A Toolset for Simulink

Improving Software Engineering Practices in Development with Simulink

Vera Pantelic, Steven Postma, Mark Lawford, Alexandre Korobkine, Bennett Mackenzie, Jeff Ong

and Marc Bender

McMaster Centre for Software Certification, Department of Computing and Software,

McMaster University, Hamilton, ON, Canada

Keywords:

Simulink, Tools, Software Engineering, Transformation, Data Flow.

Abstract:

This paper presents a set of tools that provide automatic support for application of some of the traditional soft-

ware engineering practices when developing with Simulink. The tools are the: Signature Tool, Reach/Coreach

Tool, Data Store Push-Down Tool, and Auto Layout Tool. The Signature Tool extracts the interface of a

Simulink subsystem, identifying the subsystem’s explicit, and implicit data flow mechanisms, empowering

developers to use the implicit mechanisms more effectively. The Reach/Coreach Tool identifies data and

control flow dependencies in a Simulink model and uses the information for model slicing. The view of de-

pendencies offered by the tool significantly eases the comprehension of large models. The dependencies can

also serve as indicators of alternative designs, and facilitate more effective testing and verification. The Data

Store Push-Down Tool restricts the scope of Simulink’s data stores thereby providing improved encapsulation,

and increasing modularity. Finally, the Auto Layout Tool significantly decreases the manual effort develop-

ers spend in achieving proper layout of models during design and refactoring, and can be used by automated

refactoring and transformation tools.

1 INTRODUCTION

The use of MATLAB/Simulink as a model-based de-

sign environment is wide spread across industries.

While there are a number of reasons for its popularity

(e.g., automatic code generation, rich modeling and

simulation capabilities, existence of a large number

of MathWorks and third party tools to aid develop-

ment within the environment), the environment still

lacks proper support for the application of some tra-

ditional software engineering practices. For example,

Simulink does not have facilities to provide for data

stores

1

to be declared read-only. Further, Simulink

lacks self-documenting capabilities of imperative pro-

gramming languages: for example, an analogue of a

module interface in C, as defined in C header files,

does not exist in Simulink.

The main goal of this paper is to enhance model-

based design with Simulink through the application

of some well-known software engineering principles.

Proper automatic support is crucial for integration of

these practices in design with Simulink. Therefore,

1

Data stores in Simulink are analogous to variables in

traditional programming languages.

the toolset to be presented in this paper helps a de-

veloper apply some well-known software engineer-

ing principles in an automated manner, allowing for

the proposed principles to be seamlessly integrated

into an existing Simulink model-based software de-

velopment process. We introduce four tools, namely:

the Signature Tool, the Reach/Coreach Tool, the Data

Store Push-Down Tool, and the Auto Layout Tool.

The Signature Tool extracts a Simulink subsys-

tem’s signature: a representation of the subsystem’s

interface. The concept of signatures was introduced

in (Bender et al., 2014a; Bender et al., 2014b). Sig-

natures improve subsystems’ comprehensibility, and

identify implicit data flow mechanisms in Simulink

enabling their more effective use. Further, analysis of

signatures can indicate the quality of modularization

of a Simulink design. While the core capabilities of

the tool were presented in (Bender et al., 2014a; Ben-

der et al., 2014b), the current paper presents the tool

in more detail, providing natural language require-

ments for the tool, rather than focusing on the formal

definition of signatures as in (Bender et al., 2014a;

Bender et al., 2014b). Further, signatures have previ-

ously only been defined for virtual subsystems, while

50

Pantelic V., Postma S., Lawford M., Korobkine A., Mackenzie B., Ong J. and Bender M..

A Toolset for Simulink - Improving Software Engineering Practices in Development with Simulink.

DOI: 10.5220/0005236100500061

In Proceedings of the 3rd International Conference on Model-Driven Engineering and Software Development (MODELSWARD-2015), pages 50-61

ISBN: 978-989-758-083-3

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

in the current paper the Signature Tool is extended

to support the extraction of signatures of nonvirtual

subsystems. The tool has been used by our automo-

tive industrial partner to automatically help document

subsystems’ interfaces as part of an application’s soft-

ware design description.

The Reach/Coreach Tool identifies, for specified

Simulink blocks, parts of the model that depend on

the specified blocks (Reach functionality), or parts

of the model that the specified blocks depend upon

(Coreach functionality). Both data flow and control

dependencies are accounted for. After the depen-

dencies have been identified, the extraneous blocks

can be removed: therefore, the tool provides for

model slicing. To the best of our knowledge, there

exists only one comprehensive slicing technique for

Simulink models (Reicherdt and Glesner, 2012), that

takes into account both data and control dependen-

cies. In (Reicherdt and Glesner, 2012), data depen-

dencies are calculated by traversing signal lines, and

control dependencies are derived from the calcula-

tion of Conditional Execution Contexts — Simulink

schedules for execution of blocks modeling condi-

tional dependence. Compared to the model slic-

ing approach of (Reicherdt and Glesner, 2012), our

tool accounts for not only the data flow through sig-

nal lines, but also the data flow through Simulink’s

data stores and From/Goto blocks, and provides fine-

grained data flow tracking through Simulink buses.

The Reach/Coreach dependencies extracted by the

tool significantly ease the comprehension of models,

and provide for automatic impact analysis, signifi-

cantly simplifying models’ verification and testing.

Data stores in Simulink are analogous to vari-

ables in traditional programming languages. The Data

Store Push-Down Tool identifies the data stores that

have scopes larger than necessary; for each identi-

fied data store, its declaration is then pushed down

the model hierarchy to the lowest level possible such

that all the references to the data store are still within

the data store’s scope. The push-down operation im-

proves modularity of Simulink designs. The tool was

introduced in (Bender et al., 2014b). However, its

application in (Bender et al., 2014b) was to merely

illustrate the effectiveness of a software complexity

metric introduced in that paper. In the current paper,

however, the tool’s potential applications in a model-

based software development process are discussed in

detail, and its implementation is explained.

The last tool to be presented in this paper is not

focused on the application of software engineering

principles per se, but rather on relieving a major ef-

fort in developing with Simulink: achieving a proper

layout of a model. Surprisingly, there does not exist a

comprehensive commercial automatic layout tool for

Simulink models. While novel Simulink automatic

layout algorithms have been proposed (e.g., (Klauske

and Dziobek, 2010; Klauske et al., 2012)), no tools

based on the algorithms are available for download.

Our approach reuses a graph drawing algorithm as

implemented in the open source tool Graphviz, and

further builds on it to address Simulink-specific lay-

out requirements, and to automate some useful addi-

tional transformations (e.g., splitting a subsystem into

two subsystems, transformation of a signal line into

a Goto/From connection, etc.). As opposed to other

tools described in this paper, this tool is still at the

proof-of-concept stage.

The main contribution of this work is a set of

tools to be used to aid adoption of some well-

known software engineering principles when design-

ing with Simulink. All the tools have been suc-

cessfully used on large industrial automotive mod-

els: the models contained on average 800 blocks,

with hierarchy depth of around six. However, smaller

examples have been chosen in this paper to illus-

trate the tools’ capabilities, due to proprietary na-

ture of the industrial models, and for simplicity of

exposition. We plan to release the tools in the

near future through MATLAB Central, under open

source licenses. The tools are currently available

for download from http://www.cas.mcmaster.ca/ pan-

telv/SimulinkTools.

The outline of this paper is as follows. The Sig-

nature Tool, the Reach/Coreach Tool, the Data Store

Push-Down Tool, and the Auto Layout Tool are pre-

sented in Sections 2, 3, 4, and 5, respectively. For

each of the tools, we explain and illustrate its main ca-

pabilities, implementation, foreseen usages in model-

based design with Simulink, and possible extensions.

We also present the execution times of the tools when

run on the industrial automotive models. Tools were

run on Windows 7, Intel i3-2120 @ 3.30 GHz, 8.0 GB

RAM machine. Section 6 concludes the paper, with

avenues for future work.

2 THE SIGNATURE TOOL

The Signature Tool extracts the signature of a

Simulink subsystem. The concept of signatures was

first introduced in (Bender et al., 2014a). A signa-

ture represents the interface of a Simulink subsystem,

making the data flow into and out of the subsystem

explicit.

In this section, we first present the background

needed to understand signatures and the capabilities

of the Signature Tool (Section 2.1). Then, in Sec-

AToolsetforSimulink-ImprovingSoftwareEngineeringPracticesinDevelopmentwithSimulink

51

Out2

2

Out1

1

Unit Delay

z

1

Sub1

In1

In2

Out1

Out2

Out3

Goto Tag

Visibilit

y

{Scoped1}

Goto

{Scoped1}

Gain

2

Data Store

Write B

B

Data Store

Memory B

B

Data Store

Memory A

A

In3

3

In2

2

In1

1

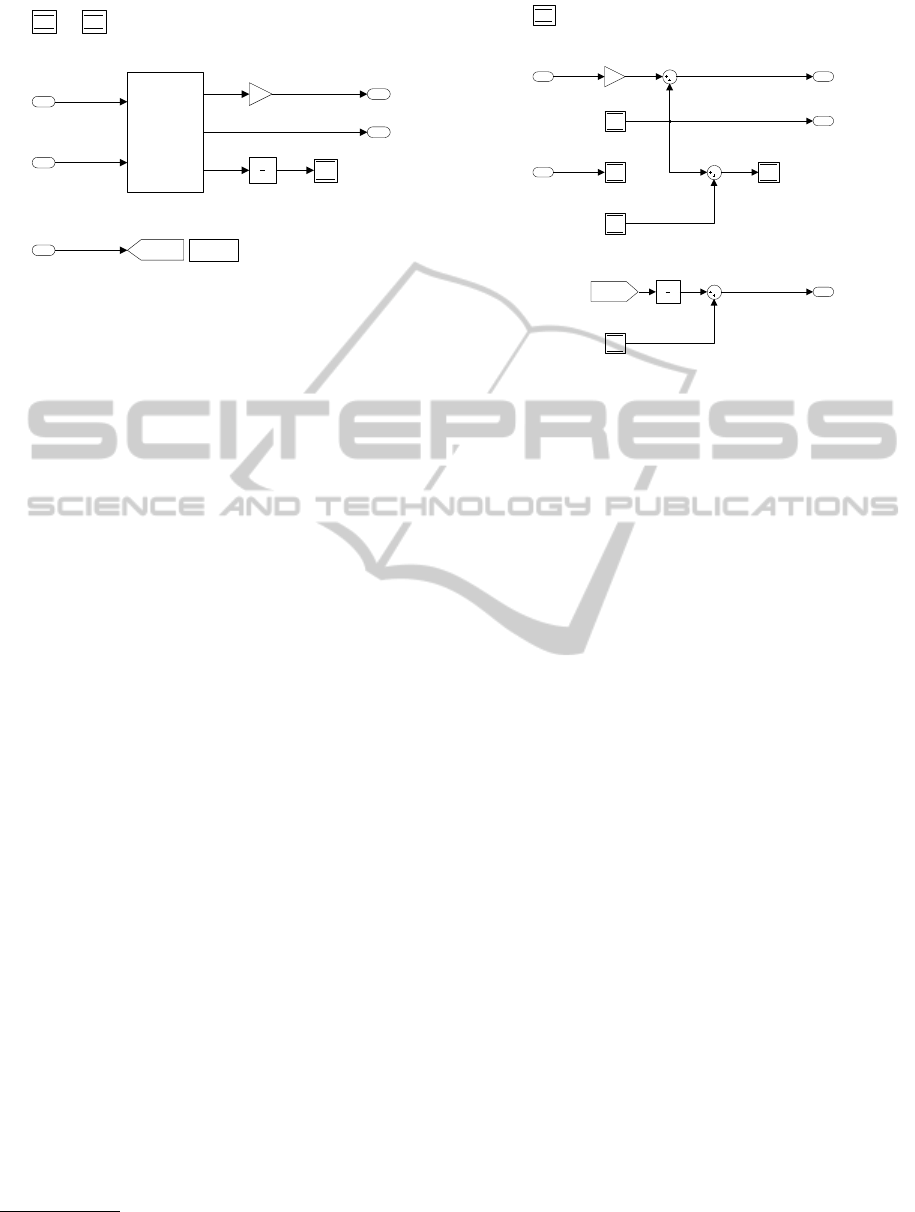

Figure 1: A Simulink model.

tion 2.2, the tool is discussed in details.

2.1 Analysis of Data Flow in Simulink

The notion of subsystem is used in Simulink to repre-

sent systems inside systems in order to provide for

hierarchical modeling. A Simulink subsystem has

inports and outports — explicit links to and from

the subsystem, respectively. We view inports and

outports as the explicit interface of the subsystem.

However, there are hidden data dependencies in the

Simulink’s subsystem: we will refer to those as the

subsystem’s implicit interface. Hidden dependencies

stem from two particular Simulink data mechanisms:

data stores and Goto/From blocks:

2.1.1 Data Store Data Flows

Data stores are used in Simulink as memory, and

are analogous to variables in traditional programming

languages. Data stores allow subsystems and refer-

enced models

2

to share data without having to use in-

ports and outports to pass the data from subsystem to

subsystem, or level to level. A data store can be de-

fined in Simulink using a Data Store Memory block.

The data store is then referenced using Data Store

Read blocks (for reading from the data store) or Data

Store Write blocks (for writing into the data store).

The scope of a data store is the subsystem where the

Data Store Memory block is located, and all the sub-

systems below it in the model hierarchy, excluding

referenced models.

In Figure 1, data store B is defined using Data

Store Memory B block. The scope of this data store

is the top level of the model and subsystem Sub1.

The data store is accessed using Data Store Write B

at the same level where it is defined, and it is read

from using Data Store Read B at subsystem Sub1.

2

Referenced model is a model referenced from another

model using Model block.

Out3

3

Out2

2

Out1

1

Unit Delay

z

1

Gain

2

From

{Scoped1}

Data Store

Write C

C

Data Store

Write A

A

Data Store

Read C

C

Data Store

Read B

B

Data Store

Read A

A

Data Store

Memory

C

In2

2

In1

1

Figure 2: Subsystem Sub1 from Figure 1.

Also, a data store can be implemented in the base

workspace using a signal object: it is then called a

global data store — it can be accessed from anywhere

in the model, including referenced models. When a

data store is located higher in the hierarchy than the

current subsystem, it will be referred to as an inher-

ited data store for the subsystem. It should be noted,

while signatures have previously been defined only

for virtual subsystems (Bender et al., 2014a), the cur-

rent implementation of the Signature Tool is extended

to support the extraction of signatures of nonvirtual

subsystems as well. Nonvirtual subsystems are sub-

systems executed as a single unit (atomic execution).

A virtual subsystem, on the other hand, is flattened in

order to derive the block update order with Simulink

ignoring the subsystem’s boundaries when determin-

ing the order — the subsystem’s boundaries do not

impact model’s behaviour.

2.1.2 Goto/From Data Flows

Another mechanism for implicit data flow in Simulink

is the Goto/From mechanism. The data fed into a Goto

block is passed to its corresponding From blocks (the

From blocks with the same tag), without a signal line

between them. Goto/From blocks are used to implic-

itly connect blocks, simplifying visual presentation of

models. A single Goto block may have multiple From

blocks, but a From block may only receive data from

a single Goto block. The scope of the Goto block is

determined by Goto block’s Tag Visibility parameter

which can take on the following values:

• Local: Goto and From blocks with the same tag

are in the same subsystem.

• Scoped: The scope of the Goto block is deter-

MODELSWARD2015-3rdInternationalConferenceonModel-DrivenEngineeringandSoftwareDevelopment

52

mined by the position of the corresponding Goto

Tag Visibility block: the Goto block and its From

blocks have to be in the same subsystem as the

Goto Tag Visibility block or lower in the model hi-

erarchy while not crossing a nonvirtual subsystem

boundary, i.e., the boundary of an atomic, condi-

tionally executed or function-call subsystem, or a

model reference. In Figure 1, scoped tag Scoped1

is defined using Goto Tag Visibility block. This

block affects the scope of the Goto block Scoped1

to its immediate left found at the same level,

while the corresponding From is found in Sub1,

as shown in Figure 2.

• Global: Goto and From blocks with the same tag

can be anywhere in the model except in locations

that span nonvirtual subsystem boundaries.

In the sequel, we will view global From/Gotos

and global data stores as a special case of scoped

From/Gotos and data stores, since global tags can be

replaced by scoped tags, with a corresponding visi-

bility tag placed in the top-level subsystem, whereas

global data stores can be replaced by normal data

stores, with the corresponding declaration moved to

the top-level subsystem.

2.2 The Tool

The signature identifies the parts of the interface of a

given Simulink subsystem:

• Explicit interface: Inports and outports,

• Implicit interface: Inherited data stores, and

scoped tags defined higher up in the model hierar-

chy,

• Imposed interface: Data stores and scoped tags

defined in the subsystem.

The Signature Tool identifies two useful signatures

for a subsystem: strong signature and weak signature.

The strong signature identifies the data mechanisms

that are accessed by the subsystem or any of its chil-

dren. The weak signature identifies the data mecha-

nisms that a subsystem can access (those which are

declared higher up in the hierarchy), but is not neces-

sarily using.

2.2.1 Strong and Weak Signatures

The strong signature of a subsystem contains:

• Inputs:

– Inports

– Implicit Inputs:

∗ All the inherited data stores that are only read

from in the subsystem or in any of its children

∗ Scoped tags with Goto Tag Visibility defined

higher in the model hierarchy, that have the

corresponding From block located in the sub-

system or in any of its children, unless the

Goto block is also in the subsystem or any

of its children. The rationale for excluding

tags with both From and Goto blocks from the

strong signature is that when the Goto block

is located in a subsystem or below it in the hi-

erarchy, it is considered local, since no other

subsystem can write into it.

• Outputs:

– Outports

– Implicit Outputs:

∗ All the inherited data stores that are only writ-

ten to in the subsystem or in any of its children

∗ Scoped tags with Goto Tag Visibility located

higher in the model hierarchy, that have the

corresponding Goto block located in the sub-

system or any of its children

• Updates: All the inherited data stores that are both

read from and written to in the subsystem or any

of its children

• Declarations: All the data stores declared in the

subsystem, and scoped tags located in the subsys-

tem

A Simulink model and the contents of its subsys-

tem Sub1 are shown in Figure 1 and Figure 2, re-

spectively. The strong signature for subsystem Sub1

as generated by the Signature Tool is given in Fig-

ure 3. The strong signature of Sub1 specifies the data

mechanisms that the subsystem or its children access.

The subsystem Sub1 both reads from and writes to

the inherited data store A — hence, the data store is

included in the Updates set of the signature. Sub1,

however, only reads from the data store B — conse-

quently, the data store is in the Inputs set of the sig-

nature. The subsystem only reads from Scoped1 tag:

that is why the tag belongs to the signature’s Inputs.

The weak signature is about a subsystem’s context

— identifying the data mechanisms the subsystem has

access to, but is not necessarily using:

• Inputs:

– Inports

– Implicit Inputs:

∗ For virtual subsystems, scoped tags declared

higher in the hierarchy with the corresponding

Goto declared higher in the hierarchy

∗ For nonvirtual subsystems, this set is empty

since From and Goto blocks cannot cross

boundaries of non-virtual subsystems

AToolsetforSimulink-ImprovingSoftwareEngineeringPracticesinDevelopmentwithSimulink

53

• Outputs:

– Outports

• Updates:

– Inherited data stores

– Scoped tags located higher in the model hier-

archy that do not have corresponding Goto de-

clared higher in the hierarchy

• Declarations: All the data stores declared in the

subsystem and scoped tags located in the subsys-

tem

The weak signature of Sub1 from Figure 2 (as the

subsystem of system in Figure 1), as extracted by the

Signature Tool, is given in Figure 4. Since the weak

signature is about the resources that are at Sub1’s dis-

posal, all inherited data stores (A and B) are in Up-

dates since they can be both read from and written to.

Sub1 cannot write into Scoped1 since the root level

model is already writing into it

3

— that is why the tag

is in the signature’s Inputs.

The Signature Tool can extract a subsystem’s sig-

nature (strong or weak), and then either include it in

the subsystem itself, or export it to external documen-

tation. The tool supports virtual and nonvirtual sub-

systems. The data items in the signature generated

by the Signature Tool are presented in the following

way (see Figure 3 and Figure 4) for the case when

the signatures are included in the subsystem: Data

Store Read blocks and Data Store Write blocks and

scoped Froms are fed into terminators; all input ports

are fed into local Gotos, and output ports are fed from

local Froms (our industrial automotive partner uses

this technique whenever a port needs to be used mul-

tiple times in a model). It is argued in (Bender et al.,

2014a) that the behaviour of the subsystem does not

change when the signature is included in it.

2.2.2 Implementation and Applications

The Signature Tool is implemented using MATLAB

functions executed from the command line. The weak

signature is implemented as a recursive top-down al-

gorithm on the system tree of a model, while the

strong signature is implemented by a bottom-up re-

cursive algorithm. The tool has been used on large

industrial automotive Simulink models each imple-

menting a vehicle function: the signature extraction

function runtime was below five minutes for each

model.

The benefits and applications of signatures are nu-

merous. Signatures represent a simplified view of

3

There cannot be two Goto blocks for the same tag.

data flow in and out of the subsystem explicitly iden-

tifying hidden dependencies in Simulink models, al-

lowing for easier comprehension of models. Also, the

Signature Tool has the capability of extracting strong

signatures into external documentation: the generated

documentation effectively represents interface speci-

fication of a subsystem as a part of the subsystem’s

software design description documentation. There-

fore, this capability automates part of the process of

software documentation production: this is exactly

how our industrial partner uses the tool.

However, we believe that the future use of the tool,

appropriately extended where needed, can go far be-

yond a simple comprehension aid and documentation

generator:

• Signatures can be used to instil software engineer-

ing discipline in design with Simulink. For ex-

ample, the actual interface of a subsystem can be

refined from its weak signature generated by the

tool: e.g., a data store should be removed from

the signature’s Updates and included in Inputs if

it is to be read-only by the subsystem. The signa-

tures therefore enable information hiding and en-

capsulation within a Simulink model. Further, if

a (interface) specification of a subsystem is given

as its signature, and if its weak signature (as ex-

tracted by the Signature Tool) has mechanisms not

contained in the specification, this is an indica-

tion of the subsystem’s potential to access data

flow mechanisms that may cause unintended in-

terference with other subsystems in the model hi-

erarchy. In fact, a metric based on signatures has

been defined in (Bender et al., 2014b) that mea-

sures the difference in the number of mechanisms

in the subsystem’s weak and strong signature: the

larger values in the metric indicate potential prob-

lematic design as the subsystem has access to far

more resources than it is actually using. The tool

supports the calculation of the metric.

• A lack of proper consideration of implicit data

flow in Simulink testing tools was first noted in

(Bender et al., 2014a). Exisiting testing tools typ-

ically neglect to account for data flow via data

stores when generating a test harness for a subsys-

tem. The subsystem’s strong signature extracted

by the Signature Tool can be used to generate a

test harness that properly accounts for all the in-

coming/outgoing signals, with the additional ben-

efit of the harness being easily detachable.

• Signatures can be used to classify dynamic inputs

(inputs that often change through a simulation

run) vs. static (inputs that rarely change through

a simulation run). Since signatures make scoped

tags as explicit (visible) as inports, applying the

MODELSWARD2015-3rdInternationalConferenceonModel-DrivenEngineeringandSoftwareDevelopment

54

Inputs

Data Store Reads

Scoped Froms

Updates

Outputs

Declarations

3

2

1

z

1

[GotoOut13]

[GotoOut12]

[GotoOut10][GotoIn9]

[GotoIn15]

2

{Scoped1}

[GotoOut13]

[GotoOut12]

[GotoOut10]

[GotoIn9]

[GotoIn15]

{Scoped1}

A

B

C A

C

B

A

C

2

1

Figure 3: Subsystem Sub1 with included strong signature as generated by the Signature Tool.

Inputs

Scoped Froms

Updates

Outputs

Declarations

3

2

1

z

1

[GotoOut13]

[GotoOut12]

[GotoOut10][GotoIn9]

[GotoIn15]

2

{Scoped1}

[GotoOut13]

[GotoOut12]

[GotoOut10]

[GotoIn9]

[GotoIn15]

{Scoped1}

B

A

C A

C

B

A

C

2

1

Figure 4: Subsystem Sub1 with included weak signature as generated by the Signature Tool.

discipline of e.g., using scoped Goto/Froms for

static inputs and using inports for dynamic inputs,

would significantly declutter the explicit interface

of the subsystem.

• When the subsystem signatures are included in the

model, they can be used to incorporate strong typ-

ing into subsystems’ interfaces. For more details,

an interested reader is referred to (Bender et al.,

2014a).

3 THE REACH/COREACH TOOL

In this section, we present the Reach/Coreach Tool.

First, basic capabilities of the tool are introduced.

Then, its implementation and applications are ex-

AToolsetforSimulink-ImprovingSoftwareEngineeringPracticesinDevelopmentwithSimulink

55

plained.

3.1 Tool’s Capabilities

The Reach/Coreach Tool identifies dependencies in a

Simulink model in two different ways:

• Reach: For a specified set of blocks (e.g., a set

of inports), the tool identifies parts of the model

that depend on the specified blocks. The reach-

able model (the submodel of the original model

that consists of the identified blocks, and signals

that connect them) is then highlighted.

• Coreach: For a specified set of blocks (e.g., a set

of outports), the tool identifies parts of the model

that the specified blocks depend on. The coreach-

able model (the submodel of the original model

that consists of the identified blocks, and signals

that connect them) is then highlighted.

Once the Reach/Coreach submodel is identified and

marked in the Simulink model, the unmarked parts of

the model can be trimmed away: the remaining sub-

model represents a model slice.

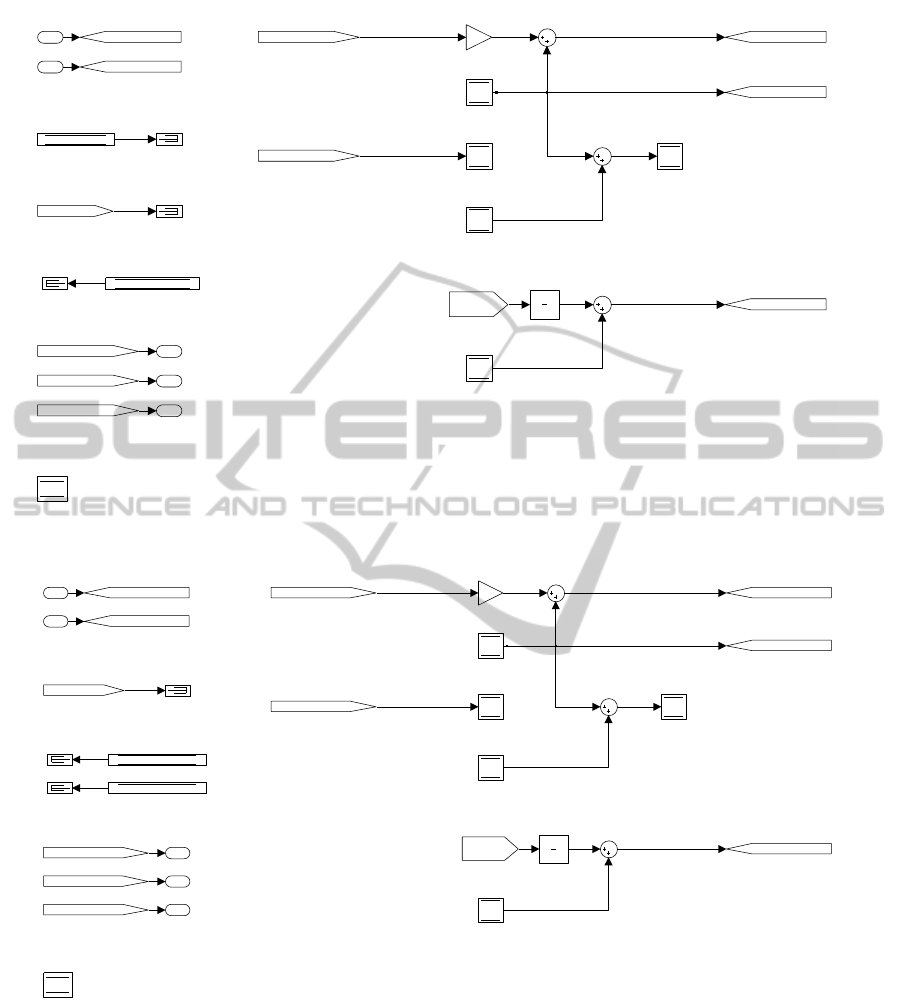

The application of the tool on a simple example

is illustrated in Figures 5, 6, and 7. The coreachabil-

ity analysis for outport Out1 results in the submodel

marked in blue/yellow colours as shown in Figure 5

(with subsystem WhileSub from Figure 5 shown in

Figure 6). The reachability analysis done on inports

In1, In2, and In3 would result in the same submodel

being highlighted. The reachability analysis for Data

Store Write A in Figure 5 is highlighted in red/black,

with the subsystem Sub1 shown in Figure 7. Both

reachability and coreachability analysis preserve the

hierarchical structure of the model.

The Reach/Coreach Tool tracks and highlights

both data flow (data dependencies) and control flow

(control dependencies) in the model:

Data Flow. Data flow in Simulink is explained in

more detail in Section 2. The Reach/Coreach Tool

tracks the explicit data dependencies — the data flow

through signal lines. Assuming that changes to an in-

put propagate to changes in any output for any block

(except a subsystem), that is, any input can influence

any output of a block that is not a subsystem, and by

deducing the input-output influence relation of a sub-

system from the structure of its components, it is pos-

sible to construct the signal line dependency of the

model. However, as elaborated in Section 2, there are

hidden data dependencies in Simulink: the implicit

data flow through data stores and Goto/From blocks.

The Reach/Coreach tool tracks these data dependen-

cies as well. For example, in Figure 5, the flow from

the Data Store Write A block is tracked to Out2: this

comes from the fact that the data store is being read

in Sub1. Therefore, the Reach/Coreach Tool accounts

for implicit data flow in a model: the tool tracks not

only the data flow through inports/outports, but also

the data flow via data stores, and Goto/From blocks.

This is a major difference between our tool and that

of (Reicherdt and Glesner, 2012): their definition of

data dependency in Simulink does not account for the

implicit data flow. Also, it should be noted that the

Reach/Coreach Tool provides for fine-grained track-

ing of the data flow through Simulink buses.

Control Flow. Control flow logic in Simulink can be

implemented using If block and If Action subsystems

(for if-else logic), Switch Case block and Switch Ac-

tion subsystems (for switch logic), and While Iterator

and For Iterator subsystems (for loops). For example,

the outputs of If block are used to trigger If Action sub-

systems, depending on the evaluation of a specified

condition on inputs of the If block. Action subsystems

have an Action Port block: when the input at the port

evaluates to true, the subsystem executes. Inputs of If

block (Switch Case block) are reached to all the out-

puts of the block, all the Action subsystems and their

outputs. If coreachability analysis is performed from

the block whose input is the output of an Action sub-

system, it will trace back to Action Port, as well as

the data input(s) of the Action subsystem determined

by coreachability analysis inside the subsystem; Ac-

tion Port will be further traced back to all the inputs

of the If (Switch Case) block. Note that this is, in gen-

eral, an overapproximation of actual dependency: an

output of If (Switch Case) block can depend only on

one of the block’s inputs. When it comes to an Iter-

ator subsystem, each block in the subsystem is (con-

trol) dependent on the Iterator block in the subsystem,

and, therefore, on its inputs. For example, in Figure 5,

Out1 is dependent on all the inputs of WhileSub sub-

system, since the While Iterator (Figure 6) executes

contents of the subsystem based on IC (initial condi-

tion) and cond inputs.

4

Conditional subsystems Enabled Subsystem, Trig-

gered Subsystem, Enabled and Triggered Subsystem,

and Function-Call subsystems have a control input in

addition to data inputs: when this input satisfies a con-

dition, the corresponding subsystem is executed. For

each of those subsystems, outputs are dependent on

control inputs: when coreachability analysis is done

for one of these subsystems, it traverses through its

4

At the beginning of a time step, if the IC input does not

hold, the subsystem is not executed in that time step. If the

IC input does hold, the subsystem gets executed, and then,

if the cond input is true, the iterator executes the subsystem

again. The iterations continues while cond input is true and

the number of iterations is less than or equal to the Maxi-

mum number of iterations.

MODELSWARD2015-3rdInternationalConferenceonModel-DrivenEngineeringandSoftwareDevelopment

56

Out2

2

Out1

1

WhileSub

In1

In2

IC

Out1while { ... }

Sub1

In1

Out1

Data Store

Write A

A

Data Store

Memory A

A

In5

5

In4

4

In3

3

In2

2

In1

1

<signal1>

<signal2>

<signal3>

<signal4>

Figure 5: Illustration of Analysis with the Reach/Coreach Tool: Reach for Data Store Write A (red/black), Coreach for Out1

(blue/yellow); Subsystems WhileSub and Sub1 are shown in Figures 6 and 7, respectively.

Out1

1

While Iterator

while {

...

}

cond

IC

Unit Delay

z

1

IC

3

In2

2

In1

1

Figure 6: Subsystem WhileSub from Figure 5.

control input. Similarly, if reachability analysis tra-

verses to the control input of a conditional subsystem,

it is further propagated to all of the subsystem’s out-

puts. Of course, the dependency of outputs on data

inputs is determined by the Reach/Coreach analysis

inside the subsystem.

3.2 Implementation and Applications

The Reach/Coreach Tool is implemented using MAT-

LAB’s object-oriented programming facilities. The

Reach and Coreach algorithms are fixed-point algo-

rithms, that identify the immediate reached/coreached

blocks of a current set of blocks, starting from the ini-

tial specified set of block on which the Reach/Coreach

analysis is to be performed. The analyses times do not

exceed two seconds for any of the industrial models

that were used.

Out1

1

Data Store

Read

A

In1

1

Figure 7: Subsystem Sub1 from Figure 5.

Next, we elaborate on how the tool can be used in

a model-based development process.

Refactoring. The tool can be used to find in-

dependent/weakly dependent data flows — these

might be candidates to be separated into different

subsystems.

Comprehension. The Reach/Coreach Tool depicts

the dependencies in a Simulink model, effectively

representing its dependency diagram. While the sig-

natures address the comprehension issue at the level

of a subsystem, the Reach/Coreach Tool offers an

abstracted view of data and control flow from given

blocks backwards to inputs, or forwards to outputs.

Both the views generated by the Signature Tool, and

the views generated by Reach/Coreach Tool, are data

flow views — and, as claimed in (Quante, 2013):

“such views can be very helpful for tracking data

flows through a system — especially when there

AToolsetforSimulink-ImprovingSoftwareEngineeringPracticesinDevelopmentwithSimulink

57

S

1

DS

M

A

DS

M

B

S

UB

2

S

2

R

1

F

1

SUB

3

S

3

S

UB

4

S

4

DSR

A

B

1

B

2

B

3

B

4

B

5

S

UB

5

S

5

DSW

A

B

6

B

7

DSR

B

Figure 8: Data store push-down: before.

are additional hidden dependencies.” Further, by

trimming the extraneous blocks from a model, it is

possible for a user to gain a greater understanding

of the structure of the model. For review purposes,

the Reach/Coreach analyses can assist reviewers in

fully grasping data and control dependencies in a

model: understanding the flow in complex models is

very hard without proper abstractions even when the

models are well-documented.

Dead Code. The tool can be used to find unreach-

able parts of a model: once the reachability analysis

is performed on all of model’s inputs (inports),

non-marked blocks/signals represent unreachable

parts of the model. When the coreachability analysis

is performed on all of model’s outputs (outports), the

extraneous blocks are unnecessary in the sense that

they have no (data or control) effect on the outputs of

the model.

Impact Analysis. Since the tool identifies the

parts of a model affected by a change of a given

block, it provides for impact analysis. The impact

analysis can be of great value in indicating what

effect a change in requirements can have on system’s

design. During both initial design and refactoring, the

tool can be used for preliminary evaluation of differ-

ent designs with respect to the extent that the future

anticipated requirements changes will have on the

system’s design. Therefore, the tool would help the

developer design for change. Further, impact analysis

can be extremely beneficial in alleviating verification

efforts, which are typically very large, especially

in the case of safety-critical systems. Verification

efforts can be decreased by focusing on the parts

of the system that the outputs (or, more generally,

the data items) of interest depend on: we view the

Reach/Coreach Tool as a useful means of providing

impact analysis that avoids the costly analysis of the

parts of the system that are not affected by a change.

S

1

S

UB

2

S

2

R

1

F

1

SUB

3

S

3

DS

M

A

S

UB

4

S

4

DSR

A

B

1

B

2

B

3

B

4

B

5

S

UB

5

S

5

DSW

A

B

6

B

7

DSM

B

DSR

B

Figure 9: Data store push-down: after.

4 THE DATA STORE

PUSH-DOWN TOOL

We have noticed that some of the industrial models

we have been working with define most of their data

stores at the top level of a model’s hierarchy. This

practice is analogous to programming using a large

number of global variables, and it is considered a bad

software engineering practice.

Data stores, like variables in traditional program-

ming languages, should be properly scoped in order

to disable inadvertent/unwanted access to the data

stores. Also, the proper scoping declutters the in-

terface of a subsystem by hiding low-level details of

the subsystem, therefore providing proper encapsula-

tion. Proper data store scoping also reduces the num-

ber of (implicit) inputs for testing, resulting in pos-

sibly fewer generated tests (test steps). Therefore,

proper scoping of data stores enhances comprehen-

sibility, maintainability, testability, and reusability of

Simulink subsystems.

In this section, the concept of the data store push-

down operation is discussed first. Then, tool’s imple-

mentation and applications are detailed.

4.1 Illustration of Data Store

Push-down Operation

We have already discussed scope associated with data

stores and Goto/From blocks. A block falls within the

scope of another block b if it is contained in a system

that belongs to the scope of the block b. Our goal is

to limit the scope of data stores as much as possible.

For example, if a Data Store Memory occurs high in

the model hierarchy, and there are two data store ref-

erences (Data Store Read or Data Store Write blocks)

lower in the hierarchy, the goal is to push-down the

data store (Data Store Memory block) to the smallest

MODELSWARD2015-3rdInternationalConferenceonModel-DrivenEngineeringandSoftwareDevelopment

58

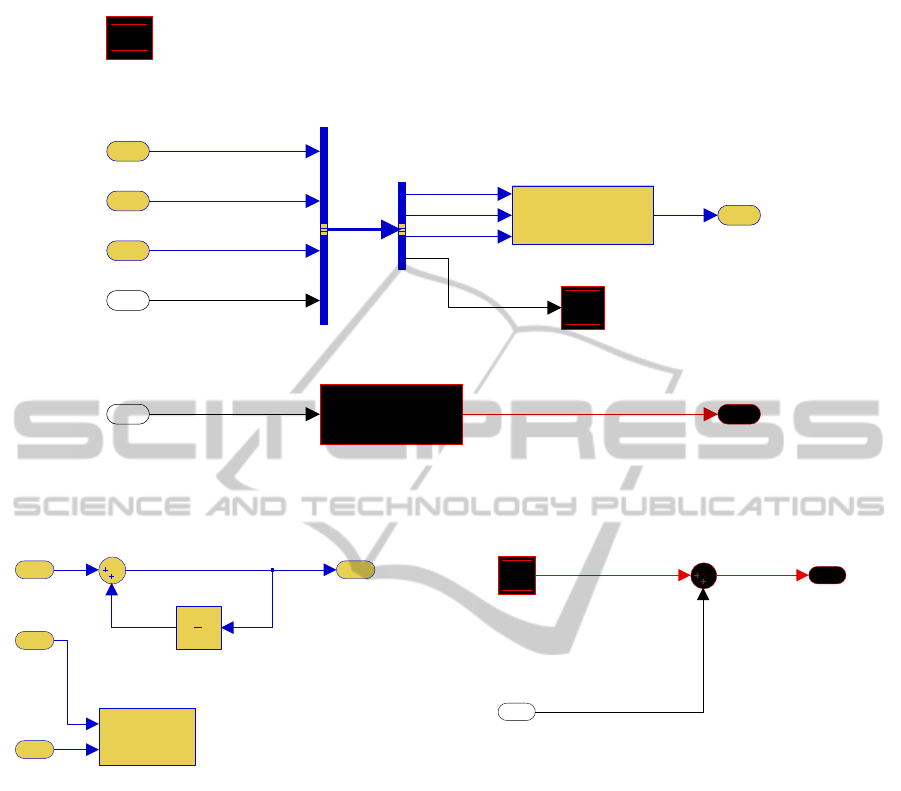

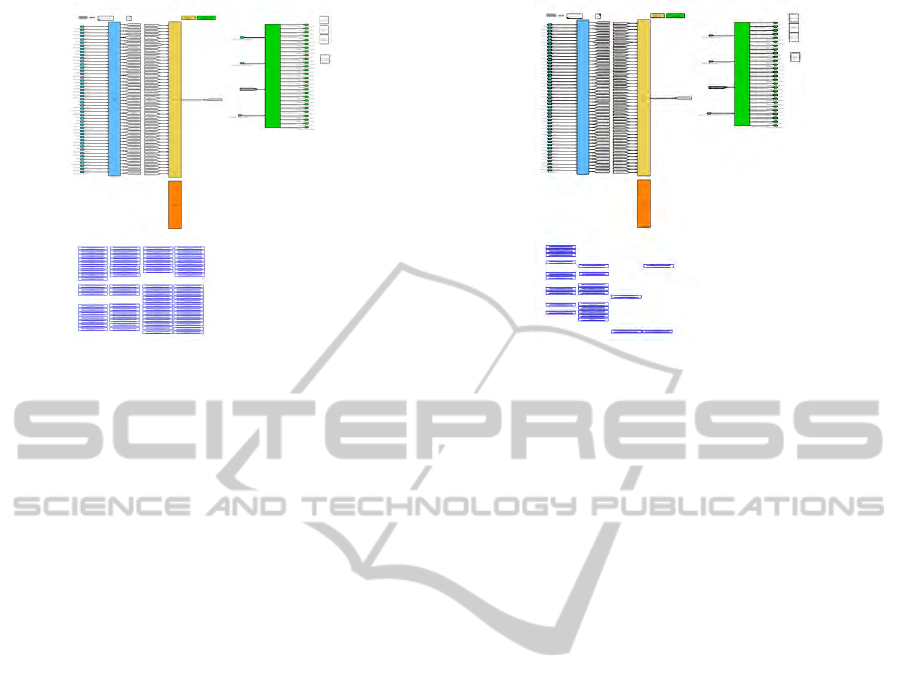

Figure 10: The top level of the industrial model before the

push-down operation.

subsystem such that both references are still within

the scope of the data store.

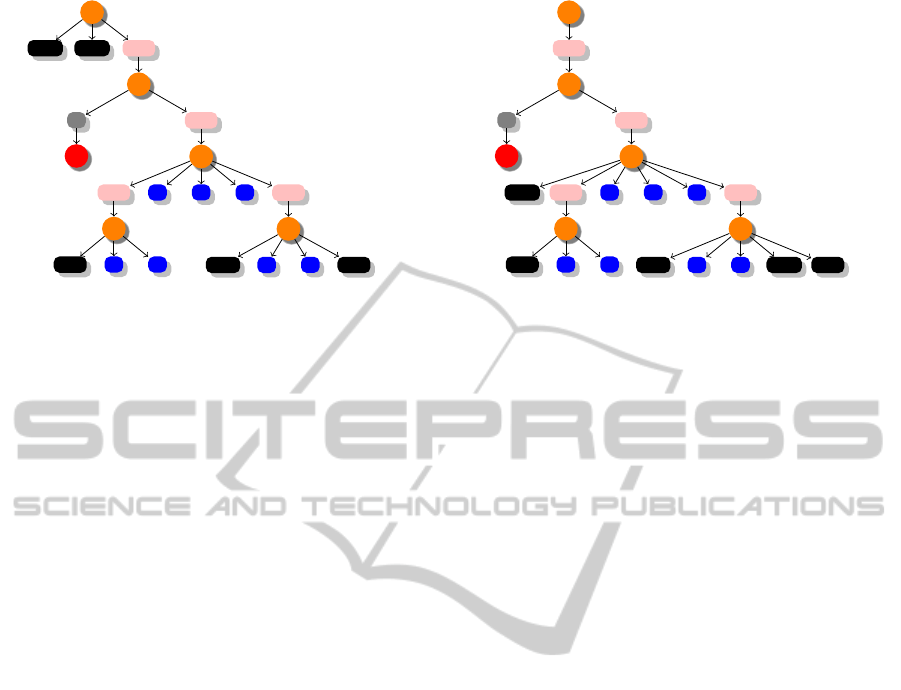

In Figure 8, a system is represented before the

data store push-down operation has been applied to

it. The orange nodes represent systems, the rectangu-

lar elements are blocks, the pink blocks are subsystem

blocks. Grey blocks are reference blocks (blocks that

refer to a block in another file, here denoted by a red

node). Arrows emanating from systems to blocks de-

note membership of the block in the system. An arrow

emanating from a subsystem block to system denotes

that the system is associated with the subsystem; sim-

ilar relationship exists for references and files. Fig-

ure 9 shows the system after the data store push-down

operation has been applied to it.

4.2 Implementation and Application

The push-down algorithm is implemented as a single

iterative MATLAB function. Firstly, the push-down

algorithm searches the model for all Data Store Mem-

ory blocks. Then, it searches for all the corresponding

Data Store Read and Data Store Write blocks. The ad-

dresses of these corresponding Data Store Read and

Data Store Write blocks are then parsed to find their

lowest common ancestor. Lastly, unless the lowest

common ancestors reside in a library linked subsys-

tem, the Data Store Memory blocks are then pushed

to their respective lowest common ancestors. Exe-

cution times of the algorithm on the large industrial

models (containing many Data Store Memory blocks

at the top level (around 50) and deep model hierarchy

(of depth 6)) do not exceed one second.

Given its importance, we propose proper scop-

ing of variables to be included in the modeling style

guidelines for Simulink. With Simulink/Stateflow

Figure 11: The top level of the industrial model after the

push-down operation.

emerging as a leading environment for model-based

design of embedded systems, a number of guide-

lines have been created to assist designers in mod-

eling. Guidelines typically provide a wide range

of rules/recommendations (e.g., naming conventions,

usage of Simulink patterns for different constructs

(e.g., case constructs), grouping of blocks into sub-

systems, etc.). In the automotive industry, the most

notable modeling standard is published by The Math-

Works Automotive Advisory Board (MAAB) (Math-

Works, 2014b). In addition, companies use in-house

guidelines to improve the quality of their software. In-

house guidelines typically contain a number of checks

from standard guidelines. Adherence to the rules

improves software testability, understandability, and

maintainability. Also, the compliance enhances sim-

ulation and code generation capabilities. For exam-

ple, each of the MAAB rules/recommendations for

Simulink/Stateflow is justified by one or more of the

following:

• Easily understood algorithms (readable models,

uniform appearance of models, code, and doc-

umentation, clean interfaces, professional docu-

mentation),

• Effective development process and workflow

(ease of maintenance, rapid model changes,

reusable components, etc.),

• Efficient simulation and analysis,

• Generation of code that is efficient and effective

for embedded systems,

• Ability to verify and validate a model and

generated code (requirements traceability, test-

ing, problem-free system integration, clean inter-

faces).

In order to include proper scoping of data stores in

modeling guidelines, a rule can be formulated to re-

AToolsetforSimulink-ImprovingSoftwareEngineeringPracticesinDevelopmentwithSimulink

59

4

3

2

1

In1

In2

Out1

Out2

1/s

1/s

1/s

1/s

1/s

1/s

1/s

1/s

[B]

[A]

0.5

0.5

[B]

[A]

3

2

1

green

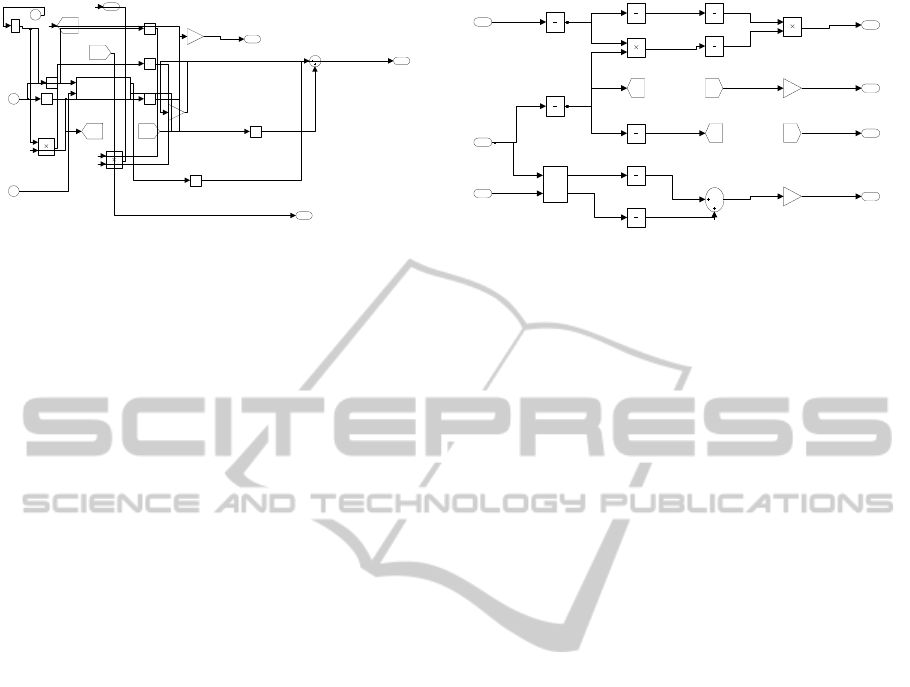

Figure 12: Simulink Model: Before Layout.

quire that each data store (with certain exceptions) be

defined at the lowest hierarchy level such that all the

references to the data store are still within its scope.

The exceptions account for situations where a de-

veloper might desire to leave a data store defined at

a higher hierarchy level than currently needed fore-

seeing that the data store will be used in future by

other subsystem(s) at the same or higher hierarchy

levels. Therefore, the user of the tool should be able

to choose the data stores that should not be pushed

down the hierarchy. Our tool supports this feature. A

straightforward modification of our tool can then be

used to check for the compliance of a Simulink model

with the rule, and then repair the model (perform the

push-down operation) if needed so that the model ad-

heres to the rule.

An interesting synergy between signatures and the

push-down operation was demonstrated in (Bender

et al., 2014b). The push-down operation was ap-

plied on an industrial automotive model shown in

Figure 10. The number of data stores at the root

level (data stores are represented by blue rectangles

at the bottom of the figure) has been significantly de-

creased by the push-down operation as illustrated by

Figure 11 (not all the details in models in both fig-

ures are legible for confidentiality purposes). From a

software engineering perspective, the push-down op-

eration clears the interfaces of model’s subsystems

at different hierarchy levels: the impact of the push-

down operation is the largest for the subsystems at

the model’s root level. This change in subsystems’

interfaces is obvious with simple visual inspection of

their signatures as generated by the Signature Tool.

Further, the Signature Tool was used on the model’s

subsystems to calculate the difference in the number

of data items in a subsystem’s weak and strong sig-

nature: this metric as formalized in (Bender et al.,

2014b) and, as explained in Section 2, indicates the

quality of modularization of designs in Simulink. The

values of the metric for model’s subsystems, before

and after the push-down operation, indicate the sig-

nificant improvement in modularity realized by the

push-down operation.

4

3

2

1

In1

In2

Out1

Out2

1

s

1

s

1

s

1

s

1

s

1

s

1

s

1

s

[B]

[A]

0.5

0.5

[B]

[A]

3

2

1

green

Figure 13: Simulink Model: After Layout.

5 THE AUTO LAYOUT TOOL

In a modeling environment such as Simulink, the

readability of models is largely determined by graph-

ical layout of blocks and lines in the model. Since

most refactoring operations perturb model layout and

manual readjustment of model layout is a tedious and

error-prone process if performed manually, automatic

layout is viewed as an essential component of model

refactoring. However, there does not exist a com-

mercial tool that comprehensively tackles the auto-

matic layout of Simulink models. There are a number

of commercial tools that check Simulink models for

compliance with modeling style guidelines (MXAM

by Model Engineering Solutions (Model Engineer-

ing Solutions, 2014), Simulink Model Advisor by the

MathWorks (MathWorks, 2014a) with the Verification

and Validation Toolbox (MathWorks, 2014c), etc.).

These tools also offer automatic repair for some of the

rules once a model fails a rule; however, the repair

capabilities of these tools are modest at best. While

a number of layout algorithms have been proposed

(e.g., (Klauske and Dziobek, 2010; Klauske et al.,

2012)), to the best of our knowledge, no tools based

on these papers are available for download.

Our layout tool uses an already existing graph

drawing algorithm (Gansner et al., 1993) imple-

mented in Graphviz. Graphviz is a set of open-source

tools for drawing graphs represented by the DOT

graph description language. More precisely, our tool

harnesses the Graphviz’s layout engine dot for the au-

topositioning of model blocks; lines are then autogen-

erated using Simulink’s built-in automatic line posi-

tioning support. Graphviz’s tool dot uses the algo-

rithm of (Gansner et al., 1993) to rearrange blocks and

lines in a consistent, organized manner to maximize

readability (the same algorithm is also partially used

by (Klauske and Dziobek, 2010)). The tool resizes

blocks based on number of inputs and outputs, and

organizes the lines such that the number of crossings

is minimized. See Figure 12 for a model before au-

MODELSWARD2015-3rdInternationalConferenceonModel-DrivenEngineeringandSoftwareDevelopment

60

tomatic layout, and Figure 13 for the model after au-

tomatic layout. Note that model comprehension and

readability have markedly improved.

As opposed to the tools described in the previous

sections, this tool is at the proof-of-concept stage. We

are currently refining the layout engine to accommo-

date Simulink-specific layout requirements (for ex-

ample, outports should be placed on the right side,

unless they are moved to prevent crossings). Fur-

ther, we are also implementing a number of refactor-

ing transformations that are not natively automatically

supported by Simulink: e.g., splitting/merging sub-

systems.

6 CONCLUSIONS

Automated support is an essential part of any soft-

ware development process. This paper presents a set

of tools that help automate the application of some

traditional software engineering practices when de-

signing with Simulink. While the paper illustrates the

use of the tools on simple toy examples, the tools have

been proven on large, industrial models from the au-

tomotive industry, that could not be presented in the

paper due to their proprietary nature. The concepts

presented in this paper, and tools based on the con-

cepts, represent the beginning of our investigation of

the issues of integrating some traditional software en-

gineering practices in design with Simulink.

REFERENCES

Bender, M., Laurin, K., Lawford, M., Ong, J., Postma,

S., and Pantelic, V. (2014a). Signature required:

Making Simulink data flow and interfaces explicit.

In Proceedings of 2nd International Conference

on Model-Driven Engineering and Software De-

velopment (MODELSWARD 2014), pages 119–131.

SCITEPRESS.

Bender, M., Laurin, K., Lawford, M., Pantelic, V., Ko-

robkine, A., Ong, J., Mackenzie, B., Bialy, M., and

Postma, S. (2014b). Signature required: Making

Simulink data flow and interfaces explicit. In Science

of Computer Programming, Special issue on Model-

Driven Development. Submitted in June.

Gansner, E. R., Koutsofios, E., North, S. C., and Vo, K.-P.

(1993). A technique for drawing directed graphs. Soft-

ware Engineering, IEEE Transactions on, 19(3):214–

230.

Klauske, L., Schulze, C., Spnemann, M., and von Hanxle-

den, R. (2012). Improved layout for data flow dia-

grams with port constraints. In Cox, P., Plimmer, B.,

and Rodgers, P., editors, Diagrammatic Representa-

tion and Inference, volume 7352 of Lecture Notes in

Computer Science, pages 65–79. Springer Berlin Hei-

delberg.

Klauske, L. K. and Dziobek, C. (2010). Improving

modeling usability: Automated layout generation for

simulink. In Proceedings of the MathWorks Automo-

tive Conference, MAC.

MathWorks, T. (2014a). Model Advisor. http://www.

mathworks.com/help/simulink/ug/consulting-the-

model-advisor.html. [Online; accessed September

2014].

MathWorks, T. (2014b). The MathWorks Auto-

motive Advisory Board. http://www. math-

works.com/automotive/standards/maab.html. [On-

line; accessed September 2014].

MathWorks, T. (2014c). Verification and

Validation Toolbox. http://www. math-

works.com/products/simverification/. [Online;

accessed September 2014].

Model Engineering Solutions (2014). MES Model

Examiner (MXAM DRIVE). http://www. model-

engineers.com/en/model-examiner.html. [Online; ac-

cessed September 2014].

Quante, J. (2013). Views for efficient program understand-

ing of automotive software. Softwaretechnik-Trends,

33(2).

Reicherdt, R. and Glesner, S. (2012). Slicing MATLAB

Simulink models. In Software Engineering (ICSE),

2012 34th International Conference on, pages 551–

561. IEEE.

AToolsetforSimulink-ImprovingSoftwareEngineeringPracticesinDevelopmentwithSimulink

61