Analytical Model of SSD Parallelism

Jinsoo Yoo

1

, Youjip Won

1

, Sooyong Kang

1

, Jongmoo Choi

2

, Sungroh Yoon

3

and Jaehyuk Cha

1

1

Department of Computer and Software, Hanyang University, Seoul, Korea

2

Dankook University, Yongin, Korea

3

Seoul National University, Seoul, Korea

Keywords:

Flash, SSD, Parallelism, Simulation, Modeling.

Abstract:

SSDs support various IO parallel mechanisms such as channel parallelism, way parallelism, and plane par-

allelism to increase IO performance. To measure an SSD’s performance in a simulation environment, the

simulator has to support the parallel IO operations of an SSD by modeling its internal IO behaviors. In this pa-

per, we developed an analytical model to calculate the IO latency of multi-channel and multi-way architected

SSDs. In formulating the IO latency model, we categorized SSDs’ IO types into two operations: single page

read/write operations and multiple page read/write operations. With the IO latency model, we can calculate

the IO performance of a real SSD, Intel X25-M, with a 3.8% offset.

1 INTRODUCTION

NAND flash based storage, such as an SSD, made its

way to main storage device in all types of comput-

ing devices, e.g., smartphones, TVs, PCs, and servers

(Wong, 2013). An SSD is a complex device consist-

ing of flash chips, micro-controller, e.g., ARM, mem-

ory, which is DRAM or SRAM, and host interface,

e.g., SATA or PCIe. The software component of an

SSD is called Flash Translation Layer (FTL). It is

responsible for (i) translating a logical address into

physical address, (ii) evenly distributing the wear-

outs, and (iii) consolidating the invalid pages. In de-

signing an SSD, it is very important that all design

parameters, e.g., the number of channels, the number

of ways, physical page size, address translation algo-

rithms, garbage collection algorithms, etc., are deter-

mined, properly incorporating the interactions among

these components and the SSDs’ workload character-

istics (or target usage).

There exist a number of approaches in predict-

ing the behavior of an SSD under various design pa-

rameters: analytical formulation (Desnoyers, 2012),

trace driven simulation (Agrawal et al., 2008), (Kim

et al., 2009), (Cho et al., 2012), virtual machine based

simulation (Yoo et al., 2013), and FPGA based pro-

totyping (OpenSSD, 2011), (Lee et al., 2010). An-

alytical formulation (Desnoyers, 2012) is most flex-

ible, but it is the least accurate way of predicting

the performance of an SSD. FPGA based prototyp-

ing (OpenSSD, 2011) (Lee et al., 2010) is the most

expensive and inflexible way of predicting the perfor-

mance. However, it enables users to closely examine

the real time behavior of a given FTL algorithm and

its performance implications.

Virtual machine based simulation (Yoo et al.,

2013) provides the benefits of both methods. The

hardware configurations, e.g., the number of chan-

nels/ways and DRAM size, and software algorithms,

e.g., address mapping and garbage collection algo-

rithm, can be changed in a versatile manner. It also

enables users to examine the host performance with

reasonable accuracy. VSSIM emulates the real time

performance of an SSD (X-25M) within a 5% error

rate (Yoo et al., 2013).

A key technical ingredient is how to introduce the

proper I/O latency in an “algorithmic way. An SSD

consists of a number of physical components, e.g.,

NAND chips, bus, micro-controllers. These compo-

nents work independently (or in a synchronized man-

ner) which yields multiple concurrent activities in the

device. A latency of an I/O request is governed by

the concurrent processing of this I/O request among

a number of SSD components. This work focuses on

developing an efficient way of modeling the concur-

rent behavior of SSD components. Instead of emu-

lating the individual components, e.g., NAND flash

chips, as a thread, we developed an elaborate delay

model to compute the latency for a given IO com-

mand. The proposed delay model enables us to emu-

551

Yoo J., Won Y., Kang S., Choi J., Yoon S. and Cha J..

Analytical Model of SSD Parallelism.

DOI: 10.5220/0005011605510559

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 551-559

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

late the parallel behaviors of SSD components with-

out modeling each component with a thread.

By allocating a thread to each individual compo-

nent, we can easily model the concurrent behaviors

and their interactions with other SSD components.

However, the lock contentions and the context switch

overheads can become significant and can negatively

affect the emulator accuracy. For example, to emulate

Intel X25-M SSD (Intel, 2009), which has 10 chan-

nels and 2 ways, there can be as many as 30 threads

to model 20 flash planes and 10 channels of X25-M.

In this work, we developed an analytical model

that calculates IO delays in multi-channel/multi-way

SSDs. The proposed delay model precisely computes

the latency of a read (or write) request which is ser-

viced by multiple NAND flash chips across the chan-

nels and ways. This model enables an emulator to

emulate the parallel behavior of SSD components us-

ing a single thread. For example, when receiving an

IO request, the thread calculates IO latency with our

latency model and imposes a proper amount of delay

using busy waiting method. This way, a single thread

IO emulator can be implemented without a multi-

threaded method. When we compared the result of

our IO latency model with a real SSD, Intel X25-M,

the IO latency model showed less than a 3.8% error

rate.

2 BACKGROUND

I/O Buffer

DRAM

Enqueue

Dequeue

Data

Command

Channel 0 Channel 1

Channel 3

NAND

Flash

NAND

Flash

NAND

Flash

NAND

Flash

NAND

Flash

NAND

Flash

NAND

Flash

NAND

Flash

Channel 2

Host Interface (SATA, PCIe)

Flash

Memories

%QOOCPFSWGWG

CPU

Firmware

(NCUJEQPVTQNNGT

Figure 1: Organization of an SSD (4 channels, 2 ways).

Figure 1 shows the internal block diagram of an SSD

with 4 channels and 2 ways. Through host interface

(SATA, PCIe, etc.), the SSD receives IO commands

which include the starting sector number (512Byte

per a sector) and the sector length. The IO request

from the host is enqueued in the command queue and

the accompanying data is stored in the device buffer.

This device buffer is often called the write buffer

(Kim and Ahn, 2008). The firmware of the SSD lo-

cates the NAND flash blocks to where the incoming

IO request is directed and issues an IO command to

the respective NAND controllers.

Block 0

Block 4094

ㄾ

Page Register

Block 1

Block 4095

ㄾ

Page Register

Block 4096

Block 8190

ㄾ

Page Register

Block 4097

Block 8191

ㄾ

Page Register

Block 2

Block 3 Block 4098 Block 4099

Page 0

Page 1

ㄾ

Page n

Page 0

Page 1

ㄾ

Page n

Page 0

Page 1

ㄾ

Page n

Page 0

Page 1

ㄾ

Page n

Plane 0 Plane 1 Plane 2 Plane 3

Figure 2: Internal Architecture of NAND Flash Memory

(Samsung, 2006).

Flash Memory Read and Write: Figure 2 shows the

internal architecture of Samsung NAND flash mem-

ory (Samsung, 2006). Flash memory consists of mul-

tiple pages and each page is 2 ∼ 8KByte in size. Flash

memory conducts erase operations in units called a

block which consists of multiple pages. The set of

blocks that use the same register to transfer data is

called a plane. In a write operation, flash controller

writes data to a register. After the register write is

done, the data in the register is programmed in a free

page in flash memory. Read operations are processed

in the opposite direction of write operations. In a read

operation, flash memory reads data from a flash page

and writes it to a register. When it is completed, the

flash controller takes the data through a channel.

SSDs exploit various levels of IO parallelism,

such as plane parallelism, channel parallelism, and

way parallelism, to boost up the I/O performance and

to hide latency of flash write and read operations.

Reg Write Cell Programming

Cell ProgrammingIdle

Idle

PLANE 0

PLANE 1

time

Reg Write

Figure 3: Plane Parallelism Timing Diagram.

Plane Parallelism: The internal IO behavior of flash

memory can be implemented in parallel by using mul-

tiple registers at the same time. In Figure 2, flash

memory can process 2-page IOs in parallel. After

sending data to a register in Plane 0, the flash con-

troller transfers second data to a register in Plane 1.

As the registers share the same channel, the flash con-

troller cannot access the two registers at the same

time. After each data transfer from the flash controller

to a register is completed, each plane starts program-

ming the data in a free page in each plane. Since the

data transfer time between the flash controller and a

register (82usec for Samsung NAND flash (Samsung,

2006)) is much shorter than the programming time

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

552

of the flash page (900usec for Samsung NAND flash

(Samsung, 2006)), the two-page programming opera-

tion can be conducted in parallel. This is called ‘plane

parallelism’. Figure 3 shows the timing diagram of

plane parallelism. Plane parallelism can also be used

for read operations.

Channel 0

Flash 0

Page A

Flash 2

Channel 1

Flash 1

Page B

Flash 3

Flash controller

(a) Channel Parallelism

Channel 0

Flash 0

Page A

Flash 2

Page B

Channel 1

Flash 1

Flash 3

Flash controller

(b) Way Parallelism

Figure 4: Channel and Way Parallelism of an SSD .

Reg Write Cell Programming

Cell Programming

Flash 0

Flash 1

time

Reg WriteCh

Idle

Figure 5: Channel Parallelism Timing Diagram.

Channel Parallelism: Using several channels, the

flash controller concurrently processes multiple IOs.

This is called ‘channel parallelism’. For example,

Figure 4(a) shows the connection between flash mem-

ories and the flash controller in 2 channels, 2 ways

SSD. Because Flash 0 and Flash 1 are used by differ-

ent channels, Page A and Page B can each be written

in different flash memories using channel parallelism.

The timing diagram of the 2-page write operation is

shown in Figure 5. Before the flash controller writes

data to Flash 1, channel switching delay, denoted as

Ch, occurs. Because channel switching delay is suf-

ficiently short (33usec (Yoo et al., 2011)), the flash

controller can write the pages to each flash memory

at about the same time.

Reg Write Cell Programming

Cell Programming

Flash 0

Flash 2

time

Reg WriteWayIdle

Idle

Figure 6: Way Parallelism Timing Diagram.

Way Parallelism: Flash memories in the same chan-

nel can process IOs in parallel. This is called ‘way

parallelism’. In Figure 4(b), the flash controller can

utilize way parallelism using Flash 0 and 2 in Channel

0. Because the flash memories share the same chan-

nel, a flash memory in the channel can transfer data

with flash controller only if the channel is not occu-

pied by another flash memory operation. The timing

diagram of way parallelism is shown in Figure 6. As

both Flash 0 and Flash 2 use Channel 0, the flash con-

troller can implement Page B operation after the end

of the register write operation of Page A. Before the

start of Page B operation, way switching delay(Way)

occurs because Flash 0 and Flash 2 are connected to

different ways. After way switching delay, the flash

controller transfers Page B data to Flash 2 and then

Flash 2 starts page write operation.

By using these kinds of IO parallel methods, SSDs

achieve higher IO bandwidth.

3 MODELING THE LATENCY

In this section, we developed IO latency models for

SSDs that are structured multi channels and multi

ways. When developing an IO latency model, we

haveto consider concurrent IO processing of the SSD.

First, we describe the single page IO latency model.

Then, we expand the model to the multiple page IO

latency model. We define the term IO latency as the

time interval between the arrival of the IO command

from the host to the device and the time when the I/O

device sends the IO interrupt notifying the completion

of an IO command. Terms used in each IO latency

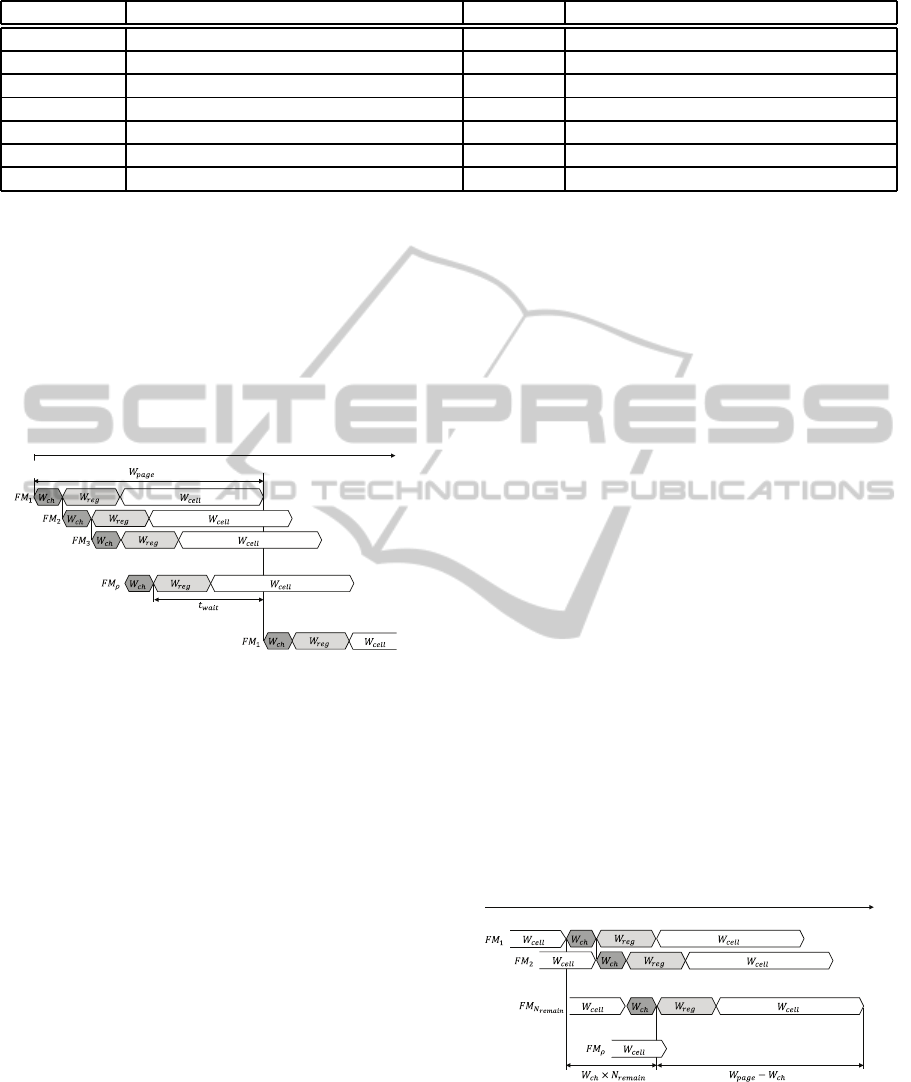

model are listed in Table 1.

3.1 Modeling Single Page Write/Read

For a write operation, IO latency varies widely de-

pending on when the device sends completion inter-

rupt. The device can send completion interrupt ei-

ther when the incoming data is written at device write

buffer or when data is stored at NAND flash. In the

former case, the write latency is governed by the in-

terface speed and the amount of data to be written.

In this work, we focus on the latter case, when the

host requests the data to be written to the storage me-

dia, e.g., with “O

DIRECT option”. From the defini-

tion, single page write latency of an SSD can be rep-

resented by Eq. 1. That is, the total page write time

(W

page

) is a summation of 3 processing times: chan-

nel switching delay(W

ch

), data transfer delay between

a flash controller and a flash memory register(W

reg

),

and data programming delay in a free page in a flash

memory (W

cell

).

W

page

= W

ch

+W

reg

+W

cell

(1)

We also define the read latency as the time from

the arrival of the read command to the SSD to the

time when the SSD sends the IO completion inter-

rupt to the host. Then, using Eq. 1, we can get the

single read latency model as Eq. 2. Single page read

AnalyticalModelofSSDParallelism

553

Represent Description Represent Description

S

page

Page size N

plane

The number of planes per flash

W

ch

/ R

ch

Channel switching delay for write / read ρ The maximum number of IOs per cycle

W

reg

/ R

reg

Register write / read delay S

file

File size

W

cell

/ R

cell

NAND write / read delay S

record

Record size

W

page

/ R

page

1 Page write / read delay N

page

The number of pages per record

N

ch

The number of channels N

cycle

The number of cycles per record

N

way

The number of ways N

remain

The number of IOs in the last IO cycle

Table 1: Parameters in the SSD IO Performance Modeling.

latency(R

page

) is the aggregation of channel switching

delay(R

ch

), NAND page read delay(R

cell

), and regis-

ter read delay(R

reg

).

R

page

= R

ch

+ R

reg

+ R

cell

(2)

3.2 Write Operations

ㄾ

Cycle 1

Cycle 2

time

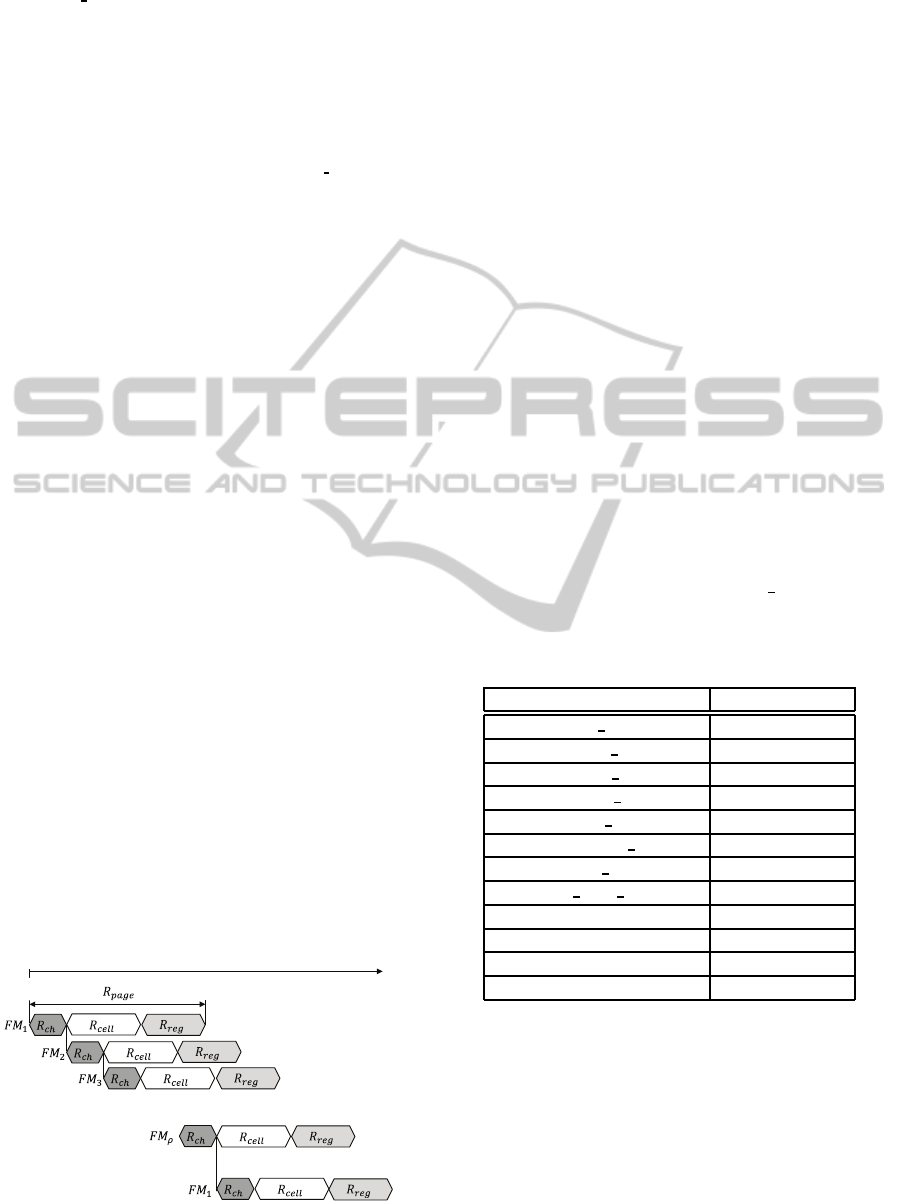

Figure 7: Sequential Write Timing Diagram.

A host request can include more than a one page I/O

request. For example, when a 512KByte SATA write

command is received, an SSD with 4KByte page

size operates 128 page writes. When multiple page

write requests are received, a multi-channel/multi-

way structured SSD concurrently processes the oper-

ations by utilizing IO parallelism. Figure 7 illustrates

a timing diagram of each flash memory behavior in

processing multiple page write requests.

When an SSD uses channel parallelism, way par-

allelism, and plane parallelism, we denote the maxi-

mum number of pages that can be processed in par-

allel at the same time as ρ. In other words, an SSD

can process ρ page writes in a one cycle. In each

cycle, a flash memory which deals with 1 ∼ ρ page

IOs is denoted as FM

1

∼ FM

ρ

. First, the flash con-

troller sends a page write request to FM

1

and channel

switching delay W

ch

is imposed. After that, a regis-

ter write delay (W

reg

) occurs followed by NAND page

write delay (W

cell

). The summation of these opera-

tion times is a one page write time of the SSD and is

denoted as W

page

. After channel switching delay for

FM

1

has occurred, the flash controller writes data to

the register in FM

1

while sending another page write

request to FM

2

. Before data is written to FM

2

, chan-

nel switching delay also occurs. This is because FM

1

and FM

2

are used in different channels. In the same

way, after channel switching delay for FM

2

has oc-

curred, the flash controller sends another page write

request to the next flash memory. The flash controller

repeats this process until it sends a page write request

to FM

ρ

. Figure 7 shows the start of the second cycle

after the first cycle is done. To start the first write op-

eration of second cycle at FM

1

, the write operation of

FM

1

should be completed. The waiting time of the

second cycle before starting the first page write op-

eration is denoted as t

wait

which is formulated as Eq.

3.

t

wait

=

W

page

−W

ch

× ρ if W

page

> W

ch

× ρ

0 otherwise

(3)

If the single page writing time(W

page

) is suffi-

ciently short, ‘t

wait

’ becomes 0 and the second cycle

can start its first page write operation without waiting.

The processing time for a cycle is the time from

the start of first page write of a cycle to the start of

first page write of the next cycle. It is denoted as t

cycle

and can be calculated as Eq. 4.

t

cycle

= W

ch

× ρ+ t

wait

(4)

ㄾ

Cycle n

time

ㄾ

Figure 8: Sequential Write Timing Diagram (2).

Timing diagram of the last cycle n is shown in Fig-

ure 8. In some cases, the number of IOs conducted in

the last cycle can be less than ρ and then is denoted as

N

remain

. From Figure 8, we can easily get the process-

ing time of the last cycle as follows:

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

554

t

cycle

last

= W

ch

× (N

remain

− 1) +W

page

(5)

Using Eq. 5, we can calculate t

record

, which repre-

sents the processing time of a host write request. For

a write request, the number of cycles that an SSD has

to repeat is denoted as N

cycle

. Then, t

record

is calcu-

lated as follows:

t

record

= t

cycle

× (N

cycle

− 1) +t

cycle

last

= (W

ch

× ρ+ t

wait

) × (N

cycle

− 1)

+W

ch

× (N

remain

− 1) +W

page

= W

ch

× (ρ× (N

cycle

− 1) + N

remain

− 1)

+t

wait

× (N

cycle

− 1) +W

page

Because ‘ρ × (N

cycle

− 1) + N

remain

’ equals the to-

tal number of pages in a record, N

page

, we can get the

write latency model, t

record

, as follows:

t

record

= W

ch

× (N

page

− 1) + t

wait

× (N

cycle

− 1) +W

page

(6)

3.3 Read Operations

We can define the read latency model as the same way

we did for the write latency model. Using Eq. 6, the

read latency model can be formulated as Eq. 7.

t

record

= R

ch

× (N

page

− 1) + t

wait

× (N

cycle

− 1) + R

page (7)

In some cases, Eq. 7 can be further simplified.

Figure 9 shows such a case. An important feature in

this case is that there is no waiting time (t

wait

) when

a cycle changes. This results from the NAND read

operation being much faster than the NAND write

operation (50usec for a read operation vs. 900usec

for a write operation in Samsung NAND flash (Sam-

sung, 2006)). In this case, ‘t

wait

’ in Eq. 7 becomes 0

and the read latency model is simplified as ‘t

record

=

R

ch

× (N

page

− 1) + R

page

’.

ㄾ

Cycle 1

Cycle 2

time

Figure 9: Sequential Read Timing Diagram.

4 EXPERIMENT

In this section, we validate the accuracy of the IO la-

tency models with a real SSD, Intel X25-M. Using

analytical models, we calculated the IO performance

of an SSD that is configured the same way as X25-M

under various workloads. Then, we measured the IO

performance of X25-M performing the same work-

loads and compared both results. Next, we compared

the theoretical performance with VSSIM SSD simu-

lator (Yoo et al., 2013). From this experiment, we are

assured that the IO latency models can be used in VS-

SIM as an IO emulator module.

4.1 Validation with X25-M

To validate the single page IO latency model (Eq. 1,

Eq.2) and write/read latency model (Eq. 6, Eq. 7),

we compared the theoretical performance from the la-

tency models with the measured performance of X25-

M. Table 2 shows the SSD configurations of X25-M.

The performance of the NAND flash memory used in

X25-M is described in Table 3. For X25-M, chan-

nel switching delay for read operation is 16usec (Yoo

et al., 2011) and channel switching delay for write op-

eration is 33usec (Yoo et al., 2011). When writing or

reading data with X25-M, we used O

DIRECT op-

tion and opened X25-M as a raw device to minimize

the filesystem interference and to measure the NAND

page write/read IO latency of the SSD.

Parameter Value

PAGE SIZE 4 KByte

SECTOR SIZE 512 Byte

FLASH NB 20

BLOCK NB 4096 blocks

PAGE NB 256 pages

CHANNEL NB 10

WAY NB 2

PLANE PER FLASH 2

Sequential Read 250 MByte/sec

Sequential Write 70 MByte/sec

Sequential 4KByte Read 35,000 IOPS

Sequential 4KByte Write 6,600 IOPS

Table 2: Intel X25-M SSD Specifications.

We compared the result of single page write/read

latency model with the IO performance of X25-M.

The workload consisted of writing (or reading) a

512MByte file with page size in a random offset. For

calculating single page IO performance, we used Eq.

1 for single page write latency and Eq. 2 for sin-

gle page read latency. In calculating analytical per-

formance, we adjusted NAND programming delay

AnalyticalModelofSSDParallelism

555

REG WRITE DELAY 82 usec

REG READ DELAY 82 usec

CELL PROGRAM DELAY 900 usec

CELL READ DELAY 50 usec

BLOCK ERASE DELAY 2000 usec

Table 3: NAND Flash Memory Specifications Used in Intel

X25-M (29F32G08CAMC1).

(W

cell

, 900usec) and NAND read delay (R

cell

, 50usec)

to 940usec and 140usec, respectively, to account for

the performance degrade of X25-M used in the exper-

iment which become worn out by intensive IO tests

(Dijkstra, 1982). Table 4 shows the theoretical per-

formance of the single page IO latency model and the

measured performance of X25-M. The error rates of

single page latency model were 0.5% and 1.0% for

write and read operations, respectively.

Workload Delay Model X25-M Error

Write 947.9 IOPS 944.6 IOPS 0.5%

Read 4201.7 IOPS 4158.0 IOPS 1.0%

Table 4: Single Page Write/Read Latency Model Validation

with X25-M (Filesize 512MByte, Record size 4KByte, raw

device, O

DIRECT).

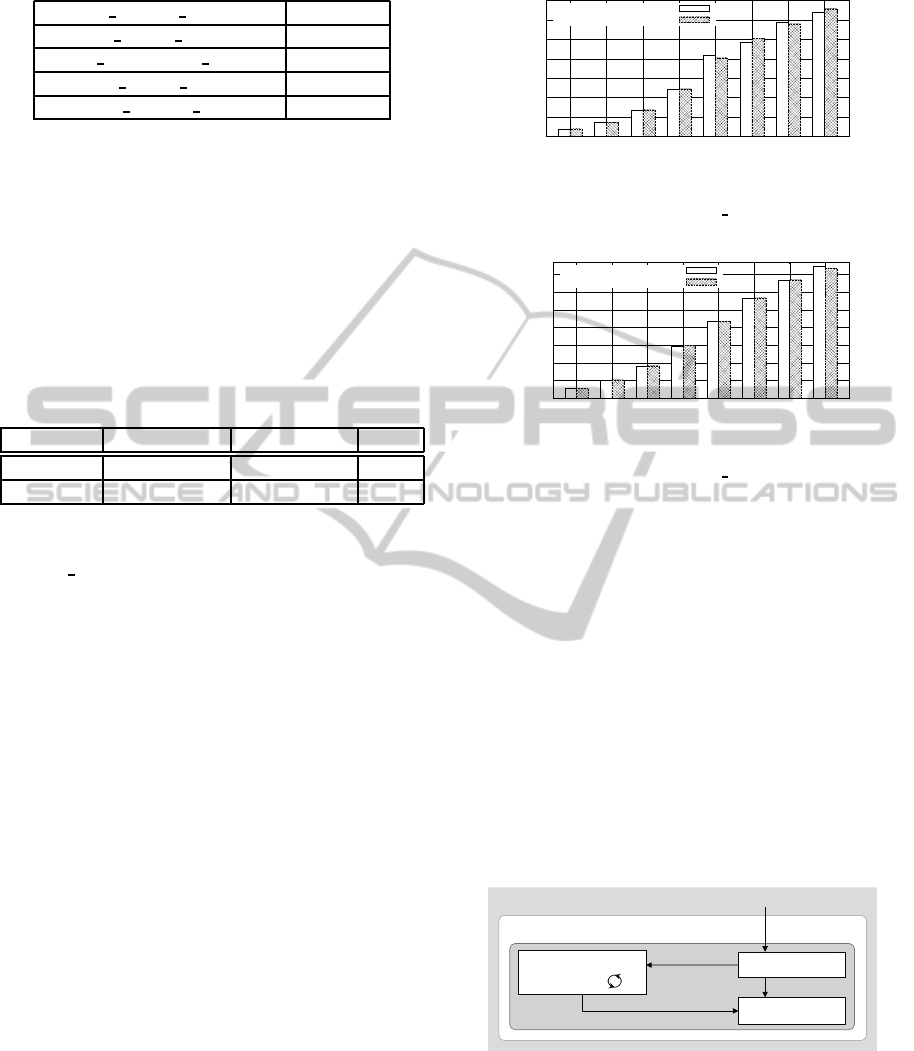

Using write workloads that cause multiple page

write requests, we validated the accuracy of the write

latency model (Eq. 6). The workloads consisted

of writing a 512MByte file sequentially with record

sizes of 512KByte, 256KByte, 128KByte, 64KByte,

32KByte, 16KByte, 8KByte, and 4KByte. In Eq. 6,

we adjusted NAND programming delay, W

cell

, from

900usec to 940usec to account for the wear level of

the actual X25-M used in the experiment. Figure

10 shows the performances based on the write la-

tency model versus actual X25-M. The predicted re-

sults from our model differed from the actual results

by 4%.

The read latency model showed more accurate

results than the write latency model. To validate

the read latency model, 8 sequential read work-

loads were performed: the workloads consisted of

reading a 512Mbyte file sequentially with record

sizes of 512KByte, 256KByte, 128KByte, 64KByte,

32KByte, 16KByte, 8KByte, and 4KByte. In cal-

culating the theoretical performance with Eq. 7, we

adjusted NAND read delay, R

cell

, from 50usec to

140usec to account for the performance degrade level

of the actual X25-M used in the experiment. Figure

11 shows the results. For sequential read workloads,

the difference between our models calculations and

the actual results were within 1.3%.

From the validation results with X25-M, we con-

0

10

20

30

40

50

60

4 8 16 32 64 128 256 512

Bandwidth(MB/s)

Record Size(KByte)

Intel X25-M

Write Latency Model

Figure 10: Write Latency Model Validation with X25-M

(Filesize 512MByte, raw device, O

DIRECT).

0

30

60

90

120

150

180

210

4 8 16 32 64 128 256 512

Bandwidth(MB/s)

Record Size(KByte)

Intel X25-M

Write Latency Model

Figure 11: Read Latency Model Validation with X25-M

(Filesize 512MByte, raw device, O

DIRECT).

firmed that the read/write latency models precisely

describe the parallel IO processing of an SSD.

4.2 Validation with VSSIM

We compared the IO performance from IO latency

models with that from VSSIM SSD Simulator (Yoo

et al., 2013) using the same SSD configurations.

Thereby, we confirmed that our IO latency model can

be used as an IO emulator in an SSD simulator. VS-

SIM is a virtual machine based SSD simulator which

can measure the host performance operating on top

of the simulator. With VSSIM, a user can specify a

virtual SSD which processes IO requests based on its

configurations.

IO Emulator Module

(IO Latency )

FTL Module

SSD Monitor

page read/write

erase

Performance Information

read/write

SSD Module

IO Information

SATA Command from Host

QEMU

Figure 12: VSSIM SSD Module Architecture.

VSSIM consists of QEMU, SSD module, and

RAMDISK. A guest OS installed on QEMU regards

the RAMDISK allocated in main memory as an SSD.

The architecture of VSSIM SSD module is shown in

Figure 12. SSD module is composed of FTL module,

IO emulator module, and SSD monitor. FTL module

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

556

maintains mapping information between logical page

address and physical page address. IO emulator man-

ages IO behavior of SSDs by generating IO latency.

SSD monitor shows the SSD performance informa-

tion to users by graphic user interface.

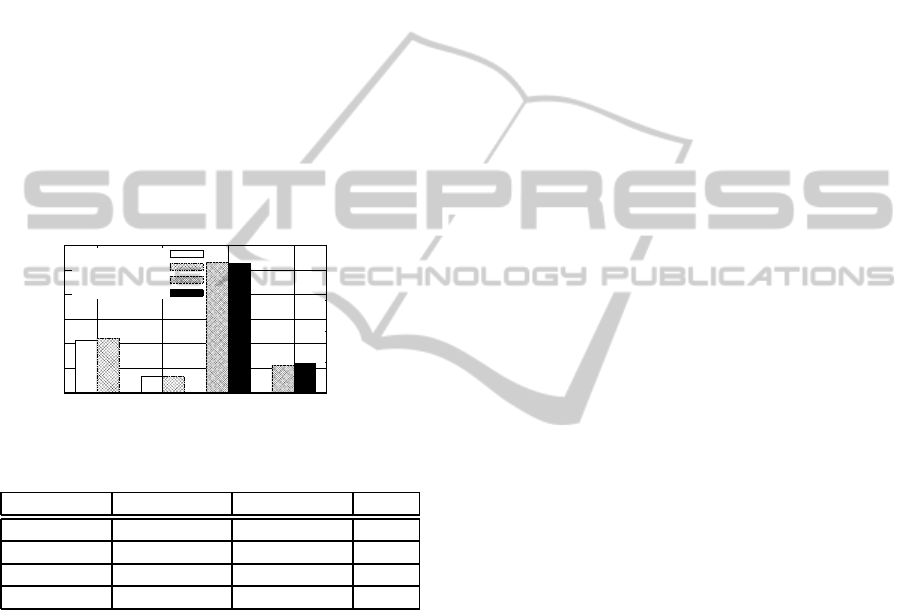

For validating IO latency models with VSSIM,

we used 4 workloads: sequential write/read and ran-

dom write/read. For sequential IO workloads, we

wrote and read a 512Mbyte file sequentially with a

512Kbyte record size. For random IO workloads, we

wrote and read a 512Mbyte file in random offset with

a 4KByte page size. The virtual SSD in VSSIM was

configured the same way as X25-M specifications.

The same configurations were also used in IO latency

models. Linux guest OS is installed on VSSIM and

the IO performance is checked on the Linux. The

performance results from VSSIM and the IO latency

models on the 4 workloads are shown in Figure 13

and Table 5.

0

100

200

300

400

500

Seq Read

Seq Write

Rand Read

Rand Write

0

1000

2000

3000

4000

Bandwidth(MB/s)

IOPS

VSSIM (Seq)

IO Model (Seq)

VSSIM (Rand)

IO Model (Rand)

Figure 13: IO Latency Model Validation with VSSIM.

VSSIM IO Model Error

Seq Read 211.9 MB/s 220.3 MB/s 4.0 %

Seq Write 67.3 MB/s 65.7 MB/s 2.4 %

Rand Read 4235.1 IOPS 4201.7 IOPS 0.8 %

Rand Write 880.6 IOPS 947.9 IOPS 7.6 %

Table 5: IO Latency Model Validation with VSSIM.

Compared with VSSIM, the IO latency models

showed sequential read and write performances with

4.0% and 2.4% offset, respectively, and random read

and write performances with 0.8% and 7.6% offsets,

respectively. From the validation results, we con-

firmed that the IO latency models can be used in IO

emulator to impose proper amount of delay.

5 RELATED WORK

Analytic modeling of write performance (Desnoyers,

2012) provides block cleaning performance in terms

of the Write Amplification Factor (WAF): the ratio

between the number of page writes from the host to

the number of page writes that happen in an SSD. Al-

though this work provides a precise closed-form solu-

tion for the block cleaning performance for LRU and

greedy collection algorithm, it cannot be used to pre-

dict the IO latency of SSDs.

There has been much research on simulating the

performance of SSDs or flash memory. One of

the SSD simulators is NANDFlashSim (Jung et al.,

2012). NANDFlashSim simulates a single flash mem-

ory and can configure a page size, IO latency, the

number of dies in a flash memory, and the number

of planes. It supports various IO modes such as cache

mode, internal data move mode, multi-plane mode,

and interleaved mode. NANDFlashSim uses local

clock domain, and all flash memories are synchro-

nized with it. At every clock, NANDFlashSim checks

the progress of each flash memory and changes its

state. Because NANDFlashSim only simulates flash

memory, it cannot measure the performance of SSDs

using channel, way, and plane parallelism.

CPS-SIM (Lee et al., 2009) can simulate SSDs

that use channel parallelism. Similar to NANDFlash-

Sim, CPS-SIM is a clock-driven simulator, which

synchronizes its state machine with local clock. For

IO processing, each flash memory is managed by

a finite state machine. CPS-SIM checks each flash

memory for the completion of IOs and changes its

state. For higher accuracy of the simulation result,

clock-driven simulators have to use higher clock fre-

quency. At the same time, clock driven simulators

need enough clock intervals to check and change the

state of every flash memory. These conflicting needs

make it difficult for clock-driven simulators to guar-

antee the accuracy of their simulation results.

There are simulators that provide a virtual

flash device in a main memory, such as NAND-

Sim (NANDSim, 2008) and Flash Disk Simulator

(El Maghraoui et al., 2010). A host uses virtual de-

vices as a primitive flash memory or as a block de-

vice. This enables us to check the performance of

the host, which operates on top of the virtual de-

vices. However, the simulators only simulate a flash

memory. Thus, we cannot get IO performance of an

SSD, which utilizes multi-channel and multi-way par-

allelism. Flash-DBSim (Jin et al., 2009) also provides

a virtual flash device to upper layer. Flash-DBSim

creates a virtual flash disk in memory which is man-

aged by MTD (Memory Technology Device) module.

MTD Module supports interfaces for Flash Trans-

lation Layer (FTL) to manipulate the virtual flash

disk. Unlike NANDSim, Flash-DBSim uses a trace

as workload. Because Flash-DBSim only simulates

a flash memory, it cannot test various IO parallelism

supported in an SSD.

AnalyticalModelofSSDParallelism

557

Trace driven SSD simulator is also widely used

to examine the internal behavior of SSDs. DISKSim

SSD Extension (Agrawal et al., 2008) and Flashsim

(Kim et al., 2009) are developed to simulate an SSD

based on DiskSim (Bucy et al., 2008). With these

simulators, users can configure the number of flash

memories, the number of planes per flash memory, the

page read/write latency, a page size, a block size, etc.

However, these simulators calculate the SSD perfor-

mance without imposing IO processing delay, which

means that they cannot be used to observe the host IO

performance in real time.

6 CONCLUSION

In this work, we developed an analytical model that

calculates the IO latency of an SSD. For modeling, we

considered concurrent IO processing of an SSD, such

as channel parallelism, way parallelism, and plane

parallelism. We classified SSDs’ IO types into single

page read/write request or multiple page read/write

request and developed IO latency model for each IO

type. Compared with the performance of a real SSD,

Intel X25-M, the latency models showed less than a

4% error rate in various workloads. We also proved

that the IO latency models can be used in an SSD

simulator by validating their results with VSSIM. The

IO performances calculated by our analytical models

were close to the simulation results of VSSIM with

a 0.8% ∼ 7.6% offset. Using the IO latency models,

SSD simulators can calculate and impose the desired

amount of IO latency for an IO request. Thus, the

simulator can simulate the IO performance of multi-

channel and multi-way SSDs without using multi-

threaded methods.

ACKNOWLEDGEMENTS

MLC SSD: This work is sponsored by IT R&D pro-

gram MKE/KEIT. [No.10035202, Large Scale hyper-

MLC SSD Technology Development].

REFERENCES

Agrawal, N., Prabhakaran, V., Wobber, T., Davis, J. D.,

Manasse, M., and Panigrahy, R. (2008). Design trade-

offs for SSD performance. In Proc. of Annual Techni-

cal Conference(ATC), USENIX, pages 57–70, Boston,

Massachusetts, USA.

Bucy, J. S., Schindler, J., Schlosser, S. W., and Ganger,

G. R. (2008). The disksim simulation environment

version 4.0 reference manual (cmu-pdl-08-101). Par-

allel Data Laboratory.

Cho, S., Won, Y., Kang, S., Cha, J., Choi, J., and Yoon,

S. (2012). Influence of number of channels and ftl

on ssd power consumption. In Proc. of International

Conference of Electrical, Computer, Electronics and

Biomedical Engineering (ICECEBE), Bangkok, Thai-

land.

Desnoyers, P. (2012). Analytic modeling of ssd write per-

formance. In Proc. of the Annual International Sys-

tems and Storage Conference(SYSTOR), ACM, Haifa,

Israel.

Dijkstra, E. W. (1982). Stepwise program construction.

Springer.

El Maghraoui, K., Kandiraju, G., Jann, J., and Pattnaik,

P. (2010). Modeling and simulating flash based

solid-state disks for operating systems. In Proc. of

WOSP/SIPEW, pages 15–26, San Jose, California,

USA.

Intel, C. (2009). Intel x25-m sata solid-state drive.

Specification. http://download.intel.com/design/

flash/nand/mainstream/mainstream-sata-ssd-

datasheet.pdf.

Jin, P., Su, X., Li, Z., and Yue, L. (2009). A flexible sim-

ulation environment for flash-aware algorithms. In

Proc. of the Conference on Information and Knowl-

edge Management(CIKM), ACM, pages 2093–2094,

Hong Kong, China.

Jung, M., Wilson, E., Donofrio, D., Shalf, J., and Kandemir,

M. (2012). Nandflashsim: Intrinsic latency variation

aware nand flash memory system modeling and sim-

ulation at microarchitecture level. In Proc. of Mass

Storage Systems and Technologies(MSST), IEEE, Pa-

cific Grove, CA, USA.

Kim, H. and Ahn, S. (2008). BPLRU: A buffer management

scheme for improving random writes in flash storage.

In Proc. of the conference on File and Storage Tech-

nologies(FAST), USENIX, volume 8, pages 1–14, San

jose, CA, USA.

Kim, Y., Tauras, B., Gupta, A., and Urgaonkar, B. (2009).

Flashsim: A simulator for nand flash-based solid-state

drives. In Proc. of the International Conference on

Advances in System Simulation(SIMUL), IEEE, pages

125–131, Washington, DC, USA.

Lee, J., Byun, E., Park, H., Choi, J., Lee, D., and Noh,

S. H. (2009). CPS-SIM: configurable and accurate

clock precision solid state drive simulator. In Proc. of

the Symposium on Applied Computing (SAC), ACM,

pages 318–325, Honolulu, Hawaii, USA.

Lee, S., Fleming, K., Park, J., Ha, K., Caufield, A. M.,

Swanson, S., Arvind, and Kim, J. (2010). Bluessd:

An open platform for cross-layer experiments for

nand flash-based ssds. In Proc. of The Workshop

on Architectural Research Prototyping(WARP), Saint-

Malo, France.

NANDSim (2008). Memory Technology Device.

www.linux-mtd.infradead.org.

OpenSSD (2011). Project. http://www.openssd-project.org.

Samsung, E. (2006). 2g x 8 bit / 4g x 8 bit nand flash mem-

ory (k9xxg08uxm). Specification.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

558

Wong, G. (2013). SSD market overview. In Proc. of Inside

Solid State Drives (SSDs), Springer, volume 37, pages

1–17.

Yoo, B., Won, Y., Cho, S., Kang, S., Choi, J., and Yoon, S.

(2011). SSD characterization: From energy consump-

tion’s perspective. In Proc. of HotStorage, USENIX,

Portland, OR, USA.

Yoo, J., Won, Y., Hwang, J., Kang, S., Choi, J., Yoon, S.,

and Cha, J. (2013). VSSIM: Virtual machine based

ssd simulator. In Proc. of Mass Storage Systems and

Technologies(MSST), IEEE, Long Beach, CA, USA.

AnalyticalModelofSSDParallelism

559