Design and Development of an Energy Efficiency Knowledge Center

(EEKC)

Bhaskaran Gopalakrishnan

1

, Mohammad S. Jalali

2

, Subodh Chaudhari

3

,

Deepak Gupta

4

and Ed Crowe

5

1

Industrial and Management Systems Engineering, West Virginia University, Morgantown, WV, U.S.A.

2

Industrial and Systems Engineering, Virginia Tech, Falls Church, VA, U.S.A.

3

Global Energy Services – Hudson Technologies, Tulsa, Oklahoma, U.S.A.

4

Industrial and Manufacturing Engineering, Wichita State University, Wichita, KS, U.S.A.

5

National Research Center for Coal & Energy, West Virginia University, Morgantown, WV, U.S.A.

Keywords: Energy Efficiency, Knowledge Management, Energy Assessment Center, Pre-Assessment, Energy

Assessment, Post-Assessment, EEKC.

Abstract: Over the last two decades, the Industrial Assessment Center (IAC) at West Virginia University has worked

with more than 500 small and medium sized manufacturing companies to identify energy and productivity

saving opportunities. The savings, which keep adding up year after year, are appreciable but do not fully

capture the potential impacts of the IAC Program. On average, the implementation rate of the

recommendations has been only about 40%. This rate was expected to improve with the use of a knowledge

center. Energy Efficiency Knowledge Center (EEKC) is a regional system which includes the development

and deployment of technical resources to assist industrial facilities in energy assessment phases. It supports

continuous improvement by incorporating the knowledge of IAC experts and the plant personnel. The

EEKC provides information to clients on how to obtain baseline energy use for their specific energy

systems using tools such as Quick Plant Energy Profiler (Quick PEP) by the US Department of Energy

(DOE). It helps users to evaluate the energy efficiency measures during the pre-assessment and assessment

phases. In this research, the IAC activities and tasks are studied and the steps to develop an online

knowledge center are reviewed.

1 INTRODUCTION

Industrial Assessment Centers (IAC) are supported

by the US Department of Energy's Advanced

Manufacturing Office (AMO). The objectives of the

IAC program are energy savings, resource efficiency

and a trained workforce for addressing energy

challenges, waste reduction, and productivity

enhancement. Incessant improvement in work

processes and assessment reports is one of the main

assignments of the IAC program (US DOE, 2011). It

is anticipated that managing information and

knowledge within the IAC program augments the

continuous improvement process of the centers. To

manage the information and knowledge, a dynamic

and secure system is needed in which information

and knowledge can be saved, maintained, and

shared. Recently knowledge management systems

(KMS) have gained wide acceptance as enabling

technologies for effective and efficient knowledge

management (Maier, Hädrich, 2006). The primary

goal of a KMS is to bring knowledge from the past

to bear on present activities, thus resulting in

increased level of organizational effectiveness

(Lewin, Minton, 1998).

1.1 Research Objectives

This research project aims to design and develop a

KMS, called Energy Efficiency Knowledge Center

(EEKC), for energy efficiency projects at the IAC at

West Virginia University. Research objectives

include the extraction of knowledge from regular

energy assessment reports and enter them into the

knowledge center database; save and share the

obtained knowledge; as well as archive, maintain,

692

Gopalakrishnan B., Jalali M., Chaudhari S., Gupta D. and Crowe E..

Design and Development of an Energy Efficiency Knowledge Center (EEKC).

DOI: 10.5220/0005024606920699

In Proceedings of the 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2014), pages 692-699

ISBN: 978-989-758-040-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

and manage the documents so that the IAC

members, plant personnel, and other stakeholders

can continuously interact with the knowledge center.

1.2 Needs for a Knowledge Center

to Improve the IAC Processes

Continuous improvement in energy assessments

requires that the knowledge is captured and shared

efficiently so that it is readily accessible and

manageable by the IAC members. The EEKC will

become a source of information for knowledge

developed by the IAC at West Virginia University

through energy assessments at regional medium to

large manufacturing plants under Enhanced Energy

Assessment Process (EEAP). The targeted region to

use the EEKC includes West Virginia, western

Pennsylvania and eastern Ohio. The expanded

region also includes Tennessee and Kentucky. The

EEKC will utilize database driven internet protocols

containing energy efficiency knowledge. The clients

from industrial facilities will be able to access the

EEKC via a secure portal. The EEKC will provide

information and knowledge to clients on how to

obtain baseline energy use for their specific energy

systems, provide the client plant with specific details

regarding a particular assessment recommendation,

any tax incentives or rebates available for

implementation in that geographical region, or a

sensitivity analysis of product, process, and system

related parameters with respect to energy savings

and payback.

2 LITERATURE REVIEW

In this section, the basic materials for design and

development of the EEKC are briefly reviewed. The

general concepts of knowledge management,

knowledge modeling methods and knowledge

engineering process as well as Web 2.0 tools, Wiki

pages, and their applications in the EEKC are

reviewed.

2.1 What Is Knowledge?

Knowledge can only be completely understood if

two things are known (Milton, 2007): (1) How it is

structured, i.e. what components it is made from,

and (2) the ways they are linked together.

Knowledge can be generally divided into three

categories: Explicit knowledge which is the type of

knowledge that an individual has acquired mainly in

the school and university; Explicit knowledge that

implies factual statements about material properties,

technical information, and tool characteristics; and

Tacit knowledge which is deeply rooted in an

individual’s experience (Nonaka, 1995). Knowledge

Engineering involves integrating knowledge into

computer systems through which acquired

knowledge is organized, shared, and validated.

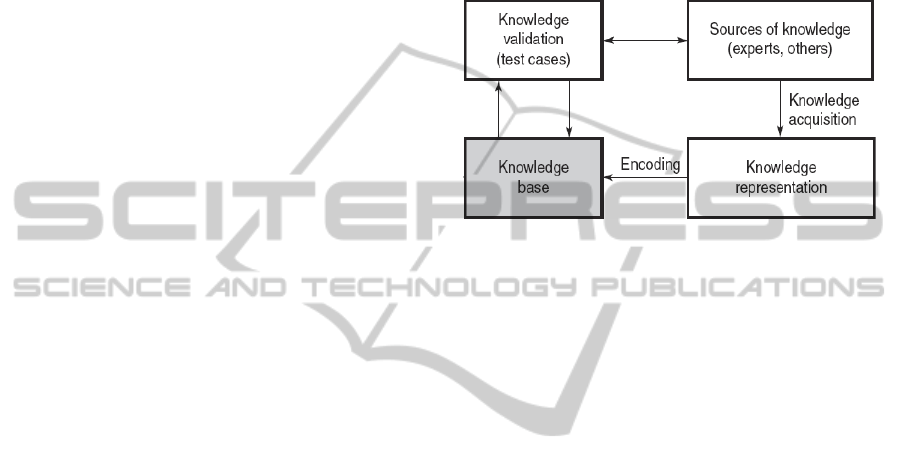

Figure 1 presents a simplified overview of the

knowledge engineering process.

Figure 1: Simplified process of knowledge engineering.

(Turban, Aronson, et. al., 2006).

2.2 Web 2.0

The term “Web 2.0” refers to the second generation

of the web that aims to facilitate communication and

to secure information sharing, interoperability, and

user centered design. The principles of Web 2.0 and

Knowledge Management (KM) are very similar.

Most of the Web 2.0 attributes have roots in KM

tools. Wiki page is a common application of Web 2

which facilitates the creation and editing of web

pages using a simplified markup language based text

editor. Wiki is chosen as the main platform in the

EEKC.

2.3 Semantic Wiki

Wiki is essentially a database for creating, browsing,

and searching through information. A semantic Wiki

is a Wiki engine that uses technologies from the

semantic Web to embed formalized knowledge,

content, structures, and links in the Wiki pages

Formalized knowledge is represented using semantic

web frameworks and is accessible and reusable by

web applications.

2.4 Knowledge and EEKC

Knowledge may be viewed from several

perspectives including a state of mind, an object, a

process, a condition of having access to information,

or a capability (Alavi, Leidner, 2001). Knowledge,

especially tacit knowledge, needs to be modeled

DesignandDevelopmentofanEnergyEfficiencyKnowledgeCenter(EEKC)

693

using automatic methods and documented into the

EEKC. This starts the development of the EEKC.

The users would be able to update the knowledge.

To extract and model the knowledge in processes,

some protocols need to be designed to use the EEKC

by the members. Information should be evaluated to

ensure that they are reliable. All documents and files

can be archived and members can upload and

download the last version of each Assessment

Recommendation (AR). Once information is saved

and archived under a respective domain, the IAC

directors would be able to monitor the system.

3 IAC WORK PROCESSES

AND APPLICATIONS IN EEKC

An important step in designing the EEKC is to

understand the work processes at the IAC. The IAC

work is generally divided into three main processes:

pre-assessment, assessment, and post-assessment.

3.1 IAC Assessments

IAC assessments and tasks are performed by local

teams of engineering faculty and students from 24

participating universities across the country. IAC

team conducts a survey of the eligible plant,

followed by a one or two-day site visit, taking

engineering measurements as a basis for

recommendations. The team performs an analysis

related to the energy use, energy savings, and

estimate of costs, performance, and payback times.

The DOE Best Practices software tools (Milton,

2007) such as Process Heating and Assessment

Survey Tool (PHAST), AIRMaster+, Fan System

Assessment Tool (FSAT), Pump System Assessment

Tool (PSAT), Steam System Assessment Tool

(SSAT), and Steam System Scoping Tool (SSST)

are also used. Within 60 days of the on-site visit, a

confidential report with details and

recommendations is sent to the plant (Milton, 2007).

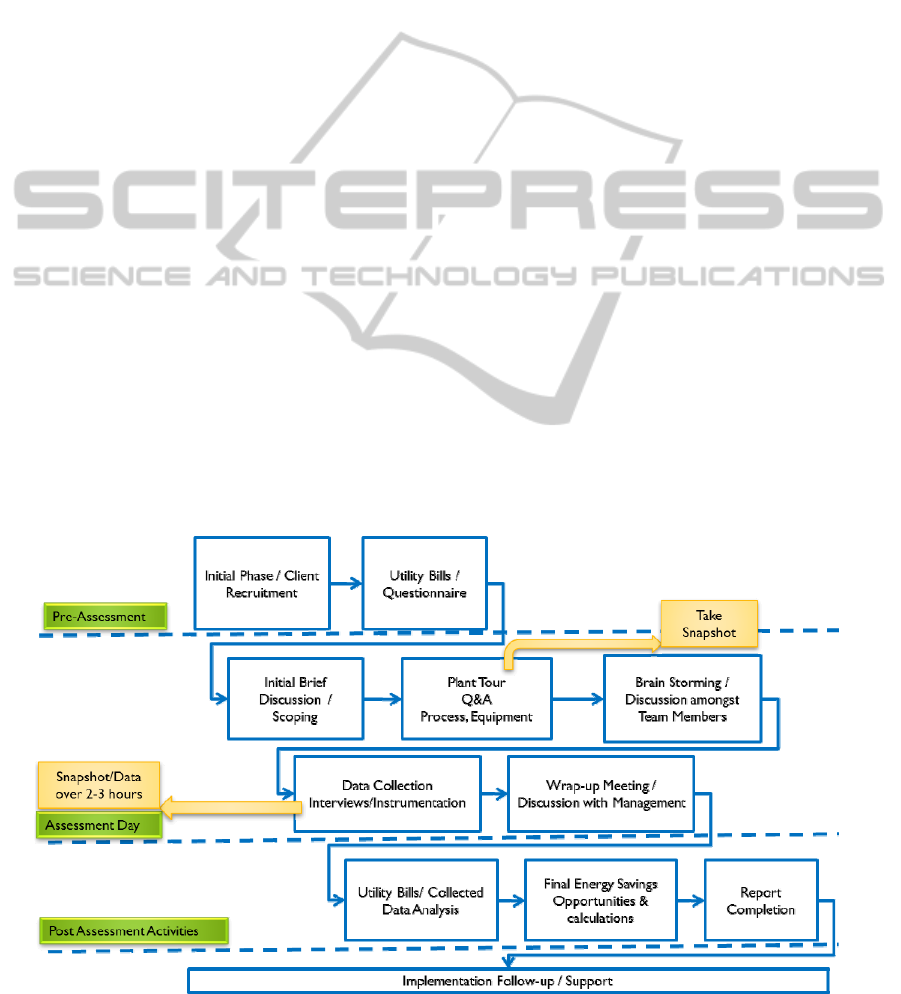

The main stages of the assessment processes are pre-

assessment, assessment, and post-assessment. A

traditional IAC cross-cut assessment process is

represented in Figure 2.

3.2 Better Buildings, Better Plants

Program

Better Buildings, Better Plants Program is another

form of IAC assessments which pays attention to,

and provides services at, various stages of the

assessment process with a strong focus on enhancing

the implementation of Energy Efficiency Measures

(EEM) as well as training of plant personnel. These

assessments include activities described in the

following pre-assessment phase, assessment phase,

and post assessment phase sub-headings.

3.2.1 Pre-Assessment Processes

This step involves engaging the plant personnel and

utility company personnel through conference calls

Figure 2: Traditional IAC cross-cut assessment process (Chaudhari, Gupta, et al., 2013).

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

694

to discuss energy consumption, manufacturing

process, and key energy utilization indicators.

Information gathered during this process would

be the first to be entered into the EEKC which

initiates the energy profile for the company. Then a

QuickPEP analysis is done to identify potential

Energy Efficiency Measures (EEMs). There is a

specific section in the EEKC for the QuickPEP

results providing solutions to benchmark and

compare the savings with other companies’ results.

Using the IAC database, same type of manufacturers

can be studied. The IAC database is analyzed on

potential EEMs based on the manufacturing

characteristics of the plant. This knowledge needs to

be entered in the specific Wiki page for particular

AR. Then, the main function is to benchmark the

energy usages of the facility with similar facilities

that have had an IAC assessment from the IAC at

West Virginia University in the past. This capability

can be expanded to include other databases such as

US Department of Energy’s (DOE) IAC database.

Using the other similar reports, the EEKC will be

able to generate useful information to benchmark the

energy usage of the plant.

The rebate and incentive programs section in the

EEKC archives all programs offered for different

manufactures. The assessment team will be able to

identify existing rebates and incentives offered in the

local area from the state and federal sources as well

as from the utility companies. A review is done on

the DOE’s Best Practices fact sheets for possible

application in development of an EEM. The DOE’s

Best Practices fact sheets are gathered and

hyperlinked in the respective sub-systems in the

EEKC. These pages are also linked to the related

ARs in respective report.

3.2.2 Assessment Processes

The first step in the assessment processes is to

interview the management personnel at the plant and

to discuss the preliminary findings from the pre-

assessment. Next, a discussion regarding the

characteristics of the manufacturing process and the

energy utilization aspects on major energy systems

is conducted. The EEKC will help create the energy

profile of the company. An assessment tool case in

the EEKC is used which includes the checklist and

essential questions. The data measurement process is

critical as effective control cannot be achieved

without effective measurement (IAC – UFL, 2011).

A discussion with plant personnel about

operational constraints and barriers to implement

EEMs in specific energy systems with respect to

factors such as the integrity of the manufacturing

process, product quality, and worker safety/health is

also conducted. Then, the plant tour and observation

of the manufacturing process and operation of the

energy systems is done and followed by a planning

meeting within the assessment team. After the

planning meeting within the assessment team,

intensive data collection efforts, observations, and

interaction with plant personnel follow. In the

energy profile for the plant, there is a data bank

which includes all data gathered during the

assessment, which is accessible to the EEKC users.

Lastly the team exposes the plant personnel to the

DOE’s services and commercialized energy efficient

technologies that may apply and discusses energy

efficient technology “gaps” that may be of interest.

3.2.3 Post-assessment Processes

The main objective of the post-assessment process is

development of ARs based on EEM calculations.

The assessment recommendations that are developed

in the report make use of the data measured through

loggers and/or instrumentation. The ARs reference

best practices knowledge, interaction with company

personnel, and solid engineering principles and have

a strong potential for implementation. The

assessment report consists of: (1) the data and other

information derived from discussions, records and

measurements made during the assessment; and (2)

the specific recommendations, together with

respective assumptions and engineering calculations.

An important objective of the EEKC is how it

conveys the information about saving opportunities

for the company. The final report and full text of

each AR are stored in the EEKC, although the

objective is not only to show the entire report, but

also to present the practical information and

knowledge extracted from each particular AR. This

may be initiated by summarizing and enhancing

each AR.

The information gathered in this process is

potentially valuable. The hidden reasons that an

energy saving idea cannot be implemented or should

not be implemented are identified in this process.

Since the plant personnel are granted access to their

plant assessment page in the EEKC, they can obtain

baseline energy usage for their specific energy

systems as well as practical tips to save energy.

They can also add information and comments as the

implementation and post implementation phase

progresses. ARs can be changed to accommodate

practical shortcomings. Since improvement in ARs

is a continuous activity, having access to all previous

DesignandDevelopmentofanEnergyEfficiencyKnowledgeCenter(EEKC)

695

versions and the last edited version (and more

importantly the validated version) would help the

IAC members and other stakeholders save time on

preparing reliable results and increase the quality of

work for future. The EEKC will also offer a

powerful platform to track progress on

organizational energy efficiency goals.

4 DESIGN AND DEVELOPMENT

OF THE EEKC

This section describes the different aspects of

designing the EEKC, its architecture, flow, and core

functions.

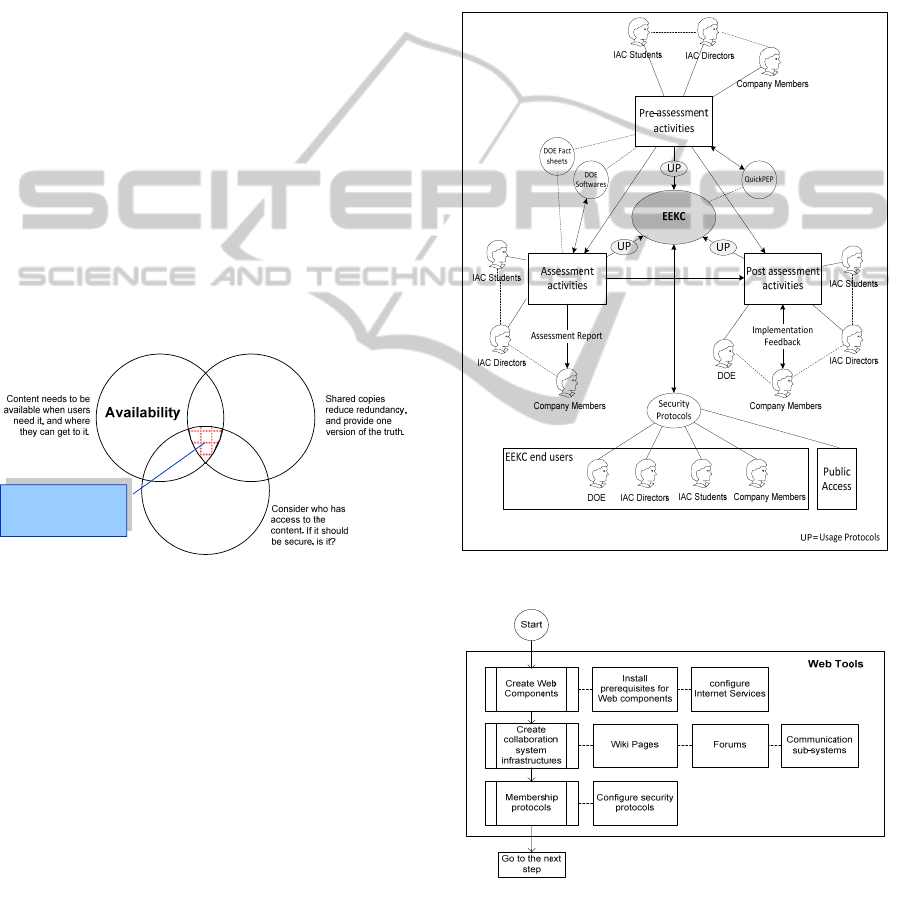

4.1 EEKC Architecture

EEKC architecture determines how the information

and knowledge in the EEKC–its Web pages,

documents, lists, and spreadsheets–are organized

and presented to the users. For energy efficiency

content in the EEKC, the factors in Figure 3 should

be considered.

Successfulknowledge

Management&Sharing

Integrit

y

Securit

y

Figure 3: Three important factors to be considered in the

EEKC architecture.

4.2 Information Flow in IAC/EEKC

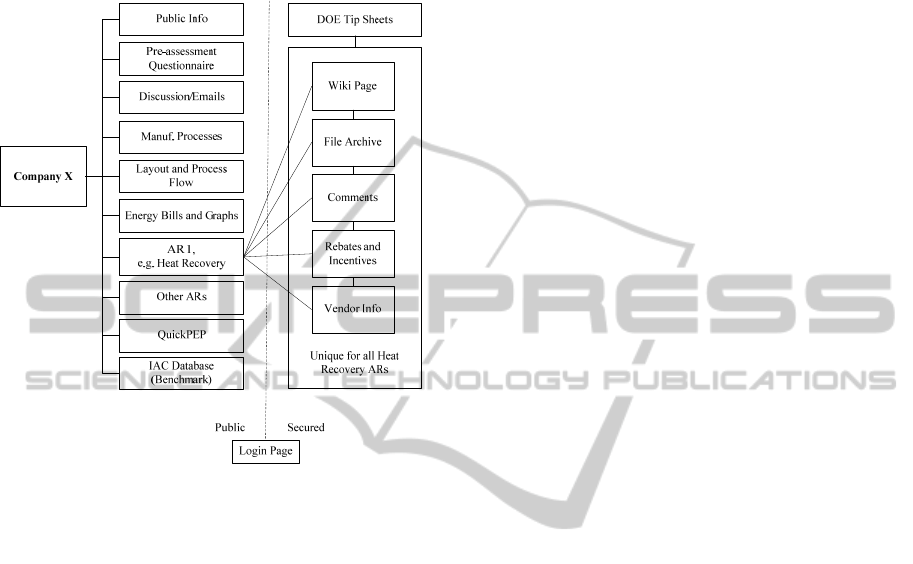

The information flow is presented in Figure 4.

4.3 Design of EEKC

An attempt was made to establish a server and

database for the EEKC, but establishing and

maintaining a server needs a large amount of

resources. Therefore, a built-in server in a third-

party company (Google) is used in which high

security technologies are used. The next step was to

develop the web tools as shown in Figure 5. All

pages in the EEKC are created using Wiki

technology and are easily customizable. The first

page of the EEKC is public and anyone can see the

page using with its web address. To get into

particular assessments or the private pages, users

need to be authorized. The first layer of the client

profile is public and lower layers such as pages for

AR bank and vendor information are private. Each

major equipment type has sub-pages for different

kind of ARs. The sub-pages contain AR file, the

Wiki (from now on, the page designed for saving

and sharing knowledge is called as Wiki), vendor

information, rebates, and tax incentives.

Figure 4: Information flow in IAC.

Figure 5: Steps to prepare the web tools.

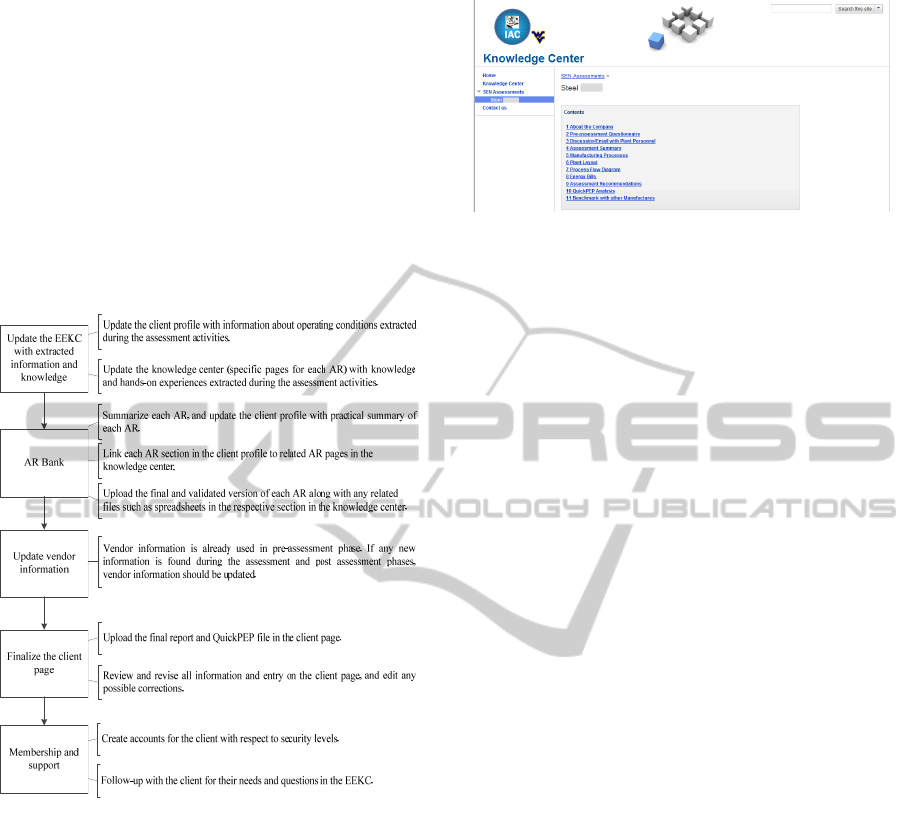

4.4 Usage Protocols

The output of this study is not only to design a

knowledge center but also to develop protocols to

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

696

use the EEKC in energy efficiency assessments.

Three protocols are designed to use in each of the

pre-assessment, assessment, and post-assessment

phases. An example protocol for post assessment is

shown in Figure 6.

The protocols should be reviewed after few

assessments and updated on a regular basis to catch

proper results and facilitate continuous

improvement. In order to improve the protocols,

feedback from IAC members, plant personnel, and

other stakeholders is crucial. The EEKC platform

facilitates feedback, response, and interaction

through the system.

Figure 6: Post-assessment protocol.

4.5 Knowledge Center and Company

Profile

The table of content of the company profile is shown

in Figure 7. Contents are made up with information

and knowledge extracted from different assessment

phases. To develop a new profile, the first step is to

create a new page for the company. A company

profile can be created as shown in Figure 7.

Knowledge Center is accessible through the site

navigator. The categories and subtitles are created

based on the particular assessment selected. For

future assessments, more categories and subtitles can

be added as appropriate. DOE tip sheets are also

available in the related page linked into the

Knowledge Center page. To ensure that all users can

share their feedbacks on any content, a section to

Figure 7: Table of content for a company profile.

upload attachment and comments is designed on the

bottom side of pages. The Knowledge Center section

becomes more and more comprehensive over time.

Currently, to log into the EEKC, users need to have

a Google account which uses (hypertext transfer

protocol secure) https protocol. If the IAC directors

or the EEKC administrator would like to give

permission to some people to view or edit the private

sections of the EEKC, they can easily invite those

people by entering their email addresses into

permission section on top of the page.

4.6 Case Study, Company X

The protocols were followed for the selected

assessment (Company X) and the information was

entered into the EEKC as shown in Figure 8. Pages

and sub-pages presented in Figure 8 along with

explanations to prepare their required contents were

based on the pre-assessment, assessment, and post-

assessment phases.

4.7 Subscriptions

The EEKC users can sign-up for email notification.

Once a user is subscribed, an email will be sent each

time the site or page is updated, someone makes a

comment on the site or page, or someone uploads an

attachment to the site or page. If they prefer not

receiving notification emails in their Gmail but in

another email address, they can auto-forward their

Gmail account to any other address. The Google

interface covers variety of Web 2.0 technologies.

4.8 Evaluation and Continuous

Improvement

The EEKC needs to be continuously evaluated to

find any possible bugs or improvement suggestions.

The Plan-Do-Check-Adjust (PDCA) cycle can be

used for continuous improvement of the EEKC. Not

only the system should be evaluated by the IAC

DesignandDevelopmentofanEnergyEfficiencyKnowledgeCenter(EEKC)

697

directors and lead students but also user

collaboration level with the system needs to be

evaluated. Then, based on needs identified, the

PDCA could be used to implement identified

improvements.

Figure 8: Profile and related pages for company X.

4.9 Scope and Limitation

The motivation of this research was to essentially

develop a regional clearinghouse for energy

efficiency for the area served by the Industrial

Assessment Center at West Virginia University.

There is vast amount of engineering, business, and

implementation knowledge already in existence and

creating a regional clearinghouse is a massive

undertaking. This paper is merely a first step

towards achieving the vision of central knowledge

center that can act as a smart resource for energy

efficiency engineers, project administrators, as well

as researchers. The EEKC system was designed to

increase the efficiency of report development as well

as involve plant personnel as active collaborators. It

also presents a platform for company personnel to

develop and monitor their energy efficiency targets

over time.

This research tried to develop a prototype using

few energy assessments undertaken by IAC at West

Virginia University. It is not tested by implementing

the framework for using knowledge from other

assessments. This system is limited to existing

recommendations for a given company and does not

let them evaluate a different recommendation and its

impact on the overall energy consumption of the

plant. Though the wiki format encourages

interactions, it does not support text mining that

could be used in future versions of this system.

4.10 Authors’ Contribution to Existing

Systems

According to the U.S. Bureau of Labor Statistics in

2012 (US BLS, 2014), private sector workers had

median tenure of 4.2 year. Similarly, a major portion

of IAC staff consists of center students with an

average tenure of less than two years. This results in

serious problems in terms of knowledge capture and

management. Since most small and medium sized

manufacturing companies do not have a knowledge

database, the knowledge and expertise developed

during a worker’s tenure is lost after they leave the

company. Development of the EEKC is a step in the

right direction to help such companies and capture

the knowledge not only from the company people

but also from the IAC staff. This is expected to help

the company set long-term energy efficiency goals

and monitor their progress over time even after

changes in the people responsible for the same.

Similarly, such a system will help the IAC staff

manage this information in an efficient fashion

instead of reinventing the wheel after key IAC

students graduate and leave the center.

Currently, the IAC program maintains a database

for recommendations form all 24 centers without

their details (US DOE – IAC, 2014). In fact, it even

generalizes the titles of recommendations to

maintain confidentiality. The IAC database is

designed only to find the extent of savings

opportunities. It does not intend to develop or

maintain any knowledge and/or collaborative efforts

between the plant personnel and the IAC staff. The

authors appreciate the maintenance of such a

database considering its intended use and the user

groups. However, the EEKC is meant to involve the

plant personnel as active users during all the phases

of an energy assessment.

5 DISCUSSIONS

AND CONCLUSIONS

The IAC program helps manufacturing facilities cut

back on expenditure from inefficient energy use,

ineffective production procedures, waste production,

and other production-related problems. Continuous

improvement in work processes of the energy

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

698

efficiency assessment reports is one of the main

missions of the IAC program. It is expected that

managing information and knowledge within the

IAC enhances the IAC assessment process. In

addition to the IAC members, clients can also use

the EEKC and view their assessment results in the

system. If they are given permission, they would be

able to navigate into knowledge center and other

private parts of the EEKC. The funding agency

personnel can also navigate into the entire system

and monitor/extract information from it.

To manage the information and knowledge, the

EEKC was designed in which information and

knowledge can be securely saved, validated, and

shared. The EEKC helps the IAC not only reduce

the report development time by preparing the

necessary applications, information, and knowledge,

but also helps increase the productivity and report

quality.

Future work can be conducted as an extended

study by increasing the number of reports entered

into the EEKC. Huge amount of data and

information will be saved in the system in which

knowledge extracted in Wiki could be still as short

as possible. An advanced tool i.e. text mining can be

used to analyze the data and text in each AR. The

relationships between different ARs and their effects

on each other could be automatically identified. This

may significantly help the IAC program enhance the

energy efficiency reports and improve the

implemented amount of savings by manufacturing

facilities (Jalali, 2011).

ACKNOWLEDGEMENTS

The authors are thankful to the US Department of

Energy for funding this research through their

regional Save Energy Now (SEN) – Better Buildings

Better Plants initiative.

REFERENCES

Alavi, M., Leidner, D., 2001. Review: Knowledge

Management and Knowledge Management Systems:

Conceptual Foundations and Research Issues. MIS

Quarterly, Vol. 25, No. 1, pp. 107-136.

Chaudhari, Subodh, Gupta, D. and Gopalakrishnan, B.,

2013. Using IAC Database for Longitudinal Study of

Small to Medium Sized Automotive Industry

Suppliers’ Energy Intensity Changes. SAE

International Journal of Materials & Manufacturing,

Vol. 6, No. 3, pp. 427-435.

IAC – UFL. (online) Available at:

http://www.ise.ufl.edu/iac/assessments.htm (Accessed

15 July, 2011)

Jalali, S. M., 2011. Design and Development of an Energy

Efficiency Knowledge Center (EEKC). MS Thesis,

West Virginia University.

Lewin, A. Y. and Minton, J. W., 1998. Determining

organizational effectiveness: Another Look and An

Agenda for Research. Management Science, Vol. 32,

No. 5, pp. 514-553.

Maier, R. and Hädrich, T., 2006. Idea Group Inc (IGI)

“Knowledge Management Systems”. Encyclopedia of

Knowledge Management edited by David G.

Schwartz, pp. 442- 450.

Milton, N. R., 2007. Knowledge Acquisition in Practice: A

Step-by-step Guide (Decision Engineering), Springer.

London.

Nonaka, Takeuchi, 1995. The Knowledge Creating

Company, Oxford University Press. New York.

Turban, E., Aronson, J. E., Liang, T-P., and Sharda, R.,

2006. Decision Support and Business Intelligence

Systems, Prentice Hall. 8

th

edition.

US Bureau of Labor Statistics, 2014. (online) Available at:

http://www.bls.gov/spotlight/2013/tenure/home.htm

(Accessed 20 June, 2014)

US DOE - Best Practices, 2011, Industrial Assessment

Centers (IACs), Department of Energy. (online)

Available at:

http://www1.eere.energy.gov/industry/bestpractices/iacs.ht

ml (Accessed 20 June, 2014)

US DOE - Quick Plant Energy Profiler, 2011, Department

of Energy. (online) Available at:

http://www1.eere.energy.gov/industry/quickpep_ml/

(Accessed 20 June, 2014)

US DOE, IAC program database, 2014. (online) Available

at: http://iac.rutgers.edu (Accessed 20 June, 2014)

DesignandDevelopmentofanEnergyEfficiencyKnowledgeCenter(EEKC)

699