Reference Ontologies for Global Production Networks

Esmond Neil Urwin

1

, Claire Palmer

1

, Anne-Françoise Cutting-Decelle

2,6

, Francisco Sánchez Cid

3

,

José Miguel Pinazo-Sánchez

4

, Sonja Pajkovska-Goceva

5

and Robert Ian Marr Young

1

1

Loughborough University, Wolfson School of Mechanical and Manufacturing Engineering,

Loughborough, Leicestershire, U.K.

2

Ecole Centrale de Lille, Cite Scientifique, CS 20048, 59651 Villeneuve D'Ascq Cedex, France

3

Instituto Tecnológico de Informática, Camino de Vera s/n, Edif. 8G, Acceso B, CP 46022, Valencia, Spain

4

Ainia Centro Tecnológico, Parque Tecnológico de Valencia, Avinguda de Benjamin Franklin,

5-11, 46980 Paterna, Valencia, Spain

5

Fraunhofer Institute for Production Systems and Design Technology IPK, Pascalstraße 8-9, 10587 Berlin, Germany

6

University of Geneva, CUI, ICLE, CH 1227, Carouge, Switzerland

Keywords: Ontology, Standards, Interoperability, Global Production Network.

Abstract: The development and utilisation of flexible, reconfigurable Global Production Network organisations

presents issues for the sharing and reuse of information and knowledge between systems and domains. The

research approach put forward in this paper posits that manufacturing reference ontologies can provide the

necessary underlying flexibility in a semantic-base to support interoperability. Moreover for that to be of

real value to industry it needs to be commonly applicable across the breadth of manufacturing business and

therefore be offered as a standard.

1 INTRODUCTION

As globalisation continues at a fast pace, Global

Production Networks (GPN) are becoming ever

more important to industry and commerce. By

employing a GPN an organisation can become more

adaptive to change, adopt technology at a faster

pace, lower its costs (Coe et al., 2008) and

ultimately be more successful at fulfilling its

customer and end user needs. Indeed it can be

mooted that by utilising specific suppliers in target

markets products can become more attractive to

customers, this has often been the case for the

aerospace industry. However, a GPN can expose

organisations to a diverse range of risks. Utilising a

network spread over a geographically wide area can

induce perturbations, bringing about delays in

communication and the sharing of information.

Moreover the mere comprehension and utilisation of

information between numerous and varied suppliers

and systems within a network can sometimes be

insurmountable without considering the different

domains that each potential supplier works within.

What this means is that the structure and definition

of information is of paramount importance if

interoperability is to be achieved. The concept of

flexible and reconfigurable GPN highlights the need

for improved interoperability standards and the

development and application of reference ontologies

to help overcome boundaries between different

domains, cultures and languages.

Research presented within the literature has

focused upon interoperability for enterprises and

manufacturing, but less so upon interoperability for

GPN (Panetto and Molina, 2008; Panetto, Goncalves

and Molina, 2012; Young et al., 2007; Borgo and

Leitão, 2007). A number of manufacturing models

have been developed for the purposes of semantic

interoperability and the consolidation of production

centric standards (Chungoora and Young, 2011;

Chungoora et al., 2012; Chungoora et al. 2013a)

which aim to develop a basis for knowledge sharing

between different domains.

Young et al. (2009) set out a manufacturing

reference ontology developed from the Interoperable

Manufacturing Knowledge Systems (IMKS) project.

Aligned with this is the Manufacturing Core

Ontology (MCO) presented by Chungoora et al.

133

Neil Urwin E., Palmer C., Cutting-Decelle A., Sánchez Cid F., Miguel Pinazo-Sánchez J., Pajkovska-Goceva S. and Young R..

Reference Ontologies for Global Production Networks.

DOI: 10.5220/0005026001330139

In Proceedings of the International Conference on Knowledge Management and Information Sharing (KMIS-2014), pages 133-139

ISBN: 978-989-758-050-5

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

(2013b). These approaches focus on ameliorating the

interchange of information and knowledge between

multiple contexts and describe the organisation of

relationships between concepts for manufacturing,

assembly and design activities within an

organisation.

This paper sets out an approach being developed

by the EU FP7 FLEXINET project for the

development of reference ontologies from which to

base the flexible re-configuration of globalised

production networks. This takes into account the

potential types of interactions that are necessary

between multiple systems across multiple

enterprises. The main aims of the FLEXINET

ontological research are the following, (i) document

key semantic concepts, knowledge constraints and

inter-relationships in the context of globalised

production networks, (ii) structure and formally

model concepts, relationships, constraints and

related facts to provide an underpinning

environment against which specific network

configuration designs can be evaluated and (iii)

develop methods for ontology querying from which

to evaluate the compliance of potential production

network configurations from both OEM and SME

perspectives.

2 GLOBAL PRODUCTION

NETWORKS: THE NEED FOR

REFERENCE ONTOLOGIES

In competitive and time sensitive market places,

organisations are tasked with providing product-

service solutions that can achieve and maintain

competitive advantage. They must be able to react to

change and to understand the balance of possible

options when making decisions on complex multi-

faceted problems. A major part of the development

and delivery of such commodities is the application

and use of Information Communication

Technologies (ICT) to enable the sharing, use and

reuse of information and knowledge between

different and often disparate groups of people and

systems in different domains. Currently problems

are still encountered when trying to share

information between systems and people as

organisations’ ITC systems and software tools have

different ways in which information and knowledge

is represented, formatted, stored, sorted and accessed

relative to their business domain, requirements and

needs. Thus the aim of achieving interoperability

between such systems and tools for the supposed

seamless interchange and exchange of information

both within and between organisations is ostensibly

an arduous and problematic challenge to address. To

tackle and achieve this, improved semantic

communication is needed by way of developing and

applying reference ontologies to the problems at

hand and use standards to support these to enable a

common and shared basis with which to allow

systems to interoperate more effectively.

Fettke and Loos (2003) define a reference model

as 'a model representing a class of domains' and

describe it as a 'blueprint for information system

development'. They are used to designate

'standardized technical architectures' (ISO, 1994),

applying reference models can accelerate the

development of ICT systems and structures,

decrease costs, risks, modelling time and increase

modelling quality (Fettke and Loos, 2006).

Standards present a common format or vocabulary

with which to exchange data between systems. At

present there are a number of international standards

being developed by ISO/TC184/SC4 and

ISO/TC184/SC5 which focus upon interoperability,

for example ISO 15531-44:2010 and ISO 11354-

1:2011. These concentrate upon enterprise and

manufacturing interoperability, per se there is a need

for standards that address the sharing of information

between systems and domain boundaries, to which

ISO SC4 cites the need for formal ontologies. The

research approach put forward in this paper posits

that manufacturing reference ontologies can provide

the necessary underlying flexibility in a semantic-

base to support interoperability. Moreover for that to

be of real value to industry it needs to be commonly

applicable across the breadth of manufacturing

business and therefore be offered as a standard.

3 THE FLEXINET APPROACH

FLEXINET aims to support decision-making in the

early design of global production network

configurations based on the implementation of new

complex technologies. FLEXINET will apply

advanced solution techniques to the provision of a

set of Intelligent Production Network Configuration

Services that can support the design of high quality

manufacturing networks, understanding the costs

and risks involved in network re-configuration, and

then mitigating the impact of system

incompatibilities as networks change over time.

These are fundamental requirements for high quality

decision-making in the early design of intelligent

manufacturing system networks. These innovative

concepts will enable a fast and efficient response to

KMIS2014-InternationalConferenceonKnowledgeManagementandInformationSharing

134

market variations and be easily adaptable across

industrial sectors. The FLEXINET concept is

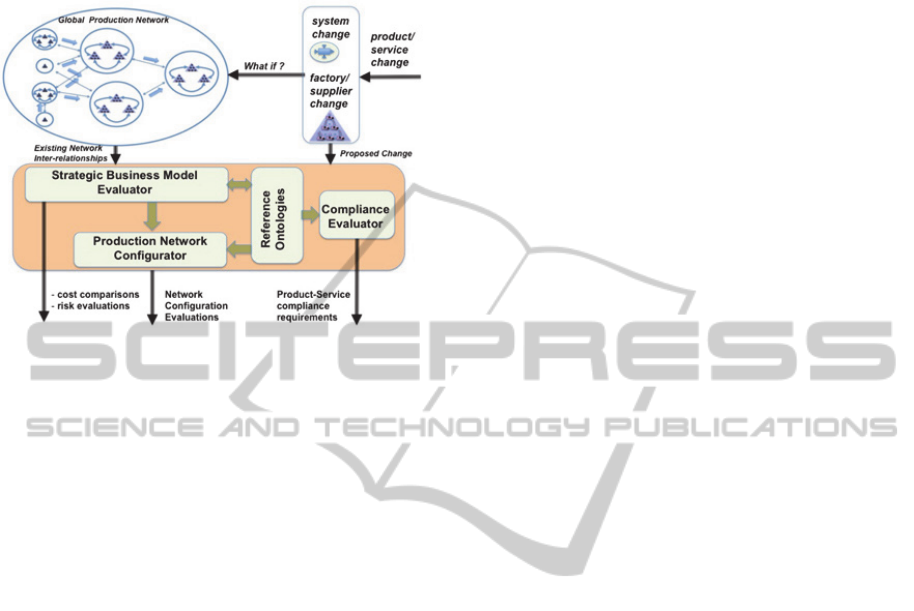

illustrated in Figure 1 below.

Figure 1: The FLEXINET Concept: Intelligent Production

Network Configuration Services.

FLEXINET takes the view that new

manufacturing business modelling methods are

needed that can model business cases and identify

the critical network relations that underlie the

business operation. Such methods and models are

essential to the ability to define both the production

network knowledge that must be captured and the

queries that must be made if new business

configuration possibilities are to be evaluated.

Product servitisation adds to the complexity of this

problem as the relationships between product

lifecycles and service lifecycles also need to be

understood and their impact on production system

networks specified within the resulting business

models.

4 DEVELOPMENT OF

REFERENCE ONTOLOGIES

FOR GLOBAL PRODUCTION

NETWORKS

The first step taken has been to underpin the

development of the FLEXINET reference ontologies

with a clear and systematic methodological

approach. A mixed methods (Creswell, 2008)

approach is being used by combining a multiple case

study approach (Yin, 2009) together with the

application of the knowledge engineering

methodology of Noy and McGuiness (2001). The

multiple case study approach consists of three

industrial case studies covering three different

industrial domains. Information and knowledge has

been elicited from these cases and is being analysed

to focus upon the key global production network

concepts that are of interest to the industrial project

partners. As part of this approach, work from the

IMKS research project, MSEE research project and

existing international standards are being assessed

and explored for applicability within the GPN

domain to utilise them where possible. The reference

ontologies that have been produced as part of the

IMKS project have been semantically expressed in

common logic (a first order logic language

expression) and formally tested in knowledge

sharing and interoperability experiments, hence

these have been corroborated and validated.

Additionally Hastilow (2013) has produced some

interesting ontological research looking at

Manufacturing Intelligence, to which an initial

appraisal of this shows that there could be a high

level of applicability to the GPN domain.

One of the main facets of the FLEXINET project

will be to develop a set of reference ontologies from

which to base the flexible re-configuration of

globalised production networks taking into account

the potential types of interactions that are necessary

between multiple systems across multiple

enterprises. This will result in a clear understanding

of the types of concepts involved in the

reconfiguration of product-service globalised

production networks and the constraints that must,

or may, be considered when reconfiguring a

network. The resulting knowledge formalisation,

extended with a fact base, developed in Common

Logic, will support network design by providing

answers to “what if” queries that can be used to

compare alternative potential network

configurations. These comparisons will identify the

extent to which interacting systems in the network

comply with the conceptual interaction requirements

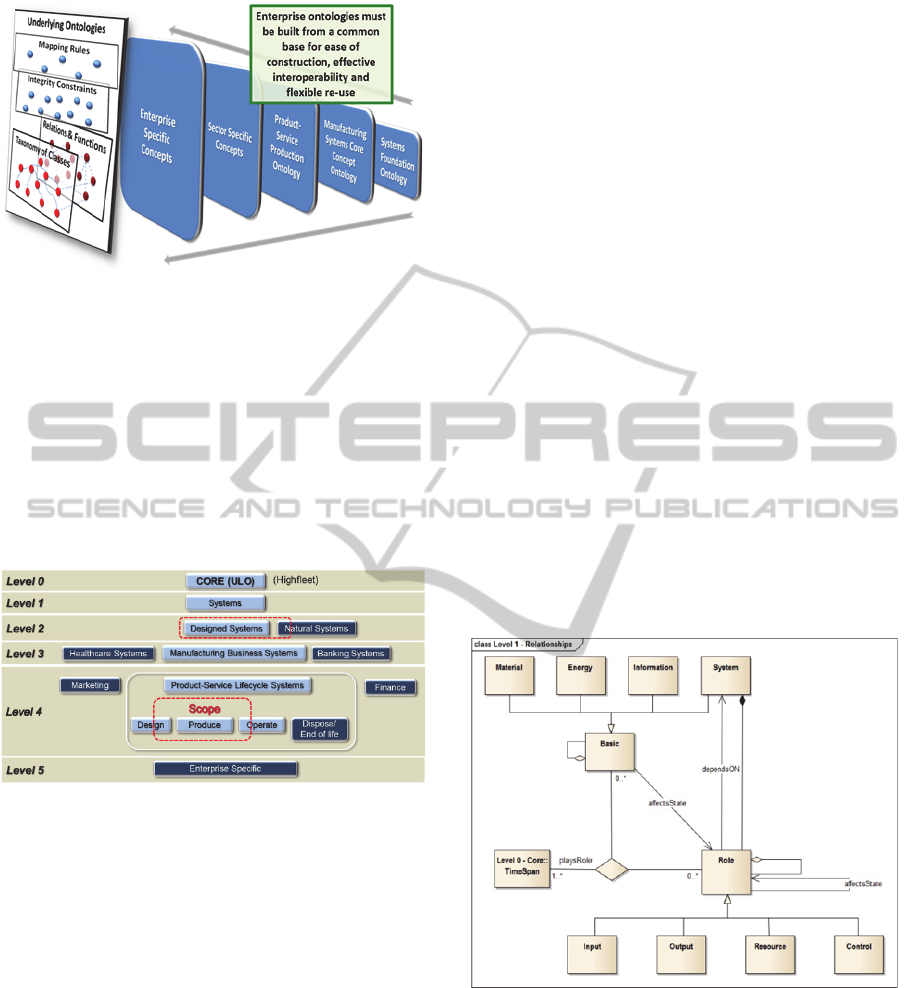

inferred from the developed ontologies. Figure 2

shows the initial FLEXINET Ontological approach,

the premise being that enterprise ontologies must be

built from a common base for ease of construction,

effective interoperability and flexible re-use. This is

illustrated by the upper three reference ontology

levels those of (i) the Systems Foundation Ontology,

(ii) the Manufacturing Systems Core Concept

Ontology and (iii) the Product-Service Production

Ontology. The next two ontology levels represent

(iv) the Sector Specific Concepts and (v) the

Enterprise Specific Concepts. For each of these

ontology levels there will be a set of mapping rules,

integrity constraints, relationships and functions,

together with a taxonomy of classes.

ReferenceOntologiesforGlobalProductionNetworks

135

Figure 2: The FLEXINET approach to ontology

development.

Subsequent research work has further developed

and refined the reference ontology approach which

is exemplified in Figure 3. Six levels have now been

defined. Levels one to five represent the FLEXINET

reference ontology. The core foundation ontology or

level zero represents foundation concepts that are

relevant to all domains. The concepts within this

level have been derived from the Highfleet Upper

Level Ontology (ULO) (Highfleet).

Figure 3: The FLEXINET reference ontology levels.

One aim of the FLEXINET project is to develop

a reference ontology by applying a heavyweight

ontological approach, this being the Knowledge

Frame Language (KFL) which is based upon

common logic (ISO/IEC 24707:2007). The approach

is being realised by utilising the Highfleet Integrated

Ontology Development Environment (IODE) which

is enabling the ontologies to be queried and applied

to the end user needs to develop solutions. This

approach will ameliorate levels of semantic

representation and definition, with a view to

enabling a common base for seamless

interoperability.

The FLEXINET levels each inherit concepts

from the respective level above but, also provide

concepts to the level below; each of the levels

becomes more specialised or domain specific. The

FLEXINET scope is highlighted in

Figure 3

by

lighter coloured domain boxes in the five levels. The

dotted lines in levels two and four illustrate that the

project’s scope extends into natural systems at level

two and design and operate at level four. These

domains are therefore being considered and studied

but not in totality.

Level one concerns systems and possess a set of

concepts that enable any system to be represented.

Level two is focused upon designed systems and

natural systems. Banathy’s (1992) classification has

been applied to aid the specialisation of the level one

‘systems’, to which designed systems represent

anything man-made, for example manufactured

goods, information or knowledge. Alternatively

natural systems represent anything natural, such as

living organisms, planets and the universe. Level

three provides a further specialised view, the main

focus being upon manufacturing business systems.

These in turn are specialised in level four by way of

Product-Service Lifecycle Systems (PSLS).

FLEXINET is focused upon global production

networks which are viewed as a specialisation of a

PSLS, the scope of these being focused upon

‘produce’ but also considers aspects of ‘design’ and

‘operate’, these are related the view of a product

lifecycle. Level five represents the end user specific

domains and related case studies.

Figure 4: The FLEXINET Level 1 ‘systems’ reference

ontology.

The level one ‘systems’ ontology is illustrated in

Figure 4, using the Unified Modeling Language

(OMG) to model the concepts and relations needed

to specify a system.

Within this level are two parent concepts, those

being ‘basic’ and ‘role’, together with a level zero

inherited concept that of ‘timespan’. Basic as a

concept (Mizoguchi et al., 2012) is independent of

KMIS2014-InternationalConferenceonKnowledgeManagementandInformationSharing

136

system and context, to which an instance of it retains

its identity, some examples of basic are material,

energy and information, it is anticipated there will be

other categories, a potential one being feature. The

ontology will be extended to include these further

categories when necessary. As per Figure 4 the

UML states that a basic can be comprised of basics,

an example of this being the basic ‘bread’ being

composed of the materials ‘wheat’, ‘yeast’, ‘water’

and ‘salt’. A TimeSpan includes the first and last

instants of a date and all the instances in between

(Highfleet).

A role is transitory and depends upon a context.

An example of the key ‘roles’ applied to a ‘designed

system’ is an IT System in which input roles are

played by the basics ‘information’ (for example in

the form of keyboard signals and numbers), output

roles are played by ‘information’ (e.g. in the form of

monitor signals and numbers), the resource role is

played by a basic ‘person’ (a Natural System) who

acts as the operator and control Roles are played by

the material ‘control unit’ and the information

‘analysis algorithm’.

A natural systems example is a tree. Input roles

are played by the basics materials ‘carbon dioxide’

and ‘water’ and energy (solar) which also play

resource roles for this system. Output roles are

played by the materials ‘glucose’, ‘oxygen’ (both

produced by photosynthesis) and ‘water’ (produced

by transpiration). Control roles are played by the

information ‘concentration of carbon dioxide’”,

‘light intensity’, ‘temperature’ (controlling

photosynthesis), ‘humidity’ and ‘wind strength’

(controlling transpiration).

The modelling of role as a specific concept is

necessary to be able evaluate whether a system is

capable of meeting specified requirements. The

division of basic and role concepts enables the

number of role instances counted to differ from the

number of basic instances playing the roles

(Wieringa et al., 1995). For example, one person

(instance of a Basic) can play two production

manager roles, over two different time periods in

two specific job roles. A basic can play more than

one role at the same time (e.g. a person could be a

production manager (context “manufacturing

business”) and a football player (context “sport”).

As per the cardinality set out in Figure 4 for a

basic ‘affectsState’ of a role, a basic does not have to

play a role as they occur independently. Conversely

a role does not have to be played by a basic, thus

unfilled roles can exist, for example a person can

leave the role of production manager, but the

position of production manager can still exist and

therefore be vacant.

The concept of system is a subtype of basic

which provides the context of roles that are

contained within it according to the ‘composition’

relation in the Figure 4.

Timespan represents the amount of time for a

basic playing a specific role, this is modelled by the

ternary relationship ‘playsRole’ For example in the

context of a manufacturing organisation system, the

basic ‘spreadsheet’ can play the role of Information

during the TimeSpan of the system.

Input, output, resource and control are the four

essential roles that represent a system. These follow

the basic concepts of systems engineering and utilise

views of information and material flows through

systems in line with IDEF0 (PUB, 1993; POP*,

2006).

5 CONCLUSIONS AND FURTHER

WORK

Knowledge elicitation and engineering are complex

and time consuming tasks that utilise a large amount

of resources to fulfil stated objectives successfully.

The FLEXINET ontological research objectives are

clear and succinct, that is to 'define reference

ontologies from which to base the flexible re-

configuration of globalised production networks'.

The domains of enterprise and manufacturing

interoperability have garnered research attention

over the past few years, but the subject of global

production networks as of yet has very few

examples of interoperability and reference ontology

research work. Thus it is important to draw upon

related reference ontologies and international

standards to explore their applicability and develop

consistent and representative reference ontologies

for the design of globalised production networks for

dynamically changing product-service systems.

This work highlights the need for well-defined

higher level core or foundation ontologies that can

act as a base for the generation and building of

reference ontologies, not only for global production

networks but other domains that are related and have

potential for interoperation.

The work has defined a key element of the

approach, which is the level 1 “systems” ontology.

This is now in the process of being formalised and

the programme of work is continuing to develop the

subsequent levels of the reference ontology and then

to test its applicability against our three

manufacturing end users requirements.

ReferenceOntologiesforGlobalProductionNetworks

137

ACKNOWLEDGEMENTS

The research leading to these results has received

funding from the European Community's 7

th

Framework Programme under grant agreement n

o

NMP2-SL-2013-608627.

REFERENCES

Banathy, B. H., 1992. A systems view of education:

Concepts and principles for effective practice.

Englewood Cliffs, New Jersey: Educational

Technology Publications.

Borgo, S., and Leitão, P., 2007. Foundations for a core

ontology of manufacturing. Integrated Series in

Information Systems, 14, pp. 751-775.

Coe, N. M., Dicken, P., and Hess, M., 2008. Global

production networks: realizing the potential. Journal

of Economic Geography, 8(3), pp. 271-295.

Chungoora, N., and Young, R.I.M., 2011. The

configuration of design and manufacture knowledge

models from a heavyweight ontological foundation.

International Journal of Production Research, 49(15),

pp. 4701 - 4725.

Chungoora, N., Gunendran, G. A., Young, R. I. M.,

Usman, Z., Anjum, N. A., Palmer, C., Harding, J. A.,

Case, K., and Cutting-Decelle, A. F., 2012. Extending

product lifecycle management for manufacturing

knowledge sharing. Proceedings of the Institution of

Mechanical Engineers Part B - Journal of

Engineering Manufacture, 226 (A12), pp. 2047-2063.

Chungoora, N., Cutting-Decelle, A-F., Young, R. I. M.,

Gunendran, G., Usman, Z., Harding, J.A., and Case,

K., 2013a. Towards the ontology-based consolidation

of production-centric standards, International Journal

of Production Research, 51(2), pp. 327-345.

Chungoora, N., Young, R. I. M., Gunendran, G., Palmer,

C., Usman, Z., Anjum, N. A., Cutting-Decelle, A. F,

Harding, J. A., and Case, K., 2013b. A model-driven

ontology approach for manufacturing system

interoperability and knowledge sharing. Computers in

Industry, 64, pp. 392-401.

Creswell, J.W., 2008. Research design: qualitative,

quantitative, and mixed methods approaches (3rd

Edition). Thousand Oaks: California, Sage

Publications Inc.

Fettke, P., and Loos, P., 2003. Classification of reference

models - a methodology and its application.

Information Systems and e-Business Management,

1(1), pp. 35-53.

Fettke, P., and Loos, P., 2006. Using Reference Models

for Business Engineering - State-of-the-Art and Future

Developments, Proceedings of the 3

rd

International

Conference on Innovations in Information

Technology, Dubai, United Arab Emirates, November

19-21, pp.1-5.

Hastilow, N., 2013. An Ontological Approach to

Manufacturing Systems Interoperability in Dynamic

Change Environments. PhD Thesis. School of

Mechanical and Manufacturing Engineering,

Loughborough University, UK.

Highfleet Ontology Library Reference, 2014. Baltimore,

MA, HIGHFLEET Inc.

Integrated ontology development environment (IODE).

http://www.highfleet.com/iode.html (accessed June

2014).

ISO 11354-1:2011, Advanced automation technologies

and their applications - Requirements for establishing

manufacturing enterprise process interoperability -

Part 1: Framework for enterprise interoperability.

Genève, Switzerland.

ISO 15531-44:2010, Industrial automation systems and

integration - Industrial manufacturing management

data - Part 44: Information modelling for shop floor

data acquisition. Genève, Switzerland.

ISO (1994). Information technology - Open Systems

Interconnections - Basic Reference Model: The Basic

Model, ISO/IEC 7498-1:1994(E), second edition,

corrected and reprinted 1996-06-15. Genève,

Switzerland.

ISO/IEC 24707:2007. Information technology – Common

Logic: a framework for a family of logic-based

languages. Genève, Switzerland.

Mizoguchi, R., Kozaki, K., and Kitamura, Y. (2012,

September). Ontological analyses of roles. Federated

Conference on Computer Science and Information

Systems (FedCSIS), Wroclaw, Poland, September 9-

12, pp. 489-496.

Noy, N. F., and McGuinness, D. L., 2001. Ontology

Development 101: A Guide to Creating Your First

Ontology, Development, 32(1), pp. 1-25.

OMG, 2012 OMG unified modeling language (OMG

UML), superstructure and infrastructure version 2.4.1

[online]. Available from: http://www.omg.org/spec/

UML/2.4.1/ [Accessed 26 June 2014].

Panetto. H., and Molina, A., 2008. Enterprise Integration

and Interoperability in Manufacturing Systems: trends

and issues. Computers in Industry, 59(7), pp. 641-646.

Panetto, H., Goncalves, R., and Molina, A., 2012.

Enterprise Integration and Networking: theory and

practice. Annual Reviews in Control, 36(2), pp. 284-

290.

POP* Revised framework Work package – A1.8, 2006.

Athena European integrated project no. 507849 public

deliverable.

PUBs, F., 1993. Integration definition for function

modelling (IDEF0). Federal information processing

standards publication, 183.

Wieringa, R. J., de Jonge, W., and Spruit, P. A., 1995.

Using dynamic classes and role classes to model

object migration, Theory and Practice of Object

Systems, 1(1), pp 61-83.

Yin, R. K., 2009. Case study research design and

methods. Thousand Oaks: California, Sage

Publications Inc.

KMIS2014-InternationalConferenceonKnowledgeManagementandInformationSharing

138

Young, R. I., Gunendran, A. G., Cutting Decelle, A-F.,

and Gruninger, M., 2007. Manufacturing knowledge

sharing in PLM: a progression towards the use of

heavy weight ontologies, International Journal of

Production Research, 45(7), pp.1505-1519.

Young, R. I. M., Gunendran, A. G., Chungoora, N.,

Harding, J. A., and Case, K., 2009. Enabling

interoperable manufacturing knowledge sharing in

PLM. Proceedings of the Sixth International

Conference on Product Life Cycle Management

PLM09, University of Bath, Bath, UK, July 6-8,

Switzerland, pp.130-138.

ReferenceOntologiesforGlobalProductionNetworks

139