Proposal of a Framework to Assess the Supply Chain Performance in

the Agri-food Sector

Luis Miguel D. F. Ferreira

1

and Amílcar José Arantes

2

1

Economics, Management and Industrial Engineering Department, University of Aveiro, Aveiro, 3810-193, Portugal

2

CESUR, Instituto Superior Técnico, Universidade Lisboa, Av. Rovisco Pais, Lisboa, 1049-001, Portugal

Keyword: Framework, Supply Chain, Performance, Composite Index.

Abstract: Companies need to excel in many areas to achieve a competitive advantage. Supply chain management is

critical for a company's overall performance. It is therefore crucial that organizations measure the

performance of their supply chains in order to define strategies that contribute to maximize the impact of

their operations. This paper aims to propose a novel framework for assessing and monitoring the supply

chain performance of companies of the agri-food sector. The framework consists of six steps to evaluate the

companies supply chain performance. The linear aggregation technique is suggested to aggregate indicators

into a unique value giving rise to a composite index considering five dimensions. The proposed framework

can be used as a valuable instrument for the monitoring of supply chain performance of agri-food

companies.

1 INTRODUCTION

The supply chain can be defined as a value system,

made up of organizations that are connected together

from the first stage of production up to the point of

consumption, with the overriding objective of

creating value along the chain (Porter, 1996). It

represents a complex network of industrial plants

and organizations with distinct, and often

conflicting, objectives (Simchi-Levi et al 2003).

Supply chain management (SCM) is a strategic

management tool that seeks to raise the

competitiveness and the profits of companies by

increasing customer satisfaction levels (Christopher,

1992).

Christopher (1992) argues that SCM is not just a

new management fad, but something that can be

used as a tool for competitive differentiation. Mertz

(1998) goes further, citing examples of quantitative

benefits: a reduction in stocks of 50%, a reduction in

the total chain cost of 20%, an increase in correct

deliveries of 40% and a reduction in lead time of

27%. He also cites qualitative improvements, such

as technical and organizational restructuring,

improvements in capabilities and relationships, and

transference of technology and knowledge between

members.

The competitiveness of companies and the

economy means that all its agents must reach levels

of performance which are in-line with the

expectations of the markets and their clients. In this

context, metrics and measures of performance

become essential for managers in their decision

making when it comes to logistics operations and

continuous improvement of the service supplied to

the customer along the supply chain (Beamon, 1999;

Gunasekaran et al 2001).

However, measuring performance in supply

chains is difficult for additional reasons, especially

when looking at numerous tiers within a supply

chain (Gunasekaran et al 2004).

The creation of a Performance Management

System (PMS) is primarily aimed at measuring the

right things at the right time, in such a way that

actions can be taken in a useful time frame. The

metrics developed by the system should supply

information to the various areas, always taking care

to avoid duplication of information and to include

the most relevant metrics. Producing good

performance metrics and measures, opens the way

for continuous improvement in the global

performance of the organization (Gunaskeran et al

2001).

The main objective of this article is to propose a

framework to assessing and monitoring the supply

chain performance of companies of the agri-food

401

Miguel D. F. Ferreira L. and Arantes A..

Proposal of a Framework to Assess the Supply Chain Performance in the Agri-food Sector.

DOI: 10.5220/0005280304010406

In Proceedings of the International Conference on Operations Research and Enterprise Systems (ICORES-2015), pages 401-406

ISBN: 978-989-758-075-8

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

sector. The proposed framework consists of six

steps, where linear aggregation technique is used to

aggregate indicators into a unique value, giving rise

to a composite index that reports the overall supply

chain performance.

The article is divided into four sections. This

section seeks to provide an introduction to the topic

and define the objective of the study. The second

section presents a literature review on agri-food

supply chain and performance measurement in

supply chains. Section 3 presents a model for

evaluating the supply chain performance of agri-

food companies. Finally, the main conclusions of the

study are drawn in section 4.

2 LITERATURE REVIEW

Over the last years the agri-food sector has been

confronted with a wide range of challenges, meaning

that it has been, and will continue to be forced to

provide effective responses for companies to be able

to carry on business (Rajurkar and Jain, 2011).

2.1 The Agri-food Supply Chain

The agri-food supply chain is a chain producing,

transforming and supplying agricultural and/or

vegetable products at the same time as maintaining a

flow of information between the various members.

This type of supply chain is notably different due to:

a) the nature of the production, being based on

biological processes, as such being more susceptible

to variations and to risk; b) the nature of the

products, with specific characteristics, for example

being perishable; c) consumers’ behaviours and

attitudes in relation to food safety, environmental

protection and animal welfare.

Generally speaking we can distinguish between

two types of agri-food supply chain: a) supply

chains for fresh produce, such as fresh vegetables,

flowers and fruit; b) supply chain for processed

products, such as tinned vegetables or deep frozen

vegetables. The agri-food supply chain has many

identifying features that distinguish it from other

types of supply chain. Among those the following

can be highlighted:

Seasonality of production;

Special conditions necessary for storage and

transport;

The quantities processed and final product

quality are dependent on biological variations,

seasonality, weather conditions, pests and

other biological maladies;

Governmental laws that cover environmental

protection and food safety;

Product characteristics, such as flavour, odour,

colour, size and appearance;

Value added to the products, as is the case for

example with ready-to-eat food;

Product security: a growing concern by

consumers with the means of production and

processing of agricultural products;

The quality as perceived by the consumer:

targeted marketing campaigns are able to

emphasise the quality of the products.

Recent studies show that the agri-food supply

chain is in constantly evolving (Aramyan et al 2007;

Fritz and Schiefer, 2008; Rajurkar and Jain, 2011;

Van der Vorst, 2000). One of the main changes is

the adoption of new strategies by producers. Their

viewpoint is no longer dominated by questions of

production but has shifted to focus on the market,

which has implied an increase in the information

flows in the chain. Another change of note in the

sector relates to innovation and the development of

new products. All these changes are the result of

consumer demand for quality and variety in the

products. In contrast, there is a growing concern

among consumers in relation to food safety and the

conditions under which the products are processed.

Many researchers have recognized the relevance

of SCM for agri-food businesses (Aramyan, 2007;

Hobs and Yong, 2000; Van der Vorst, 2000) noting

the perishability of the products and the need for a

rigorous quality control of the products as they are

passed along the chain. This can become evident

when products that were quality controlled at the

start of the chain deteriorate due to the carelessness

of a supply chain member down the line.

The phenomenon of globalization also brought

with it a considerably larger product flow, increasing

the complexity of the relations between the chain

members. This complexity pushed the agri-industry

to create networks and new models of cooperation.

Alliances were formed, vertical and horizontal

cooperation proliferated, new members were added

to the chain and innovation became one of the key

factors driving competition. In this new world,

organizations were obliged to develop and improve

the quality of their products, logistics and

information systems.

2.2 Performance Measurement of

Agri-food Supply Chains

According to Cohen and Roussel (2004), the

definition of an appropriate set of metrics allows the

ICORES2015-InternationalConferenceonOperationsResearchandEnterpriseSystems

402

performance of the activities in the supply chain to

be evaluated, contributing to the diagnosis of

problems and improvement in the decision making

processes.

A PMS can be defined as a system that allows a

company to monitor its most relevant performance

indicators – related to its products, services and

processes within a relevant time frame. The PMS

should also be able to capture that which is essential

to organizational performance and, at the same time,

ensure that the metrics are being applied to the areas

where their use is most appropriate. Another

important factor is being able to guarantee that the

organizational goals are aligned with the goals of the

PMS, as such reflecting a balance between measures

of a financial and non-financial nature (Beamon,

1999; Gunasekaran et al 2001; Thakkar et al 2009).

To be able to bolster the performance of the

supply chain as a whole, it is necessary that the

individual companies look beyond their own

frontiers and are able to analyse the supply chain in

its totality. Only in this way is it possible to establish

a cohesive PMS, capable of accounting for the most

important aspects of the supply chain, and producing

information which flows along the chain.

Gunasekaran et al (2001) found that although

many organizations had made significant advances

in developing their supply chains, they continued to

be unable to respond in an integrated way. The

authors defend the idea that it is essential that the

existing barrier between financial and non-financial

metrics be eliminated, moving decidedly towards a

more encompassing PMS which includes the two

categories. While the financial measures decisively

contribute to the strategic decisions, the day-to-day

control of production and distribution operations is

better served by non-financial metrics (Maskell,

1991).

In a later study, Gunasekaran et al (2004)

classified the KPIs by management levels (strategic,

tactical and operational) and grouped them in cells

where the supply chain activities cross-over with the

various organizational processes. The KPIs were

split according to the processes (Planning, Supply,

Manufacturing and Shipping), while also being

ordered by decreasing level of importance. Some of

them are found in more than one management level,

given that their importance traverses the different

hierarchical levels.

With the passage of time, PMS models have

undergone changes. In the past their focus was

placed on measuring costs in a short-term

management perspective. Now, however, the PMS

models envisage management policies for the

medium- and long-term, centring on non-financial

measures that make their contribution to value

creation over the whole of the chain (De Toni and

Tonchia, 2001).

To develop new PMS models, adaptations were

made of existing management tools such as the

Balanced Scorecard (Baghwat and Sharma, 2007;

Chia et al 2009; Goh and Hum, 2009) or the SCOR

model (Lockamy and McCormack, 2004; Hwang et

al 2008). These new approaches brought new

concepts and new metrics that enabled a new

perspective on supply chain performance

improvement, where the centre of management

attention swung away from financial indicators with

a short-term horizon.

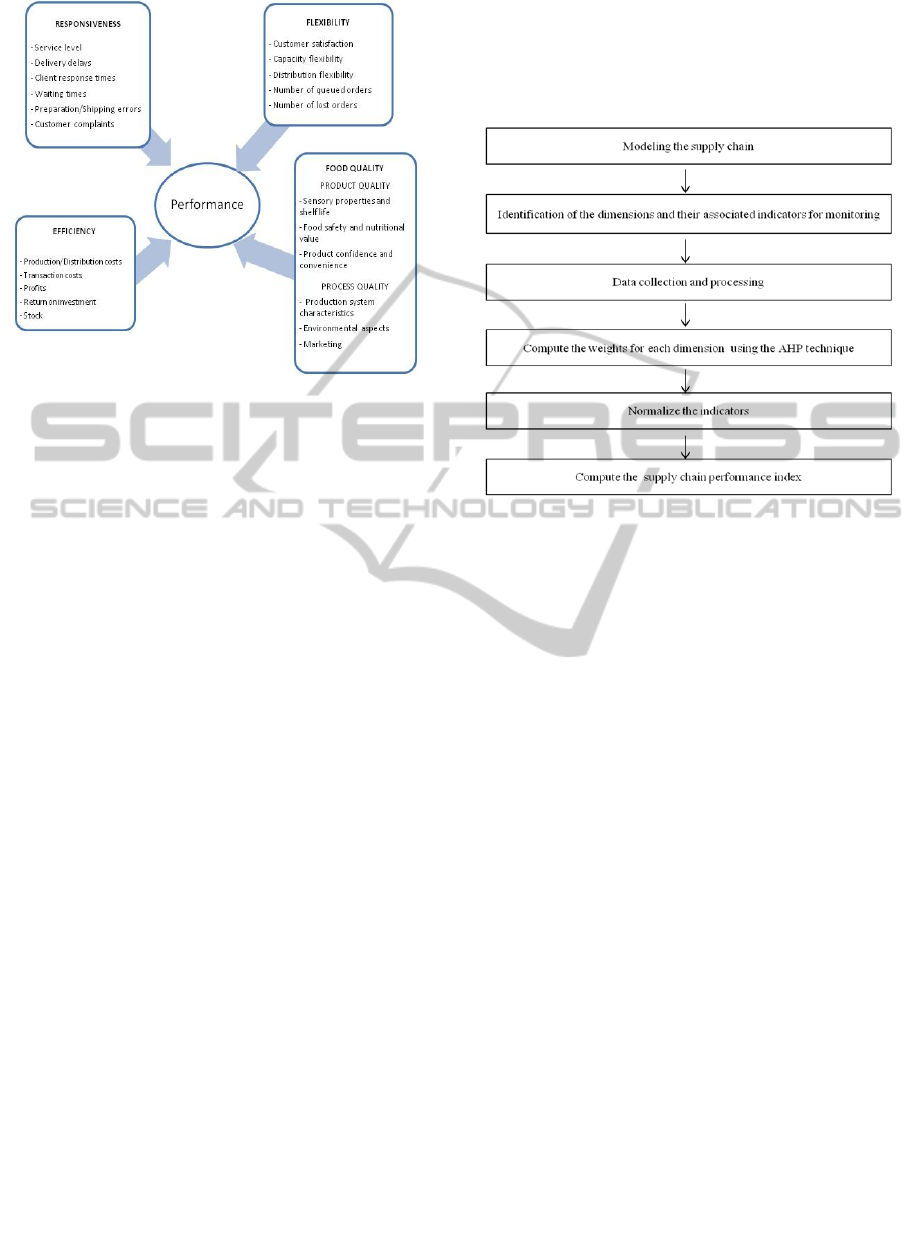

However, studies focusing on the agri-food

supply chain are relatively scarce. An exception is

the study of Aramyan (2007), where the researcher

designed a performance measurement system model

focused on agri-food supply chains (Figure 1).

The researchers divided the KPIs into four main

dimensions (1) efficiency, (2) flexibility, (3)

responsiveness, and (4) food quality. Based on these

indicators, all chain members have these four

families in common, helping to assess their

individual and collective performance:

efficiency aims to measure the way in which

resources are used;

flexibility tells us the ability of the

Performance Measurement System to adapt in

response to changes in its surrounding

environment and to extraordinary requests by

the customers;

responsiveness aims to satisfy the customer’s

request in the shortest time possible; and

food quality aims to reflect the specificities of

the sector at the process and product level.

Given that the framework proposed by Aramyan

(2007) was evaluated in one particular context (i.e.

the tomato supply chain), the author calls for the

need to conduct more empirical research. The

authors also mention that since performance of the

supply chain is the combination of different

indicators, which have different dimensions, one

suitable method of analysis could be the use of

composite indicators.

Computing aggregate values is a common

method used for constructing indices. Indices, which

can be either simple or weighted, are very useful in

focusing attention and, often simplify the problem

(Atkinson et al 1997). Such an approach allows for

the evaluation of a multitude of aspects which can be

deciphered into a single comparable index.

ProposalofaFrameworktoAssesstheSupplyChainPerformanceintheAgri-foodSector

403

Figure 1: Aramyan’s model.

3 A FRAMEWORK PROPOSAL

TO ASSESS SUPPLY CHAIN

PERFORMANCE OF AGRI-

FOOD COMPANIES

In order to address the lack of structured systems for

monitoring the performance of supply chains, the

model described below was developed. The

proposed model is based on the logic of the

Aramyan (2007) model to evaluate the performance

of the agri-food supply supply chain.

The model is displayed in Figure 2. The steps

that make up the proposed model are: 1) Study of

the supply chain process; 2) Identification of the

dimensions and their associated indicators for

monitoring; 3) Data collection and processing; 4)

Compute the weights for each dimension using the

AHP technique; 5) Normalize the indicators; 6)

Compute the supply chain performance index.

There now follows a description of the different

steps suggested for the model.

Step 1 - Modeling the supply chain.

The project must start with the study of the supply

chain in order to understand its flows, stakeholders

and particularities.

Step 2 - Identification of dimensions and their

associated indicators for monitoring.

The chosen indicators should be appropriate to each

organization and should be related to the strategic

objectives of the organization. Erol et al (2011)

argues that the indicators should follow three

criteria: measurability, data availability and the

indicators should be related to the supply chain type.

In this research a set of 24 indicators were selected.

Those indicators were adopted from Aramyan’s

(2007) model and were validated by a panel of

experts from the sector.

Figure 2: Model for measuring the performance of the

agri-food supply chains.

Step 3 – Data collection and processing.

The instrument used for collecting the necessary

data for enabling the model is a questionnaire to be

sent to all first-tier suppliers and clients. This

mailing, which will be done annually, allows the

analysis of the evolution of the indicators to be

monitored and compared with previous years. This

option represents a simple and effective way to

collect the information necessary to evaluate the

performance of the supply chain to the extent that it

is incorporated into the standard procedures that is

presently implemented for supplier evaluation in

most of the companies.

Step 4 – Compute the weights for each dimension

using the AHP technique.

AHP, was originally introduced by Saaty (1980), is a

helpful tool for dealing with complex decision

making, and helps to set priorities and make the best

decision possible. By reducing complex decisions to

a set of pair-wise comparisons, and then

synthesizing the results, the AHP helps to capture

both objective and subjective aspects of a decision.

Therefore, AHP contributes to the rationalization

of the entire decision process and comparatively

with other multi-criteria evaluation methods (electre,

ANP, promethee, etc., or even hybrid methods) is of

simpler application. A good literature review can be

found in the work of Subramanian and Ramanathan

(2012).

ICORES2015-InternationalConferenceonOperationsResearchandEnterpriseSystems

404

The goal is located at Level 1. Level 2 of the

hierarchy contains the five dimensions of the

Aramyan’s (2007) model. Level 3 of the hierarchy

contains the indicators for evaluating each

dimension.

Figure 3: AHP Model for analysis of the dimensions.

An AHP hierarchy model is used to compute the

weights for the five dimensions of the model. After

building the hierarchy a panel of experts will be

formed to assign the pair-wise comparisons to the

Level 2 used in the AHP hierarchy. With this in

mind, the pair-wise comparisons inherent to the

AHP application will be performed as a team

exercise in meetings and the final decisions will be

reached by consensus. The weights of level 3 sub-

criteria will not be computed using AHP pair-wise

comparisons (because the possible number of pair-

wise comparisons to perform would be very high).

In this case we will assume that each sub-criterion

will have the same weight. For example, if we have

5 indicators for one of the dimensions each will

weight 20%.

Step 5 – Normalize the indicators

The main difficulty in aggregating indicators into the

supply chain performance index is the fact that

indicators may be expressed in different units. The

following procedure will be used:

I

,

I

,

I

,

I

,

I

,

(1)

I

,

1

I

,

I

,

I

,

I

,

(2)

Where I

,

is the normalized indicator i with

positive impact from group of indicators j (Eq. 1)

and I

,

is is the normalized indicator i with negative

impact from group of indicators j (Eq. 2). In this

way, it is possible to integrate different kinds of

quantities with different units of measurement. One

of the advantages of the proposed normalization is

the clear compatibility of different indicators, since

all indicators are normalized (Krajnc and Glavic,

2005).

Step 6 – Compute the supply chain performance

index

At this stage, the focus of the study was placed on

the development of a methodology for measuring the

performance of the supply chain. Because each

indicator has different units, not comparable with

each other and also have a different importance a

supply chain performance index is proposed.

Equation 3 calculates the supply chain performance

index:

SC

_

Perf

_

Index

_

sc

∑∑

W

W

I

(3)

where:

__ - Score of the supply chain

performance index

W

i

– Weight of the i

th

dimension (calculated

through the AHP judgments)

W

ij

- Weight of the j

th

subcriteria of the i

th

dimension

I

ij

– Normalized score for the j

th

element of the

i

th

dimension.

The follow-up phase for the index is carried out

jointly by the supply chain manager and other

management departments. In the event that there are

deviations from the targets established, an action

plan should be put in place in accordance with the

principles of the continuous improvement cycle,

present in the PDCA cycle.

4 CONCLUSIONS AND

OPPORTUNITIES FOR

FUTURE RESEARCH

Over the last years the agri-food sector has been

confronted with a wide range of challenges and

demands, meaning that it has been, and will continue

to be forced to provide effective responses for

companies to be able to carry on business. In this

context the topic of supply chain performance

measurement has become a relevant subject for

companies in this sector.

In this paper is proposed a framework for

assessing and monitoring the supply chain

performance of companies of the agri-food sector.

The framework consists of six steps to evaluate

the companies supply chain performance. The linear

aggregation technique is suggested to aggregate

ProposalofaFrameworktoAssesstheSupplyChainPerformanceintheAgri-foodSector

405

indicators into a unique value giving rise to a

composite index considering five dimensions. The

proposed index results from the aggregation of

indicators adapted from the model of Aramyan

(2007). The proposed index proposes different

weights for each of the dimensions and also for the

corresponding indicators using the AHP technique

with a panel formed by experts from the sector.

The proposed framework to assess supply chain

performance is very friendly and easy to understand

representing an important contribution to managers.

Using this framework, managers can assess the

impact of their strategies and management practices

on their supply chain performance through the

supply chain performance index value.

The practical application of the proposed

framework to a case study should confirm its

applicability and relevance trough the contribution

to the improvement of supply chain performance of

companies in the agri-food sector.

REFERENCES

Aramyan, L., 2007. Measuring supply chain performance

in the agri-food sector, Ph.D thesis, Wageningen

University.

Aramyan, L., Oude, A.L., van der Vorst, J., van Kooten,

O., 2007. Performance measurement in agri-food

supply chains: a case study. Supply Chain

Management: An International Journal, 12 (4), 304-

315.

Atkinson, G. D., Dubourg, R., Hamilton, K., Munasignhe,

M., Pearce, D. W., Young, C., 1997. Measuring

Sustainable Development: Macroeconomics and the

Environment. Edward Elgar, Cheltenham.

Beamon, B. M., 1999. Measuring supply chain

performance. International Journal of Production and

Operations Management, 19 (3), 275-292.

Goh, M., Hum, S., 2009. Performance measurement in

supply chain entities: balanced scorecard perspective.

Benchmarking: An International Journal, 16(5), 605-

620.

Christopher, M., 1992. Logistics and Supply Chain

Management, Pitman, London.

Cohen, S., Roussel, J., 2004. Strategic supply chain

management: the five disciplines for top performance,

Mc Graw Hill.

De Toni, A., Tonchia, S. 2001. Performance measurement

systems: models, characteristics and measures.

International Journal of Operations & Production

Management, 21(1/2), 46-70.

Erol, I., Sencer, S., Sari, R., 2011. A new fuzzy multi-

criteria framework for measuring sustainability

performance of a supply chain. Ecological Economics,

70 (6), 1088-1100.

Fritz, M., Schiefer, G., 2008. Food Chain Management for

Sustainable Food System Development: a European

Research Agenda. Agribusiness, 24(4), 440-452.

Gunasekaran, A., Patel, C., McGaughey, R. E., 2004. A

framework for supply chain performance

measurement. International Journal of Production

Economics, 87(3), 333-47.

Gunasekaran, A., Patel, C., Tirtiroglu, E., 2001.

Performance measures and metrics in a supply chain

environment. International Journal of Operations &

Production Management, 21 (1/2),71-87.

Hwang, Y., Lin, Y., Lyu Jr, J., 2008. The performance

evaluation of SCOR sourcing process the case study of

Taiwans TFT-LCD industry. International Journal of

Production Economics, 115 (2) 411–423.

Krajnc, D., Glavič, P., (2005). A model for integrated

assessment of sustainable development. Resources.,

Conservation and. Recycling, 43(2), 189–208.

Lockamy, A., McCormack, K., 2004. Linking the SCOR

planning practices to supply chain performance.

International Journal of Operations and Production

Management, 24, 11/12, 1192–1218.

Maskell, B.H., 1991. Performance Measurement for

World Class Manufacturing

, Productivity Press,

Portland.

Porter, M., van der Linde, C., 1995. Green and

Competitive: Ending the Stalemate. Harvard Business

Review, 73, 120-133.

Rajurkar, W.S., Jain, R., 2011. Food supply chain

management: review, classification and analysis of the

literature. Int. J. Integrated Supply Management, 6(1),

33-72.

Simchi-Levi, D., Kaminsky, P., Simchi-Levi, E., 2007.

Designing and Managing the Supply Chain: Concepts,

Strategies and Case Studies, McGraw-Hill.

Subramanian, N., Ramanathan R., 2012. A review of

applications of Analytic Hierarchy Process in

operations management. International Journal of

Production Economics, 138 (2), 215-241.

Thakkar, J., Kanda, A., Deshmukh, S.G., 2009. Supply

chain performance measurement framework for small

and medium scale enterprises. Benchmarking: An

International Journal, 16(5), 702-723.

Van der Vorst, J., 2000. Effective Food Supply Chains.

Generating, Modelling and Evaluation Supply Chain

Scenarios, Ph.D Thesis, Wageningen University.

ICORES2015-InternationalConferenceonOperationsResearchandEnterpriseSystems

406