A Smart Catheter System for Minimally Invasive Brain Monitoring

Dongxuan Bao

1

, Zhuo Zou

2

, Yuxiang Huan

1

, Chuanying Zhai

2

, Tiberiu Bagaian

3

, Hannu Tenhunen

2

,

Bengt Källbäck

3

and Li-Rong Zheng

1,2

1

State Key Laboratory of ASIC & System, Fudan University, Shanghai 201203, China

2

iPack Vinn Excellence Center, KTH-Royal Institute of Technology, 164 40 Kista, Sweden

3

CathPrint AB, SE-114 19 Stockholm, Sweden

Keywords: Smart Catheter, TBI, Real-Time Monitoring, Pressure, Temperature.

Abstract: This paper demonstrates a smart catheter system with intracranial pressure (ICP) and temperature sensing

capability which is designed for real-time monitoring in traumatic brain injury (TBI) therapy. It uses a

single flexible catheter with a 1 mm (3 Fr) diameter that integrates electrodes and sophisticated silicon chip

on flexible substrates, enabling multimodality monitoring of physiological signals. A micro-electro-

mechanical-system (MEMS) catheter pressure sensor is mounted on the distal end. It can be used for

detecting both pressure and temperature by different switch configurations, which minimizes the size of

catheter and reduces the cost. The interconnects (signalling conductors) are printed on a bio-compatible

flexible substrate, and the sensor is interfaced with an embedded electronic system at the far-end. The

electronic system consists of analog front end with analog-to-digital converter (ADC), a microcontroller,

and data interface to the hospital infrastructure with a graphical user interface (GUI). The overall smart

catheter system achieves a pressure sensing root mean square error (RMSE) of ±1.5 mmHg measured from

20 mmHg to 300 mmHg above 1 atm and a temperature sensing RMSE of ±0.08 ºC measured from 32 ºC to

42 ºC. The sampling rate can be up to 10S/s. The in vivo performance is demonstrated in laboratory animals.

1 INTRODUCTION

Traumatic brain injury (TBI) is a type of acquired

brain injury, occurs when a sudden force

traumatically injures the brain. The main causes

include falls, traffic accidents, and violence. TBI is

one of the major causes of death and disability in

patients from ages 1 to 44 years. TBI results in 1.4

million reported injuries and 52000 deaths each year

in the United States (Faul, 2010). Secondary

neurological damage, a variety of events that take

place in the ensuing hours and days following the

primary injury, contribute substantially to the worse

damage caused by primary injury and accounts for

the greatest number of TBI deaths occurring in

hospitals. Raised intracranial pressure (ICP) is a

common factor in secondary injury. The causes of

raised ICP include swelling or a mass effect from a

lesion such as subdural hematoma. When the ICP

rises, the cerebral perfusion pressure (CPP)

decreased, resulting in ischemia or even brain death.

Therefore, a precise monitoring of the ICP is very

important for minimizing secondary ischemic injury

in TBI. In addition, the brain of neurosurgical

patients with severe traumatic brain injury is

extremely sensitive and vulnerable to small

temperature variations, thus fever is considered a

secondary injury to the brain (Mrozek, 2012).

Hence, continuous monitoring of intracranial

temperature is also highly recommended.

The intraventricular catheter is the most accurate

pressure monitoring method, in which catheters are

inserted into the lateral ventricle through a hole

drilled on the skull (MedlinePlus, 2014). Current

TBI care unit uses separate catheters for monitoring

multiple signals, which are collected by external

electronic system through separate cables for signal

processing and real-time data display (Stiefel, 2005).

However, a big burr hole is needed to accommodate

multiple catheters, which is susceptible to infection

and complications. Therefore a smart catheter

system providing ICP and temperature monitoring

capability with single catheter insertion is highly

desirable to minimize incision.

Thanks to the steady and considerable effort

directed towards the development of sensor

fabrication technology, some pressure sensors for

biomedical applications have been reported. They

198

Bao D., Zou Z., Huan Y., Zhai C., Bagaian T., Tenhunen H., Källbäck B. and Zheng L..

A Smart Catheter System for Minimally Invasive Brain Monitoring.

DOI: 10.5220/0005285501980203

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2015), pages 198-203

ISBN: 978-989-758-071-0

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

usually fall into two categories, pressure sensor on

solid substrate and on flexible substrate. Pressure

sensors manufactured using MEMS technology,

typically provide increased reliability and higher

precision. However, they are often expensive and

fabricated on rigid substrates (Wahab, 2008).

Meanwhile, electronics on flexible substrates is

considered as an alternative approach that enables

low-cost manufacturing of thin, flexible, light

devices. The revolutionary technologies have

enabled displays, sensors (Pritchard, 2008), antennas

on flexible substrates. Flexible pressure sensor is

highly non-linear; thus careful, frequent calibration

may be necessary. However, it provides a promising

solution for chip-system integration (Xie, 2012). In

this work, a heterogeneous system which seamlessly

integrates MEMS sensor with flexible printed circuit

board (PCB) is employed to develop a low cost

catheter. A piezoresistive MEMS pressure sensor is

employed in proposed system.

The temperature can be detected by a separate

sensor (Li, 2012). However, it is limited in

applications required more sensors because of the

small size of catheter. In (Chan, 2013), a

temperature sensor circuit which consists of a

portional to absolute temperature (PTAT) voltage

generator, a bandgap voltage generator, and a V

BE

amplifier is integrated. Nevertheless it is non-contact

sensor. Thermistors are very low cost and available

in a wide variety of packages. However, the resistive

change is relatively small. Therefore, an

amplification circuit is necessary to ensure the

output signal quality.

In this paper, a 1 mm (3 Fr) diameter smart

catheter, inserted with flexible PCB, is proposed to

sense the ICP and temperature signal for detection of

any anomaly in the patient. A piezoresistive MEMS

pressure sensor is utilized to provide accurate

pressure measurement within the very small spaces

and harsh environments of the catheter. The sensor

can also be used for detecting temperature by switch

configurations, which minimizes the catheter size.

The sensor signals are fed into an external electronic

system by flexible PCB. An instrumentation

amplifier in electronic system provides the required

amplification of the sensed signal and the

temperature sensing output can be used to

compensate pressure sensor error caused by

temperature variations. The electronic system reads

out signal and quantizes it with an integrated ADC.

Therefore, not only physiological parameters can

be shown directly in real time in vivo, but also

reduce the effects and complications caused by

surgery. To demonstrate the proof of concept, a

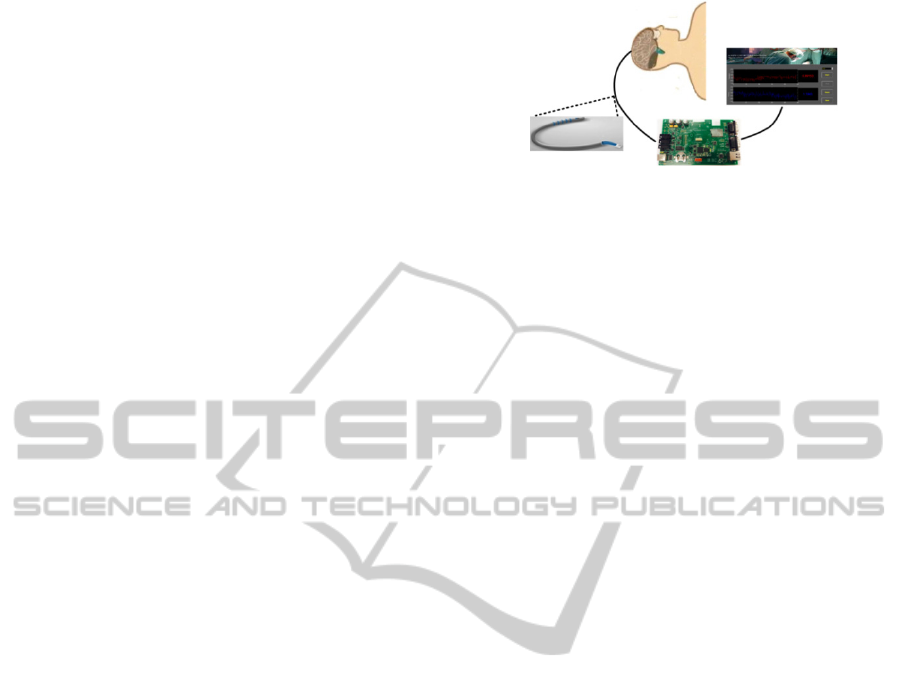

Figure 1: Smart catheter system for continuous ICP and

temperature measurement.

smart catheter system is implemented and measured

in laboratory animals.

The remainder of this paper is organized as

follows. The proposed smart catheter system is

described in Section 2. The catheter and electronic

system are elaborated in Section 3 and 4

respectively. The system characterization is

discussed in Section 5 with conclusions given in

Section 6.

2 SYSTEM DESCRIPTION

The objective is to develop a catheter for invasive

measurement of ICP and temperature and to show

that it can be produced at a low enough cost and be

integrated in current hospital procedures and

infrastructure. Due to the small size of mini-invasive

catheter, the proposed system adopts flexible PCB

for transmission such that the pre-mount sensor

information can be collected outside of the body

using an external electronic device. Fig. 1 illustrates

the whole system. The system is composed by four

major components: a catheter with pre-mount

sensors and electrodes, a sensor interface and

measurement logic, a microcontroller and a

computer with GUI. The proposed mini-invasive

catheter measures pressure and temperature in vivo

and sends the signal to the analog signal

conditioning circuitry through flexible PCB. The

output signals of sensors are collected by an analog

interface of instrumentation amplifier, which is

followed by a microcontroller-based socket board

comprised an integrated ADC and a RS-232 serial

port interfacing to the computer. The computer will

process the data received from external electronic

devices to display the situation of the patient. The

calibration algorithm will also run on the computer.

Then the corresponding pressure and temperature

can be calculated based on the measured voltage

after calibration.

ASmartCatheterSystemforMinimallyInvasiveBrainMonitoring

199

3 HETEROGENEOUS

INTEGRATION CATHETER

To measure physiological parameters, such as tissue

pressure and temperature, sensors should be

incorporated in the catheter. Moreover, a single

catheter provides multiple signal sensing capability

is highly desirable to minimize wound. In this work,

Prefab technology from CathPrint AB is adopted

(CathPrint AB, 2014) (Kallback, 2009). The Prefab

is inserted into a lumen of the customer’s extrusion

which is prepared with holes for electrodes and pre-

mounted sensors. It enables an uncomplicated

solution for connecting electrodes, sensors inside

body to external electronic and data analyzing

system.

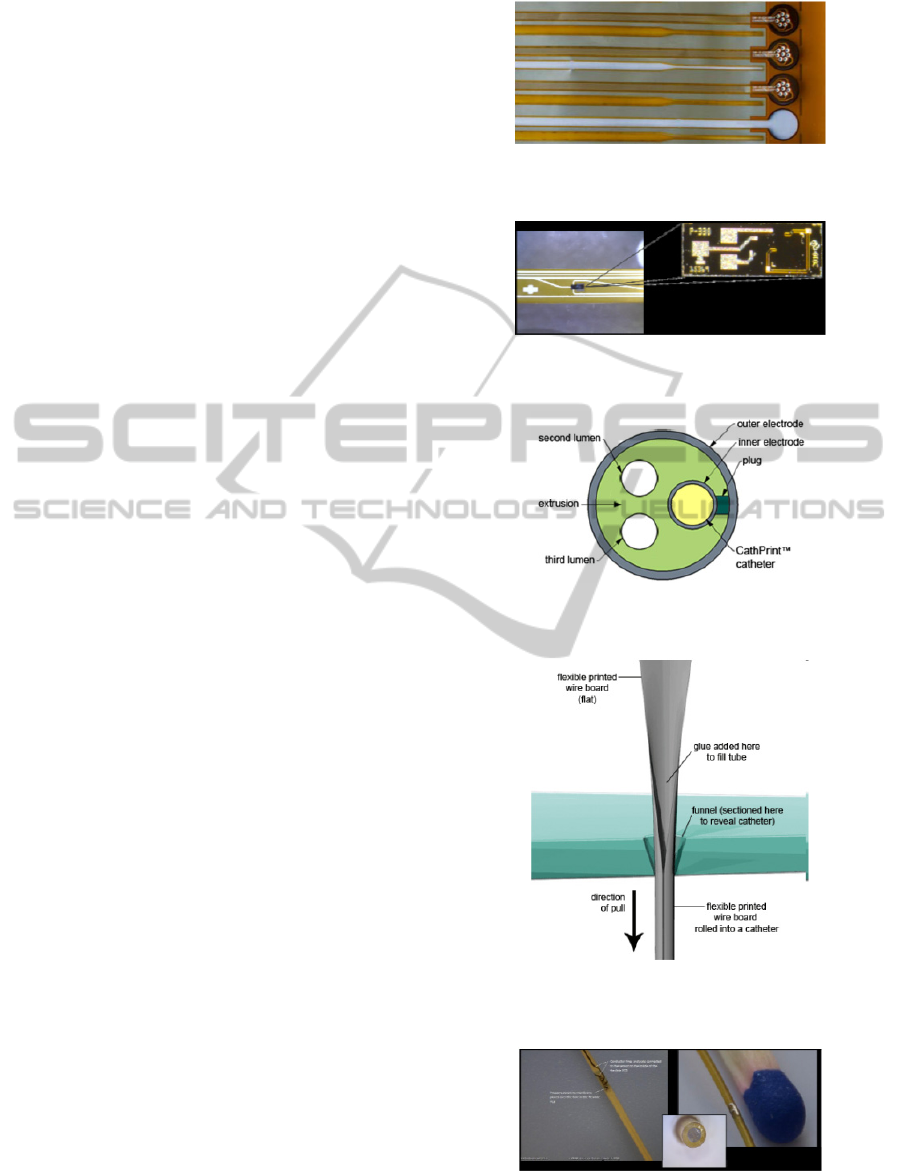

In general the catheters are long (in the order of

one meter) and thin (between 0.3 and 3 mm)

(Kallback, 2009). Therefore, a thin but long PCB

(e.g. 2 meters with 350 um diameter) is the basis for

catheter manufacturing as illustrated in Fig. 2

(CathPrint AB, 2014).

In this Prefab technology, sensors are mounted

on the flexible board, having contact with the

surrounding substance through an access hole in the

catheter for measurement use as shown in Fig. 3.

The bond pads on the flexible PCB are connected to

respective bond pads on the sensors by bonding

wires. In this work, a MEMS pressure sensor is

integrated to demonstrate the potential applications

as shown in Fig. 3 (CathPrint AB, 2014). This

heterogeneous integration catheter combines flexible

substrates based technology and silicon based

electronics which takes advantages from both

technologies. Thus the proposed heterogeneous

integration approach provides a promising solution

for mini-invasive applications. Electrodes can also

be integrated in the catheter, which are in contact

with the liquid surrounding the device for invasive

applications, such as blood oxygen detection. The

electrodes are placed outside the tube, and they are

connected to an inner catheter via a conductive plug

as shown in Fig. 4 (CathPrint AB, 2014). Therefore

it is convenient to connect the electrodes to an

electronic system at the far-end.

To enables the possibility of producing flexible

catheters with a diameter that is as small as 0.35

mm, the flexible circuit board is then rolled up to

form an extremely narrow tube, which is done by

feeding the flexible PCB through a funnel as

illustrated in Fig. 5 (CathPrint AB, 2014) (Kallback,

2009). The inner space of catheter-to-be is filled

with glue that holds the catheter in a tube shape after

the process. The resulting flexible catheter features a

Figure 2: Thin flexible PCBs for catheter (CathPrint AB,

2014).

Figure 3: Pressure sensor mounted on the flexible board

(CathPrint AB, 2014).

Figure 4: CathPrint integrated catheter with electrodes

outside (CathPrint AB, 2014).

Figure 5: The flexible PCB is pulled through a funnel

producing a catheter (CathPrint AB, 2014).

Figure 6: A miniature solid catheter with sensor inside and

electrode outside (CathPrint AB, 2014).

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

200

diameter ranging from 0.33 to 1 mm and a

maximum length of approximately 1.5 meters. This

technique significantly reduces the fabrication

process, and decreases the cost as well as the

catheter size. The proposed method for

manufacturing catheters transforms the flat circuit

board into a solid catheter which carries the sensor

inside the flexible PCB and has the electrodes

outside as shown in Fig. 6 (CathPrint AB, 2014).

4 ELECTRONIC SYSTEM

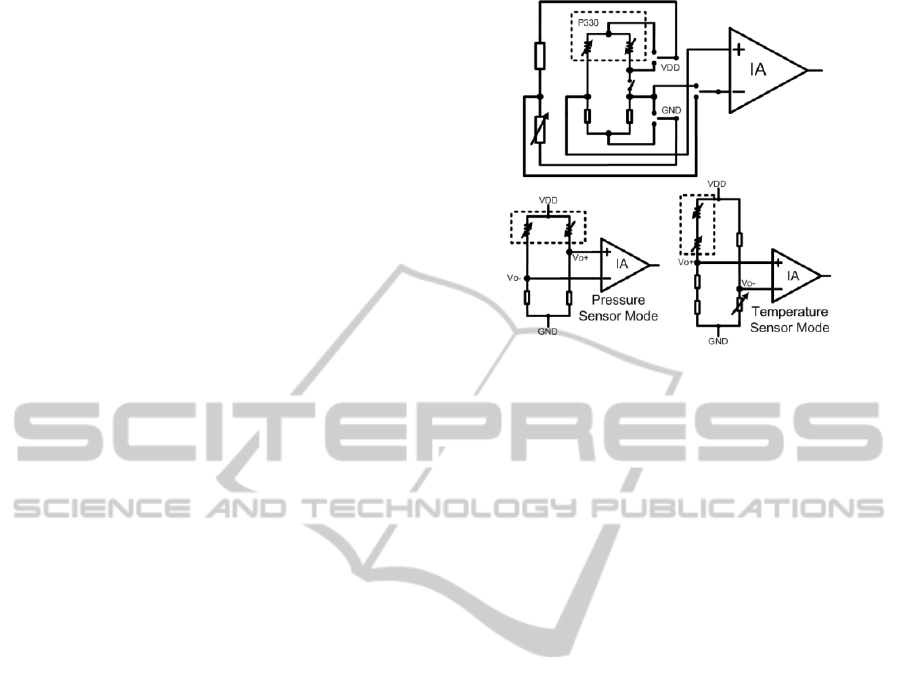

4.1 Pressure and Temperature Sensor

A switch regulator on socket board will regulate 3.3

V, which provides the power supply for the analog

interface and sensors. The pressure sensor employed

is P330 silicon MEMS pressure die, which is from

GE Measurement & Control. Its equivalent circuit is

illustrated in Fig. 7. A stable 3.3 V power supply is

applied between VDD and GND. In pressure sensor

mode, two 3.3 KΩ external resistors are utilized to

form a half bridge. When a change in pressure

causes the sensor to deflect, a corresponding change

in resistance is induced. Then the differential output

voltage on Vo+ and Vo- will also be changed by the

pressure. As the input range of ADC on socket board

is from 0 to 2 V with 14-bit effective number of bits

(ENOB), 1 LSB will be presented as 122.1 µV.

While the sensitivity of sensor in proposed system is

about 8.6

//V V mmHg

. Therefore the pressure

sensing resolution of this system is nearly

122.1/ 8.6 / 3.3 4.3

mmHg at 3.3 V power

supply. This is because the changes in strain and

resistance are extremely small. To improve the

overall resolution, in proposed sensor interface, an

instrumentation amplifier (IA), INA155 from Texas

Instruments, is used to amplify the changes in

resistance as shown in Fig. 7. INA155 is a CMOS

instrumentation amplifier (IA) with rail-to-rail

output. The gain can adjusted to any value between

10 and 50 by connecting a resistor

G

R

between the

gain pins according to the following equation (Texas

Instruments, 2014):

10 400 / (10 )

G

Gain k k R (1)

And the output voltage of IA is (Texas

Instruments, 2014)

(V )

O IN IN REF

VVGainV

(2)

Where

V

IN

and V

IN

are the input voltages and

Figure 7: Schematic of the pressure/temperature sensor

and interface circuit.

V

REF

is the reference voltage.

The pressure sensor in proposed system provides

a differential output voltage nearly 40 mV at 1 atm.

Therefore we set 0 mV to be

REF

V which

maximizes the swing range and 30 be the gain which

take full advantage of ADC’s input range. The

system performance can be estimated using

specifications. The intrinsic output voltage of IA at

1-atm pressure will be 1.2 V. If we set 20 to 300

mmHg above 1 atm to be measurement ranges, the

sensor output range will be from 1.217 V to 1.455 V

at 3.3 V power supply. Then the span of this system

including proposed sensor interface and ADC is

1951 LSBs. The overall pressure sensing resolution

is therefore nearly 0.14 mmHg. The resolution

improvement is due to amplified resistance changes

by INA155.

The resistance of resistors in pressure sensor

decreases with increasing temperature. Therefore the

pressure sensor can also be used for temperature

measurement. However, the two resistors are

sensitive to both pressure and temperature change. It

is difficult to separate the two reasons for resistance

change. Note that the 2 resistors in the half bridge

sensor are both pressure sensitive but the resistances

change in opposite directions. While these

resistances also change with temperature but in the

same direction. Hence, the series resistance of the 2

bridge resistors can be used for temperature

measurement independent of pressure. In

temperature sensor mode, the two resistors in P330

and the two external resistors compose a branch.

Due to the small changes in resistance, an on-board

reference voltage is also used in a differential

configuration with INA155 providing the required

ASmartCatheterSystemforMinimallyInvasiveBrainMonitoring

201

amplification of the sensed signal. In proposed

sensor interface, a simple voltage-divider with a

resistor and a trimmer in series is employed for

reference voltage. Moreover, the sensor has to be

switched between pressure and temperature

measurement. As shown in Fig. 7, three analog

multiplexers and one analog switch are needed. The

data amount to be transmitted is not heavy that many

off-shelf products meet the mentioned requirements.

A triple 2-channel CMOS analog multiplexers

SN74LV4053A and an analog switch TS5A1066

from Texas Instruments are used in this system at

3.3 V VDD operation. The temperature coefficient

of resistance (TCR) of sensor employed is 0.04

%/ºC, which can be used for estimating temperature

sensing resolution. The two bridge resistances are

assumed to be 3 KΩ in subsequent analysis. If 32-42

ºC is set to be measurement range and the

differential output voltage of IA is 1 V at 32 ºC, the

temperature sensor output range will be from 1 V to

1.099 V at 3.3 V power supply. Then the total range

of this system is 811 LSBs. The temperature sensing

resolution of system is about 0.012 ºC. However,

non-ideal factors will result in apparent system

performance degradation.

4.2 Data Recording and Analyzing

System

The data recording is important when the proposed

system is used for in vivo signal observing. The data

recording and analyzing system including an analog

interface PCB board, a socket board from Imsys

Technologies AB and a computer. The micro-

controller on socket board collects sensor data and

outputs it to a RS-232 serial port. With a RS232-

USB cable, the computer is allowed to connect serial

port through USB ports. The computer receives and

analyzes gathered data from socket board by

programming software. Power is also supplied to the

socket board from the USB interface of computer.

The sensor will be switched between pressure and

temperature measurement automatically by the

socket board. The sampling rate of temperature or

pressure sensing is 10S/s. A graphic user interface

(GUI) that processes the signal sent by the mini-

invasive system is installed on the computer. We can

continuously display the pressure and temperature

from the start point. The results will be displayed in

either pressure or temperature chart. And the

average values of the last 10 readings are shown in

digital format at the right-hand side of the GUI.

Calibration is executed with reference data to

increase system resolution. And then we can

Figure 8: The measurement site of the propose system.

calculate the original physiological parameters using

the gathered digital codes. The main function of this

program is to analyze and display all the data

delivered by the socket board. It also records them

into files for future statistics and analysis.

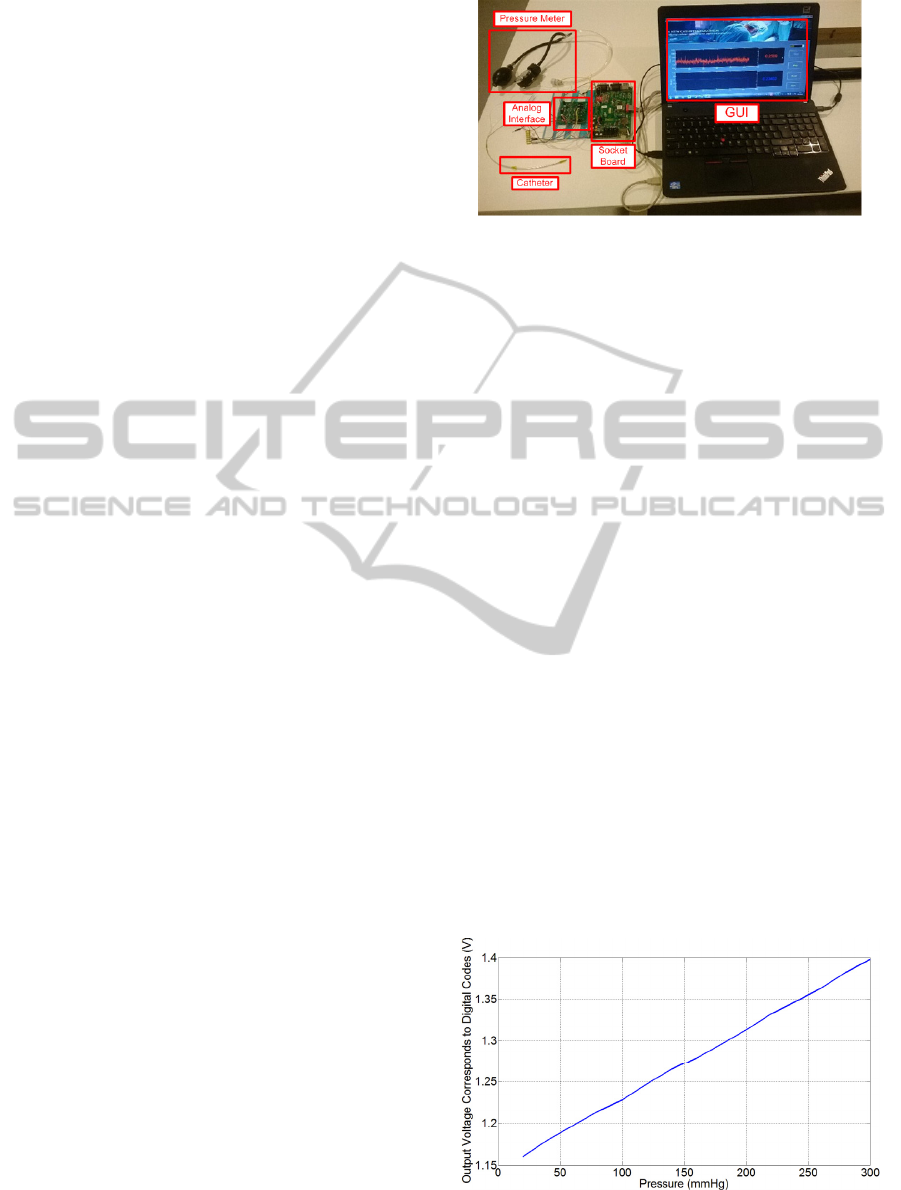

5 MEASUREMENT RESULTS

The measurement site of the system is illustrated in

Fig. 8. A blood pressure meter based device is used

to control the pressure of catheter. The device

consists of an inflatable arm cuff, a manual gauge

and a rubber bulb for pumping up the cuff. The

internal pressure of the cuff hose with a catheter in it

is controllable by the rubber bulb. The manual gauge

can measure the pressure in the chamber to calibrate

the proposed mini-invasive system with the overall

pressure range from 20 mmHg to 300 mmHg above

1 atm. An incubator with thermostat is employed for

temperature sensor measurement. A connector

joining flexible PCB together is placed at the

proximal end of catheter. The analog interface board

connects to catheter by dupont lines. The socket

board records sensor data and feeds the serial digital

signal into the data recording and analyzing

computer. The computer can process the digital

codes by the program of the GUI.

Figure 9: The linearity relative to pressure.

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

202

The linearity of the whole system for pressure

measurement is shown in Fig. 9 indicating that the

root mean square error (RMSE) is 1.43 mmHg.

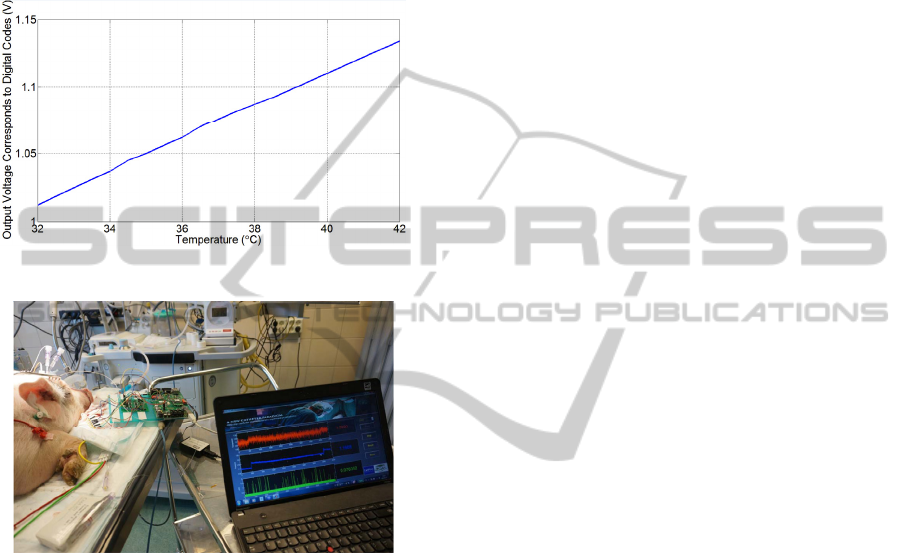

While the linearity of system for temperature

sensing is shown in Fig. 10 indicating that the

RMSE is 0.08 ºC. The catheter is also measured in

laboratory animals as shown in Fig. 11. The results

show the system works properly.

Figure 10: The linearity relative to temperature.

Figure 11: The animal experiment.

6 CONCLUSIONS

This paper proposed a smart catheter system to

acquire the ICP and temperature signal for TBI

measurement. A piezoresistive MEMS based

pressure sensor is mounted on a 1 mm (3 Fr)

diameter catheter to detect both pressure and

temperature, which minimizes the required catheter

space. Flexible PCB is inserted into the catheter for

signal transmission. An electronic system records

sensor signal and transmits the information to a

computer. Measurements results show the system is

able to sense the pressure in the range of 20-300

mmHg above 1 atm with RMSE of ±1.43 mmHg

and the temperature in the range of 32-42 ºC with

RMSE of ±0.08 ºC.

ACKNOWLEDGEMENTS

Dongxuan Bao thanks financial support from China

Scholarship Council for study at KTH-Royal

Institute of Technology. This work was supported in

part by Vinnova (The Swedish Governmental

Agency for Innovation Systems) through the Vinn

Excellence centers program.

REFERENCES

M. Faul, et al., 2010. Traumatic brain injury in the united

states: Emergency department visits, hospitalizations

and deaths 2002–2006. Centers for Disease Control

and Prevention, Injury Prevention & Control:

Traumatic Brain Injury.

Ségolène Mrozek, et al., 2012. Brain Temperature:

Physiology and Pathophysiology after Brain Injury.

Anesthesiology Research and Practice.

MedlinePlus, 2014. Intracranial pressure monitoring.

Available:http://www.nlm.nih.gov/medlineplus/ency/a

rticle/003411.htm.

Michael F. Stiefel, et al., 2005. Reduced mortality rate in

patients with severe traumatic brain injury treated with

brain tissue oxygen monitoring. J. Neurosurg. 103 (5),

805-811.

Yufridin Wahab, et al., 2008. Design of MEMS

biomedical pressure sensor for gait analysis. IEEE

International Conference on Semiconductor

Electronics. 166-169.

Emily Pritchard, et al., 2008. Flexible capacitive sensors

for high resolution pressure measurement. IEEE

Sensors. 1484-1487.

Li Xie, et al., 2012. Heterogeneous Integration of Bio-

Sensing System-on-Chip and Printed Electronics.

IEEE Tran. Emerging and Selected Topics in Circuits

and Systems. 2 (4), 672-682.

Chunyan Li, Raj K. Narayan, 2012. Development of a

novel catheter for early diagnosis of bacterial

meningitis caused by the ventricular drain. IEEE

International Conference on Micro Electro

Mechanical Systems (MEMS). 120-123.

W. P. Chan, et al., 2013. A pressure/oxygen/temperature

sensing SoC for multimodality intracranial neuro-

monitoring. IEEE Asian Solid-State Circuits Conf.

Dig. Tech Papers. 89-92.

CathPrint AB, 2014. Available: http://cathprint.se/.

Bengt Kallback, et al., 2009. Device for Invasive Use.

United States Patent Application 20090143651A1.

Texas Instruments, 2014. INA155. Available: http://www.-

ti.com/general/docs/lit/getliterature.tsp?genericPartNu

mber=ina155&fileType=pdf.

ASmartCatheterSystemforMinimallyInvasiveBrainMonitoring

203