On the Sol-gel Preparation of Selected Lanthanide Aluminium

Garnets Doped with Europium

L. Pavasaryte

1

, B. J. Lopez

2

and A. Kareiva

1

1

Department of Inorganic Chemistry, Vilnius University, Naugarduko 24, LT-03225 Vilnius, Lithuania

2

Departament de Química Inorgànica i Orgànica, Universitat Jaume I, E-12071 Castelló de la Plana, Spain

Keywords: Lanthanide Aluminium Garnets, Holmium, Terbium, Dysprosium, Doping, Europium, Sol-gel Processing,

XRD, FTIR, SEM, DLS, Fluorescence.

Abstract: A sol-gel method based on in-situ generation of mixed-metal chelates by complexing metal ions with

ethane-1,2-diol in an aqueous media has been elaborated to prepare lanthanide-ion containing garnets,

Tb

3

Al

5

O

12

(TAG), Dy

3

Al

5

O

12

(DAG) and Ho

3

Al

5

O

12

(HAG) doped with different amount of Eu. The X-ray

diffraction patterns (XRD) of the powders sintered at 1000 °C showed the formation of monophasic TAG,

DAG and HAG. The phase composition of the samples was also characterized by FTIR spectroscopy.

Microstructural features of the polycrystalline samples were studied by scanning electron microscopy

(SEM) and dynamic light scattered measurements (DLS). Luminescence properties were investigated by

laser and fluorescence spectrophotometer.

1 INTRODUCTION

The yttrium aluminium garnet (Y

3

Al

5

O

12

, YAG)

doped with a transition metal or lanthanide ions is an

important solid-state laser material widely used in

luminescence systems, window materials for a

variety of light sources, and for fiber-optic

telecommunication systems. The YAG oxides are

also widely applied as phosphors in cathode-ray

tubes (projection TV sets), field emission, vacuum

fluorescent, and electroluminescent displays and as

scintillators in X-ray and positron emission

tomographs (Harlan et al. 1997; Vaqueiro et al.

1998; Pullar et al. 1999; Ganschow et al. 1999; Kang

et al. 1999; Lu et al. 2000; Lu et al. 2002; Hreniak et

al. 2002; Pan et al. 2004; Potdevin et al. 2006; Singh

et al. 2007; Katelnikovas et al. 2007; Caponetti et al.

2007; Caponetti et al. 2007; Lipinska et al. 2007;

Katelnikovas et al. 2008; Khimich et al. 2009;

Suarez et al. 2009; Yang et al. 2009; Sun et al. 2009;

Fujioka et al. 2009; Yang et al. 2010). These

features have made rare-earth-doped YAG a relevant

material for cathode-ray tubes (CRTs), field

emission displays (FED), vacuum fluorescent and

electroluminescent displays, plasma display panel,

scintillators in X-ray and positron emission

tomographs and other luminescent applications.

The phosphors host materials have proven to be of

great importance for the optical function. The matrix

should possess good chemical, mechanical, thermal,

optical characteristics and properties. It is well

known that physical properties of crystalline

materials are very dependent on the host material,

phase purity, distribution of the grains sizes and

crystalline homogeneity. (Iida et al. 1999; Golubovic

et al. 2002; Zhang et al. 2008). For example,

transition metal and rare-earth element ions have

demonstrated lasing action in a wide variety of host

crystals. Among the compounds which can

incorporate transition metals or lanthanides several

scandium and gallium based materials were

elaborated (Vosegaard et al. 1997; Ferrand et al.

1999; Gaume et al. 2003; Muliuoliene et al. 2003;

Chenais et al. 2003; Garskaite et al. 2005; Mathur et

al. 2005; Sakirzanovas et al. 2008; Katelnikovas et

al. 2008). In the YAG all aluminium ions may be

substituted by gallium or iron ions, while pure

yttrium indium or yttrium scandium garnet is not

obtained. Besides, rare-earth aluminium garnets

have also attracted considerable attention as host

crystals for near-infrared solid-state lasers as well as

for optoelectronics devices, including computer

memories, microwave optical elements and as laser

active media with applications in medical surgery,

optical communications and coherent laser radar

(Papagelis et al. 2002; Papagelis et al. 2003;

Milanese et al. 2004).

Many different synthesis methods of synthetic

garnets are described in the literature. The solid-state

165

Pavasaryte L., Lopez B. and Kareiva A..

On the Sol-gel Preparation of Selected Lanthanide Aluminium Garnets Doped with Europium.

DOI: 10.5220/0005252901650171

In Proceedings of the 3rd International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2015), pages 165-171

ISBN: 978-989-758-093-2

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

reaction route is a widely used method for the

preparation of powders from a mixture of the solid

starting materials. Various wet-chemical methods,

which include combustion, co-precipitation,

hydrothermal, spray pyrolysis, sol-gel and emulsion

synthesis method have been developed and

successfully used for a low-temperature production

of phase-pure YAG, YGG, YIG powders and related

systems. Recently we have demonstrated that

monophasic yttrium aluminium garnet powders and

related garnet structure compounds with

homogeneously distributed lanthanide elements

within the garnet matrix can be successfully

synthesized by the simple aqueous sol-gel process.

The evaluated synthetic technique to garnet structure

compounds using acetate-nitrate-glycolate

intermediate illustrates the simplicity and superior

potential of the proposed method ( Katelnikovas et

al. 2007; Kareiva 2011; Skaudzius et al. 2014;

Zabiliute et al. 2014 ). The molecular level mixing

and the tendency of partially hydrolyzed species to

form extended networks facilitate the structure

evolution thereby lowering the crystallization

temperature. The reactivity of such precursors makes

the preparation of particular phases possible at

ambient and gentle conditions ( Livage et al. 1988;

Brinker et al. 1990; Cushing et al. 2004; Mackenzie

et al. 2007; Dubnikova et al. 2010 ).

Several lanthanide aluminium garnets (i.e.,

Tb

3

Al

5

O

12

, Dy

3

Al

5

O

12

and Ho

3

Al

5

O

12

) had not been

synthesized with various doping level of europium

using an aqueous sol-gel technique, to the best our

knowledge. Therefore, the main aim of this study

was to prepare Tb

3

Al

5

O

12

:Eu

3+

, Dy

3

Al

5

O

12

:Eu

3+

and

Ho

3

Al

5

O

12

:Eu

3+

using sol-gel technique and

investigate luminescent properties of these Eu

3+

-

doped garnets.

2 EXPERIMENTAL

The lanthanide aluminium garnet samples were

synthesized by an aqueous sol-gel method with

optimized synthesis parameters by mathematical

regression model (Katelnikovas et al. 2007;

Dubnikova et al. 2010 ). In the aqueous sol-gel

process, the following materials were used: Ho

2

O

3

(99.9 %), Tb

4

O

7

(99.9 %), Dy

2

O

3

(99.99%) and

Eu

2

O

3

(99.99%). Ho, Dy and Tb oxides were

dissolved in nitric acid (about 10 ml) with small

amount of water. Clear solutions were obtained after

stirring at 60-65 °C in beakers covered with a watch-

glass till dissolved. When oxides dissolved, mixture

washed with water till neutral pH. Then aluminium

nitrate nonahydrate and appropriate amount of

europium oxide dissolved in small amount of nitric

acid were added to above solutions and diluted till

100 ml. The resulting mixtures were stirred at 65 °C

for 1 h, followed by dropwice addition of ethane-

1,2-diol (HOCH

2

CH

2

OH) upon vigorous stirring.

The resulting sols were mixed at the same

temperature for another 1 h and then concentrated by

slow solvent evaporation at 65 °C until they turned

into transparent gels. The gels were dried in an oven

at 100 °C for 24 h. The resulting gel powders were

ground in an agate mortar and heated in air at 800 °C

for 4 h by slow temperature elevation (5 °C min

-1

).

After grinding in an agate mortar, the powders were

further sintered in air at 1000 °C temperature for

10h.

The synthesized samples were characterized by

X-ray powder diffraction (XRD) analysis, Fourier

transform infrared (FTIR) spectroscopy, scanning

electron microscopy (SEM), fluorescence

spectroscopy (FS) and dynamic light scattered

measurement (DLS). The XRD studies were

performed on D8 Bruker AXS powder

diffractometer using CuKα1 radiation. The

diffraction patterns were recorded at the standard

rate of 1.5 2θ / min. The FTIR spectra were recorded

with a Perkin-Elmer FT-IR Spectrum 1000

spectrometer. The scanning electron microscope

DSN 962 was used to study the surface morphology

and microstructure of the obtained ceramic samples.

Fluorescence data characterized by fluorescence

spectrophotometer Cary Eclipse Varian. Particle size

were identified by Zetasizer, nano series.

3 RESULTS AND DISCUSSION

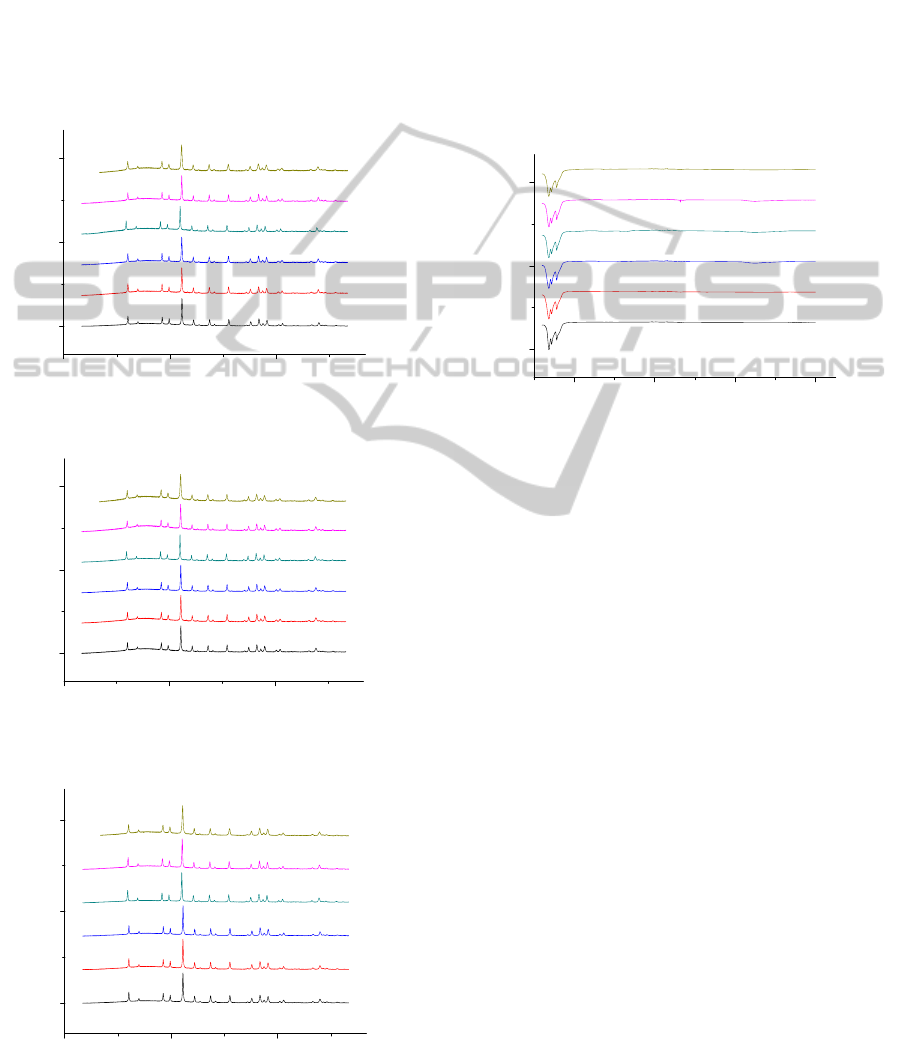

3.1 XRD Characterization of LnAG:Eu

Powders

The phase purity and compositional changes of the

LnAG doped with different amount of Eu ions were

controlled by X-ray diffraction analysis. The XRD

patterns of corresponding Tb

3

Al

5

O

12

(TAG),

Dy

3

Al

5

O

12

(DAG) and Ho

3

Al

5

O

12

(HAG), with

different doping level of Eu powders annealed at

1000

o

C are shown in Figs. 1-3, respectively.

The XRD results presented in Fig. 1 revealed that

ceramics obtained at 1000 °C consists of one

crystalline phase: terbium aluminium garnet

(Tb

3

Al

5

O

12

, TAG). The obtained XRD patterns are

in a good agreement with the reference data for

Tb

3

Al

5

O

12

(PDF [04-006-4054]). Fig. 2 shows that

only one dysprosium aluminium garnet Dy

3

Al

5

O

12

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

166

phase (PDF [04-006-4053]) was obtained after

calcination of Dy-Al-O:Eu precursors at 1000 °C. In

the case of the Ho-Al-O system, the analogous

results with of the Tb-Al-O and Dy-Al-O systems

were obtained. In Fig. 3 the X-ray diffraction

patterns of the final Ho-Al-O ceramic samples

annealed at 1000 °C are presented. The XRD

patterns prove the formation of the cubic holmium

aluminium garnets (Ho

3

Al

5

O

12

). Evidently, the

obtained XRD patterns are in a good agreement with

the reference data for Ho

3

Al

5

O

12

(PDF [04-001-

03060

0

3

6

0% Eu

0.1% Eu

0.25% Eu

0.5% Eu

0.75% Eu

1% Eu

Relative intensity

2

θ

Figure 1: XRD patterns of the Tb-Al-O:Eu gels annealed

at 1000

o

C.

03060

0

3

6

0% Eu

0.1% Eu

0.25% Eu

0.5% Eu

0.75% Eu

1% Eu

Relative intensity

2θ

Figure 2: XRD patterns of the Dy-Al-O:Eu gels annealed

at 1000

o

C.

03060

0

3

6

0% Eu

0.1% Eu

0.25% Eu

0.5% Eu

0.75% Eu

1% Eu

Relative intensity

2θ

Figure 3: XRD patterns of the Ho-Al-O:Eu gels annealed

at 1000

o

C.

9715]). Thus, we can conclude that the 1000

o

C

temperature is enough for the formation of Eu

3+

-

doped Tb

3

Al

5

O

12

, Dy

3

Al

5

O

12

and Ho

3

Al

5

O

12

garnets.

3.2 Infrared Spectroscopy

FTIR spectroscopy was used as additional tool for

the structural characterization of the ceramic

materials obtained by the aqueous sol-gel method.

The FTIR spectra of ceramic materials obtained after

the calcinations of the Ho-Al-O:Eu gels at 1000

o

C

for 10 h are shown in Fig. 4.

1000 2000 3000 4000

0

3

6

0% Eu

0.1% Eu

0.25% Eu

0.5% Eu

0.75% Eu

1% Eu

Transmittance %

Wavenumer [cm

-1

]

Figure 4: FTIR spectra of Ho

3

Al

5

O

12

:Eu

3+

garnets

synthesized at 1000

o

C.

The FTIR spectra of synthesized ceramics show

several quite intense broad bands at 675 cm

–1

, 720

cm

–1

and 775 cm

–1

,

which are typical metal-oxygen

(M-O) absorptions for the garnet-type compounds

(

Dubnikova et al. 2010; Garskaite et al. 2010; Li et al.

2005 ). The FTIR spectra of Tb-Al-O and Dy-Al-O

garnets doped with europium were very similar to

the presented in Fig. 4. The most important feature is

that intensive bands are determined in the region of

900–450 cm

-1

,

which may be also attributed to the

stretching modes of the isolated [AlO

4

] tetrahedra

and [AlO

6

] octahedra in the garnet structure, i.e.

these bands correspond to the formation of

crystalline TAG:Eu, DAG:Eu and HAG:Eu. Thus,

the observed M–O vibrations which in view of the

earlier reports are characteristic of RE–O and Al–O

stretching frequencies let us to conclude, that the

FTIR results are consistent with crystallization

process observed by XRD measurements.

Consequently, the FTIR results absolutely support

the conclusions made on grounds of the XRD

measurement and prove that there is no left organic

matter in the sol-gel derived garnet structure

compounds (

Li et al. 2005; Li et al. 2004; Xing et al.

2004; Pralad et al. 2013).

OntheSol-gelPreparationofSelectedLanthanideAluminiumGarnetsDopedwithEuropium

167

3.3 Scanning Electron Microscopy

The textural properties of the calcined Tb-Al-O:Eu,

Dy-Al-O:Eu, Ho-Al-O:Eu powders were

investigated by SEM, from which the grain size and

typical morphologies were obtained. Scanning

electron micrographs of the Tb-Al-O:0.5%Eu, Dy-

Al-O:0.5%Eu and Ho-Al-O:0.5%Eu samples

calcined at 1000

o

C are shown in Figs. 5-7,

respectively. The SEM once again proved to be a

valuable technique for the morphological

characterization of ceramic samples. Individual

particles seem to be submicro-sized plate-like

crystals and they partially

fused to form hard

agglomerates. The SEM micrograph presented in

Fig. 5 shows the formation of very homogeneous

mixed-metal oxide, and the formation of a

continuous network of crystallites is characteristic

feature for ceramic composite material during

calcination. The Ho-Al-O:Eu and Dy-Al-O:Eu

garnet particles are a little differently shaped

Figure 5: SEM micrograph of the Tb

3

Al

5

O

12

:0.5% Eu

3+

garnet.

Figure 6: SEM micrograph of the Dy

3

Al

5

O

12

:0.5% Eu

3+

garnet.

comparing with Tb-Al-O:Eu garnet (see Figs. 6 and

7). Apparently, the particles were formed with more

pronounced agglomeration, indicating good

connectivity between the grains which is

characteristic feature for ceramic composite material

(

Skaudzius et al. 2008).

Figure 7: SEM micrograph of the Ho

3

Al

5

O

12

:0.5% Eu

3+

garnet.

3.4 Dynamic Light Scattered

Measurements

The particle size distribution in Ho

3

Al

5

O

12

:Eu

garnets annealed at 1000 °C for 10 h were

investigated by dynamic light scattering (DLS). The

DLS measurements showed well size distribution of

garnets. When Eu doping level les or equal 0.1%

possible very narrow particle size distribution (~420

nm) was determined. The sample with higher

europium concentration (0.5%) were composed with

larger particles (~700 nm). When garnet doped with

0.25% - 0.75% of Eu

3+

some particles were much

more larger, and consequently the particle size is not

stable and split in a biggest range. However, the

biggest particle size was determined for the sample

with 1% of doping level of Eu. Interestingly, the

DLS results fit very well with scanning electron

microscopy data showing that 0.5% of Eu is the

optimum doping level for Tb, Dy and Ho aluminium

garnets having very homogeneous particle size

distribution.

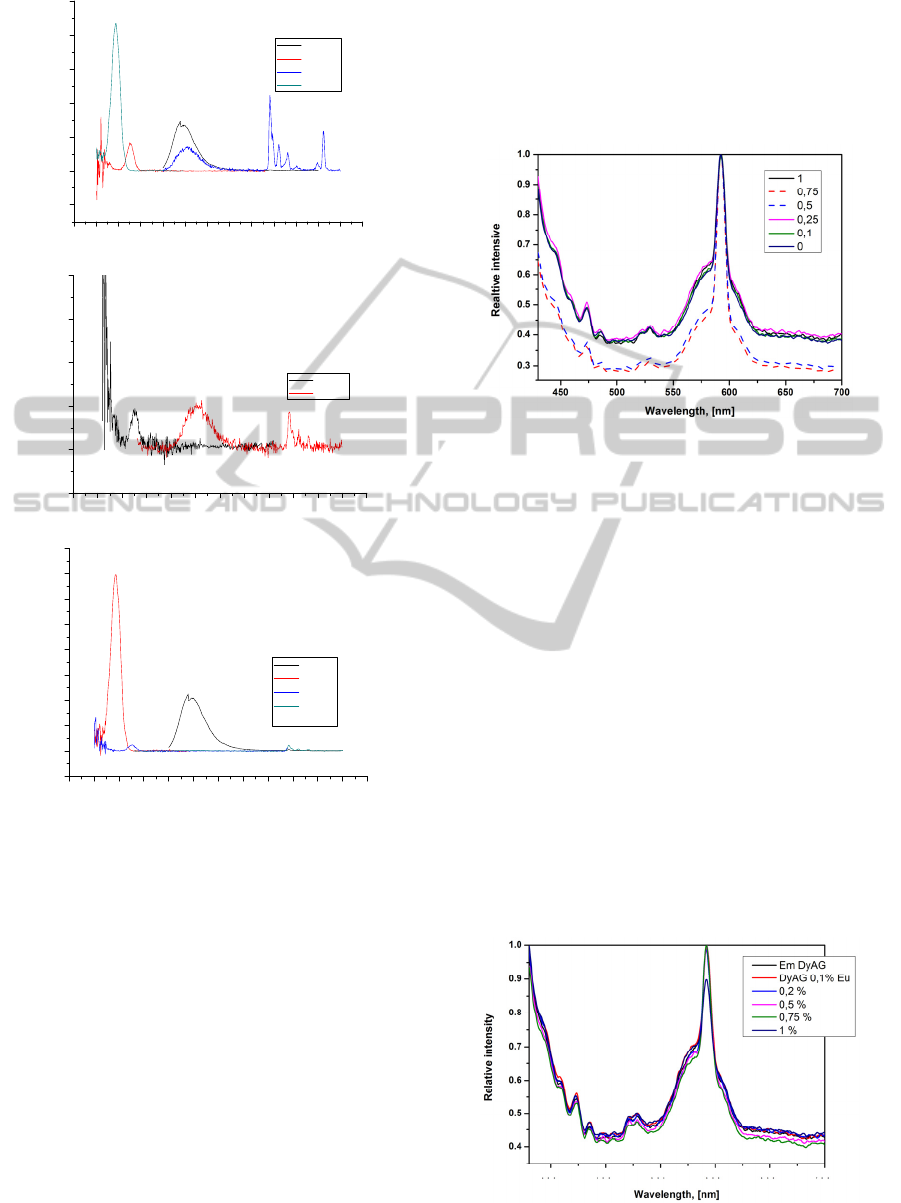

3.5 Optical Properties

The fluorescence data of Ho

3

Al

5

O

12

:Eu are shown in

Fig. 8.

As seen. the 0.5% Eu-doped sample shows the

most intensive europium peaks between investigated

the Ho-Al-O:Eu garnet structure compounds.

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

168

150 200 250 300 350 400 450 500 550 600 650 700 750 800

-20

0

20

40

60

80

100

Intensity (a.u.)

Wavelenght (nm)

ex 242

em 591

ex275

em394

HoAG 0.5%Eu

150 200 250 300 350 400 450 500 550 600 650 700 750

-0.5

0.0

0.5

1.0

1.5

2.0

Intensity (a.u.)

Wavelength (nm)

em591

ex275

HoAG 0.75%Eu

150 200 250 300 350 400 450 500 550 600 650 700 750

-5

0

5

10

15

20

25

30

35

40

Intensity (a.u.)

Wavelenght (nm)

ex242

em394

em591

ex275

HoAG 1%Eu

Figure 8: Fluorescence measurement data of

Ho

3

Al

5

O

12

:Eu

3+

garnets.

This data fit well with XRD results (peaks with

0,5% europium are shifted to the smaller 2θ). The

sample having 1% of Eu shows possible

fluorescence, however, not so intensive as with 0.5%

of Eu, but more intensive than 0.75% Eu-doped

sample. The XRD data also showed the smaller shift

for 0.75% Eu and 1% Eu samples. Finally, the

results of fluorescence measurement support the

proposition that the best doping level for HAG:Eu is

0.5% of europium.

It is particularly well known that, phosphors with

spherical shaped particles (≤ 2 µm) are of greater

importance because of their high packing density,

lower scattering of light, brighter luminescent

performance, high definition and more improved

screen packing density. This explain why 0.5

europium doping shows the best luminescent

properties (

Raju et al. 2008; Park et al. 2010).

Figs. 9 and 10 represent luminescence spectra of

Tb

3

Al

5

O

12

:Eu and Dy

3

Al

5

O

12

:Eu garnets,

respectively.

Figure 9: Luminescent (emission) spectra of

Tb

3

Al

5

O

12

:Eu

3+

garnets.

The spectra were acquired by using 394 nm and

275 nm excitation. The emission peaks were fixed

between 550 and 650 nm, and well agree with the

reported values of Eu

3+

emission transitions [56-58].

The emission spectral lines of Eu

3+

ion are sharp

which is due to the screening of 4f orbital by 5s and

5p orbitals from crystal field of the host lattice.

Spectrums show the characteristic emission of Eu

3+

arising due to

5

D

0

→

7

F

1

(591nm),

5

D

0

→

7

F

2

(611nm) and

5

D

0

→

7

F

4

(708nm) transitions (Singh et

al. 2013). As expected for the Eu

3+

ions a typical

strong red emission was present with the most

intense line at 611 nm originated from the

5

D

0

→

7

F

2

hypersensitive transition (Redenka et al. 2014). Few of

Ho

3

Al

5

O

12

:Eu doping (0.1% Eu, 0.25% Eu) do not

show any emission peaks. The results obtained are in

a good agreement with fluorescence data, beside

with this doping level peaks in XRD graphs did not

shift.

Figure 10: Luminescent (emission) spectra of

Dy

3

Al

5

O

12

:Eu

3+

garnets.

OntheSol-gelPreparationofSelectedLanthanideAluminiumGarnetsDopedwithEuropium

169

Fig. 11: represents the life time of Ho

3

Al

5

O

12

:Eu

garnets obtained after annealing at 1000 °C for 10 h.

0 5 10 15 20

5

7

6

7

ln(I) [a.u.]

Time [ms]

0,1% Eu

0,25% Eu

0,5% Eu

0,75% Eu

1% Eu

5

Figure 11: The life time measurements for the

Ho

3

Al

5

O

12

:Eu

3+

garnets.

The luminescence lifetime for the most intense

emission line at 611 nm of Eu

3+

(

5

D

0

→

7

F

1

) were

recorded using 275 nm as excitation source. The

obtained photoluminescence lifetimes show a

decrease (Fig. 12) from 2.58 to 1.98 ms with

increasing doping concentration. Upon increasing

the doping concentration, the decay becomes faster.

In our case the maximum decay time is 2.58 ms with

0,1 mol% doping concentration. Increasing doping

content may increase the number of ions occupying

the surface states in nanoscale dimensional materials

and these states may be leading to concentration –

quenching behaviour (

Packiyaraj et al. 2014;

Muenchausen et al. 2007)

. Decay time decrease with

increasing doping content. This result supports

emission and excitation spectral analysis.

0,0 0,2 0,4 0,6 0,8 1,0

1,8

1,9

2,0

2,1

2,2

2,3

2,4

2,5

2,6

2,7

Lifetime (ms)

Eu Concentration (%)

Figure 12: The decay curves for Ho

3

Al

5

O

12

:Eu

3+

garnet.

4 CONCLUSIONS

The sinterability and microstructal evolution of

synthesized lanthanide aluminium garnets by an

aqueous sol-gel process were investigated in the

present study. In this work aqueous sol-gel process

was used to prepare lanthanide-aluminium oxides

Tb

3

Al

5

O

12

,

Dy

3

Al

5

O

12

and Ho

3

Al

5

O

12

doped with

different amount of europium. It was concluded

from the XRD data that monophasic Tb

3

Al

5

O

12

:Eu,

Dy

3

Al

5

O

12

:Eu

and Ho

3

Al

5

O

12

:Eu

garnets can be

easily synthesized at 1000 °C using the proposed

sol-gel chemistry approach. Europium inside garnet

structure slightly shifted the reflection peaks in the

XRD patterns. The biggest shift was observed in the

XRD pattern of the samples with 0.5% of Eu. The

XRD results were supported by FTIR, SEM, DLS

fluorescence and luminescent measurements. It was

also determined that the amount of europium inside

garnet structure influenced the particle size. With

increasing doping level the particle size also

increased. The luminescence lifetime for the most

intense emission line at 611 nm of Eu

3+

(

5

D

0

→

7

F

1

)

was recorded using 275 nm as excitation source in

HAG and 394 nm in TAG and DAG. Upon

increasing the doping concentration, the decay

became faster in Ho

3

Al

5

O

12

:Eu. The characterization

of synthesized samples using all measurements used

in this study resulted to the conclusion that that 0.5%

of europium is optimum doping level. Thus, the

developed synthesis route offers unique

opportunities for the synthesis of optical materials,

since it is suited for the production of thin/thick

films, monoliths and fibbers.

REFERENCES

C. J. Harlan, A. Kareiva, D. B. MacQueen, R. Cook, and

A. R. Barron, 1997. Adv. Mater. 9, 68.

P. Vaqueiro, and M. A. Lopez-Quintela, 1998. J. Mater.

Chem. 8, 161 (1998).

R. C. Pullar, M. D. Taylor, and A. K. Bhattacharya, 1999.

J. Eur. Ceram. Soc. 19, 1747.

S. Ganschow, D. Klimm, P. Reiche, and R. Uecker, 1999.

Cryst. Res. Technol. 34, 615.

Y. C. Kang, I. W. Lenggoro, S. B. Park, and K. Okuyama,

1999. J. Phys. Chem. Solids 60, 1855.

J. Lu, M. Prabhu, J. Song, C. Li, J. Xu, K. Ueda, A. A.

Kaminskii, H. Yagi, and T. Yanagitani, 2000. Appl.

Phys. B 71, 469.

C. H. Lu, H. C. Hong, and R. Jagannathan, 2002. J. Mater.

Chem. 12, 2525.

D. Hreniak, and W. Strek, 2002. J. All. Comp. 341, 183.

Y. Zhou, J. Lin, M. Yu, S. Wang, and H. Zhang, 2002.

Mater. Lett. 56, 628.

Y. Pan, M. Wu, and Q. Su, 2004. J. Phys. Chem. Solids

65, 845.

A. Potdevin, G. Chadeyron, D. Boyer, and R. Mahiou,

2006. J. Sol-Gel Sci. Techn. 39, 275.

R. Singh, R. K. Khardekar, A. Kumar, and D. K. Kohli,

2007. Mater. Lett. 61, 921.

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

170

A. Katelnikovas, P. Vitta, P. Pobedinskas, G. Tamulaitis,

A. Zukauskas, J.-E. Jørgensen, and A. Kareiva, 2007.

J. Cryst. Growth 304, 361.

E. Caponetti, M. L. Saladino, F. Serra, and S. Enzo, 2007.

J. Mater. Sci. 42, 4418.

E. Caponetti, S. Enzo, B. Lasio, and M. L. Saladino, 2007

Opt. Mater. 29, 1240.

L. Lipinska, L. Lojko, A. Klos, S. Ganschow, R.

Diduszko, W. Ryba-Romanowski, and A.

Pajaczkowska, 2007. J. All. Comp. 432, 177.

A. Katelnikovas, T. Justel, D. Uhlich, J.-E. Jorgensen, S.

Sakirzanovas, and A. Kareiva. 2008. Chem. Eng.

Comm. 195, 758.

N. N. Khimich, E. N. Poddenezhnyi, A. A. Boiko, A. V.

Zdravkov, V. L. Ugolkov, L. A. Koptelova, E. I.

Grishkova, and A. O. Dobrodei, 2009. Glass Phys.

Chem. 35, 504.

M. Suarez, A. Fernandez, J. L. Menendez, and R.

Torrecillas, 2009. J. Nanomater. Art. # 138490.

H. J. Yang, L. Yuan, G. S. Zhu, A. B. Yu, and H. R. Xu,

2009. Mater. Lett. 63, 2271.

X. X. Ge, Y. H. Sun, C. Liu, and W. K. Qi, 2009. J. Sol-

Gel Sci. Technol. 52, 179.

K. Fujioka, T. Saiki, S. Motokoshi, Y. Fujimoto, H. Fujita,

and M. Nakatsuka, 2009. Ceram. Int. 35, 2393.

H. K. Yang, and J. H. Jeong, 2010. J. Phys. Chem. C 114,

226.

Y. Iida, A. Towata, T. Tsugoshi, and M.Furukawa, 1999.

Vibr. Spectr. 19, 399.

A. Golubovic, S. Nikolic, R. Gajic, S. Duric, and A.

Valcic, 2002. J. Serb. Chem. Soc. 67, 291.

L. Zhang, C. Y. Zhang, D. H. Li, Z. Y. Wei, Z. G. Zhang,

J. E. Hans, and S. Strohmaier, 2008. Chin. Phys. Lett.

25, 3988.

T. Vosegaard, D. Massiot, N. Gautier, and H. J. Jakobsen,

1997. Inorg. Chem. 36, 2446.

B. Ferrand, B. Chambaz, and M. Couchaud, 1999. Opt.

Mater. 11, 101.

R. Gaume, B. Viana, J. Derouet, and D. Vivien, 2003. Opt.

Mater. 22, 107.

I. Muliuoliene, S. Mathur, D. Jasaitis, H. Shen, V.

Sivakov, R. Rapalaviciute, A. Beganskiene, and A.

Kareiva, 2003. Opt. Mater. 22, 241.

S. Chenais, F. Druon, F. Balembois, P. Georges, A.

Brenier, and G. Boulon, 2003. Opt. Mater. 22 99.

E. Garskaite, Z. Moravec, J. Pinkas, S. Mathur, R.

Kazlauskas, and A. Kareiva, 2005. Phil. Magaz. Lett.

85, 557.

S. Mathur, H. Shen, A. Leleckaite, A. Beganskiene, and A.

Kareiva, 2005. Mater. Res. Bull. 40, 439.

S. Sakirzanovas, L. Sun, Ch. Yan, and A. Kareiva, 2008.

Mendeleev Commun. 18, 251.

A. Katelnikovas, and A. Kareiva. 2008. Mater. Lett. 62,

1655.

K. Papagelis, G. Kanellis, T. Zorba, S. Ves, and G. A.

Kourouklis, 2002. J. Phys. Condens. Matter 14, 915.

K. Papagelis, and S. Ves, 2003. J. Phys. Chem. Solids 64,

599.

C. Milanese, V. Buscaglia, F. Maglia, and U. Anselmo-

Tamburini, 2004. Chem. Mater. 16, 1232.

A. Katelnikovas, J. Barkauskas, F. Ivanauskas, A.

Beganskiene, and A. Kareiva, 2007. J. Sol-Gel Sci.

Techn. 41, 193.

A. Kareiva, 2011. Materials Science (Medžiagotyra), 17,

428.

R. Skaudzius, A. Katelnikovas, D. Enseling, A. Kareiva,

and T. Juestel, J. Lumin. 147, 290 (2014).

A. Zabiliute, S. Butkute, A. Zukauskas, P. Vitta, and A.

Kareiva, 2014. Appl. Optics, 53, 907.

J. Livage, M. Henry, C. Sanchez, 1988. Progr. Solid State

Chem. 18, 259.

C. J. Brinker, G. W. Scherrer, 1990. Sol-Gel Science: The

Physics and Chemistry of Sol-Gel Processing,

Academic Press, San Diego.

B. L. Cushing, V. L. Kolesnichenko, and C. J. O‘Connor,

2004. Chem. Rev. 104, 3893.

J. D. Mackenzie, and E. P. Bescher, 2007. Acc. Chem.

Res. 40, 810.

N. Dubnikova, E. Garskaite, J. Pinkas, P. Bezdicka, A.

Beganskiene, A. Kareiva, 2010. J. Sol-Gel Sci. Techn.

55 (2), p.213 – 219.

E. Garskaite, N. Dubnikova, A. Katelnikovas, J. Pinkas,

and A. Kareiva, 2010. Collect. Czech. Chem.

Commun. 72, 321.

Xia Li, Hong Liu, Jiyang Wang, Hongmei Cui, Shunliang

Yang, I.R. Boughton, 2005. J. Phys. Chem. Solids 66

201-205.

Xia Li, Hong Liu, Jiyang Wang, Hongmei Cui, Feng Han,

2004. J. Am. Ceram. Soc., 87 [12] 2288-2290.

Lin Xing, Luming Peng, Min Gu, Guodong Tang, 2004. J.

Alloys Comp. 491 599-604.

Nathalie Pralad, Genevieve Chadeyron, Audrey Potdevin,

Jerome Deschamps, Rachid Mahiou, 2013. J. Eur.

Ceram. Soc. 33 1935-1945.

R. Skaudzius, A. Zalga, and A. Kareiva, 2008. Materials

Science - Medziagotyra 14, 193.

G.Seeta Rama Raju, S. Buddhudu, 2008. Mater. Lett. 62

1259.

Jin Young Park, Hong Chae Jung, G. Seeta Rama Raju,

Byung Kee Moon, Jung Hyun Jeong, Jung Hwan Kim.

2010. J. Lumin. 130 478 – 482.

R. Srinivasan, R. Yogamalar, A. Chandra Bose, 2010.

Meter. Res Bull. 45.

J. Dhanaraj, R. Jagannathan, T.R.N. Kutty, C.-Hsin Lu,

2001. J. Phys. Chem. B 105 11098.

P.Packiyaraj, P. Thangadurai, 2014. J. Lumin 145 997-

1003.

S. K. Singh, Dong Gi Lee, Soung Soo Yi, Kiwan Jang,

Dong-Soo Shi, Jung Hyun Jeong, 2013. J. Appl. Phys.

113, 173504.

Redenka M., Krsmanovič Whiffen, Željka Antic, Adolfo

Speghini, Mikhail G. Brik, Barbora Bartova, Marco

Bettinelli, Miroslav D. Dramicanin, 2014. Opt. Mater.

36 1083-1091.

P.Packiyaraj, P. Thangadurai, 2014. J. Lumin 145 997-

1003.

R. E.Muenchausen, L. G. Jacobsohn, B. L. Bennett, E. A.

McKigney, 2007. J. F. Smith, J. A. Valdez, D. W.

Cooke, J. Lumin, 126 838.

OntheSol-gelPreparationofSelectedLanthanideAluminiumGarnetsDopedwithEuropium

171