Patterning of Multi-slits on Pipes for Developing Fine Diameter

Stents

Toshiyuki Horiuchi, Hiroshi Sakabe and Hiroshi Kobayashi

Graduate School of Engineering, Tokyo Denki University, 5 Senju-Asahi-cho, Adachi-ku, Tokyo, Japan

Keywords: Stent, Laser Scan Lithography, Slit Pattern, Etching, Stainless Steel Pipe.

Abstract: Precise slit patterns were delineated on fine stainless steel pipes with an outer diameter of 100 μm. The aim

of the research is to clarify the feasibility of fabricating stents with diameters of less than 1 mm by

delineating precise multi-slit patterns on fine pipes. Using a laser scan exposure system, slit patterns with

widths of 11-29 μm were successfully delineated as fundamental stent patterns. At first, the exposure shutter

was opened just before the specimen was scanned. However, swells appeared at the pattern ends. For this

reason, exposure program was changed to open the shutter after starting the specimen scan. As a result,

swells were completely diminished. In addition to simple parallel slit patterns, alternatively positioned

parallel slit patterns were homogeneously delineated. Because the delineation speed of the investigated

method is not fast, an idea of scan projection lithography was also proposed. It is feasible to fabricate stents

if the pipes are etched using the resist patterns as etching masks continuing to the lithography.

1 INTRODUCTION

Catheters and stents have become very important

operation tools and medical components for low

invasive cures of diseased circular organs, blood

vessels, ureters, and others. Speaking on the stents,

net like structures with very complicated patterns

have been proposed and used. (Baichoo and Wong

Kee Song, 2014; Chandrasekhar et al., 2014;

Consentino et al., 2014; Hanada et al., 2013; Kumar

et al., 2013; Wang et al., 2014; Zhu et al., 2013)

Such structures were conventionally fabricated by

weaving fine wires or precisely cutting pipes by a

focused laser beam, and typical outer diameter were

2-3 mm.

It is considered that stents with finer diameters

for example 0.5-1 mm are also necessary in some

cases. However, it will be difficult to fabricate stents

with such fine diameters using the conventional

methods. For this reason, a new fabrication method

of fine-diameter stents is proposed here, and the

feasibility of the method is investigated.

In the new method, it is supposed that net-like

patterns of stents are delineated by laser scan

lithography onto fine stainless-steel pipes, and the

pipes are etched to stents. It has already been

demonstrated in past researches that various helical

patterns are surely delineated onto fine pipes or

wires with diameters down to several tens microns.

(Horiuchi and Sasaki, 2012)

However, it is necessary to delineate more

complicated patterns for fabricating net-like stents.

The stents need to have net-like features that can be

extended in the radial direction by a balloon inserted

in the stents. On the other hand, they need to have

appropriate rigidity for sustaining the compressive

forces from the diseased blood vessels and ureters.

Considering these backgrounds, patterning of

net-like patterns composed of many slit patterns

alternately allocated in parallel to the pipe axis is

investigated. To clarify the ultimate technological

feasibility, stainless steel pipes with outer and inner

diameters of 100 and 60 μm were used as specimens.

Although appropriate pipe diameters were 0.5-1 mm,

such fine pipes were used instead depending on the

limitations of exposure system.

2 LASER SCAN LITHOGRAPHY

SYSTEM

Laser scan lithography system for delineating

patterns on fine diameter pipes was developed in

2003 to fabricate various cylindrical micro-

components with outer diameters of less than 500

103

Horiuchi T., Sakabe H. and Kobayashi H..

Patterning of Multi-slits on Pipes for Developing Fine Diameter Stents.

DOI: 10.5220/0005202601030108

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2015), pages 103-108

ISBN: 978-989-758-071-0

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

μm. (Joshima et al., 2004) The technology was

drastically improved by developing a new system in

which a specimen pipe was held in the vertical

direction. Specimen diameters were gradually

reduced, and the minimum diameter size was

reached to less than 50 μm. (Horiuchi and Sasaki,

2012) And, the system was used for fabricating

micro-coil springs to give contact pressure forces to

probe pins densely arrayed in circuit testers of

semiconductor devices and bio-devices. (Horiuchi et

al., 2012; Horiuchi et al., 2013)

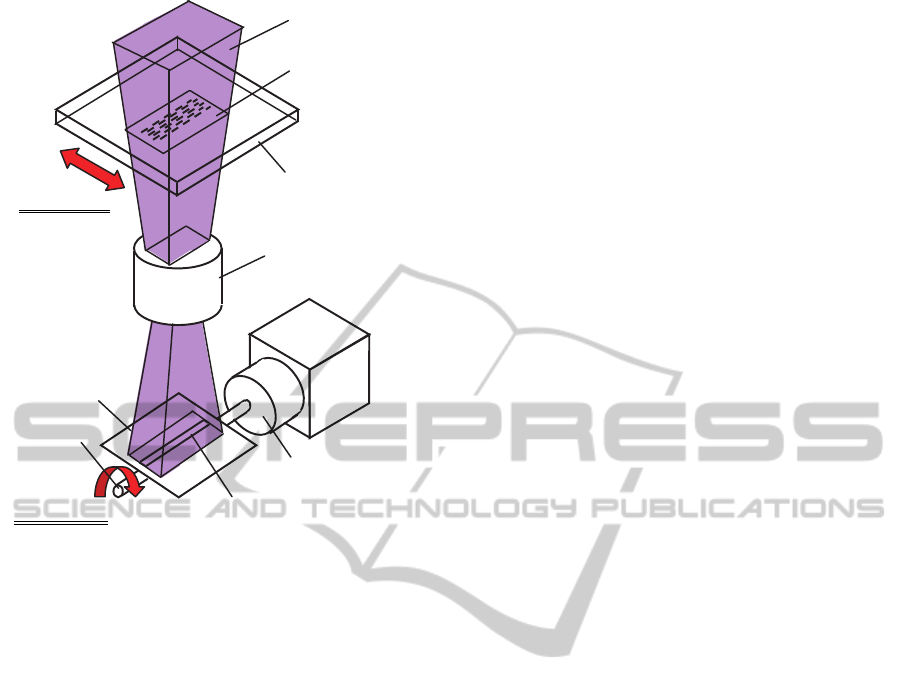

Rotation

stage

Monitor

display

Linear up-and-

down stage

Chuck

Support

guide

XYZ stages

positioning

the guide

Specimen pipe

10X objective lens

Beam splitter

2X imaging lens

1X imaging lens

Beam-spot

i

Camera

Shutter

Pinhole

Violet

laser

Base plate

Pipe

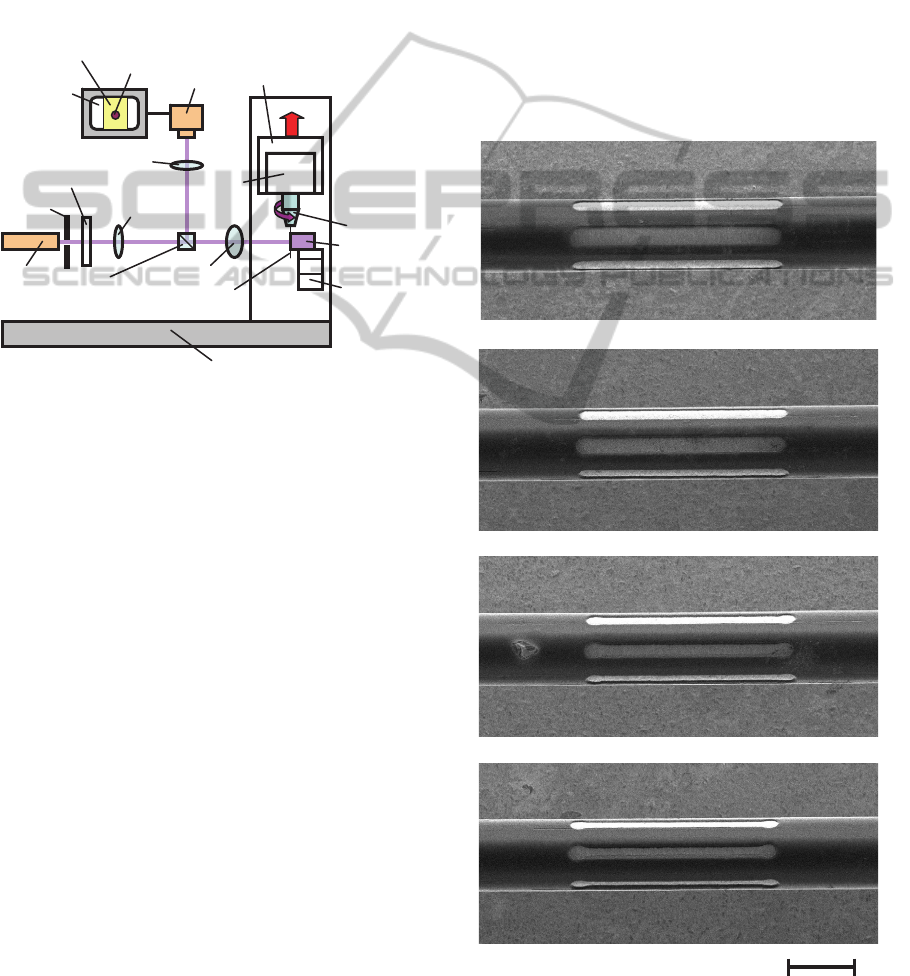

Figure 1: Fundamental structure of exposure system.

The fundamental structure of improved exposure

system is shown in Fig. 1. In the system, laser beam

is reshaped by a pinhole, and the light image of the

pinhole exit is projected onto the surface of

specimen pipe coated with a resist film. The

projection ratio of the optics was calculated to be

1/2×1/10=1/20 in total. The pipe specimen was

supported by a mechanical chuck equipped to a

rotation stage on an up-and-down stage, and scanned

to the laser beam. By moving the specimen pipe, the

resist film was scanned to the laser beam spot, and

sensitized. The exposure beam spot on the

specimen-pipe surface was monitored by projecting

it on a monitor display.

Slit patterns were delineated by vertical linear

scans of specimen pipes, and the specimen pipes

were intermittently rotated for delineating parallel

slit patterns one after another. As a resist, positive

PMER P LA-900PM (Tokyo Ohka Kogyo) was

used, and it was coated on the specimen pipes in

approximately 3 μm thick using the dip method.

(Joshima et al., 2004) This thickness was obtained

by drawing specimens up at a speed of 0.8 mm/s.

3 CONTROL OF PATTERN-END

PROFILES

3.1 Swelling of Pattern Ends

Laser scans were controlled using a mechanical

shutter, and open and shut operations were assigned

by computer programs. At first, slit patterns were

delineated according to the program that the

specimen scan in the vertical direction was started

just after the shutter was opened. Fig. 2 shows the

patterns obtained by above mentioned method. The

slit pattern length was 300 μm. It is known from the

figures that the slit pattern ends swelled according to

the increase of scan speed.

(a) 50 µm/s

(b) 100 μm/s

(c) 200 μm/s

(d) 300 μm/s 100 μm

Figure 2: Slit patterns delineated by starting the scan of

specimen pipe just after the shutter was opened.

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

104

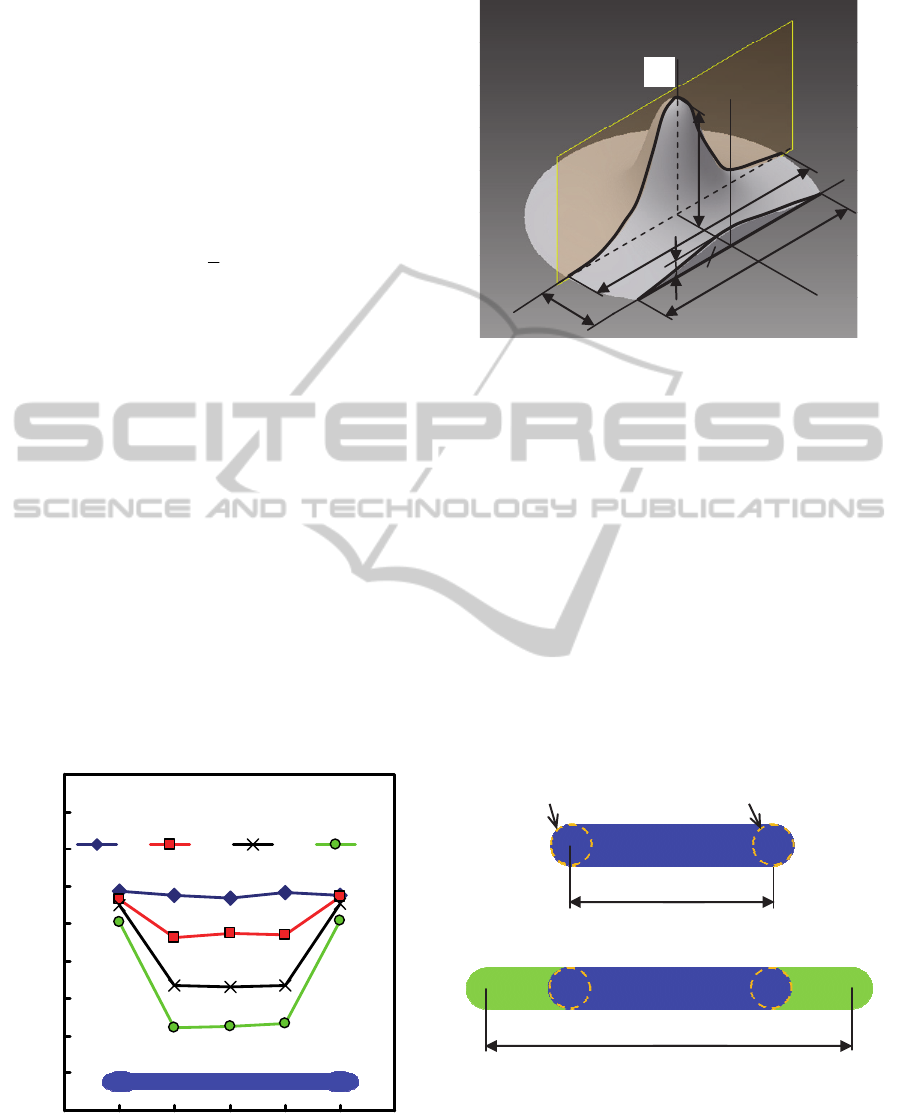

Fig. 3 shows width changes along the patterns. It

was clarified that the swells at the pattern ends

became notable when the scan speed was more than

100 μm/s.

It was considered that these swells of pattern

ends were caused by the difference between the light

beam intensity distributions of static spot exposure

and dynamic scan exposure. Distribution of single-

mode laser spot was roughly simulated by the

Gaussian curve expressed by eq. 1.

2

)(2

0

R

r

eII

(1)

Here, R is the beam radius and r is the radial

distance from the beam centre. It is supposed that

light intensity for the stopped spot exposures at the

start and terminal points distributes according to this

equation.

However, if the beam spot was scanned in x

direction, exposure dose at the distance y from the

centre line of the linear scan was decided by the area

size S

y

of the cross section of stereo beam intensity

profile in the direction parallel to the scan direction

x, as shown in Fig. 4.

The peak intensity I

y

at the distance y is the same

with that for the spot exposure, and estimated by eq.

1, if r is replaced by y. However, the cross section

profiles are different depending on y, because the

length L across the beam varies depending on y.

That is, the length L

0

at the centre is decreased to L

y

at the distance y. When y becomes large, L

y

steeply

decreases. Accordingly, S

y

steeply becomes small.

0

5

10

15

20

25

30

35

40

45

0123456

50 100 200 300

Measured

p

osition

Pattern width (μm)

Scan speed (μm/s)

Slit pattern

Figure 3: Width distribution of slit patterns delineated by

starting to scan the specimen pipe just after the shutter was

opened.

I

0

L

0

L

y

y

x

y

I

s

y

I

y

Figure 4: Figure for explaining parameters deciding the

exposure dose of linear scan.

Because the exposure dose is proportional to S

y

,

the dose also steeply decreases at the side

peripheries or at the places distant from the centre of

scan lines. For this reason, the light intensity across

the scan line distributes narrower than the static spot

exposure. Accordingly, slit pattern widths become

narrower than those at the pattern ends, and swells

of pattern ends are generated.

3.2 Improvement of Pattern Profiles at

Slit-pattern Ends

To improve swells at pattern ends, delineation

method was improved, as shown in Fig. 5.

(a) Beforeimproved.

Scan length

(b) Afterimproved.

Scan length

Beam position for

opening the shutter

Beam position for

closing the shutter

Figure 5: Improvement of timing for opening and closing

the shutter.

In the conventional method shown in Fig. 5(a),

the scan of specimen pipe was started just after the

shutter was opened

. On the other hand, in the

improved method, patterns were delineated by

PatterningofMulti-slitsonPipesforDevelopingFineDiameterStents

105

opening the shutter after the specimen pipes were

scanned, as shown in Fig. 5(b). As a result, linear

space patterns were delineated only by the genuine

scan exposure. Results for the improved method are

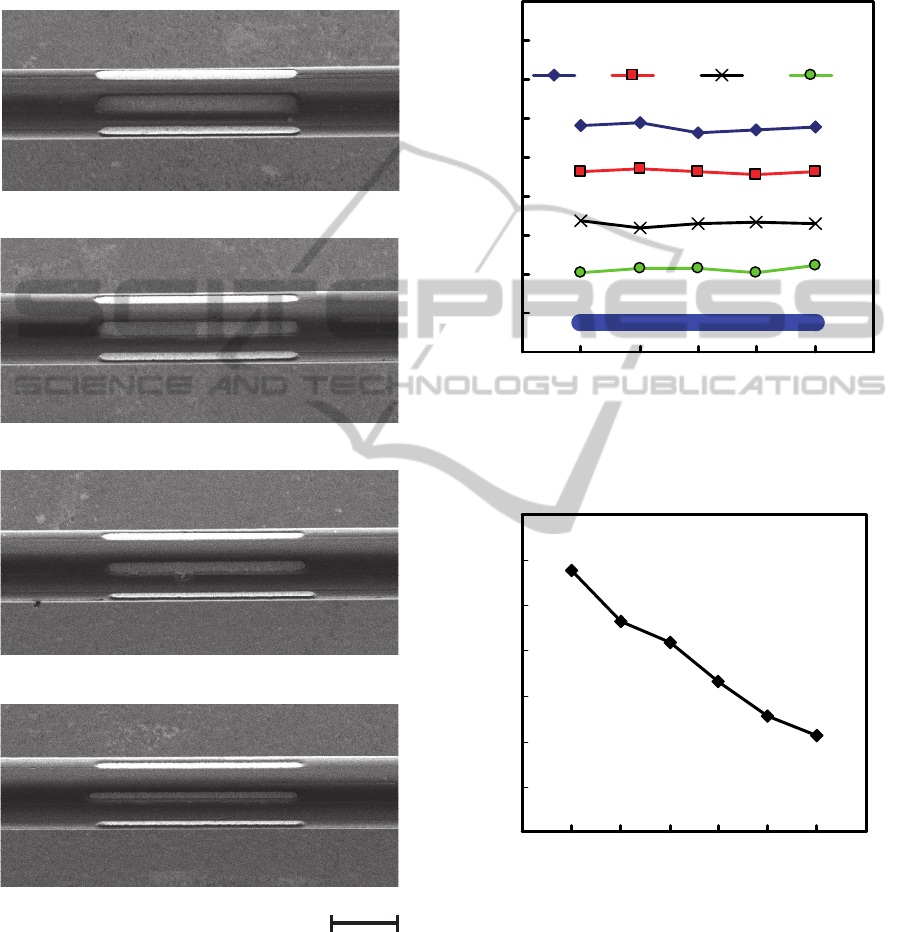

exhibited in Fig. 6.

(b)100 µm/s

(c)200 µm/s

(

d

)

300

µ

m

/

s

100 μm

(a)50µm/s

Figure 6: Slit patterns delineated by opening and closing

the shutter during the scan of specimen pipes.

It was verified that swells at pattern ends were

almost diminished by adding above mentioned

approach and over scans. The width homogeneity is

shown in Fig. 7. It was demonstrated that the straight

space patterns with homogeneous widths were

obtained for various scan speeds. It was clarified that

the mean space-pattern widths were intentionally

changed by adjusting the scan speed in a wide range

of 11-29 μm/s, as shown in Fig. 8.

0

5

10

15

20

25

30

35

40

45

012345

6

50 100 200 300

Measured position

Pattern width (μm)

Scan speed (μm/s)

Slit pattern

Figure 7: Width distribution of slit patterns delineated by

opening and closing the shutter during the scan of

specimen pipes.

0

5

10

15

20

25

30

35

0 50 100 150 200 250 300 350

Scan speed (μm)

Paqttern width (μm)

Figure 8: Space-pattern width dependence on scan speed.

4 ALTERNATELY ALLOCATED

SLIT PATTERNS

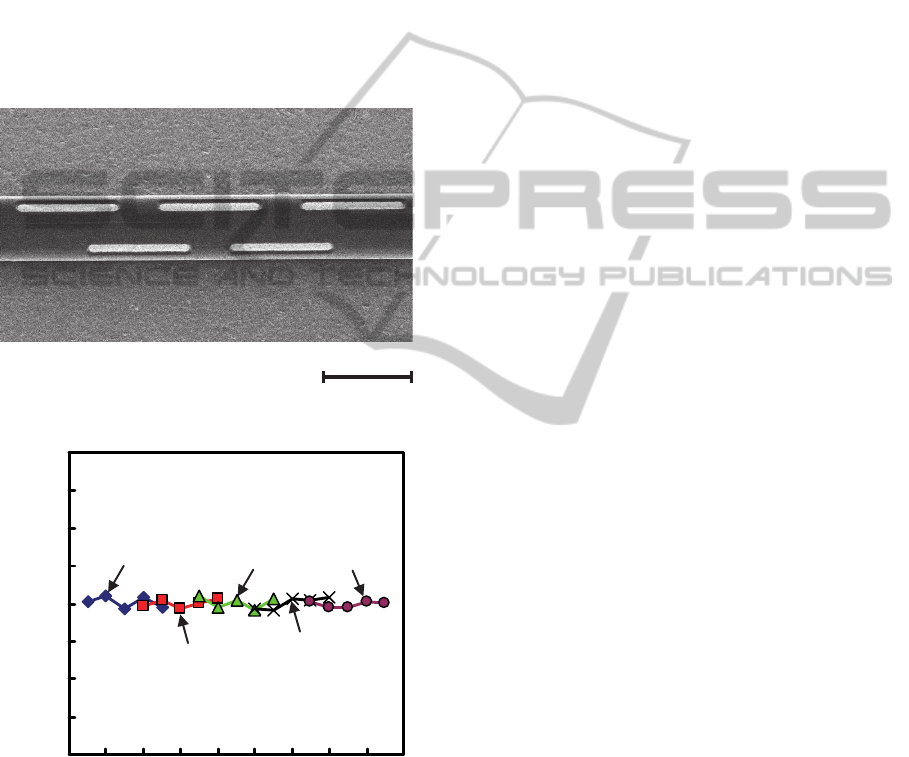

Next, alternately positioned slit patterns were

delineated supposing the fabrication of net-like

stents. Slit pattern positions were shifted by a half

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

106

pitch in the axial direction for every 90° rotation of

the specimen axis. As a result, patterns shown in Fig.

9 were successfully delineated. Measured pattern

widths were almost homogeneous, as shown in Fig.

10. If these patterns were delineated on a long pipe

with appropriate diameters and the pipes were

etched similarly to the patterns, aimed stents would

be obtained.

It seems that the space-pattern widths are too narrow,

and the resist-pattern widths are too wide. However,

pipe walls are excessively etched according to the

undercut phenomena. For this reason, space widths

seem too narrow at a glance are probably

appropriate for etching the pipes.

100 μm

A

B

C

D

E

Figure 9: Alternately positioned slit patterns.

0

5

10

15

20

25

30

35

40

0 2 4 6 8 1012141618

A

B

C

D

E

Measured

p

osition

Pattern width (μm)

Figure 10: Width homogeneity of alternately positioned

slit patterns.

5 IDEAS FOR IMPROVING

PATTERNING SPEED

Slit patterning parallel to the specimen axis was

investigated. As a result, it was clarified that slit

patterns with widths between 11 and 29 μm were

successfully delineated, and pattern widths were

sufficiently homogeneous. However, because the

maximum delineation speed is 300 μm/s, it will take

a long time to delineate practical stent patterns. The

long patterning time is caused by the exposure

principle of the system shown in Fig. 1. Because

only one small laser spot is sequentially scanned on

whole specimen surface, it takes a very long time.

This time, pipe specimens with an outer diameter of

100 μm were used, and by precisely delineating fine

patterns even on such small diameter pipes,

technical difficulty in patterning processes were

almost cleared. The first reason why such fine pipes

were used is the diameter limitation of specimen

pipes attachable to the exposure system, and the

second reason is the too long exposure times for

delineating the slit patterns. Because the resist was

coated in the parts of 20-mm near the specimen-pipe

ends, it took approximately 18 mm / 300 μm/s = 600

s =10 min for delineating only one long slit pattern.

Accordingly, it took 10 min × 6 = 60 min = 1 h for

delineating only 6 long slits on a 100-μm pipe.

However, more complicated or larger volume

patterning is required on specimen pipes with larger

diameters of 0.5-1 mm. If such large diameter pipes

were used, the total exposure time would become 5-

10 h. Therefore, much faster exposure method is

necessary.

As an exposure system for such use, scan

projection exposure system shown in Fig. 11 will be

effective. Original patterns on a reticle are projected

onto a specimen pipe surface through a projection

lens. By inserting an oblong slit aperture above the

specimen, only patterns limited in a narrow region

are printed on the almost flat top-surface of the

specimen pipe. Therefore, the patterns are replicated

clearly without being defocused. In addition, if the

specimen pipe is rotated synchronously to linear

scan movement of the reticle, all patterns on the flat

reticle are printed on the whole cylindrical surface of

specimen pipe.

Because patterns in the oblong exposure field are

simultaneously printed on the specimen pipe, the

total exposure time becomes far shorter than the

laser scan lithography investigated here. Although

the exposure time depends on the width of oblong

slit, the light source power, and the optics for

collecting the exposure light, it will be less than 1

min for a pipe with a diameter of 1 mm.

PatterningofMulti-slitsonPipesforDevelopingFineDiameterStents

107

Opaque plate

Specimen pipe

Exposure light

Exposure field

Projection lens

Rotation stage

Slit

with a slit

Reticle

Linear scan

Rotary scan

Figure 11: Scan exposure system with a high throughput

using a lamp source and a reticle.

6 CONCLUSIONS

Slit pattern delineation on fine pipes were

investigated for developing precise stents with

diameters of less than 1 mm. As a result, fine slit

patterns with widths of 11-29 μm were delineated on

fine stainless steel pipes with outer and inner

diameters of 100 and 60 μm using 3-μm thick

positive resist PMER LA-900PM.

By adding approach and over scans and

controlling the exposure shutter appropriately,

swells at pattern ends were almost diminished. As a

result, slit patterns with homogeneous widths were

obtained. In addition to simple parallel slit patterns,

alternately allocated slit patterns were also

homogeneously delineated.

Because a little long delineation time was

anticipated, scan projection methods were also

proposed as a counter measure. It is feasible to

fabricate small diameter stents, if specimen pipes

masked by the resist patterns are precisely etched.

ACKNOWLEDGEMENTS

This work was partially supported by Grant-in-Aid

for Scientific Research (C) 26390040 from Japan

Society for the Promotion of Science.

REFERENCES

Baichoo, E. and Wong Kee Song, L. M., 2014. Palliative

enteroscopic stent placement for malignant mid-gut

obstruction. Gastrointestinal Intervention, 3(1), pp.

30-34.

Chandrasekhar, J., Allada, C., O’Connor, S., Rahman, M.,

Shadbolt, B., and Farshid, A., 2014. Efficacy of non-

compliant balloon post-dilation in optimization of

contemporary stents: A digital stent enhancement

study. IJC Heart & Vessels, 3, pp. 43-48.

Consentino, D., Zwierzak, I., Schievano, S., Diaz-

Zuccarini, V., Fenner, J. W., and Narracott, A. J., 2014.

Uncertainty assessment of imaging techniques for the

3D reconstruction of stent geometry. Medical

Engineering & Physics, 36, pp. 1062-1068.

Horiuchi, T., and Sasaki, R., 2012. New Laser-Scan

Exposure Tool for Delineating Precise Helical Patterns

onto Sub-50-Micron Wires, Jpn. J. Appl. Phys., 51,

06FL01, pp. 1-5.

Horiuchi, T., Ishii, H., Shinozaki, Y., Ogawa, T. and

Kojima, K., 2012. Novel Fabrication Method of

Microcoil Springs Using Laser-Scan Helical

Patterning and Nickel Electroplating. Jpn J. Appl.

Phys., 50, 06GM10, pp. 1-5.

Horiuchi, T., Sakabe, H., Yuzawa, T. and Yamamoto, D.,

2013. Fabrication of Straight Stainless-steel Micro-

coils for the Use of Biodevice Components. Proc. 6

th

International Conference on Biomedical Electronics

and Devices (BIODEVICES 2013), pp. 114-119.

Hanada, K., Matsuzaki, K., Huang, X., and Chino, Y.,

2013. Fabrication of Mg alloy tubes for biodegradable

stent application. Material Sci. and Eng. C 33, pp.

4746-4750.

Joshima, Y., Kokubo, T., and Horiuchi, T., 2004.

Application of Laser Scan Lithography to Fabrication

of Microcylindrical Parts. Jpn. J. Appl. Phys., 43, pp.

4031-4035.

Kumar, G. P., Cui, F., Danpinid, A., Su, B., Hon, J. K. F.,

and Leo, H. L., 2013. Design and finite element-based

fatigue prediction of a new self-expandable

percutaneous mitral valve stent. Computer-Aided

Design, vol. 45, pp. 1153-1158.

Wang, A., Eggermont, J., Dekker, N., Koning, P. J. H.,

Reiber, J. H. C., and Dijkstra, J., 2014. 3D assessment

of stent cell size and side branch access in

intravascular optical coherence tomographic pullback

runs. Computerized Medical Imaging and Graphics,

38, pp. 113-122.

Zhu, Y., Hu, C., Li, B., Yang, H., Cheng, Y., and Cui, W.,

2013. A highly flexible paclitaxel-loaded poly (ε-

caprolactone) electrospun fibrous-membrane-covered

stent for benign cardia stricture. Acta Biomaterialia, 9,

pp. 8328-8336.

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

108