WSN-based near Real-time Environmental Monitoring for Shelf Life

Prediction through Data Processing to Improve

Food Safety and Certification

G. E. Biccario, V. F. Annese, S. Cipriani and D. De Venuto

Department of Electric and Informatic Engineering - DEI, Politecnico di Bari, Via Orabona 4, Bari, 70125, Italy

Keywords: Environmental Control, Food Safety, Food Certification, Shelf Life Prediction, Wireless Sensor Network.

Abstract: This position paper aims to support a control technique in the perishables goods supply-chain through a

combination of near real-time wireless sensor network (WSN) for environmental monitoring and further

data processing to predict the shelf life of the product. This approach returns a low cost, versatile and

efficient tool that can significantly improve the safety and food certification through the organoleptic

qualities control using three different sensors, i.e. temperature, light and humidity. In this article, therefore,

the advantages of the proposed technique are explained and a case study is presented to support this

approach, as well as an example of processing algorithm for shelf life evaluation.

1 INTRODUCTION

Nowadays, food safety and certification through-out

all the supply chain have become very strict

requirements, so that global associations such as the

FDA (“Food and drug administration”) or the WHO

(“World Health Organization”) are continuously in

activity to develop and promote more selective

methods of monitoring and control (FAO/WHO,

2007). Organoleptic properties of food, raw food,

cosmetics, drugs, specialty oral use and other

perishable products, affect considerably not only the

safety of the product for human use but also its

consumption and commercial success. Hence the

need to study, define and evaluate them correctly in

order to prevent their earlier degradation. In fact, the

loss of perishable products is estimated at approx.

$35 billion annually all around the world and

especially in US (Hoppough, Apr. 24, 2006).

A multitude of security and certification

protocols has been developed and spread in all areas

of the food supply chain and, among all, the “Hazard

analysis and critical control points” (HACCP)

method continues to be worldwide increasingly

prevalent. HACCP is a scientific and technical

approach for the prevention of biological, chemical,

and physical hazards, whose seven fundamental

principles are released and determined by the

standard ISO 22000 (ISO, 2005).

The HACCP aim is to identify the different

critical control points (CCPs) in food production and

to define the parameters of interest for suitably

monitoring every phase of the productive process.

This approach creates a major emphasis on food

quality, particularly with regard to health and safety,

a concept that goes beyond mere customer

satisfaction, but rather pointing to the protection of

public health (FAO/WHO, 2007).

An “ad hoc” WSN is an effective solution for

monitoring perishable goods during all their chain

supply. The near real time data availability, the low

power consumption, the possibility of expand the

WSN using the most appropriate components for

each application, the moderation of the production

costs and the adequate precision of the measures are

all great reasons that make a WSN an advantageous

solution in perishable food supply chain. The

gathered data can be used to prevent not

recommended environmental conditions, in

particular during the storage and distribution phases,

according to HACCP-like methods, in order to

prevent product rapid decay and, therefore, losses.

Moreover, they can be used to evaluate product

freshness via shelf-life (Labuza, 2001) parameter,

which is the period of time in which a perishable

product is compliant with declared nutritional data

values and sensory, chemical, physical and

microbiological characteristics, without becoming

unhealthy for use or consumption, when stored

under well-defined conditions (Institute of Food

777

Biccario G., Annese V., Cipriani S. and De Venuto D..

WSN-based near Real-time Environmental Monitoring for Shelf Life Prediction through Data Processing to Improve Food Safety and Certification.

DOI: 10.5220/0005102407770782

In Proceedings of the 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2014), pages 777-782

ISBN: 978-989-758-039-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

Science and Technology, 1993). In this paper, a

WSN-based environmental monitoring is described

as a case study to prove the effectiveness of this

approach. An algorithm for later data processing is

proposed for the near real-time availability of shelf-

life evaluation.

The paper is organized as follows: sections 2 and

3 propose related works and WSN architecture,

including (in section 4) a demonstrative monitoring

of three storage conditions affecting the organoleptic

properties of perishable goods, i.e. temperature,

relative humidity and light exposition, as case study.

The measurements have been realized in a

warehouse for storage of agricultural products. The

section 5 shows an algorithm for the processing of

the obtained data: a shelf life estimation through a

calculation algorithm based on the Arrhenius law.

The paragraph 6 shows an attempt of financial

statement.

2 RELATED WORKS

A Wireless sensor network (WSN) is an

infrastructure composed by wireless nodes, with

little memory and a low-performance CPUs, capable

of performing measurements, processing and

communicating wirelessly to a central point, where

the data are managed (Sohraby, 2007). The structure

typically involves several wireless scattered nodes in

a specific area periodically sending the collected

data to a coordinator point (gateway), which

manages the network and forwards them to another

remote system for further processing (Dargie, 2010).

The wireless access is usually a “contention-oriented

random access” type, as defined in the IEEE 802,

but IEEE 802.15.4 is the most commonly used

standard, in particular ZigBee standard. This is due

to IEEE 802.15.4 applicative advantages like

worldwide defined operative band (2.4 GHz ISM),

good data rate (250 kbps) and range of action

(several tens of meters), low power consumption,

possibility of routing and retransmission in case of

errors (Lee, 2007).

WSN effectiveness has been proved in many

applications concerning agro-food context (Yoo,

2007). In (Garcia-Sanchez, 2011) ZigBee-based

WSN is used for data-monitoring and video

surveillance in precision agriculture over distributed

crops. Other examples of monitoring during the

production phase are precision viticulture, as

presented in (Matese, 2009), and greenhouse control

(Dae-Heon Park, 2011). As concern storage

monitoring, WSN solution has been employed in

grain warehouse (Zhao, 2010) and fresh food

supermarket (Yang Chenwei, 2011). As described in

(Ko, 2014), WSN have proved to be an excellent

solution for real time traceability and monitoring of

agricultural product.

Although WSNs have already been effectively

employed in environment monitoring from

production to distribution phases, so that gathered

data can be used to generate alarms when specific

events are detected (Dennis J. A. Bijwaard, 2011),

they are not supported by a shelf-life evaluation,

which would ensure product adequate quality along

the supply chain.

In this paper a WSN-based monitoring,

supported by shelf-life valuation from environmental

variables, is presented; the collected data are used in

a simple degradation model to calculate shelf-life

which is communicate to the users through an

algorithm and can be used to send alarms when

recommended conditions are not verified anymore.

3 WIRELESS SENSOR

NETWORK ARCHITECTURE

The WSN used for the monitoring activity consists

of several nodes equipped with three different

sensors to obtain information about the

environmental light, temperature and humidity

(figure 1). Each unit sends data to a coordinator

whose task is to make them available in almost real

time (neglecting the communication delays). The

communication between each node and gateway is

wireless using Zigbee protocol. Subsequently, the

gateway uploads the data to a cloud using an internet

connection. The data are available on the web using

a tablet, a smartphone, a PC or any device with

internet connectivity by logging in the data cloud

Figure 1: Architecture of the employed WSN.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

778

that manages the data. An appropriate authentication

system allows access only to authorized users.

In figure 2 there is a demonstrative diagram

about the overall architecture of a single node.The

small size (6.85 cm x 6.35 cm x 3.30 cm) and the

independent power supplyallow proper positioning

of the sensors. Due to the use of the Zigbee

technology and to its low power consumption, the

battery life is durable.

Table 1 summarizes the main performance of

each node. The analog outputs of the sensors are

digitized by a 12 bit resolution ADC and then are

Figure 2: Architecture of a node of the WSN.

Table 1: Node sensor performances.

Specification Value

Power

supply

Read-sleep

cycle/ battery

life

1 per 30s/ 1.5 y

1 per 60s/ 2.5y

AC input V 3 x AA 1.5V

b

atter

y

Temp.

sensor

Ran

g

e -18 to +55 °C

Accurac

y

+/- 2

Ambient

light

sensor

Bandwidth

Ran

g

e

360 to 970 n

m

Wavelength of

p

eak sensitivit

y

570 n

m

Luminance

range

10 to 1000 lux

(+/-20%)

Relative

humidity

sensor

Range 0 to 95% RH

Interchangeabil

ity

+/- 5% (0 to 59%

RH)

+/- 8%(60 to 95%

RH)

Accurac

y

+/- 3.5% RH

Zi

g

bee

transmiss

ion

RF date rate 250kbps

Frequenc

y

ISM 2.4GHz

Indoor/line of

si

g

ht ran

g

e

40m / 120

m

processed for transmission. sensor specifications

should match the requirements of the product they

are intended to monitor. since this wsn has a

demonstrative purpose their values have to be

considered suggestive.

4 WSN IN A PERISHABLES

GOODS SUPPLY-CHAIN:

EXPERIMENTAL RESULTS

In this paragraph a case study is described to

demonstrate the feasibility and effectiveness of the

proposed solution. An “ad-hoc” solution requires an

adequate choice of the smart sensor selected once

inside the “working” environment and a positioning

and mapping phase of the nodes to get the

traceability of the product.

4.1 Sensor Performance Analysis

A preliminary performance analysis of the nodes had

Figure 3: from the top: illuminance, temperature and

relative humidity values collected during sensor accuracy

analysis and compared to the reference ones.

WSN-basednearReal-timeEnvironmentalMonitoringforShelfLifePredictionthroughDataProcessingtoImproveFood

SafetyandCertification

779

been performed: using comparative reference,

sensors accuracy have been evaluated. During one

hour session20 samples have been collected and

compared with those of more accurate instruments

(hygrometer–thermometer: Testo 608-H1; luxmeter:

Yokogawa 510 O2).

Measurements were carried out indoor with

artificial lights. The obtained values are shown in

figure 3, where the red dashed line represents the

values given by the instrument used as reference.

Sensors average values (table 2) have been

compared with reference average value to calculate

accuracy; standard deviation from average values is

useful to evaluate sensors precision. Sensors

performances are sufficient for an environmental

monitoring which therefore does not require extreme

precision.

Table 2 Illuminance, temperature and relative

humidity sensor averages and standard deviation for

accuracy and precision evaluation.

Average [lux] Std. Dev. [lux]

S1

385.6 19.78

S2

580.05 28.73

S3

491.05 22.48

S4

603.65 44.30

S5

449.45 27.47

S6

540.75 21.24

Ref.

628.1 -

Average [°C] Std. Dev. [°C]

S1

21.54 0.11

S2

22.84 0.16

S3

19.05 0.12

S4

21.21 0.086

S5

21.22 0.06

S6

20.50 0.22

Ref.

22,21 -

Average [rh%] Std. Dev. [rh%]

S1

53.32 0.0060

S2

54.89 0.0132

S3

54.06 0.0036

S4

54.57 0.0045

S5

55.56 0.0041

S6

53.95 0.0035

Ref.

52.68 -

4.2 WSN-based Monitoring of a

Dehydrated Agricultural Product

Warehouse

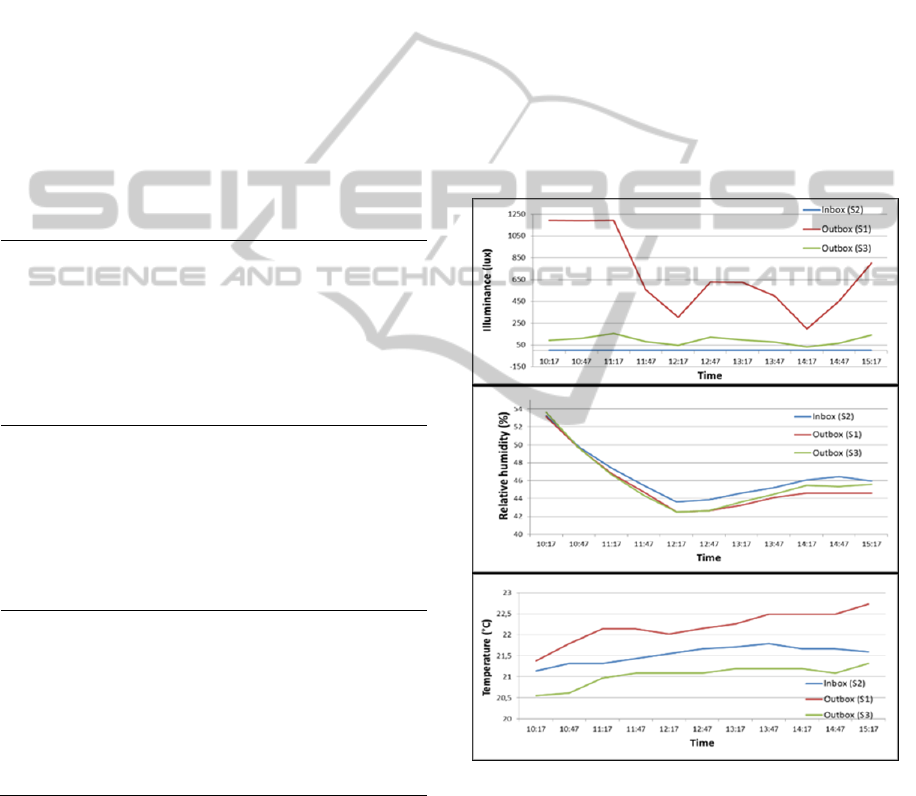

The presented WSN has been employed for the

monitoring of a warehouse of dehydrated

agricultural products. Three multi-sensor nodes have

been used to monitor three different pallets in the

same environment. Figure 4 shows collected data

values of the temperature, relative humidity and

light exposition during a 5 hours monitoring, from

10:17 to 15:17; three values per second were

collected and then averaged to reduce data through-

put. One node was placed in an indoor pallet (blue

curve), the others out of the pallet but in the

warehouse. Thanks to the battery life durability, it

would be possible a monitoring of the entire food

chain it in the same way. However, sampling data

could be significantly reduced to increase node lives.

This would promote transparency in the food chain,

becoming a guarantee for the consumer, a powerful

low-cost tool for the producer and a simple control

method for the predisposed organs. The collected

data became available to any authorized user in the

world almost in real time, neglecting a little latency

due to communication (few tens of ms).

Figure 4: from the top, illuminance (lux), relative humidity

(%) and temperature (°C) values collected during the

monitoring of a dehydrated agricultural products.

5 SHELF LIFE ESTIMATION

FROM QUALITY

DEGRADATION RATE

Shelf-life evaluation depends on the nature of the

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

780

considered product and, thus, on the environmental

factors involved in its degradation. Temperature,

light exposition and humidity affect product quality

at the same time but as concern the products in the

presented study, the implementation of Arrhenius

and Lambert law in a calculation algorithm has been

considered to estimate the degradation rate of the

agricultural products, and thus their shelf life,

assuming that recommended characteristics are

known.

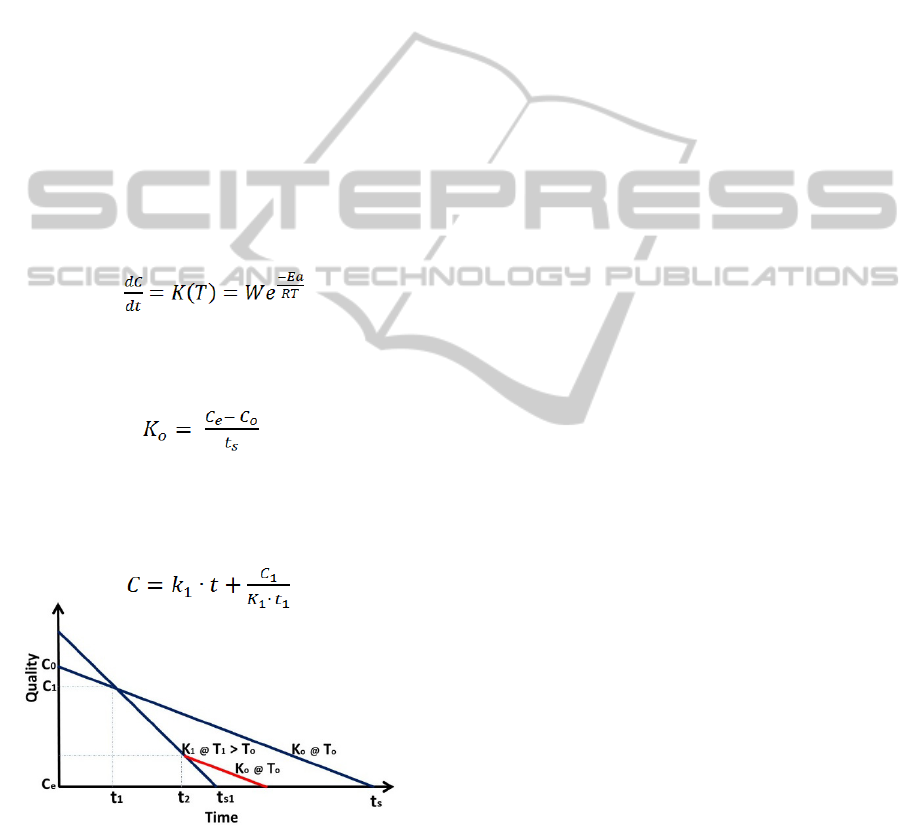

5.1 Linear Mathematical Model of

Quality Degradation Prediction

The relationship between product’s quality and time

is considered approximately linear (Figure 5):

stands for the food quality (

: recommended

condition;

: minimum quality level),

for the

shelf time, for the quality degradation speed. K

depends on the temperature according to Arrhenius

law [4]

(1)

,

,

,

, the recommended storage temperature,

have to be considered known (reference situation).

So

, the reference degradation speed is given by:

(2)

If at time

the temperature rises up to

,

above a certain threshold, it’s possible to estimate

(the new degradation speed) using eq. (1). The new

characteristic can be expressed as:

(3)

Figure 5: Linear model of quality degradation.

The new perspective produces a lower shelf-time

. If the temperature returns from

to

, the

shelf life must not change: by now the product

quality has been spoiled.

5.2 Algorithm for Shelf Life Prediction

Similarly to (Azanha, 2005), an algorithm for shelf

life prediction is proposed, according to the model

described above. The purpose is to create an

application for smartphone and tablet which is able

to calculate in real time how long the product

preserve the quality specifications in that

environment.

I. Store input data about standard shelf life (SLo

[h]), temperature (To), Humidity (Rho) and

illuminance (Lxo) of recommended value. Acquire

from the WSN information about current T, Rh, Lx,

than show them.

II. Verify if the current conditions are above

certain thresholds from the reference ones (the

chosen range is due to sensors performances). If not,

calculate the

. The SL is the same as the

reference SL (stored in input).

III. If the product is not in the standard condition,

create an alert signal. Than calculate the new

degradation speed coefficient (K) through Arrhenius

equation (1) and estimate the new shelf life as a

fraction of the standard one: the new shelf time is

calculated using the ratio between the current

degradation speed and the previous one. In order to

perform these calculation, a database with all the

required constant values is needed. Finally set the

new SL as a optimistic value: the product has been

spoiled (in a preventive view) and the SL cannot be

restored (even if returning in the recommended

conditions).

IV. Show remaining shelf time and repeat the loop

every hour.

5.3 Accuracy of Shelf-Life Prediction

The calculation system proposed exhibits a certain

degree of approximation. Firstly, the calculation is

made assuming the degradation as a linear function

of time although in reality it is not. Moreover,

considering that the temperature sensors have an

accuracy of + / - 2 ° C, we can reasonably assume

that the new value of the rate of degradation

is to

be understood between a

and

, evaluated

according to the Arrhenius law (equation (1)) at

2° and

2° respectively. Therefore the

shelf life is valid in an interval between

and

, according to eq. (3), using respectively

and

.

The accuracy of the system can surely be

improved by using more accurate sensors for the

measurement of the temperature and implementing a

method of calculation based on a more specific

WSN-basednearReal-timeEnvironmentalMonitoringforShelfLifePredictionthroughDataProcessingtoImproveFood

SafetyandCertification

781

mathematical (even better if the model is

differentiated by class of foods).

6 FINANCIAL CONSIDERATION:

COSTS AND BENEFITS

The proposed solution is not expensive and allows a

safe monitoring of several typology of goods. Just

for give an estimation of the costs let's try to make a

budget statement. If produced in a supply chain, we

can estimate the cost of each node of about €15

(considering nodes of high quality with re-

programmability and reusability characteristics) and

about €500 for each gateway. A system made by 3

gateways and 45 sensors (considered sufficient to

manage a medium-sized productive environment)

would cost about € 2,175. Estimating the lifetime of

the gateway (changing individual nodes is not a

problem) for about 4 years, we are talking about €

544 annually. Regarding the shelf life estimation and

the implementation of the dedicated application, we

can assume that in a supply chain cost is negligible

if compared to the WSN one. These costs would

certainly be overcome by the consequent reduction

of wastage in perishables chain and the

corresponding increase in sales (due to the added

value that such a monitoring system can provide the

product).

7 CONCLUSIONS

Safety and certification for food production is not an

objectionable topic but a strong need: WSN can be

used as an effective tool to allow both a reduction of

the waste in the supply chain through corrective

actions when recommended conditions are not

satisfied anymore and an improvement of food

safety through shelf-life estimation. A case study of

warehouse monitoring with a WSN architecture has

been described to support the feasibility and low

cost characteristic of this solution; three

environmental conditions, affecting the organoleptic

properties of perishable goods, i.e. temperature,

humidity and light exposition have been used in a

proposed algorithm, based on the Arrhenius law, to

estimate shelf life. Our work was therefore just a

demonstration of feasibility, but future prospects are

even more persuasive thanks to the several

application fields (not only agri-food) and the

flexibility of WSN architectures.

REFERENCES

Azanha, A., 2005. Use of mathematical models for

estimating the shelf-life of cornflakes in flexible

packaging. Packaging Technology and Science, 18(4),

pp. 171-178.

Dae-Heon Park, e. a., 2011. A Study on Greenhouse

Automatic Control System Based on Wireless Sensor

Network. Wireless Pers Commun, Volume 56, pp.

117-130.

Dargie, W. a. P., 2010. Fundamentals of wireless sensor

networks: theory and practice. s.l.:C.John Wiley and

Sons.

Dennis J. A. Bijwaard, e. a., 2011. Industry: using

dynamic WSNs in smart logistics for fruits and

pharmacy. Seattle, USA, Proceedings of the 9th ACM

Conference on Embedded Networked Sensor Systems,

pp. 218-213.

FAO/WHO, 2007. FAO/WHO guidance to governments

on the application of HACCP in small and/or less-

developed food businesses. s.l.:s.n.

Garcia-Sanchez, A. J., 2011. Wireless sensor network

deployment for integrating video-surveillance and

data-monitoring in precision agriculture over

distributed crops. Computers and Electronics in

Agriculture, 72(2), pp. 288-303.

Hoppough, S., Apr. 24, 2006. Shelf life. Forbes.

Institute of Food Science and Technology, 1993. Shelf-life

of foods: guidelines for its determination and

prediction. London: s.n.

ISO, 2005. ISO22000, Food Safety Management System.

s.l.:s.n.

Ko, D., 2014. Real Time Traceability and Monitoring

System for Agricultural Products Based on Wireless

Sensor Network. International Journal of Distributed

Sensor Networks, Volume 2014.

Labuza, T. P. S. L., 2001. Open dating of Foods. II ed.

Trumbull, Connecticut, USA: Food and Nutrition

Press.

Lee, J., 2007. A Comparative Study of Wireless Protocols:

Bluetooth, UWB, ZigBee, and Wi-Fi. Taipei, Taiwan,

s.n.

Matese, A. D. G. S. F., 2009. A wireless sensor network

for precision viticulture: the NAV system. Computer

and Electronics in agricolture, 69(1), pp. 51-58.

Sohraby, K., 2007. Wireless sensor networks: technology,

protocols, and applications. Hoboken, New Jersey:

John Wiley and Sons.

Yang Chenwei, L. D. Y. D. Y. S. L. Z., 2011. Design of

Monitor-and-control System for Supermarket Fresh

Area Based on ZigBee. Wuhan, IEEE, pp. 1302-1305.

Yoo, S., 2007. A2S: Automated agriculture system based

on WSN. Irving, ISCE 2007. IEEE International

Symposium on Consumer Electronics.

Zhao, Y., 2010. The grain depot temperature

measurement system’s research based on wireless

sensor networks. Jinan: IEEE.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

782