Shape Memory Alloy-based High Phase Order Motor

Claudio Rossi

1

, Zongjian Yuan

2

, Chao Zhang

1

, Antonio Barrientos

1

and William Coral

3

1

Centre for Automation and Robotics CAR UPM-CSCI, Madrid, Spain

2

Northwestern Polytechnical University, Xi’an Shaanxi, China

3

Universidad Polit

´

ecnica de Madrid, Madrid, Spain

Keywords:

Shape Memory Alloys, Stepper Motor, Artificial Muscles, Smart Materials, High Phase Order Motor.

Abstract:

In this paper, we present our current work in the design and characterisation of a new shape memory alloy

(SMA)-based High Phase Order Motor (HPOM). The motor can be used either in stepping mode or in servo

mode of operation. Each phase of the motor consists of an SMA wire with a spring. The principle of operation

of the HPOM is presented. In its operation the motor resembles a stepper motor though the actuation principles

are different and hence has been characterised similar to a stepper motor.This motor can be actuated in either

direction depending on which SMA is actuated, which are presented in this work. The motor is modelled and

simulated and the results of simulations and experiments are presented.

1 INTRODUCTION

The Shape memory effect refers to the ability of cer-

tain materials to ”remember” a determined shape at

a specified temperature (Coral et al., 2012). Due to

their unique behaviour, they are also called intelligent

or smart material. Generally, NiTi (Nickel-Titanium)

SMAs are the most common alloys used. NiTi SMAs

work based on the shape memory effect, which es-

sentially takes place by the influence of temperature.

Heating this material by joule effect we obtain a con-

traction in the material, i.e. applying an electric cur-

rent we can heat this material and thus produce move-

ment. By definition, the electric resistivity is linked

to the length of material, this means that the internal

electrical resistance of the SMA changes when it con-

tracts. Basically this allows us to use the SMA as an

actuator and sensor simultaneously. In fact, most of

the applications involving position linear control of

SMAs, feedback electrical resistance measurements

to estimate the motion generated by the actuator. This

avoids the inclusion of external position sensors for

closing the control loop.

Due to its characteristics compared to conven-

tional technologies such as hydraulic/pneumatic ac-

tuators or electric motors/servomotors the SMAs of-

fer improvements in the size, weight, strength, etc.

for this reason in Robotics some applications have

been developed using SMA (Rossi et al., 2010),(Rossi

et al., 2011a) (Rossi et al., 2013), and (Colorado et al.,

2012). The actuators based on SMAs can be broadly

classified into Limited Motion Type and Unlimited

Motion Type. Under limited motion type both lin-

ear and rotary type actuators are presented in litera-

ture. Under unlimited motion type actuators only one

type of motor was presented (Reynaerts and Brussel,

1998). This motor used springs made of SMA wires

for actuation. Using SMA wire is possible to de-

sign actuator in tension mode (wire actuator), torsion

mode (spring actuator) and bending mode (strip ac-

tuator), as presented by (Otsuka and Wayman, 1998)

and (Reynaerts and Brussel, 1998). In terms of En-

ergy Density the SMA actuator designed using SMA

strips has 46 J/kg (Reynaerts and Brussel, 1998) while

compared to SMA actuator designed using SMA wire

has an energy density of 466 J/Kg. It is evident that

the SMA used in tension mode has 100 times more

energy density compared to SMA used in bending

mode. Therefore, in this paper, we present our work

to build a High Phase Order Motor, which uses SMA

wires in tension mode. For the same volume of SMA

material used the motor generates more torque com-

pared to the motor designed with spring or strip type

SMA actuator. it was noted (Kuribayashi, 1989) that

SMA spring or strip generates force as a non-linear

function of its deformed length. The actuation used in

the present work generates a constant effective force

throughout its operating range. The motor presented,

works in stepping mode (Kuo and Tal, 1979), (Kuo,

1979) generating incremental motion and servo mode

562

Rossi C., Yuan Z., Zhang C., Barrientos A. and Coral W..

Shape Memory Alloy-based High Phase Order Motor.

DOI: 10.5220/0005114805620568

In Proceedings of the 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2014), pages 562-568

ISBN: 978-989-758-040-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

generating continuous motion. The SMA wire based

motor presented has better dynamic response com-

pared to the motors that use SMA strips or springs.

Analyzing the energy efficiency in the SMA actua-

tor, it can never have a greater efficiency compared to

a Carnot cycle between heating and cooling tempera-

tures. Therefore, an SMA actuator will never compete

directly with classical electric actuators. But the SMA

has very high power to weight ratio and power to vol-

ume ratio compared to the conventional electric actu-

ators and hydraulic actuators (Reynaerts and Brussel,

1998). There are several applications where the en-

ergy efficiency is not significant but a large power has

to be generated with a compact size and light weight

actuator. Therefore, SMA has found wide usage in

Space, Robotics and Medical application due to its

compact size, light weight, extremely cheap, capable

of working at low voltages, easily available commer-

cially

1

non magnetic property, large force-weight ra-

tio, large life cycles, negligible volume, sensing ca-

pability, noise-free operation, smooth and insensitiv-

ity to space radiations, namely, electrons, protons and

heavy ions. The experience gained during the last

years at the Bioinspired Systems Lab

2

of CAR UPM-

CSIC with previously designed robots has demon-

strated that by (i) finding suitable niches of applica-

tion, (ii) dedicated mechatronics design, and (iii) ad-

hoc control strategies, SMAs can effectively be used

as an alternative actuation technology in a wide spec-

trum of applications and robotic systems.

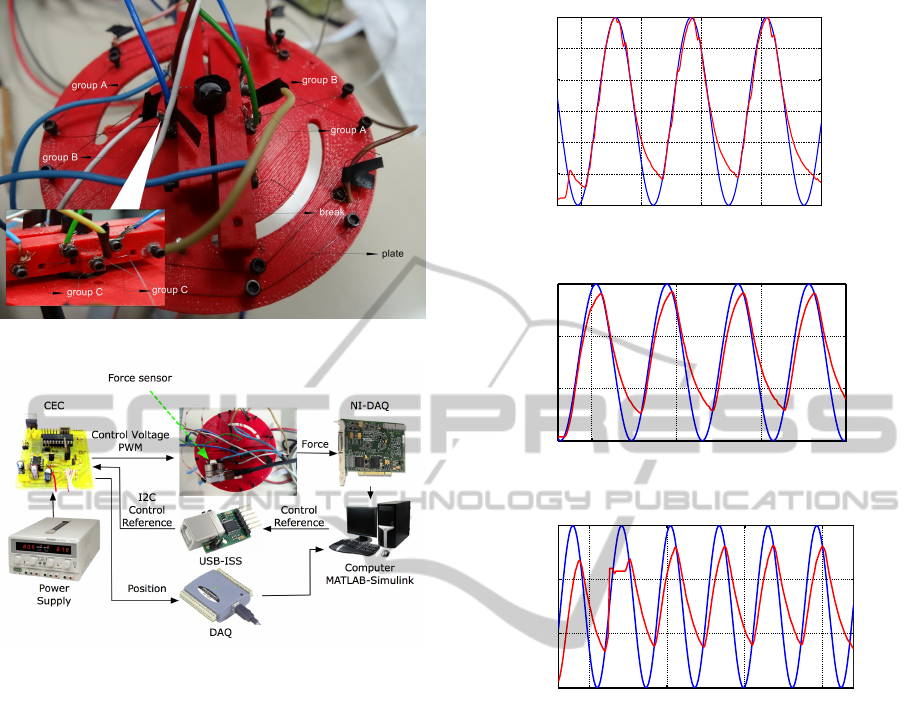

2 MECHANICAL DESIGN

Following the same principle of a conventional elec-

tric motor, the proposed actuator is composed of two

parts, stator and rotor. Here, the stator and the rotor

are called, respectively, break and plate. Both parts

of the actuator have been prototyped in ABS and pro-

duced with a 3D Printer. Three groups of SMA work

on the actuator. We name them as group A, B, C (see

Figures 2 and 4). All SMAs adopted have a diameter

of 150µm , a pull force of 321 grams-force, a power

consumption of 410mA at room temperature, and a

nominal contraction time of 1 second. Note that con-

traction time can be improved by overloading (Rossi

et al., 2010). The diameter size of the SMA wires has

been chosen as a trade-off between current consump-

tion, pull force and contraction time.

1

NiTi (Nickel-Titanium), such as NiTinol

R

are the

most commonly commercially available SMAs.

2

http://www.disam.upm.es/˜ crossi/Bio Inspired Robots/

Bio Home.html.

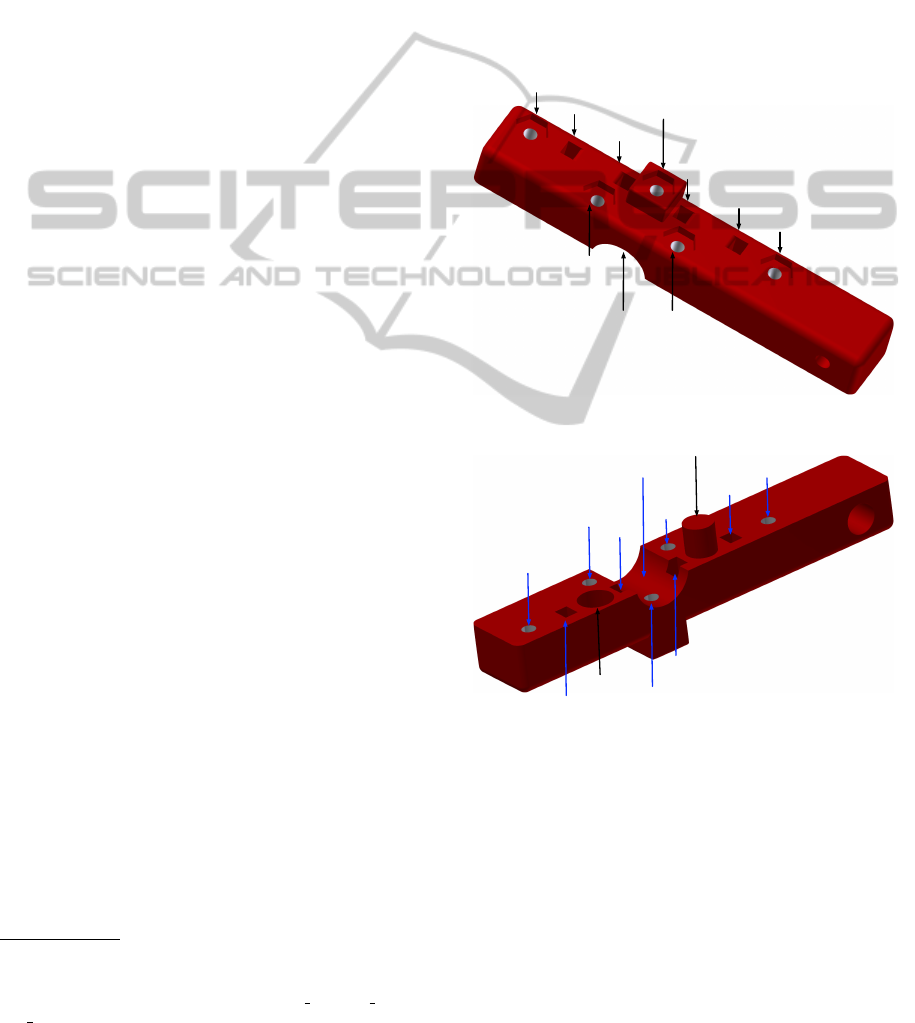

2.1 Brake

Is composed by two identical arms, each facing each

other. The figure 1 shows the Top and Bottom view

in one of this arms. This part moves the shaft in both

directions (clockwise and counterclockwise) or block

and prevent undesirable movements. Both functions

by grasping the shaft between the Shaft Hole. This

functions are achieved by controlling the contraction

of the SMAs located within the two brake arms as

show in the figure 2.

Left

Brake

Bolt

Right

Brake

Bolt

Center

Brake

Bolt

Left

Hole

1

Left

Hole

2

Right

Hole

2

Right

Hole

1

Left

Rotor

Bolt

Right

Rotor

Bolt

Shaft

Hole

(a) Top view.

Left

Brake

Bolt

Center

Brake

Bolt

Left

Hole

2

Left

Hole

1

Left

Rotor

Bolt

Shaft

Hole

Right

Rotor

Bolt

Right

Hole

2

Right

Hole

1

Right

Brake

Bolt

Guide

Hole

Guide

Bar

(b) Bottom view.

Figure 1: Break arms.

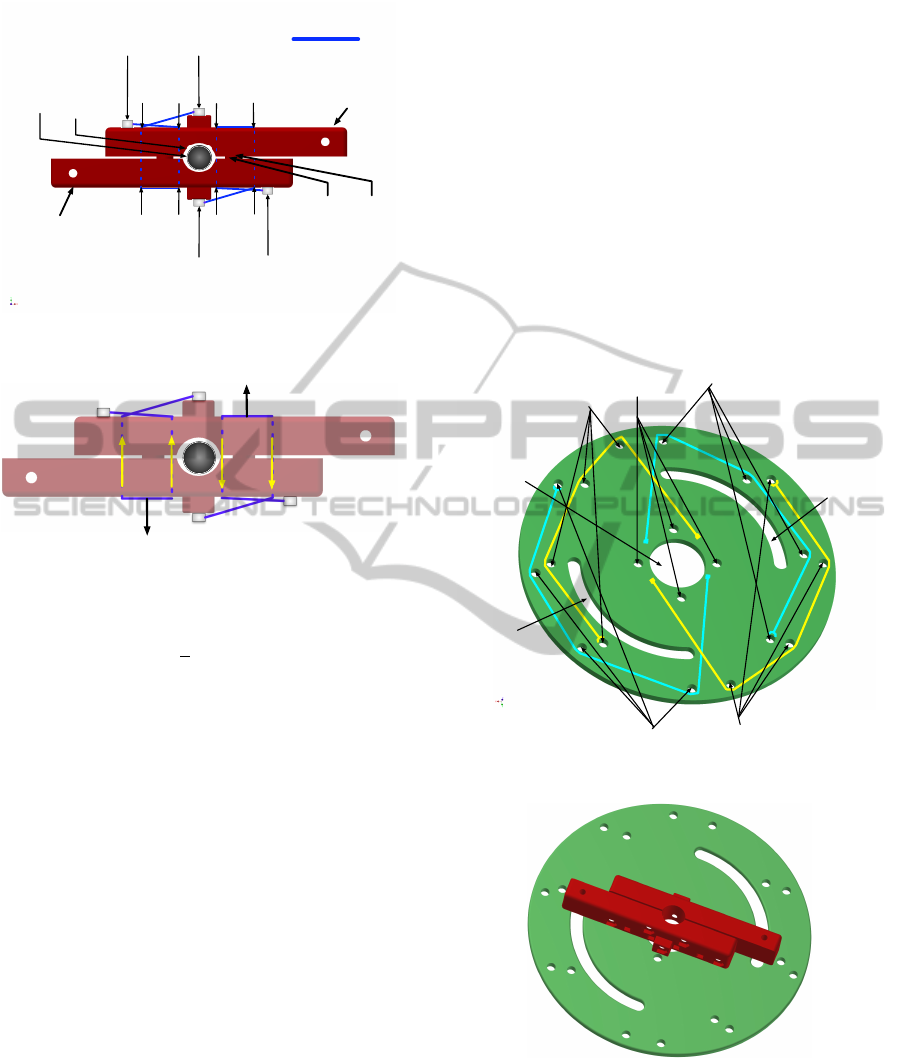

There are two pairs of SMA wires called Group

C that can be actuated by separate or at same time

to increase the amount of forces applied to the shaft.

Each of these connect the two arms in two sections

and 8 Points. In this way the force to grasp the shaft

is multiplied by four times the force of the SMA.

The force diagram is show in the figure 3 and it is

represented in the equations below.

ShapeMemoryAlloy-basedHighPhaseOrderMotor

563

SMA "Group C"

A

Left

Brake

Bolt

A1

Left

Hole

1

A2

Left

Hole

2

B

Center

Brake

Bolt

E1

Arm 1

E2

Arm 2

B1

Right

Hole

2

B2

Right

Hole

1

D2

Left

Hole

1

D1

Left

Hole

2

C1

Right

Hole

1

C2

Right

Hole

2

D

Left

Brake

Bolt

C

Center

Brake

Bolt

Shaft

Shaft

Hole

Guide

Hole

Guide

Bar

Figure 2: Arrangement of the SMA wires actuating the

break.

F

T

1

F

S

1

F

S

1

F

S

2

F

T

2

F

S

2

Figure 3: Forces acting on the brake.

F

T

1

= F

S

1

+ F

S

1

F

S

1

=

1

2

F

SMA

1

F

T

1

= F

SMA

1

(1)

F

T

2

= F

SMA

2

(2)

F

SMA

1

= F

SMA

2

F

T

= F

T

1

+ F

T

2

(3)

2.2 Plate

This is the base where the brake is housed. Is com-

posed by only one part. The most function of this

part is to houses the SMAs that allow to rotate the

brake, that will act as a rotor. The radius of the

plate is set in such a way to allow arranging a large

segment of the SMAs, which is passes through set

of guides. Such arrangement, shown in Figure 4 is

needed since the SMA wires only contracts approxi-

mately a 4% of their length, and this group of SMAs

determines the number of degrees that the brake can

rotate. The speed and the amount of rotation over the

brake is determined controlling the contraction of the

SMAs. Two pairs of SMA wires that can be actuated

individually or at same time depending of the amount

of force to be applied to the break to rotate the shaft

(when it is blocking it) and how much force is to be

applied.

The Group A allows to rotate the brake clockwise

and the Group B counterclockwise. Each phase is

composed by one ”Group A and B” the Figure 4a

show only one phase. Each time that another phase

is required (for improved speed) we only need to add

other plate more like in a sandwich. Note that at rest

position SMAs A are fully extended, while SMAs B

are loose, in such a way not to prevent SMAs A to

contract. When SMAs A are contracted, SMAs B will

be fully extended and thus ready to contract to bring

the brake back to the start position.

The force applied to the brake to rotate it for ev-

ery wire is 321 grams-force this because the friction

between the SMA and the screw is negligible.

Shaft

Hole

Fixation

Holes

Trail Guide

Arm1

Trail Guide

Arm2

Holes

Group B

Arm1

Holes

Group A

Arm1

Holes

Group B

Arm2

Holes

Group A

Arm2

(a)

(b)

Figure 4: Arrangement of the SMA wires used to rotate the

brake (a) and arrangement of the two parts (b).

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

564

3 OPERATION PRINCIPLE

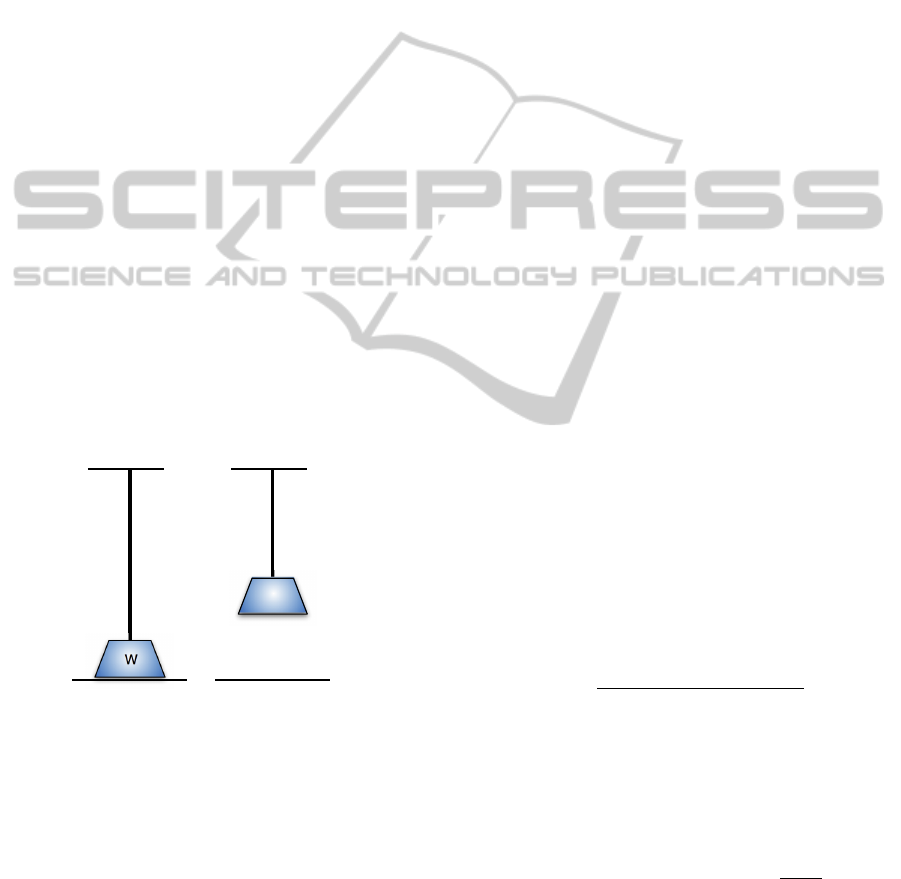

3.1 Principle of One Way Shape

Memory Effect

The ability to remember a predetermined shape af-

ter several deformation is called Shape Memory Ef-

fect (SME). The Martensite phase transformation

is responsible for the shape changes with tempera-

ture variation. Commonly SMA wires are made of

metal alloys (nickel-titanium) and they are known as

NiTi. The NiTi alloy is trained to remember a short

length at high temperature by heat treatment. In cold

state (Martensite) the SMA is malleable and can be

stretched to a longer length with a small force. Nor-

mally in SMA actuators a biasing force is applied dur-

ing the cold condition to stretch the SMA wire to a

designed length faster. this process is known as pre-

loading. Pre-loading is usually done by using a spring

in series with the SMA wire or a weight (W) to gen-

erate force by gravity (figure5). When the SMA is

heated to high temperature (Austenite), SMA shrinks

to the trained length. While shrinking, the SMA be-

comes hard, and can pull much larger force than what

is required to stretch SMA at low temperature. The

proposed High Phase Order motor is designed using

one way SMA wires.

///////// /////////

W

W

/////////////

/////////////

Low

Temperature

High

Temperature

Figure 5: One way SMA actuation.

3.2 Shape Memory Alloy-Based HPOM

Operating Principle

The principle of functioning can be explained in 5

steps (always actuating the SMA Groups A, B, and

C) as shown below.

• Step 1: The ”Group C” (phase 1) is actuated and

the shaft is locked.

• Step 2: While the ”Group C” (phase 1) is actuated

, the ”Group A or B” (phase 1) (depending on the

the way of rotation, clockwise or counterclock-

wise) is actuated simultaneously. To simplify the

explanation we decided to actuate the ”Group A”

• Step 3: When the ”Group A” (phase 1) is fully

contracted we release it and the ”Group C” from

the phase 2 is actuated.

• Step 4: The ”Group C” (phase 1) is released and

the ”Group A” (phase 2) is actuated.

• Step 5: When the ”Group A” (phase 2) is fully

contracted we release it and the ”Group C” from

the phase 2 is released.

4 MODELING AND CONTROL

Both parts (brake and plate) are controlled with a PID

controller with an external force feedback loop con-

trol. Using the changes over the internal resistance of

the SMA it is possible to implement as well a posi-

tion control. Force/position control strategies provide

an effective framework to deal with tasks involving

interaction with the environment.

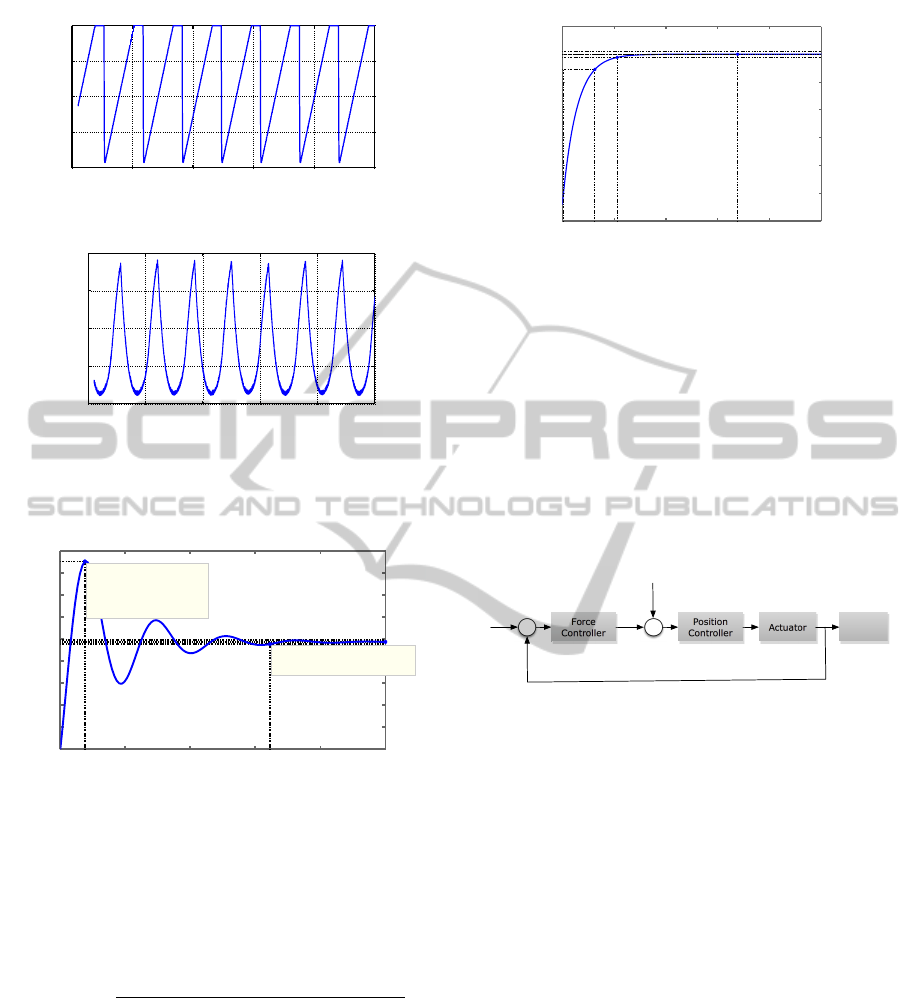

4.1 System Identification and

Controller

Using the force feedback loop we can linearize the

behaviour of the SMA. In this way we obtain experi-

mentally the model for the brake and plate. The input

signal used to actuate the SMA and the output sig-

nal obtained by the force sensor due to this action is

show in the Figure 6. After system identification, car-

ried out using the ”ident” tool box of MATLAB

R

,

the transfer function obtained is:

G(s) =

0.002697s + 0.0001736

s

2

+ 0.02438s + 0.003559

The step response of G(s) in open loop is shown

in Figure 7.

For the control, we used a PID (proportional-

integral-derivative) controller, which responds to the

equation:

u(t) = K

p

e(t) + K

i

Z

t

0

e(t)dt + K

d

de(t)

dt

, (4)

where e(t) is the signal error and u(t) is the control

input of the process. K

p

, K

i

, K

e

are the proportional,

integrative and derivative gains. We have tuned the

values to the three parameters (K

p

, K

i

, K

d

) of the PID

controller based on the analysis of the open and close

ShapeMemoryAlloy-basedHighPhaseOrderMotor

565

0 10 20 30 40 50

0

2

4

6

8

Time

Voltage

Voltage Vs Time

(a)

0 10 20 30 40 50

100

200

300

400

500

Force Vs Time

Time

Force

(b)

Figure 6: SMAs step response in open loop (a) Input, Volt-

age (V) Vs Time (s), (b) Output, Force (gf) Vs Time (s).

Step Response

Time (seconds)

Amplitude

0 100 200 300 400 500

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

System: G

Peak amplitude: 0.0853

Overshoot (%): 74.9

At time (seconds): 37.8

System: G

Settling time (seconds): 322

Figure 7: G(s) Step response in open loop.

loop of the system to be controlled. The PID con-

troller gains obtained are:

K

p

= 50000, K

i

= 1000, K

d

= 100

and the transfer function including the PID con-

troller and the feedback is:

GLC3(s) =

2.697s

3

+ 135s

2

+ 8.95s + 0.01736

3.697s

3

+ 135s

2

+ 8.953s + 0.01736

Figure 8. shows the step response of function

GLC3(s).

4.2 Control Schema

In the control system (Fig. 9), the force error is con-

verted in a suitable reference trajectory for the inner

position controller which is defined in the Cartesian

space or the angular space (De Schutter and van Brus-

sel, 1988). When there are no constraints due to the

Step Response

Time (seconds)

Amplitude

0 0.1 0.2 0.3 0.4 0.5

0.7

0.75

0.8

0.85

0.9

0.95

1

1.05

Figure 8: Step response function GLC3(s). Peak Response

0.338s, Settling Time 0.106s, Rise Time 0.06s.

environment, the force controller will be without ef-

fect and the position controller will continue to con-

trol the system. When constraints appear, the force

controller allows the control of the generated efforts.

This configuration makes it possible to control the

force and the position simultaneously. The force con-

trol loop is designed to prevail over the position con-

trol loop the event of a conflict (Ferguene and Re-

douane, 2009). This means that the force controller

dominates the position controller

Force

Controller

Position

Controller

Actuator Output

+

+

+

-

F

d

F

e

U

X

d

X

c

∆X

Figure 9: Control schema (X

d

: Desired Position; F

d

: De-

sired Force; ∆X: Modifier resulting from the force control

loop; X

C

: Position command; U: Control Reference; F

e

:

Environment Force).

5 EXPERIMENTAL RESULTS

This section primarily describes the experimental

tests, along with a comparison of the results with the-

oretical predictions. The experimental tests were per-

formed at different excitation frequencies but same

amplitude while keeping the same input signal (sine

wave)

The experimental setup for the system identifi-

cation was made using the Control Electronic Cir-

cuit (CEC) (Rossi et al., 2010), (Rossi et al., 2011a),

(Rossi et al., 2011b). Its allows to measure voltages

and current through the SMA wires as well as to pro-

gram the PIC microcontroller embedded on the circuit

to directly control the SMA without external devices.

It is also possible to communicate with this through

the I2C Bus, SPI Bus or Serial Port. Using the voltage

and current we can estimate the value and the changes

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

566

Figure 10: Experimental testbed, Plate and Brake.

Figure 11: Experimental testbed.

over the internal resistance in the SMA and is possible

in this way to know the actual percentage of shrink-

ing. The method consists in measuring the electrical

resistance of an SMA element (Teh and Featherstone,

2008), calculating a maximum safe heating current

as a function of measured resistance, and ensuring

that the actual heating current does not exceed this

maximum value. In fact resistance is being used as a

form of temperature measurement, and the maximum

safe heating current is designed to prevent overheat-

ing. The force response is measured using a Nano

17 transducer (ATI Industrial Automation, ) through

a data acquisition card (NI-DAQ) NI PCI-6220 (Na-

tion Instruments, ). It has a 0.318 gram-force of res-

olution. The figure 10 shows the testbed used. This

also shows the data acquisition device (DAQ) USB-

1208FS (Measurement Computing, ) used to mea-

sure the voltages from the CEC and the USB-ISS al-

lows communication between the Computer and CEC

through I2C Bus. The complete setup is depicted in

figure 11.

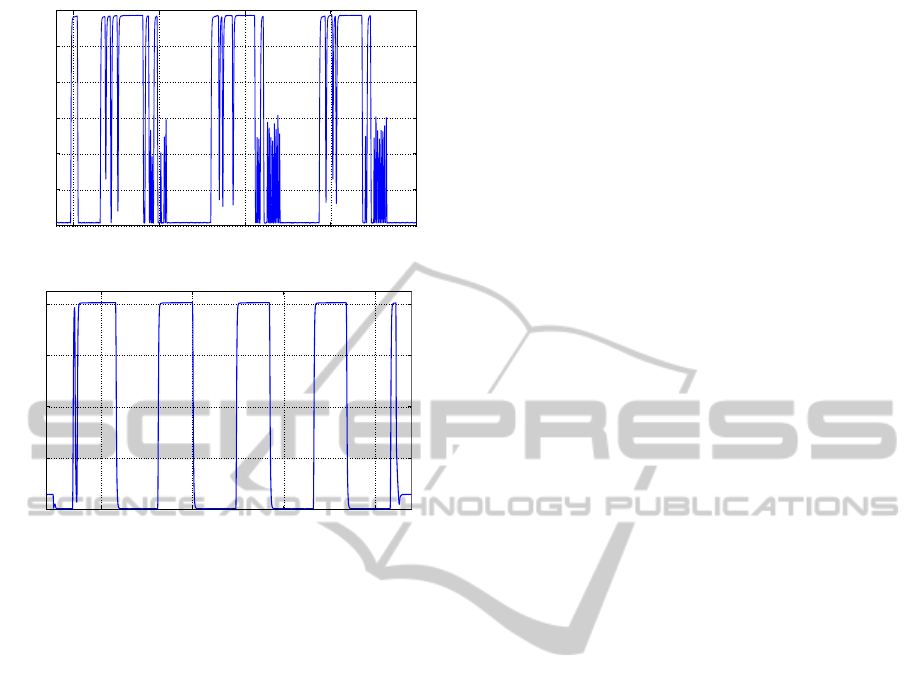

When the frequency increase the tracking error

also increases but increasing the ISMA the speed re-

sponse improves. In this way the tracking error is re-

5 10 15 20 25

0

100

200

300

400

500

600

Force Response 1Hz

Time (s)

Force (Grams−Force)

(a)

5 10 15 20

0

200

400

600

Force Response 1.5Hz

Time (s)

Force (Grams−Force)

(b)

5 10 15 20

0

200

400

600

Force Response 2Hz

Time (s)

Force (Grams−Force)

(c)

Figure 12: Experimental results: (a) Force response at 1 Hz,

(b)1.5 Hz, (c) 2 Hz.

duced. Theoretically the maximum force produced

from the SMA in the Group A was 642 grams-force

experimentally we obtained a force (frequency 1Hz)

of 600 grams-force.

6 CONCLUSIONS

In this study we built and characterised a novel actua-

tor based in Shape Memory Alloy (SMA) wires. The

actuator can be instrumented to measure input power

and output force and SMA electric resistance for a

wide variety of force inputs and actuation speeds. Be-

cause each of the force inputs are replicable, the ac-

tuator can be actuated with thousands of combina-

tions of force parameters while providing valuable

data on force and power. The broad range of capa-

bilities of this actuator make it an excellent tool to be

ShapeMemoryAlloy-basedHighPhaseOrderMotor

567

5 10 15 20 25

0

0.1

0.2

0.3

0.4

0.5

Time(s)

I

SMA

(A)

(a)

5 10 15 20

0

2

4

6

8

Time (s)

Vin (V)

(b)

Figure 13: Experimental results: (a)ISMA (A) Vs Time (s)

at 1Hz, (b)Vinput (V) Vs Time (s) at 1.5 Hz.

used like a steeper motor (because we can control the

contraction length and have resolution of steps from

less than a millimeterr) or continuous motor in ap-

plications where the weight a size are critical, and in

particular to make less complex robots reducing the

control and hardware cost.

ACKNOWLEDGEMENTS

William Coral acknowledge to the Administrative

Department of Science, Technology and Innova-

tion (COLCIENCIAS) (grant call 568 2013) and

COLFU TU RO (grant call 2012) from Colombia for

its support. The authors acknowledge the support

of the Robotics and Cybernetics Group at the Cen-

tre for Automation and Robotics UPM-CSIC, the

project ROBOCITY 2030 (Community of Madrid S-

0505/DPI/000235) and the project ROTOS (Ministry

of Science And Innovation of Spain DPI2010-17998).

REFERENCES

ATI Industrial Automation. F/T Sensor: Nano17.

http://www.ati-ia.com. Accessed June 6, 2013.

Colorado, J., Barrientos, A., and Rossi, C. (2012). Biome-

chanics of smart wings in a bat robot: morphing wings

using SMA actuators. Bioinspiration & Biomimetics.

Coral, W., Rossi, C., and Monta

˜

no, J. C. (2012). SMA-

Based Muscle-Like Actuation in Biologically Inspired

Robots: A State of the Art Review. page 30. INTECH.

De Schutter, J. and van Brussel, H. (1988). Compliant robot

motion ii. a control approach based on external control

loops. International Journal of Robotics Research.,

7(4):18–33.

Ferguene, Farid, T. and Redouane (2009). Dynamic exter-

nal force feedback loop control of a robot manipulator

using a neural compensator, application to the trajec-

tory following in an unknown environment. Interna-

tional Journal of Applied Mathematics and Computer

Science, 19(1):113–126.

Kuo, B. C. (1979). Step motors and control systems. Incre-

mental motion control. SRL Pub. Co.

Kuo, B. C. and Tal, J. (1979). Incremental Motion Con-

trol: Step motors and control systems, edited by B.

C. Kuo. Incremental Motion Control. SRL Publishing

Company.

Kuribayashi, K. (1989). A new servo motor using shape

memory alloy. In Industrial Electronics Society, 1989.

IECON ’89., 15th Annual Conference of IEEE, pages

139–144 and 238–243.

Measurement Computing. USB-1208FS.

http://www.mccdaq.com/usb-data-acquisition/USB-

1208FS.aspx. Accessed June 6, 2013.

Nation Instruments. NI PCI-6220.

http://sine.ni.com/nips/cds/view/p/lang/es/nid/14130.

Accessed June 6, 2013.

Otsuka, K. and Wayman, C. M. (1998). Mechanism of

shape memory effect and superelasticity. Shape mem-

ory materials.

Reynaerts, D. and Brussel, H. V. (1998). Design aspects

of shape memory actuators. Mechatronics, 8(6):635–

656.

Rossi, C., Colorado, J., Coral, W., and Barrientos, A.

(2011a). Bending continuous structures with SMAs: a

novel robotic fish design. Bioinspiration & Biomimet-

ics, 6(4):045005.

Rossi, C., Coral, W., and Barrientos., A. (2010). SMA Con-

trol for Bio-mimetic Fish Locomotion. In Interna-

tional Conference on Informatics in Control, Automa-

tion and Robotics (ICINCO), Madeira.

Rossi, C., Coral, W., and Barrientos, A. (2013). Robotic

Fish to Lead the School. In Palstra, A. P. and Planas,

J. V., editors, Swimming Physiology of Fish, pages

407–421. Springer Berlin Heidelberg.

Rossi, C., Coral, W., Colorado, J., and Barrientos, A.

(2011b). A motor-less and gear-less bio-mimetic

robotic fish design. In Robotics and Automation

(ICRA), 2011 IEEE International Conference on,

pages 3646–3651.

Teh, Y. H. and Featherstone, R. (2008). An architecture

for fast and accurate control of shape memory alloy

actuators. International Journal of Robotics Research,

27(5):595–611.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

568