Amperometric Urea Sensor

Enzyme Immobilization into Adjustable Membrane and Mathematical

Characterization of the Biosensor

Julija Razumiene

1

, Ieva Sakinyte

1

, Vidute Gureviciene

1

and Karolis Petrauskas

2

1

Institute of Biochemistry, Vilnius University, Mokslininku 12, 08662, Vilnius, Lithuania

2

Faculty of Matchematics and Informatics, Vilnius University, Naugarduko 24, Vilnius Lt- 03225, Lithuania

Keywords: Urea Biosensor, Adjustable Membrane, Enzyme, Amperometry, Mathematical Modelling.

Abstract: The prototype of amperometric biosensor for urea determination was designed. The enzyme electrode, made

of a specially developed modified graphite (MG) paste, was produced by covering the electrode surface

with adjustable membrane containing immobilized urease from Canavalia ensiformis (E.C. 3.5.1.5.). Simple

methodology of urea determination in real time has been proposed. The experimental study and the

mathematical model of the biosensor action have been performed.

1 INTRODUCTION

Rapid and simple determination of urea is very

important in clinical analysis. Generally, abnormal

urea concentration indicates kidney disease. The

main procedure of urea level monitoring for patients

is haemodialysis – blood filtering procedure. Filtered

blood flows back to the patient and the leaked out

dialysate is disposed as waste. Certainly, there are

modern apparatus for blood dialysis using ratio

Kt/V, where K is the dialyzer urea clearance, t is the

treatment time, and V is the patient’s urea

distribution volume, to quantify the dialysis dose

(Jensen et al., 2004). Unfortunately, the parameter

Kt/V is not based on real time measurements. In

fact, it is widely accepted that during 4 hours of

haemodialysis Kt/V reaches value about 1.3 and this

is an indication to finish dialysis procedure.

Actually, urea level in blood is highly affected by

stress, physical activity or nutrition and Kt/V would

be relevant only if urea concentration was known

just before dialysis started. Thus, it is very

promising to determine the concentration in real

time. Definitely, the non-invasive and cost-saving

methods are preferable. Thus, in this study we

propose amperometric detection system allowing

detecting urea in waste product - dialysate at any

time of the haemodialysis procedure.

Though the great number of urea determination

methods are based on photometric or conducto-

metric determination of NH

4+

(Patton and Crouch,

1977; Soldatkin et al., 2014) or using a piezo-

electric sensor (Miglior et al., 2007), their

application for express analysis, and especially in

turbid media, is rather complicated. In this case the

amperometric biosensors are most promising. The

electrochemical approach for rapid detection of urea

have been proposed in (Sant et al., 2011) and also in

our previous work (Razumiene et al., 2013).

The goal of this work was on a base of previous

studies to design the urea analyser prototype. The

core of this device is biosensor using especially

developed modified graphite (MG) electrode and

adjustible membrane containing immobilized urease.

The mathematical model was proposed for

characterisation of biosensor action.

2 EXPERIMENTAL

2.1 Preparation of Membrane

Poly(urethane-urea) (PUU) microparticles from

poly(vinyl alcohol) (PVA) and hexamethylene

diisocyanate (HMDI) were synthesized by one-step

method in dimethyl sulfoxide/water (99/1 vol.%)

solution according to previously described protocol

(Budriene et al., 2007).

.

Initial concentration of PVA

was 0.1 M. Initial molar ratio of PVA and HMDI

was 1.0:5.0.

144

Razumiene J., Sakinyte I., Gureviciene V. and Petrauskas K..

Amperometric Urea Sensor - Enzyme Immobilization into Adjustable Membrane and Mathematical Characterization of the Biosensor.

DOI: 10.5220/0005274501440149

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2015), pages 144-149

ISBN: 978-989-758-071-0

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

Immobilization of urease onto PUU microparticles

was carried out in 0.1 M phosphate buffer solution,

pH 7.2. The mixture of the enzyme, buffer and PUU

carrier (in folowing ratio: 1540 U of urease for 0.5 g

of polymeric carrier) was stirred at 25 °C for 30 min

(immediately after synthesis) and then left at 4 °C

overnight. Next day the immobilized enzyme was

thoroughly washed with buffer and 2 µl of

suspension were droped onto terylene film

agglutinated to the rubber ring.

2.2 Preparation of MG and Biosensor

Modified graphite particles were synthesized from

pristine graphite (Merck KGaA) by oxidizing it with

potassium ferricyanide K

3

[Fe(CN)

6

] in alkaline

media. Titration analysis revealed the presence of

small amount (0.14 – 0.17 mmol/g) of basic surface

functional groups.

It was determined that the MG sample suitable

for biosensor design contains a fine fraction of 63 %

with an average diameter of the graphite particles of

20 nm.

MG powder was mixed with the pasting liquid

consisting of 10 % polyvinyl dichloride in acetone

and used for design of the electrodes.

Aiming to design working electrodes MG mixed

with pasting liquid was extruded by forming tablet

(Voitechovic et al., 2010). The tablet was sealed in a

Teflon tube. Electrodes were washed with bidistilled

water, and dried before use. Working urease-MG

electrode (biosensor) was designed by mechanically

attaching the membrane containing polymeric

carriers with immobilized urease to the surface of

MG. (Fig. 1).

2.3 Amperometric Measurements

Urea measurements were performed using a home-

made analyser equipped with a three-electrode

system comprised of a platinum plate electrode as

auxiliary electrode, a saturated Ag/AgCl electrode as

reference and urease-MG (2 mm diameter) as

working electrode (biosensor) (Fig. 2).

The response of the biosensor to the addition of

substrate was investigated under potentiostatic

conditions at 0.2 V (vs. Ag/AgCl) in a stirred buffer

solution. Phosphate buffer solution, pH 7.2,

containing 1 M of urea or dialysate was used as a

substrate. The specially created program and

Origin Pro 8.0 (free trial version from

http://www.originlab.com, OriginLab Corporation,

US) were used for data analysis.

2.3.1 Measurements in Dialysate

Dialysate was analysed using the developed analyser

comprised with the biosensor. Prior the

measurements analyser was tested with standard 1 M

of urea solution. For each measurement 2, 3, 5, 7

and 10 µl of the solution were added into

electrochemical cell containing of 1 ml of buffer

solution. Taking into account that the concentration

of urea in dialysate during the haemodialysis could

be outside the working range of the biosensor, a

dilution of the samples were necessary prior to

analysis to adjust the sample concentration to the

linear range of the biosensor. For this purpose, the

samples of dialysate were 10 times diluted with

buffer solution and analogous experiments were

carried out by adding probes in the electrochemical

cell.

2.4 Mathematical Model

Mathematical model was built aiming to have a tool

for analysing behaviour of the biosensor, impact of

its parameters and to lower number of required

experiments (Amatore et al., 2006). The biosensor is

considered as a reaction-diffusion system when

defining its mathematical model (Baronas et al.,

2010). Due to the biosensor symmetry, the model is

formulated in the one-dimensional space – a line

segment perpendicular to the active surface of the

biosensor. The model is composed of three layers

representing correspondingly the enzyme layer,

terylene membrane and a Nernst diffusion layer that

forms on the external surface of the terylene

membrane. No diffusion of the urea and its products

is assumed in the layer of the MG paste.

The urea detecting process is modelled as a two-

step reaction. In the first step the urea (S) is detected

by the urease (E) in an enzymatic hydrolysis

reaction with production of intermediate compound

carbamic acid (P) and ammonia (P’),

'.PPS

E

(1)

The carbamic acid is finally electrooxidised (not in

one-step mechanism) with production of ammonia

and carbon dioxide (P’’)

'.'' PPP

e

(2)

Electrons released in this reaction are collected by

the MG electrode and form a biosensor response

current.

Reaction (1) takes place in the thin layer,

between the terylene membrane and the MG

electrode. Kinetics of the urea and the carbamic acid

A B

AmperometricUreaSensor-EnzymeImmobilizationintoAdjustableMembraneandMathematicalCharacterizationofthe

Biosensor

145

are described by the following reaction-diffusion

equations:

,

max

2

2

1

SK

SV

x

S

D

t

S

(3)

,

max

2

2

1

SK

SV

x

P

D

t

P

(4)

where S and P are concentrations of the urea and the

carbamic acid, D

1

is a diffusion coefficient, K

M

stands for the Michaelis constant, V

max

is the

maximal reaction rate, t is a time from the start of

the experiment and x stand for a distance from the

electrode surface. Only mass transfer by diffusion is

considered in the terylene membrane and the

external Nernst layer,

,3,2,,

2

2

2

2

i

x

P

D

t

P

x

S

D

t

S

ii

(5)

where D

i

, i=2, 3 are diffusion coefficients of the

species in the corresponding medium.

The experiments start at a moment (t=0) when

the urea is poured into the buffer solution, although

it is still absent in the biosensor. We also assume

zero concentration of the carbamic acid in the

biosensor at this time.

Boundary conditions are defined for the external

bound of the Nernst diffusion layer and the surface

of the graphite electrode. On the upper boundary of

the Nernst diffusion layer, constant concentration

(S

0

) is assumed for urea and the carbamic acid is

absent,

.0,

33

0

xx

PSS

(6)

On the surface of the MG electrode, non-leakage

condition applies to the urea. Electrode oxidation of

the carbamic acid takes place on the surface of the

electrode, thus, a gradient of the carbamic acid is

considered to be equal to the rate of the oxidation

process,

,,0

2

0

1

0

R

x

P

D

x

S

xx

(7)

where R2 stands for the rate of the oxidation

process:

,

0

12

x

PkR

(8)

where k is a heterogeneous oxidation rate constant

and γ is a rate of the active surface of the electrode

to its area.

Response of the biosensor is derived from the

current, produced the oxidation of the carbamic acid

on the surface of the MG electrode. Response

current at a time t is defined as:

,0,)(

2

tFRAnti

e

(9)

where A is an area of the active surface of the

biosensor, n

e

is a number of electrons exchanged in

one reaction event and F stands for the Faraday

constant.

The proposed model consists of a system of non-

linear partial differential equations. Analytical

solutions for such systems are known only for

separate cases, therefore a numerical model was

derived and results obtained by performing

computer simulations.

MG paste is not represented in this model

explicitly. It was assumed, that the MG paste

increases active surface of the electrode and its

impact can be modelled by increasing γ – ratio of the

active electrode surface to its area.

3 RESULTS

3.1 Principle of Urea Biosensor

The urease-MG electrode (biosensor) is illustrated in

Figure 1. The biosensor consists of a Teflon tube (6)

with sealed tablet of MG (4), contact zone for MG

(5), contact wire (7) and adjustable membrane

comprising of immobilized enzyme (3),

semipermeable film (2) and rubber ring (1). The

amperometric urea detection principle is based on

registration of oxidation current observed during the

enzymatic reaction of the intermediate product in

urease-catalyzed hydrolysis of urea (Laurinavicius et

al., 2013).

Figure 1: Principal scheme of urea biosensor.

The biosensor incorporated in to the three-

electrode electrochemical cell is the core of

proposed urea analyser.

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

146

3.2 Characterization of Urea Biosensor

Biosensor based on the urease-MG electrode after

addition of urea in to electrochemical cell shows

substrate-dependent anodic response. The biosensor

response is fast (90 % of steady state current

achieved in 10 s) and this feature is desirable for

analytical instruments. The urea calibration curve

and the linear range are presented in Figure 2.

Figure 2: The urea calibration curve and the linear range

(solid line). Applied urese-MG electrode potential 0.2 V,

Phosphate buffer solution, pH 7.2.

While the linear range of urea biosensor is up to 6

mM the concentration of urea in dialysate during the

haemodialysis will be outside the working range of

the biosensor. Thus, for adjusting the sample

concentration to the linear range of the biosensor a

dilution of the samples were necessary prior to

analysis and the sensitivity of the sensor allows it.

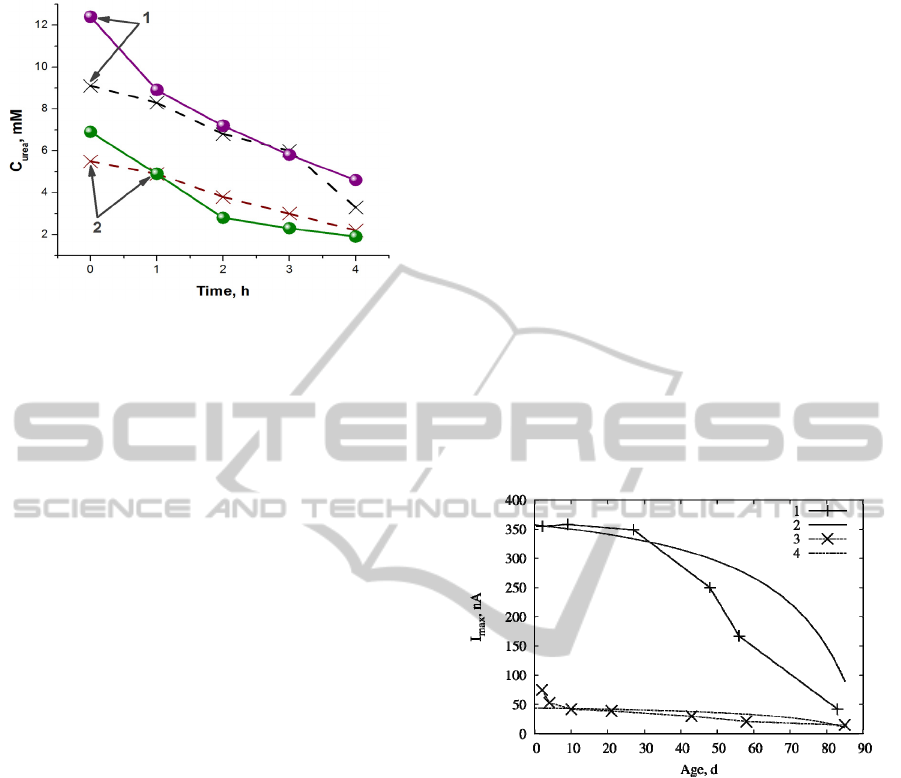

3.3 Urea Biosensor Stability

Stability of the biosensor designed using MG and

membrane containing immobilized urease was

investigated during 85 days (Fig. 3). The responses

Figure 3: Intensity of responses to 3 mM of urea obtained

by proposed analyser at 2 – 85 day.

to the standard urea solution (3 mM) were

periodically recorded at 20 °C and it was detected

that the residual response of the biosensor was not

less than about 50 % of initial magnitude over the

period of 20 days. After 85 days the biosensors

activity decreased up to 20 % of residual.

As can be seen in Figure 3, not only intensity of

responses but also the shape was changed. A

physical explanation and a digital modelling of this

ageing process are following.

3.4 Urea Analyser

The proposed urea analyser is shown in Figure 4.

Figure 4: The prototype of urea analyser based on

amperometric biosensor.

The urea measuring system consists of

electrochemical three-electrode cell, a home-made

potentiostat, peristaltic pump, stirrer and thermostat

and response recorder.

3.5 Urea Determination in Dialysate

Amperometric type of sensors beside other well-

known advantages such as comparable instrumental

sensitivity and amenability to miniaturization also

have one of very important feature – acceptability

for functioning in turbid media. Thus, in this report,

we present simple approach of the biosensor for

determination of urea in dialysate. The

measurements have been carried out by investigating

dialysate leaked out from patients during

haemodialysis. The samples were taken each hour of

blood filtration procedure and in parallel they were

examined at the hospital laboratory. Urea

concentration data for two patients obtained by both

methods are presented in Figure 5.

AmperometricUreaSensor-EnzymeImmobilizationintoAdjustableMembraneandMathematicalCharacterizationofthe

Biosensor

147

Figure 5: Comparison of urea concentration of two

patients (1 and 2) obtained in dialysate using proposed

analyser (solid line) and in the hospital laboratory (dashed

line).

As can be seen in Figure 5, it was observed good

correlation between data obtained by using analyser

and in the hospital laboratory.

3.6 Computation

Numerical simulations were performed in order to

validate the model, to investigate the biosensor

ageing process as well as impact of the MG paste.

The following parameter values were used in all the

simulations:

,150,12,5

23121

mxxxxx

(10)

,107.3,105.1

1210

2

10

1

smDD

(11)

,3,107.6

0

1210

3

mMSsmD

(12)

,25,5.1

1

max

mMKmMsV

(13)

.3

2

mmA

(14)

The heterogeneous oxidation rate constant k was

not known during this investigation therefore the

product γ×k was used as a single parameter when

performing numerical simulations.

The proposed model does not consider the

decrease of a biosensor response. It will be analysed

in the further investigation. In order to compare

simulation results with the experimental ones,

maximal response current of the experiment was

used.

Initial simulations were performed in order to

characterise the biosensor ageing process and impact

of the MG paste on its response. For the first

attempt, an assumption was made, that the

inactivation of the urease decreases linearly over the

time,

,/)(

maxmax0max

TTTekV

cat

(15)

where T is an age of the biosensor, T

max

is assumed

to be time, during which the enzyme is inactivated

completely, k

cat

= 10

4

s

-1

is the catalytical constant of

the urease, e

0

is the effective concentration of the

urease in the layer between the electrode and the

terylene membrane. Its value was theoretically

estimated to be e

0

< 0.02 mM and derived by fitting

simulation results to be 0.01 mM. Dependence of the

biosensor response on the ageing is shown in Figure

6.

As can be seen in Figure 6, simulated results are

close to the experimentally obtained values only in

some cases. The results show, that increase of the

active area of the electrode surface can have similar

impact as the addition of the MG paste to the

response of the biosensor, although further

investigation is needed to check, if the impact

remains the same at different urea concentrations

and other parameter variations.

Figure 6: Dependence of the biosensor response on the age

on the biosensor. Curves (1, 3) represent experimental

measurements and (2, 4) stand for simulations for the

biosensor with addition of MG paste (1, 2) and without it

(3, 4).

The simulations show, that the inactivation of the

biosensor is not linear as the simulated results do not

fit with the simulations when changing biosensor’s

age. Exponential inactivation rate was also

considered, although no close fit with experimental

data was found.

4 CONCLUSIONS

The biosensor comprised of especially devoted

electrode material MG and adjustable membrane

containing immobilized urease can be applied for

urea analyser.

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

148

Good data correlation with certified method

confirmed that the proposed analyser can be used for

rapid and simple detection of urea in dialysate.

Besides proposed application, the focus of our future

research will be adjustment of the analyser for

veterinary or environment.

Preliminary simulations show, that the sensitivity

of the urea biosensor can be increased by applying

the MG paste to the urease-MG electrode.

ACKNOWLEDGEMENTS

This work was funded by the European Social Fund

under National Integrated Programme Biotechno-

logy and Biopharmacy, grant VP1-3.1-SMM- 08-

K01-005.

REFERENCES

Amatore, C., Oleinick, A. Svir, I., da Mota, N., Thouin, L.,

2006. Theoretical modeling and optimization of the

detection performance: A new concept for

electrochemical detection of proteins in microfluidic

channels, Nonlinear Anal. Model. Control, 11, pp.

345–365.

Baronas, R., Ivanauskas, F., Kulys, J 2010. Mathematical

Modeling of Biosensors; Springer Series on Chemical

Sensors and Biosensors, Springer: Dordrecht.

Netherlands, vol 9.

Budriene, S., Romaskevic, T., Pielichowski, K.,

Pielichowski, J., 2007. Synthesis and characterization

of polyurethane microspheres and their application for

immobilization of maltogenase. Polym. Adv. Technol.,

vol. 18, no. 1, pp. 67-71.

Jensen, P. S., Bak, J., Ladefoged, S., Andersson-Engels,

S., Friis-Hansen, L., 2004. Online monitoring of urea

concentration in dialysate with dual-beam Fourier-

transform near-infrared spectroscopy. Journal of

Biomedical Optics, vol. 9, no. 3, pp. 553-557.

Laurinavicius, V., Razumiene, J., Gureviciene, V., 2013.

Bioelectrochemical conversion of urea on Carbon

Black Electrode and Application. IEEE Sensors

Journal, vol. 13, no. 6, pp. 2208-2213.

Miglior, F., Sewalem, A., Jamrozik, J,. Bohmanova J.,

Lefebre, D.M., Motore, R.K., 2007. Genetic Analysis

of Milk Urea Nitrogen and Lactose and Their

Relationships with Other Production Traits in

Canadian Holstein Cattle. J. Dairy Sc., vol. 90, no. 5,

pp. 2468-2479.

Patton, C.J., Crouch,. S.R., 1977. Spectrophotometric and

kinetics investigation of the Berthelot reaction for the

determination of ammonia. Anal. Chem., vol. 49, no.

3, pp. 464-469.

Razumiene, J., Sakinyte, I. Kochane, T. Maciulyte, S.,

Straksys, A., Budriene, S., Barkauskas J., 2013.

Carbon Electrode based Urea Sensor - Modification of

Graphite and New Polymeric Carriers for Enzyme

Immobilization. Proceedings of the BIODEVICES

2013, 6

th

International Conference on Biomedical

Electronics and Devices, pp. 197-201. Available from:

SCITEPRESS.

Sant, W., Temple-Boyer, P., Chanié, E., Launay, J.,

Martinez, A. 2011. On-line monitoring of urea using

enzymatic field effect transistors. Sensors and

Actuators B: Chemical, vol. 160, no. 1, pp. 59-64.

Soldatkin, O. O., Kucherenko, I.S., Marchenko, S. V.,

Ozansoy Kasap, B., Akata, B., Soldatkin, A. P.,

Dzyadevych, S. V., 2014. Application of

enzyme/zeolite sensor for urea analysis in serum.

Materials Science and Engineering: C, vol., no. 42,

pp. 155-160.

Voitechovic, E., Razumiene, J., Sakinyte, E., Barkauskas,

J., 2010. Investigation of bioelectrocatalytic systems

with PQQ-dependent GDH and carbonaceous

materials. Biologija, vol. 56, no.1-4, pp. 83-87.

AmperometricUreaSensor-EnzymeImmobilizationintoAdjustableMembraneandMathematicalCharacterizationofthe

Biosensor

149