12 GHz CMOS MEMS Lab-on-chip System for Detection of

Concentration of Suspended Particles in Bio-suspensions

Subhajit Guha, Alexander Wolf, Marco Lisker, Andreas Trusch,

Chafik Meliani and Christian Wenger

IHP, Leibniz Institue of Innovative Microelectronic, Im Technologie Park 25, Frankfurt(Oder), Germany

Keywords: CMOS/MEMS, Lab-on-chip, Biosensor, High Frequency Bio-Sensor, CMOS Biosensor.

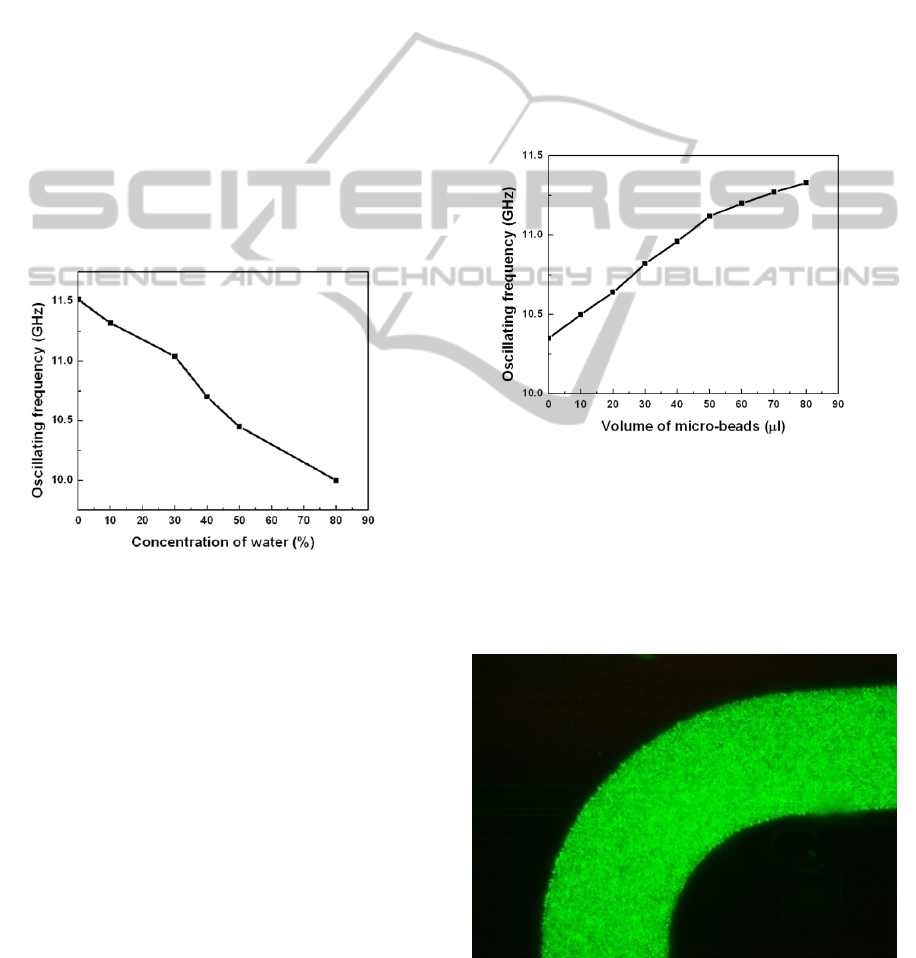

Abstract: This work presents a high frequency (X-band) CMOS dielectric sensor with hybrid microfluidic integration,

applied to biosensing techniques; primarily to detect concentration of suspended particles in a solution. The

detection technique is based on capacitive sensing of varying permittivity of the aqueous solution caused by

different concentrations of suspended particles. The sensor chip is fabricated in 0.25 µm SiGe:C BiCMOS

technology of IHP with post processed PDMS microfluidic hybrid integration. The operating frequency of

the sensor is 12.3 GHz and draws a DC power of approximately 35 mW from 3 V power supply. The

dielectric sensitivity of the chip was characterized and calibrated using different organic fluids (alcohols); a

sensitivity of 100 MHz/permittivity was measured with the sensor. After the calibration phase, the sensor

was further used to measure the concentration of glucose in a homogeneous glucose solution. Frequency

down-shift of 250 MHz/10% increase in water concentration in the homogeneous solution was observed. In

order to analyse the concentration of suspended particles in a solution various concentrations of micro-beads

in acetone solution were measured. Approximately a frequency up-shift of 125 MHz/10 µl increase in bead

volume in acetone was observed. The overall chip size is 2.76 mm

2

.

1 INTRODUCTION

Miniaturized sensors applied to biological and

diagnostic purposes have led to approaches where

measurement and analysis of extremely small

volumes of assays are feasible. With the advent of

micro-fabrication technique and its extension to

microfluidic technology, analysis of samples in the

order of few pico litres has become a reality. Such

complex systems are termed as lab-on-chip (LOC)

devices due to high level of miniaturization and also

parallel analysis capabilities, analogous to a state of

the art biotechnology laboratory. However, detection

and sensing technique in such established LOC

devices rely mainly on optical measurement

techniques as explained by Pires et al (2014).

Although optical measurements often provide a

more visually precise result, the measurement

systems are governed by bulky optical devices and

test-benches. Therefore, the advantages of

developing miniaturized LOC devices are no longer

rational. Added to this, optical measurement

techniques require bio-markers, referred as

fluorescent markers and these markers can

additionally alter the properties of the assays.

Therefore, adapting to a label free sensing approach,

based on “all electrical” technique is absolutely

imperative.

Established electrical analysis methods of

biological suspensions rely on static amperometric

techniques or impedance measurements demons-

trated by various research groups like, Goh and Ram

(2010), Krommenhoek et al (2006), Faenza et al

(2012) and Rassaei et al (2012). Usually impedance

measurements are performed at frequency range of

100 KHz to a few MHz as described by

Krommenhoek et al (2006). In this frequency range

(“low frequency”) biological suspensions show

dielectric dispersions based on the properties of

suspended particles, for example cells. Therefore,

measurement and sensing in this frequency regime

are competent for detection of low frequency

properties of suspended particles or cells (for e.g. in

case of cells, membrane capacitance). However, in

order to detect concentration of particles or cells in a

suspension such dispersions can be highly

cumbersome and can lead to falsified measurement

data. Additionally, “low frequency” measurement

techniques also bring in electrode polarization

49

Guha S., Lisker M., Trusch A., Wolf A., Meliani C. and Wenger C..

12 GHz CMOS MEMS Lab-on-chip System for Detection of Concentration of Suspended Particles in Bio-suspensions.

DOI: 10.5220/0005219300490057

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2015), pages 49-57

ISBN: 978-989-758-071-0

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

mechanism at the electrode electrolyte (biological

suspension) interface, leading to another dispersion

mechanism called the “α dielectric dispersion”,

described by Faenza et al (2012). Also double layer

capacitance at the electrode electrolyte interface

influences the impedance measurement and requires

thorough modelling in order to incorporate its effects

on the measurements. Thus, at lower frequencies,

irrelevant dispersion effects and surface electro-

chemistry have a strong influence, often making

measurement and especially detection of

concentration of suspended particles in a solution

extremely complex. On the other hand,

amperometric techniques allow very precise

measurement but suffer from real miniaturization

issues as a bulky reference electrode is needed for

maintaining solution potential, as can be seen in

approaches like the one described by Rassaei et al

(2012). High frequency (in the order of tens of GHz)

sensors can offer a potential solution to evade the

aforementioned problems. The compatibility of such

sensors with standard CMOS or BiCMOS process

technology would further reduce fabrication costs,

making them highly lucrative for biosensing

approaches.

The advances in RF engineering have led

research groups to explore high frequency

characterization of biological suspensions and

biomaterials. Grenier et al (2013) have demonstrated

the distinction of living and dead cells using

dielectric spectroscopy form 1 GHz to 40 GHz with

a passive interdigitated electrode sensor. Ferrier et al

(2009) have also shown interferometric microwave

sensors for detection of single cells. A coplanar

waveguide approach to characterize yeast cells was

exhibited by Yang et al (2010). However, most of

the aforementioned characterizing sensors are

primarily passive structures realized on PCBs,

therefore, pressing an ever increasing demand for

complete CMOS or BiCMOS sensor system. In

previous works, for e.g. Guha et al (2013), Guha et

al (2014), we have demonstrated C-band to X-band

complete CMOS microwave sensors for dielectric

characterization of glucose solutions, biomaterials

and also imaging of biomaterials. In this work, we

report a complete CMOS/microfluidic system for

dielectric detection of suspended particles in

biological suspensions in the frequency range of 12

GHz. Hybrid integration of the microfluidic system

to the CMOS chip is performed as a post process

step after the chip fabrication. Simultaneous

electrical and optical measurements of suspended

particles in a solution depict close correlation of

both the measurement. The X-band sensor described

in this work aids in avoiding low frequency

dispersion mechanisms described previously. Thus,

concentration of suspended particles can be

unambiguously detected using such a high frequency

sensor approach.

The dielectric sensing is based on capacitive

scaling of an inetrdigitated capacitor (IDC),

embedded in a CMOS cross coupled oscillator,

analogous to a voltage controlled oscillator as

explained by Lee (1998). In this report, the IDC acts

as the variable capacitor. The capacitive scaling

results in shift of resonant frequency of the CMOS

oscillator. Therefore, the change of capacitance

caused by the permittivity variation of the IDC

ambient is read out as the resonant frequency shift of

the oscillator. The permittivity variation is caused by

the dielectric properties of the solutions flowing

within the microfluidic channel aligned on top of the

sensor.

2 SENSOR SYSTEM DESIGN

The complete sensor system design includes a two-

step process. The CMOS dielectric active sensor

chip (CMOS oscillator with the embedded IDC) is

fabricated in the standard 0.25 µm SiGe:C BiCMOS

technology of IHP. The microfluidic system is made

from polydimethylsiloxane (PDMS) using soft

lithography technique with SU8 master mold. The

sensor chip is diced from the wafer and bonded to

the microfluidic system using oxygen plasma

bonding technique.

2.1 Sensor Design

A multi-fingered planar IDC is used as the sensor in

this work. The sensing principle is based on the

variation of fringing electric fields between the

fingers of the IDC, due to the change of permittivity

on top of it. Fig. 1 (a) shows the 3D structure of an

IDC with material under test (MUT) placed on top

of it. The 2D IDC geometry shown in Fig. 1(b)

defines the spatial wavelength of the structure λ

spc

,

which is the distance between two successive fingers

on the same electrode, also given as λ

spc

= 2(w+s). In

this report, the length l of the finger is 50 µm, width

w is 10 µm and the spacing s is 20 µm. The 2D

simulation of a unit cell of the IDC in Fig. 1(c)

shows the electric field patterns between two

adjacent fingers of the IDC penetrating into the

MUT. The permittivity of the MUT influences the

electric fields and also the capacitance of the IDC.

The fringing field capacitance can be analysed based

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

50

on the quasi static approximation of Maxwell’s

equations. Such an approximation can be utilized

when the spatial wavelength (λ

spc

) of the IDC is

comparatively much smaller than the operating

wavelength (λ

em

) of the same. The operating

wavelength is the wavelength of the electromagnetic

wave defined by the frequency (ω=2πf) of operation,

12.3 GHz in our work. Therefore, the spatial

wavelength (λ

spc

= 60 µm) is considerably smaller

compared to the operating wavelength (λ

em

= 2.5

cm), and hence, quasi static approximation of

Maxwell’s equation holds well. The intensity of the

electric field decays exponentially along the z

direction as shown with simulation results in Fig.

1(c). The penetration depth (P

d

) of the electric field

is defined as the distance from the IDC surface along

the z direction, where the strength of the electric

field is 1/e times the maximum field strength. Thus

such a sensor can be effectively used for near field

sensing approaches.

(a) (b)

(c) (d)

Figure 1: (a) 3D structure of IDC with MUT on top. (b)

2D geometry of the IDC. (c) 2D simulation of electric

field in IDC (d) Modelling of IDC showing the different

capacitive contributions.

The total per unit length capacitance of the unit

cell of the IDC is the summation of the capacitive

contributions due to the fringing fields penetrating

into the substrate and the MUT and the parallel plate

capacitive contribution due to the height of the

fingers. The various capacitive contributions are

shown in Fig. 1 (d). The mathematical formulation

of the capacitive contributions can be expressed as,

(1)

The fringing field capacitance per unit length

due to the MUT and substrate is given by,

√

(2)

where, K(k) is the solution of the infinite

elliptical integral dependent on the geometry of the

IDC. The total capacitance of the IDC is given as,

1

(3)

For a given geometry of the sensor, all the other

capacitive contributions being effectively constant,

the fringing field capacitance due to the MUT is the

unique variable, depending on the permittivity of the

MUT. The operating frequency of the sensor

determines the frequency at which the electric fields

within the MUT change their polarity. Thus, the

permittivity of the MUT as sensed by the IDC is

essentially the permittivity at the operating

frequency.

In addition to the geometry, another very

significant parameter of the sensor structure

designed for high-frequency sensing technique is the

self-resonating frequency (SRF) of the structure.

SRF of a structure is defined as the frequency at

which the capacitive contribution of the structure is

nullified by its self-inductive contribution and the

structure is purely resistive. The self-resonating

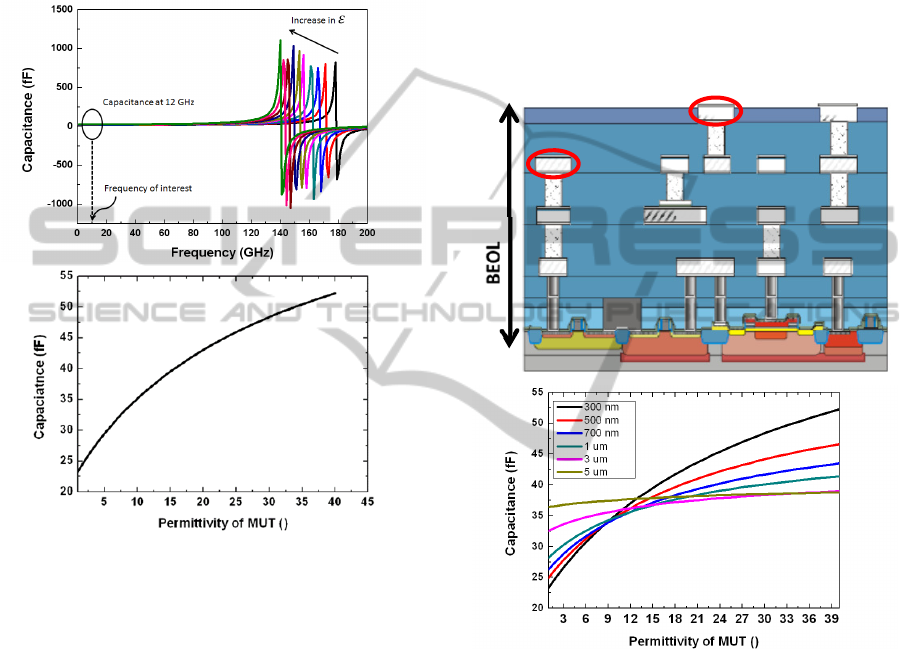

phenomenon is shown in Fig. 2(a), where the

resonance peak in the capacitance vs. frequency

curve defines the frequency at which the IDC’s self-

inductance nullifies the capacitive contribution. The

SRF is dependent on the size of the sensor and also

on the permittivity of the substrate and the MUT.

For a given geometry of the IDC on a specific

substrate, the SRF is only dependent on the

permittivity of the MUT. With the increase of the

permittivity of the MUT the capacitance of the IDC

increases and the SRF reduces as shown in Fig. 2(a).

It is significant to design the operating frequency of

the sensor system considerably lower than the SRF

of the IDC. Fulfilment of such a condition ensures

that the electric field in the IDC is rotation free and

the structure is essentially capacitive. The simulated

SRF of the IDC structure used in this work is

beyond 150 GHz and the operating frequency of the

oscillator circuit is 12 GHz. Thus, the structure is

purely capacitive in the operating frequency range

and Maxwell’s equation in quasi static

approximation can be applied, as discussed

12GHzCMOSMEMSLab-on-chipSystemforDetectionofConcentrationofSuspendedParticlesinBio-suspensions

51

previously. Equation 2 shows that the capacitance of

the IDC increases with increase in the permittivity of

the MUT, and the same is shown in the simulation

results in Fig. 2(b) for the operating frequency

around 12.3 GHz range. With respect to the sensing

mechanism this up-shift of capacitance would be

read out as a downscale of the resonant frequency of

the oscillator.

Figure 2: (a) Impedance simulation of IDC showing

constant capacitance at desired frequency. The self -

resonating frequency is far from the operating frequency.

(b) Variation of capacitance of IDC with permittivity of

MUT.

2.1.1 Fabrication of IDC

The IDC structure along with the CMOS oscillator is

fabricated in the BiCMOS process line of IHP. Fig.

3(a) shows the planarised 0.25 µm SiGe:C BiCMOS

back end of line (BEOL) stack with four metal

layers. The bottom metal layers are lossy due to

relatively small thickness as compared to the two top

metal layers termed as TM1 and TM2. The IDC is

designed in the lower loss TM2 metal layer of the

BiCMOS stack. One major implication of the choice

of the metal layer for designing the IDC, along with

the influence on its quality factor is the influence of

passivation layer. Passivation layer in micro-

fabrication or CMOS technology is an insulation

layer grown on top of the metal layers (electrodes) to

protect the metal layers from external environment.

The passivation layer for a standard BiCMOS

process is 400 nm of Si

3

N

4

(silicon nitride). In this

work, in order to bond the PDMS microfluidic

channel without further fabrication assisted steps,

the standard Si

3

N

4

passivation layer is replaced by

an SiO

2

(silicon dioxide) layer, followed by a

Chemical Mechanical Polishing (CMP)

planarization described by Lisker et al (2013).

Therefore, when the IDC is designed on the topmost

metal layer of the BiCMOS stack, as is done in this

work, the passivation thickness is that of the height

of SiO

2

and has a permittivity of 4.1.

Figure 3: (a) Schematic cross section view of IHP’s

BiCMOS stack. The sensor is fabricated on the topmost

metal layer of the stack. (b) Simulation of variation of

capacitance with permittivity for different thicknesses of

the SiO

2

layer layer.

The thickness and the permittivity of the SiO

2

layer influence the sensor sensitivity. If the IDC is

designed on the TM1 layer of the BiCMOS stack,

the SiO

2

layer has a thickness of approximately 5

µm. This is the combined height of SiO

2

on TM1

and SiO

2

on TM2. Fig. 3(b) shows the simulation of

the influence of thickness of SiO

2

layer on the

variation of capacitance due to permittivity change

of MUT. The sensitivity of the stand-alone IDC is

defined as the change of capacitance per unit change

of permittivity, which is also given by the slope of

the capacitance permittivity curve. The slope as

TM2

TM1

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

52

noted is reduced with the increase in the thickness of

the SiO

2

layer as shown in Fig. 3b. Such a result is

intuitive from the previous section, where the

strength of the electric field was expected to decay

exponentially along the z direction. The effect of

SiO

2

is of wide interest for near field bio sensing, as

often the electrodes are passivated to prevent them

from coming in direct contact with the bio materials.

It is shown with simulations that the sensor is

sensitive up to a passivation thickness of 5 µm and

thus can be efficiently used in near field bio sensing

applications.

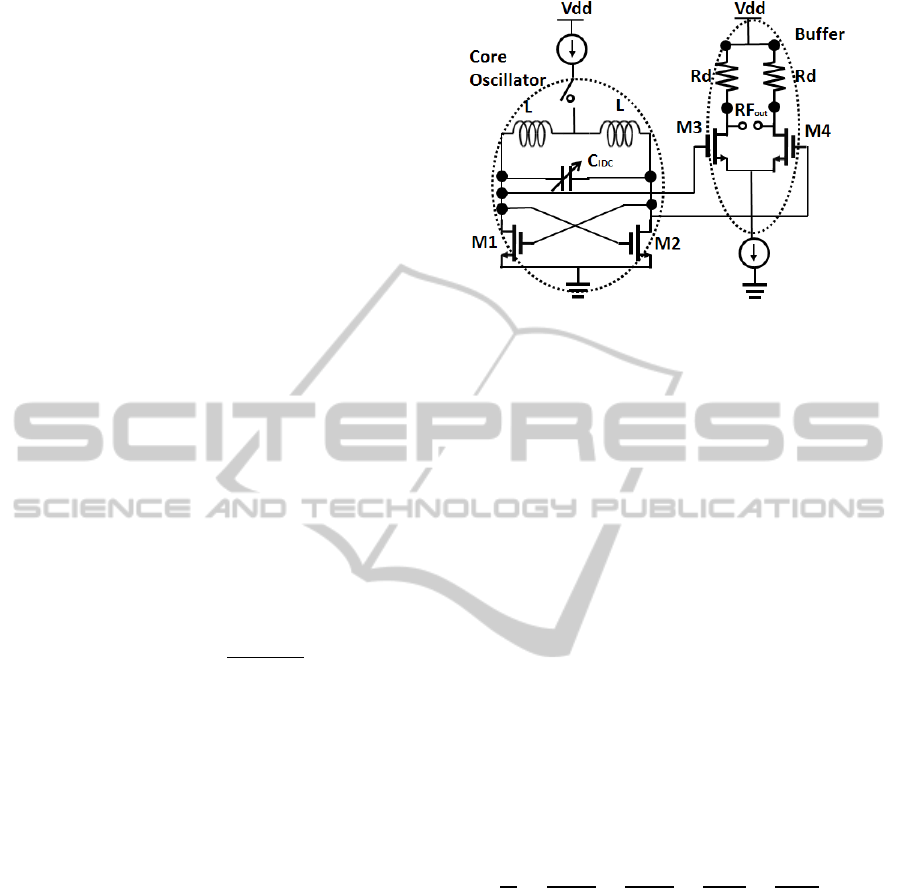

2.1.2 Sensor Circuit Design

The IDC is coupled with a pair of inductors to form

an LC resonator. The inductor is also fabricated on

the topmost metal layer of the BiCMOS stack

(TM2). The simulated inductance of the inductor is

500 pH, and has a quality factor of approximately 15

at the operating frequency of 12 GHz. The resonant

frequency of the oscillator is the function of the

capacitance of the IDC. The schematic of the

oscillator core with the sensor IDC and the inductors

is shown in Fig. 4. A cross coupled pair of nMOS

transistors drive the oscillation of the resonant LC

oscillator. The resonant frequency of the oscillator

core in the first order approximation is given as

1/2

2

(4)

where, L is the inductance of the individual inductor

and C

total

is the total capacitance of the IDC and the

additional parasitic capacitances due to the

transistors used in the active circuit. The total

capacitance can be mathematically expressed as,

(5)

The parasitic capacitances originate from the cross

coupled transistors driving the oscillations of the LC

resonator tank and also due to the transistors used in

the buffer stage. The buffer stage isolates the

oscillator core from subsequent stages of circuitry.

The parasitic capacitance due to the transistors is

dependent on the size of the transistors. For a

transistor with a greater width of the channel

(w

channel

), the parasitic capacitance is higher due to

the area of the channel. On the other hand the

channel width of the cross coupled nMOS transistors

cannot be made sufficiently small, as wider

transistors are required for sufficient

transconductance (g

m

), to sustain the oscillation of

the oscillator.

The total transconductance of the cross coupled

transistors of the oscillator system nullifies the

Figure 4: CMOS sensor circuit in cross coupled oscillator

topology. The sensor IDC is used as the variable capacitor

in the oscillator.

parasitic resistance of the inductor which would

otherwise result in the damping and eventually dying

of the oscillations. g

m

is directly proportional to the

width of the channel, w

channel

. Hence there exists a

trade-off between the channel width required for

sufficient transconductance of the transistors and the

parasitic capacitance due to the width of the channel.

Parasitic capacitance reduces the sensitivity of the

sensor system as they are in parallel to the sensor

capacitance. For a given transistor size defined for

the sufficient transconductance of the transistor, the

parasitic capacitance is constant which is dependent

only on the width of the transistor. The change of

permittivity due to varied materials on top of the

IDC, would change the C

IDC

contribution of the total

capacitance and in turn change the oscillating

frequency of the oscillator. The sensitivity of the

sensor which is the change of oscillating frequency

with the change of permittivity on top of the IDC

can be mathematically expressed as,

(6)

The output resistance Rd at the buffer stage is 50

ohms in order to match the resistance of the

measuring probes. A standard DC power supply is

used as the source for 3 V V

dd

source as shown in

the circuit schematic. A Rohde and Schwarz X-band

spectrum analyser is used for measurement of the

spectrum.

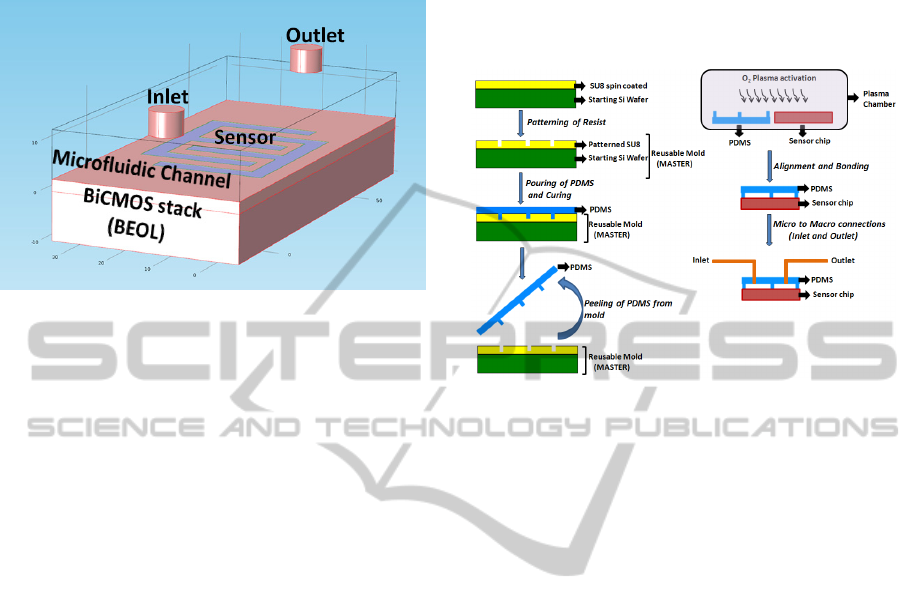

2.2 CMOS/Microfluidic Integration

PDMS (Polydimethylsiloxane) microfluidic chan-

nels of width 500 µm and height 50 µm was

fabricated using SU8 master mold using soft

lithography technique. The PDMS channel was

12GHzCMOSMEMSLab-on-chipSystemforDetectionofConcentrationofSuspendedParticlesinBio-suspensions

53

further bonded to the CMOS chip using oxygen

plasma bonding technique. Fig. 5 shows the

schematic view of the CMOS microfluidic system.

Figure 5: Schematic of hybrid CMOS/Microfluidic

dielectric sensor system. The sensor is shown on top of the

BiCMOS BEOL stack. The microfluidic channel is

aligned on top of the sensor.

The BiCMOS wafer was polished using CMP

(Chemical Mechanical planarization) technique to

obtain a planar surface for precise bonding of the

PDMS microfluidic system to the chip.

The master mold was fabricated from SU8

photoresist patterned on a 4 inch silicon wafer. SU8

is most commonly used for such fabrication

techniques because of the capability of producing

high aspect ratio structures with it. PDMS was

prepared using Sylgard 184 Silicone elastomer base

(Monomer) and its curing agent (hardener). The

monomer and the hardener were mixed in the ratio

10:1. Other ratios of monomer to hardener were also

tried for different elasticity of the PDMS structure.

However, the above combination of monomer and

hardener was chosen as it gave the best bonding

strength. After thorough mixing, the solution was

poured on the master mould and cured at a

temperature of 70°C for ninety minutes. Room

temperature curing is also possible but takes a longer

time of approximately a day. The obtained PDMS

structure was carefully peeled off from the mold and

stored in a salinized chamber.

Oxygen plasma bonding of the PDMS

microfluidic channel to the CMOS chip was

performed in the Reactive Ion Etching (RIE)

chamber. Plasma pressure of 16 Pa was used for a

time of 30 seconds with an RF power of 65 Watt.

Using higher RF power reduces the bonding strength

as the PDMS surface which is changed from

hydrophobic to hydrophilic due to the plasma action,

to enable the bonding process, is transformed back

to hydrophobic with higher RF power. Careful

alignment of the channel on top of the sensor was

the limiting factor of the bonding time. The bonding

time was kept within one minute in order to keep the

PDMS in the activated state. Fig. 6 shows the

process steps of the PDMS/CMOS hybrid

microfluidic system.

Figure 6: Fabrication steps of PDMS microfluidic

channels and bonding to the silicon chip. The PDMS

microfluidic channel is bonded to the silicon chip using

oxygen plasma bonder.

3 RESULTS AND DISCUSSION

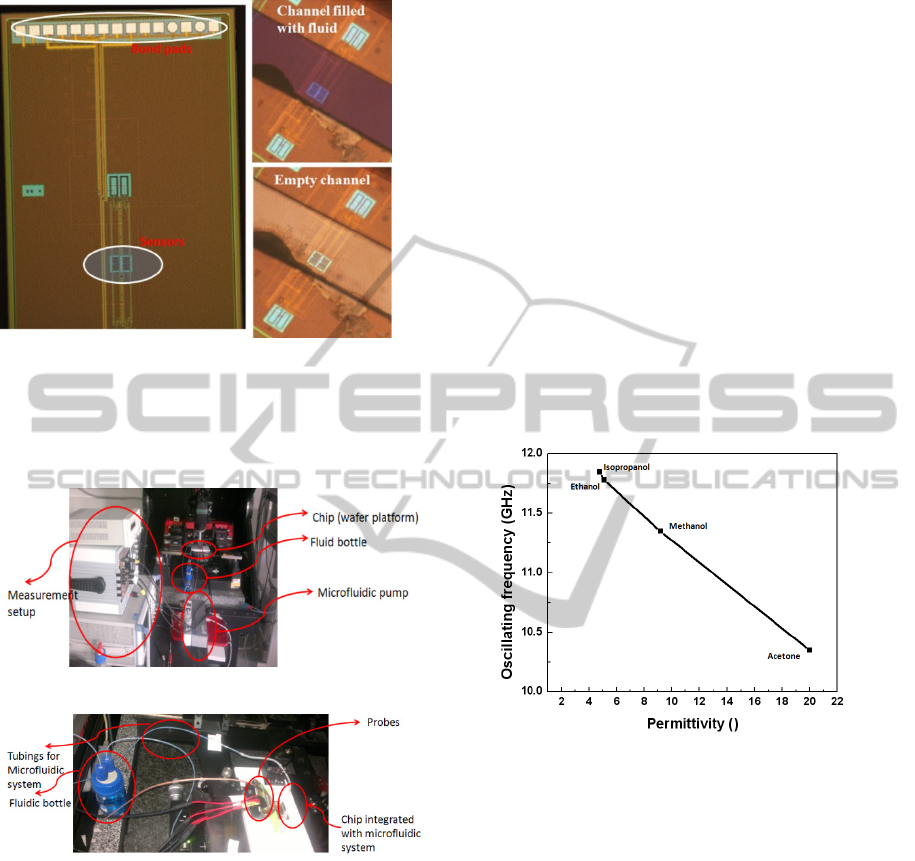

The silicon chip bonded to the microfluidic system

was measured in two steps. Initially microfluidic

characterization of the chip was performed to check

for leakage of the fluid. Leakage can often occur due

to feeble bonding strength. Leakage of fluid from the

microfluidic channel causes spreading of the fluid on

the bond pads, thus, affecting the probes used for

measurements or damaging the bond wires used for

on board measurements. Therefore, once no leakage

was confirmed, electrical measurements were

performed on a wafer platform for stable

measurements. Fig 7 shows the chip layout and the

microfluidic tests after the hybrid integration of

PDMS microfluidic channel. The channel is aligned

on top of the sensor with the test fluid having no

effect on the inductor coils.

The measurements were conducted in three

steps. Calibration of the sensor was performed using

organic fluids (Alcohols) of known permittivity in

order to establish the sensitivity of the sensor and the

detection limits.

Subsequently glucose solution was measured with

varying concentration of water in the solution and

finally concentration of suspended particles in

acetone was measured. The measurement setup is

shown in Fig. 8

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

54

(a) (b)

Figure 7: (a) Chip layout showing the sensors and the

inductor coils. (b) Microfluidic channel with test fluid in

it. The fluid flows only on top of sensor without

influencing the inductors. (c) Empty microfluidic channel.

(a)

(b)

Figure 8: Measurement setup for the CMOS microfluidic

system. The measurement is performed on the wafer

station, shown in panel a. A DC power supply and a

spectrum analyser is needed for measurement. Panel b

shows the chip with the probes used for the measurement.

3.1 Calibration

The CMOS chips were characterized electrically

prior to microfluidic experiments. The current drawn

by the chip was 12 mA at an operating voltage of 3

V. The oscillating frequency was measured to be

12.32 GHz with an output power of -5 dBm. Further

characterization of the chip was performed after

plasma bonding of the PDMS microfluidic channel

with the chip. The DC operating values of the chip

remained unaltered, while the oscillating frequency

was measured to be 12.20 GHz. The 100 MHz shift

of the oscillating frequency was accounted for the

influence of the PDMS on the inductor coils used in

the design of the oscillator. This resonant frequency

served as the reference for further measurements, as

the microfluidic channel was empty.

The variation of oscillating frequency of the

dielectric sensor with materials of different

permittivities was characterized by using organic

fluids in the microfluidic system. A downshift of

oscillating frequency was observed with increasing

permittivity of the organic fluids, in this case

alcohols. Fig. 9 shows the variation of the resonant

frequency for different alcohols. At 12 GHz

isopropanol and ethanol have almost the same

permittivity (Ɛ= 3.8~4.2), as shown by Belrhiti et al

(2012) and can be seen in the frequency output plot

to be close to each other.

Figure 9: Calibration of sensor with organic fluids. Four

different alcohols with different permittivites at 12 GHz

were measured.

It is also noted that although the static

permittivity of methanol is higher than the static

permittivity of acetone, at 12 GHz, the permittivity

of methanol is less than the permittivity of acetone

described by Kung et al (1997) and the

corresponding shift of resonant frequency shows the

same.

Sensitivity of 100 MHz/permittivity was

observed with the measurements performed with the

organic alcohols. In order to estimate the

measurement reproducibility microfluidic channels

were bonded to five different sensor chips from the

same wafer. Maximum frequency variation of 4

MHz was observed for same measurements and was

negligible compared to the sensitivity of the sensor.

The detection limit of the sensor can also be

estimated with the measurement of isopropanol and

(

c

)

12GHzCMOSMEMSLab-on-chipSystemforDetectionofConcentrationofSuspendedParticlesinBio-suspensions

55

ethanol. The alcohols have a permittivity difference

of 0.7 at 12 GHz and still show a considerable

frequency shift as shown in Fig. 9.

3.2 Glucose Solution Measurement

The CMOS/microfluidic system was then used to

study the effect of water in a homogeneous glucose

solution. The variation of resonant frequency with

different concentration of water depicts the variation

of permittivity of the glucose solution with water

content. Fig 10 shows the downshift of resonant

frequency of the oscillator with increasing water

content. Pure glucose solution has a permittivity of 8

at 12 GHz given by Meriakri et al (2006). The

corresponding oscillating frequency is measured to

be 11.52 GHz. This is close to the value measured

for methanol (Ɛ= 9.2) during calibration. The

obtained results can be extended to determine

permittivity of the glucose solution with different

concentration of water.

Figure 10: Measurement of water content in glucose

solution using the dielectric sensor. The oscillating

frequency down-shifts with increasing water content.

This can be related to the high permittivity of water

at 12 GHz (Ɛ =45). With increasing water content

the permittivity of the overall solution increases. The

downshift of the oscillating frequency indicates an

increase in permittivity with increasing

concentration of water in the glucose solution.

Every 10% increase in the water content shows a

frequency down-shift of 250 MHz, which indicates a

permittivity increase of approximately 2.5.

3.3 Micro-beads Measurement

Concentration of suspended particles in a bio

suspension was emulated with micro-beads in

acetone. Acetone was chosen as it showed the

highest frequency shift during calibration of the

sensor. The influence of micro-beads or particles in

a solution can be understood by the hindrance of

molecular motion given by the Stokes-Einstein

Debye equation described by Basey-Fisher et al

(2011). From the mathematical relation it can be

understood that the characteristic Debye relaxation

time increases or the characteristic frequency

reduces with increasing concentration of particles in

a suspension. In the higher GHz region where γ

dispersion is predominant, the increase in particle

concentration reduces the permittivity of the

solution. In our measurement system we used micro-

beads of diameter 10 µm in different concentrations

in a fixed volume of acetone 2 ml. The beads were

thoroughly mixed in order to prepare a

homogeneous solution.

Figure 11: Measurement of micro-beads in acetone using

the dielectric sensor. The oscillating frequency up-shifts

with increasing concentration of beads.

Fig. 11 shows the variation of the oscillating

frequency with increasing concentration of micro-

beads. This is because the microfluidic channel is

completely filled with the beads after a certain

concentration of beads. This is shown in Fig. 12

Figure 12: Fluorescent marked micro-beads showing the

microfluidic channel being completely filled with the

beads.

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

56

4 CONCLUSIONS

In this work a complete CMOS high frequency

dielectric sensor with hybrid microfluidic integration

was demonstrated. The operating frequency of the

sensor is 12.3 GHz. A sensitivity of 100

MHz/permittivity was measured in the calibration

phase performed with different organic liquids.

Concentration of water in a homogeneous glucose

solution was further measured using the sensor. 250

MHz/10% increase in water content in the glucose

solution was observed. This could be further

interpreted as an approximate increase of 2.5 in the

permittivity of the solution. Concentration of

suspended particles in a solution was further

measured with micro-beads in acetone. Frequency

up-shit of 125 MHz/10 µl increase in bead content in

acetone was measured. All in all a complete CMOS

high frequency sensor with hybrid integrated

microfluidic system was described. The advantages

of using high frequency technique to detect

concentration of particles in a suspension was

investigated and demonstrated in this report.

ACKNOWLEDGEMENTS

The authors would like to thank IHP technology

department for the fabrication of the chip.

REFERENCES

Pires, N.M.M, Dong, T., Hanke, U., Hoivik, N. (2014)

Recent Developments in Optical detection

technologies in Lab-On-a-Chip Devices for

Biosensing Application. Sesnors.14. p. 15458-15479.

Goh, S., and Ram, R.J. (2010) Impedance spectroscopy for

in situ biomass measurements in microbioreactor. 14

th

International conference on Miniaturized Systems and

Life Sciences. Netherlands. p. 1556-1558.

Krommenhoek, E.E., Gardeniers, J., Bomer, J., Van den

Berg, A., Li, X., Ottens, M., van der Wielen, L., van

Dedem, G., Van Leeuwen, M., van Gulik, W.,

Heijnen, J. (2006) Monitoring of yeast cell

concentration using micromachined impedance sensor,

Sensors and Actuators,B. 115.p. 384-389.

Faenza, A., Bocchi, M., Pecorari, N., Franchi, E.,

Guerrieri, R.(2012) Impedance measurement

technique for high sensitivity cell detection in

microstructures with non-uniform conductivity

distribution. Lab Chip 12(11). P.2046-2052.

Rassaei, L., Goluch, E.D., Lemay, S. (2012). Substrate

dependent kinetics in tyrosinase-based biosensing:

Amperometry vs Spectrophotometry. Analytical and

Bioanalytical Chemistry. 493. p.1577-1584.

Grenier, K., Dubuc, D., Chen, T., Artis, F., Chretiennot,

T., Poupot, M., and Fournié, J-J. (2013). Recent

Advances in Microwave-based Dielectric Spectro-

scopy at the Cellular Level for Cancer Investigations

IEEE-TMTT 61(4).p. 2023-2030.

Ferrier, G.A., Romanuik, S.F., Thomson, D.J., Bridges,

G.E., Freeman, M.R. (2009). A microwave interfero-

metric system for simultaneous actuation and detection

of single biological cells. Lab on a Chip. 9. p. 3406-

3412.

Yang, Y., Zhang, H., Zhu, J., Wang, G., Tzeng, T.-R.,

Xuan, X., Huang, K., Wang, P. (2010). Distinguishing

the viability of a single yeast cell with an ultra-

sensitive radio frequency sensor. Lab on a Chip. 10. p.

553-555.

Guha, S., Jamal, F.I., Schmalz, K., Wenger, Ch., Meliani,

Ch. (2013). CMOS lab on a chip device for dielectric

characterization of cell suspensions based on a 6 GHz

Oscillator. European Microwave Conference,

Germany.

Guha, S., Jamal, F.I., Schmalz, K., Wenger, Ch., Meliani,

Ch. (2014) An 8 GHz CMOS Near Field Bio-sensor

Array for Imaging Spatial Permittivity Distribution of

Biomaterials. IEEE MTT-S, Interantional Microwave

Symposium, USA.

T.Lee (1998) The design of CMOS Radio Frequency

Integrated Circuits,Cambridge.

Lisker, M. Trusch, A., Fraschke, M., Kulse, P.,

Borokhovych, Y., Tillack, B., Ostermay, I., Krämer,

T., Schmückle, F.-J., Krüger, O., Krozer, V., Heinrich,

W. (2013). InP-Si BiCMOS Heterointegration Using a

Substrate Transfer Process ECS Transactions.

53(245).

Belrhiti, M.D., Bri, S., Nakheli, A., Haddad, M.,

Mamouni, A. (2012). Dielectric constant determina-

tion of liquid using rectangular waveguide structure

combined with EM simulation. J.Mater.Environ.Sci.

3.p. 575-584.

Kuang, W., Nelson, S.O. (1997). Dielectric relaxation

charcterization of fresh fruits and vegetables from 3 to

20 GHz. J. of Micrwave power and electromagnetic

energy. 32. p. 114-122.

Meriakri, V V., Chigrai, E E., Kim, D., Nikitin, I.P.,

Pangonis, L.I., Parkhomenko, M.P., Won, J.H. (2006).

Dielectric properties of glucose solutions in the

millimetre-wave range and control of glucose content

in blood. IOP, Meas. Sci. Technology. 18.p. 1-6.

Basey-Fisher, T.H., Hanham, S.M., Maier,S.A., Stevens,

M.M., Alford, N.M., Klein, N.( 2011).Microwave

relaxation analysis of Dissolved Proteins:Towards free

solution biosensing. Applied Physics Letters 99.

12GHzCMOSMEMSLab-on-chipSystemforDetectionofConcentrationofSuspendedParticlesinBio-suspensions

57