A Component-based Approach to Realize Order Placement

and Processing in MSMEs

M. Saravanan

1

and J. Venkatesh

2

1

Ericsson Research India, Chennai, India

2

Department of Information Technology, MSE College, Chennai, India

Keywords: Micro Small and Medium Scale Enterprises, Middlemen, Order Placement and Processing, JSON, Android,

and Cloud Environment.

Abstract: Micro, Small and Medium scale Enterprises (MSMEs) hold an unfailing distinction of being pillars of

equitable economic growth. Lack of proper business platforms and knowledge of marketing strategies

render MSMEs vulnerable to middlemen exploitation. In view of the advancements and customers’ growth

in the telecommunications field, we utilize the mobile platform to offer trading solutions to MSMEs. In this

paper, we propose a mobile phone-based Order Placement and Processing components for MSMEs that can

achieve disintermediation and is developed as an android application integrated with cloud services to

provide easy access - anytime, anywhere. Our proposed component-based framework encompasses essential

trading operations and extends 24 x 7 supports to MSMEs. An economic order calculator and order

parallelizer sub-components helps limited budget MSMEs with small warehouse to survive the market by

efficiently managing the warehouse, scheduling payments and parallelizing the order depending on its

requirements. The other two sub-components custom specific negotiator and effective Order tracker helps in

customizing the product and keeps track of the parallelized order respectively, thus assisting buyers in

tracking their order to give an end-to-end solution. The envisioned framework will boost MSME margins,

build healthy business-ties and transform MSMEs into self-sufficient establishments equipped with full-

fledged trading systems that operate in mobile distributed environment.

1 INTRODUCTION

Micro, Small and Medium Scale Enterprises

(MSMEs) hold a trustful distinction of being pillars

of equitable economic growth and account for 90%

of global businesses. The current MSME market

requires small-scale manufacturers to depend on

group of middlemen like wholesalers, distributors,

agents and brokers to carry out essential trading

tasks. These middlemen hold business-ties with

various consumer MSMEs in order to negotiate and

sell products on behalf of the seller MSMEs and in

return they charge a per cent of the MSME's revenue

as commission. Hence these intermediaries primarily

focus on identifying interdependencies in the

market, in terms of 'exchange opportunities' between

MSMEs, so that they can misuse their market

knowledge and business leads to rather reap

excessive profits, than to promote small-scale

businesses. Realizing this, MSMEs often lay claim

of middlemen pocketing their margins besides

indulging in unfair trading practices like adulteration

and hoarding. This middlemen involvement not only

has an effect on the revenues of MSMEs, but they

also affect the cost of the end product. The only

solution to the above problem is to eliminate

middlemen completely to boost MSME revenues,

which is assumed to be possible through several

existing web based and E-commerce solutions. But

in reality, MSMEs turn to another class of

middlemen to carry out their online trading.

Consequently, MSMEs end-up paying two different

classes of middlemen; hence they fail to obliterate

intermediation. However, small business owners are

unable to comprehend and use PC-based Internet

solutions due to limited knowledge of technologies.

Also, these web based solutions for order placement

and processing do not specifically solve the

problems of small-scale manufacturers or MSMEs

with a small warehouse and limited financial budget.

All the above said issues were addressed in our

proposed solution for a new order placement and

258

Saravanan M. and Venkatesh J..

A Component-based Approach to Realize Order Placement and Processing in MSMEs.

DOI: 10.5220/0005105002580265

In Proceedings of 3rd International Conference on Data Management Technologies and Applications (DATA-2014), pages 258-265

ISBN: 978-989-758-035-2

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

processing component that automates the activities

performed by middlemen and extend 24 × 7 support

to MSMEs through mobile phones. Hence we have

provided a specific solution for emerging

organization with a small budget to survive at the

market and achieve greater profits. For this, we have

developed an android application along with the

mobile cloud to support the calculation of the

optimal order quantity and the minimal buffer

quantity of raw materials using the Optimal

Inventory Calculator sub-component. When the

inventory nears the minimal buffer quantity, the

system suggests the reorder quantity from statistical

analysis of purchase history. The system also

provides provisions to parallelize order to efficiently

use the small warehouse, though they have a limited

budget using a Just-in-time inventory technique, thus

reaping extra profits.

Custom-specific negotiator component is used to

help buyers order custom-made products according

to their interests and requirements. We also have an

order tracker which keeps track of the undelivered

and pending orders, making it easy for the MSMEs

to keep track of them. The invention on the whole

provides a never before seen platform for MSMEs to

hold direct negotiations with each other, thereby

eliminating need for intermediation.

2 RELATED WORK

The recent past has witnessed development of a

multitude of applications and services to assist

MSMEs. Popular web applications provide CRM

systems (Achuama and Usoro, 2010) and human

resources management (Andersen, 2003) solutions.

Research has also been carried out to introduce ERP

systems for MSMEs (Upadhyay and Dan, 2010).

Most of the web solutions aim at providing a

business platform for the small-scale firms to sell

their produces in the online market. E-commerce

applications have been developed to cover business

transactions (Olatokun and Kebonye, 2010). In

reality, MSMEs are unable to comprehend the

technology involved. They turn to another class of

middlemen to carry out their online trading (Cooke,

2000). Consequently, MSMEs end-up paying two

different classes of middlemen.

A method (Nakamoto et al., 2002) processes a

simplified order placement and reception in a system

comprising a host computer and a PDA. The method

includes storing stocked-product data and estimation

data in an order placement and reception information

database provided in the host computer, then

transmitting from the host computer to the PDA, and

placing an order from the screen on which the

stocked-product data are displayed in the PDA.

These features support the order processing and in

addition, it allows the buyer to choose the most

nearby MSME to prioritize the orders depending on

the cost, thus reducing the delivery time when the

product is needed immediately without any

compromise on the price as well.

Mobile cloud, considered as the next generation

technology, is extensively used to provide services

to mobile phone networks (Taylor et al., 2011).

Location-based services are highlights of mobile

cloud applications. Main reason for utilizing mobile

clouds for businesses is the ability to carry out

remote computing. Mobile phones have limited

processing and storage capabilities. Hence storage

and computing tasks are delegated to remote Virtual

Machines (VMs) on mobile cloud that provide

Infrastructure As A Service (IAAS) (Sushil et al.,

2010).

Moreover, cloud developing platforms like

Eucalyptus and OpenStack (Pepple, 2011) extends

infinite scalability in processing of orders.

Nowadays, mobile phones are increasingly used as

entry points to cloud services (Giurgiu et al., 2012).

The Amazon EC2 is one of the recent developments

in the field of cloud computing that offers many

cloud related solutions as web services (Varia,

2010). The other paper describes a highly scalable

system developed for MSMEs using the ontology

engineered framework that uses cloud for data

storage and processing (Saravanan et al., 2012). The

android application has remote access to framework

components that run on cloud, for effective and

efficient processing.

3 COMPONENT-BASED

APPROACH

The proposed order placement and processing

component has the following four sub-components

under them which executes linearly for each

product’s order placement and processing as shown

in Fig 1. The involvement of these components

improves the order processing system in MSME

sustainable development.

AComponent-basedApproachtoRealizeOrderPlacementandProcessinginMSMEs

259

Figure 1: Order Placement & Processing.

3.1 Optimal Inventory Calculator

Unlike any online website this in-built component

calculates profitable order quantity based on

statistical analysis of stocking, ordering and holding

costs. And whenever the MSME inventory is in the

verge of being empty, a re-order point is set and

helps in advising the MSME that it has to order new

inventories when the re-order point is reached. Thus

it protects the warehouse with undisrupted

continuous business as shown in Fig 2.

We first obtain user input for annual demand

quantity, fixed cost per order, annual holding cost,

daily demand quantity, lead time, and safety stock to

calculate economic Order quantity and re-order

point quantity. We then order the optimized quantity

from the preferred supplier MSME through the

Order Parallelizer component. The MSME then

starts the manufacturing and sale of finished

products, and after that it verifies whether the

remaining available quantity is less than or equal to

the re-order point quantity. If re-order point is

reached, MSMEs re-order new set of products

(optimal quantity). Else, continue with manufacture

and sale of finished products.

Figure 2: Workflow of Optimal Inventory Calculator.

3.1.1 Economic Order Quantity

Economic order quantity is the order quantity that

minimizes total inventory holding costs and ordering

costs. It is one of the oldest classical production

scheduling models (Hax and Candea, 1984). Thus

we determine the optimal number of units to order

so that we minimize the total cost associated with

the purchase, delivery and storage of the product.

EOQ applies only when demand for a product is

same throughout the year.

New order is delivered in full when inventory

reaches zero or when the re-order point is

reached.

Fixed cost for ordering

Cost for storage (% of purchase cost)

Lead time is fixed

Only one product is involved

Purchase price should be constant

The following variables were used for calculation

P = Purchase Price

Q = order quantity

Q*= optimal order quantity

D = annual demand quantity

S = fixed cost per order (not per unit, typically cost

of ordering and shipping and handling)

H = annual holding cost per unit (also known

as carrying cost or storage cost)(warehouse space,

refrigeration, insurance, etc)

Total Cost = purchase cost + ordering cost + holding cost

(1)

- Purchase cost: This is the variable cost of goods:

purchase unit price × annual demand quantity. This

is P×D

- Ordering cost: This is the cost of placing orders:

each order has a fixed cost S, and we need to order

D/Q times per year. This is S × D/Q

- Holding cost: the average quantity in stock

(between fully replenished and empty) is Q/2, so this

cost is H × Q/2

TC = PD + (DS/Q) + (HQ/2) (2)

To determine the minimum point of the total cost

curve, partially differentiate the total cost with

respect to Q (assume all other variables are constant)

and set to 0:

0 = - (DS/Q

2

) + (H/2) (3)

Solving for Q gives Q* (the optimal order quantity):

(4)

DATA2014-3rdInternationalConferenceonDataManagementTechnologiesandApplications

260

(5)

Q* is independent of P; it is a function of only S, D,

H.

3.1.2 Calculation of Re-Order Point

Another important technique used along with the

economic order quantity is the Re-order Point (ROP)

by maintaining safety stock.

ROP quantity reflects the level of inventory that

triggers the placement of an order for additional

units.

The quantity associated with safety stock

protects the company from stock outs or

backorders. Safety stock is also known as a

“buffer”

ROP= Daily usage*Lead time (in days) (6)

When a safety stock is maintained, then the

reorder point is written as the following :

ROP = [Demand (Daily usage)*Lead time

(in days)] +safety stock

(7)

Demand - Quantity of inventory used or sold each

day

Lead Time - Time (in days) it takes for an order to

arrive when an order is placed

Safety Stock - The quantity of inventory kept on

hand in case there is a unpredictable event like

delays in lead time or unexpected demand.

3.2 Order Parallelizer

This sub-component helps in parallelizing the order,

thus obtaining different quantities of same product

from different sources. It helps the firms with small

warehouse and limited budget who immediately

want to purchase raw materials and start

manufacturing their products by partially ordering

an initial quantity of raw materials from nearby

sellers (priority is given in the order of distance, cost

and quality) and then order the remaining quantities

of the same product from different distant sellers

(priority is given in the order of quality, cost and

distance). Quality depends on whether the two

MSMEs have had previous business transactions.

More priority is given to MSMEs with whom the

buyer MSME has had previous transactions, as it

makes that MSME transaction more reliable

compared to the rest. This also reduces the burden

on the buyer MSME, as he need not pay the cost of

buying all the products from all sellers at the same

time and is a cost-effective measure. He has to pay

only for the product he buys from a particular seller

as he has now parallelized the order. MSMEs with a

small warehouse can use order parallelization as

they will not have sufficient space to store all the

required quantities in their warehouse by

parallelizing the order quantity depending on the

space available at the buyer’s warehouse. This saves

the buyer from renting a separate warehouse to store

the products. The component is also designed in

such a manner that the time required to empty the

warehouse (manufacturing and sale of initially

bought products) is the time to deliver the next set of

parallelized products from another seller. Hence

small firms which use this system can efficiently

utilize the warehouse though it is small.

Figure 3: Work flow of Order Parallelization.

Let’s consider the following variables for

explaining the flow of events shown in Fig 3.

T = Total no of products the warehouse can hold

H = No of products the ware house is already

holding

A = No of products that have space for storage at

warehouse (A

procurement

+A

produced

)

A = T-H (8)

IQ = Initially Required Quantity to start manufacture

in case of immediate delivery

RQ = Required Quantity (Calculated by EOQ

formula)

T

d

= Time to deliver vector = t

1

, t

2

, t

3

, ..t

n

AComponent-basedApproachtoRealizeOrderPlacementandProcessinginMSMEs

261

T

s

(Time to sell/produce vector = ts

1

, ts

2

, ts

3

, ..ts

m

where m<<n

Q

s

= Quality bought vector = q

1

, q

2

, q

3

,..q

n

P = Product Vector/Product Measurement

In this component we first check whether the

order requires immediate delivery to start production

at the earliest. If yes, choose MSMEs using a Filter

Function F (Distance, Cost, Quality) which gives

high priority to distance (nearest MSME), then to

cost and then to quality. Then we further narrow

down the search to find MSMEs whose available

number of products for immediate sale, is greater

than or equal to the IQ (Initial required quantity).

After narrowing down, we order q1 quantity of

products at the chosen nearest MSME. Note that q1

shall be lesser than or equal to A

procurement

. If q1 is

equal to required quantity, then the order placement

process is complete. If not then we choose another

set of MSMEs using a different Filter Function F

(Quality, Cost, Distance), which gives high priority

to MSMEs with whom there has been previous

contracts, whose quality is good though they are at a

farther distance. Also choosing MSMEs also has

another criteria which specifies that the time to

deliver the present ordered quantity (t

i

+1) ≥ (t

si

) time

to sell previous ordered quantity. This type of time

constraint helps in efficient use of the inventory and

is called the Just-in-time Inventory. The MSMEs are

listed in ascending order of the time to deliver value,

where (i=1) if q1 exits, else (i=0 and t

s0

=0). Parallel

orders are placed at different MSMEs, with variable

quantities q1, q2, q3. Check if sum of (q1, q2, q3…)

≤ required quantity. If yes, repeat the above process,

if not then the required quantity is ordered and the

parallelized order placement component is complete

the process.

Table 1: Product-wise Ordering.

MSME Product

Count

Distance Price Quality

Service

MSME 1

(m

1

)

p

1

d

1

pr

1

0

MSME 5

(m

5

)

p

5

d

5

pr

5

1

MSME 7

(m

7

)

p

7

d

7

pr

7

0

MSME 9

(m

9

)

p

9

d

9

pr

9

1

….

MSME n

(m

n

)

p

n

d

n

pr

n

1

3.2.1 How the MSMEs are Filtered

Let m

1

, m

5

, m

7

, m

9

, .., m

n

be the MSMEs with

available requested products.

Product availability (m

1

, m

5

, m

7

, m

9

, .., m

n

)

Product count (p

1

, p

5

, p

7

, p

9

, ..., p

n

)

Distance (d

1

, d

5

, d

7

, d

9

, ..., d

n

)

Price of product (pr

1

, pr

5

, pr

7

, pr

9

, ..., pr

n

)

In Table 1, quality of service is defined as ‘0’

and ‘1’ depending on whether the buyer MSME has

had previous business transaction with them or not

respectively. From the above table using query

processing, the information is filtered depending on

the following condition:

When the order is immediate,

o D = User specified distance

o P = User specified price

o F (distance, cost, quality)

Filter depending on distance < D

Filter the resulting rows depending on

price < P

Display the MSMEs with quality of

service = 1

When the Order is not Immediate,

o D = User specified distance

o P = User specified price

o F (quality, cost, distance)

Filter the MSMEs with quality of

service = 1

Filter the resulting rows depending on

price < P

Filter the resulting depending on

distance < D

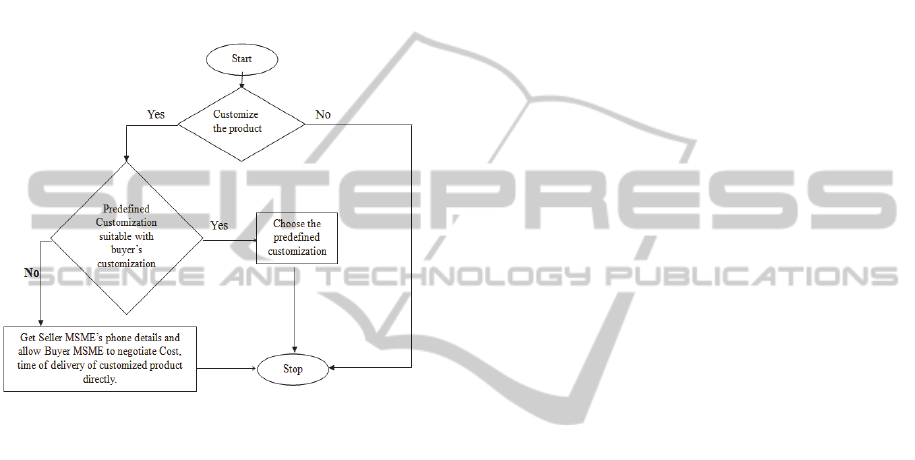

3.3 Custom Specific Negotiator

This is a platform to negotiate product

customizations, price and time-to-deliver. Predefined

customizations are available along with their price

and time to deliver. If the predefined customization

is not suitable to the buyer’s customization then this

platform helps MSMEs to hold direct negotiations

with each other about the buyer’s custom-specific

products, thereby eliminating need for

intermediation. In order to hold direct negotiations,

the component helps in making direct phone

conversation with other MSME, thus making

negotiations easier and eliminating intermediation

completely.

According to Fig 4, this component first checks

if the user wishes to customize the product. If yes,

then the component checks if seller MSME’s

predefined customization is suitable to the buyer’s

customization. If yes the buyer chooses the

DATA2014-3rdInternationalConferenceonDataManagementTechnologiesandApplications

262

predefined customization, the buyer MSME should

also be fine with the price and time to deliver of the

predefined customized product. If not, then the

component realizes that the predefined

customization is not suitable to the buyer’s

preferences, so now the buyer MSME is given the

details of the seller MSME so that direct

negotiations of custom specific products can be done

through the phone conversations. Once it is done, a

customized product is successfully negotiated and

ordered.

Figure 4: Workflow of Custom Specific Negotiator.

3.4 Order Tracker

Track pending orders module notifies the associated

MSMEs and assist in easy management of bulk

orders. The immediate available product quantity is

dispatched by the supplier and the remaining

quantity is calculated and is tracked by the order

tracker. The order tracker holds information about

the remaining amount of products yet to be

delivered, along with the time taken to deliver the

remaining product, thus summoning the MSME if

the order is not delivered in time.

A detailed workflow of the Order tracker

component is specified in Fig 5, here the component

first checks whether the order has been parallelized,

if yes the component keeps track of the order by

storing MSME Name, last date for delivery of order,

remaining quantity to be delivered of each supplier

MSME in the parallelized order. If not then the

component just keeps track of the order by storing

only the single supplier MSME’s Name, last date for

delivery of order and remaining quantity to be

delivered. The system continuously checks if the

delivery time has reached, if yes then both the seller

and buyer MSMEs are alerted. The algorithm used

by order tracker is defined below:

If (order has been parallelized)

Track MSME Name, Delivery Time,

(Remaining Quantity = Total Ordered

Quantity-Delivered Quantity) for each

MSME in the parallelized order

Else

Track that single MSME Name, Delivery

Time, (Remaining Quantity = Total Ordered

Quantity-Delivered Quantity)

If (Current Date ≥ Delivery Date-3)

Alert both buyer and seller MSMEs that the

delivery date is nearing

If (Delivery Date ≥ Current Date)

Alert both buyer and seller MSMEs that the

delivery has not yet arrived

4 REALISATION OF ORDER

PLACEMENT & PROCESSING

A detailed sketch of the workflow is depicted in Fig

6. MSMEs have to register with the service provider

by submitting appropriate identity proof. Once their

identity is verified, the MSME can download the

application on their android phones. A registered

MSME has to undergo Password authentication.

Once authenticated, the MSME can search for raw

materials/products. Optimal order quantity

calculation is carried out by employing Economic

Order Quantity (EOQ) (Hax and Candea, 1984)

concepts and techniques. The order quantity

calculation performs statistical analysis of previous

purchases and suggests the profitable order quantity.

Besides, MSME can parallelize the order and split

the quantity required to many divisions and purchase

from a combination of MSMEs – similar to

purchasing from assorted stock owned by

distributors. Once the order is parallelized, then

using the custom specific negotiator, the order can

be customized according to the buyer’s need. After

that the order is placed at the click of a button. Later

the ordered quantity, quantity delivered, last date of

delivery of ordered components are all self managed

by the order tracker, which continuously tracks these

details and alerts the MSME if it is not delivered on

time. For example, consider a buyer MSME who

would like to purchase logs of Burma Teak wood,

the MSME first logs into the application and

specifies the inputs to calculate the economic order

quantity. He also specifies whether the order is

urgent or not. Then the application displays all

AComponent-basedApproachtoRealizeOrderPlacementandProcessinginMSMEs

263

details of MSMEs whose available quantity is

greater than the required economic order quantity;

the MSMEs are listed depending on whether the

order is urgent or not. Then order quantity is

automatically initialized by the system, which can be

changed if the buyer wishes. Once the order quantity

is finalized, at the click of a button the order is

placed, then the MSME is taken to the product

customization where he can customize his order.

The remaining process of tracking the order is

completely taken care by the Order Tracker.

Figure 5: Workflow of Order Placement and Processing.

5 OTHER RELATED

COMPONENTS

The proposed component-based approach executes

on a mobile cloud for efficient information

processing and storage. The architecture of the

mobile cloud environment is very similar to that of

EC2 (Varia, 2010) cloud. The mobile cloud extends

various services to the mobile phone registered with

the system. The cloud spawns a new virtual machine

containing an instance of the framework for every

new session. This ensures a highly scalable multiple-

user environment. The entire system, with the

framework on cloud accessible from android phone,

is said to provide Infrastructure As A Service

(IAAS) (Sushil et al., 2010). Infrastructures provided

as service include persistent remote storage and

remote computing.

The android application acts as an entry point to

the mobile cloud. Using the android application,

MSMEs can search for products, take advice on

optimal order quantity, parallelize order quantity to

purchase from a combination of different MSMEs,

customize order specifications to suit the ever-

changing needs. Hold negotiations and transactions

directly with the concerned MSMEs to track

products and obtain delivery updates as simple text

messages.

6 ADVANTAGES

This system completely removes intermediation and

has automated the order placement and processing

phase in the MSME business transaction cycle. It

makes the whole process easier for those involved

MSMEs because of its automation and user friendly

where it uses the android environment.

All the extra costs incurred in paying

intermediaries can be avoided as this component

helps in direct business between the MSMEs.

The component automatically calculates the

EOQ, ROP values, making it easier for the

MSMEs to make decisions when it comes to

deciding the order quantity. It also alerts the

MSME regarding when it is supposed to re-

order the quantity.

This invention supports order parallelization.

Through Order parallelization, even MSMEs

with a very small financial budget can survive

the market as they parallelize the order and need

to make only partial payments of the products

they buy. They are not burdened to pay the

entire amount; hence even an industry with a

small warehouse can be lead in the market.

Custom Negotiator helps in producing

customized products, making it more satisfying

to the buyer as he gets the product with all his

custom requirements installed. Also direct

negotiations are win-win model, satisfying both

the parties and there is no room for confusions

in customization as it is specified directly to the

manufacturer and not through any middlemen.

Order Tracker helps the MSME in tracking the

order. As everything is automated, the MSME

can be tension free. The delivery date alert,

along with the entire order is all maintained by

the order tracker and can be accessed by the

buyer MSMEs, even remotely using his mobile

phone and the android application.

DATA2014-3rdInternationalConferenceonDataManagementTechnologiesandApplications

264

7 CONCLUSION

Our proposed component-based approach makes

MSMEs independent on middlemen during order

placement and processing that has been analyzed

and provided with an mobile phone-based

implementation. It is evident from the

implementation with mobile cloud and android

application surely avoids the vital role played by

middlemen in the order processing task. From the

experiments conducted, we understand that the

proposed approach comparatively outperforms the

other traditional systems and give an end-to-end

solution in order placement and processing.

Introduction of this type of component-based

approaches improves the MSME business to new

level and creates sustainable development in B2B

sector.

REFERENCES

Abigail, T., Cooke, 2000. New Role for the Middlemen.

Inet2000 Proceedings on E-Commerce and EBusiness.

Jinesh Varia, 2010. Architecting for Cloud: Best Practices,

Amazon, Inc., Tech. Re p., Jan. 2010.

Pius M.Achuama, Abel Usoro, 2010. Dancing with the

Stars: E-CRM and SMEs in Developing Countries,

Journal of Economic Development, Management, IT,

Finance and Marketing.

Stuart Taylor, Andy Young, Neeraj Kumar, James

Macaulay, 2011. Taking Care of Business in the

Mobile Cloud. CiscoIbsg Research Uncovers New

Opportunities for SPS to Prosper in the Mobile Cloud

Market.

Wole Michael Olatokun, Mohotetsi Kebonye, 2010. e-

Commerce Technology Adoption by SMEs in

Botswana, International Journal of Emerging

Technologies and Society.

Yusho Nakamoto, Hiroshima; Tomio Muneishi,

Hiroshima; Takamichi Teraoka, Hiroshima; Takashi

Kanbara, Hiroshima, 2002 Simplified order-placement

and reception processing method and system Sep. 19,

2002

Saravanan, M., Amirtha Varsani, M., and Brindha, S.,

2012. Ontology Engineered MSME Framework,

International Conference on Data Engineering, DATA

2012, Rome, Italy.

Hax, AC and Candea, D, 1984. Production and

Operations Management, Prentice-Hall, Englewood

Cliffs, NJ, p. 135.

Ken Pepple, 2011. Deploying OpenStack (First

Edition),United States of America : O’Reilly Media,

Inc.

Sushil Bhardwaj, Leena Jain, Sandeep Jain, 2010. Cloud

Computing: A Study Of Infrastructure As A Service

(Iaas), International Journal Of Engineering And

Information Technology

Upadhyay Parijat & Dan P.K, 2010, User’s Perspective of

Factor(s) influencing for ERP implementation in Small

and Medium Enterprises in India, Innovation in

Information and Communication Technology, ISBN-

0230-63714-0, MacMillan Publication.

Andersen, T, 2003. HRM in SME’s – first findings on

structure and practices. LOK- conference at

Kongebrogarden, Middlefart, Dec 1-2,2003.

Ioana Giurgiu , Oriana Riva , Gustavo Alonso, Dynamic

software deployment from clouds to mobile devices,

Proceedings of the 13th International Middleware

Conference, December 03-07, 2012, ontreal, Quebec,

Canada

AComponent-basedApproachtoRealizeOrderPlacementandProcessinginMSMEs

265