

Tuantranont, A. (2008). MEMS-based micropumps in

drug delivery and biomedical applications. Sensors

and Actuators B: Chemical, 130(2), 917-942.

Teymoori, M. M., & Abbaspour-Sani, E. (2005). Design

and simulation of a novel electrostatic peristaltic

micromachined pump for drug delivery applications.

Sensors and Actuators A: Physical, 117(2), 222-229.

Junwu, K., Zhigang, Y., Taijiang, P., Guangming, C., &

Boda, W. (2005). Design and test of a high-

performance piezoelectric micropump for drug

delivery. Sensors and Actuators A: Physical, 121(1),

156-161.

Hwang, S. R., Sim, W. Y., Kim, G. Y., Yang, S. S., &

Pak, J. J. (2005, May). Fabrication and test of a

submicroliter-level thermopneumatic micropump for

transdermal drug delivery. In Microtechnology in

Medicine and Biology, 2005. 3rd IEEE/EMBS Special

Topic Conference on (pp. 143-145). IEEE.

Guo, S., & Fukuda, T. (2004, April). SMA actuator-based

novel type of micropump for biomedical application.

In Robotics and Automation, 2004. Proceedings.

ICRA'04. 2004 IEEE International Conference on

(Vol. 2, pp. 1616-1621). IEEE.

Su, Y. C., & Lin, L. (2004). A water-powered micro drug

delivery system. Microelectromechanical Systems,

Journal of, 13(1), 75-82.

Li, P. Y., Shih, J., Lo, R., Saati, S., Agrawal, R.,

Humayun, M. S., ... & Meng, E. (2008). An

electrochemical intraocular drug delivery device.

Sensors and Actuators A: Physical, 143(1), 41-48.

Li, P. Y., Sheybani, R., Gutierrez, C. A., Kuo, J. T., &

Meng, E. (2010). A Parylene bellows electrochemical

actuator. Microelectromechanical Systems, Journal of,

19(1), 215-228.

Sheybani, R., & Meng, E. (2012). High-Efficiency MEMS

Electrochemical Actuators and Electrochemical

Impedance Spectroscopy Characterization.

Pirmoradi, F. N., Jackson, J. K., Burt, H. M., & Chiao, M.

(2011). A magnetically controlled MEMS device for

drug delivery: design, fabrication, and testing. Lab on

a Chip, 11(18), 3072-3080.

Yi, Y., Buttner, U., & Foulds, I. G. (2013, October).

TOWARDS AN IMPLANTABLE PULSED MODE

ELECTROLYTIC DRUG DELIVERY SYSTEM. In

Proc. Micro Total Analysis Systems.

Maruyama, J., Inaba, M., Katakura, K., Ogumi, Z., &

Takehara, Z. I. (1998). Influence of Nafion® film on

the kinetics of anodic hydrogen oxidation. Journal of

Electroanalytical Chemistry, 447(1), 201-209.

Yi, Y., Buttner, U., Fan, Y., & Foulds, I. G. (2013, May).

3-Coil resonance-based wireless power transfer system

for implantable electronic. In Wireless Power Transfer

(WPT), 2013 IEEE (pp. 230-233). IEEE.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

298