Latest Achievements in Chemical Composition Optimization of

Photo-Thermo-Refractive Glass and Its Applications

S. A. Ivanov, N. V. Nikonorov and A. I. Ignatiev

ITMO University, 49 Kronverksky ave., St.Petersburg, Russia

Keywords: Hologram, Refractive Index, Volume Bragg Gratings, VBG, Photo-Thermo-Refractive Glass, PTR Glass,

Photo-Thermo-Inducted Crystallization, PTI Crystallization.

Abstract: Review on latest modification applied to chemical composition of PTR glass was made. Advancements of

updated chemical composition of PTR glass was shown in comparison with commercially produced glass.

Such properties as refractive index change, optimal exposition and optical losses in visible range for the

glass with recorded hologram was studied. In work samples of two chemical compositions were studied.

Conditions of matching included equal regimes of thermal treatment and expose dosages as well as

optimized parameters for each composition. Also the study of holograms received at optimal parameters for

each glass was made on three different wavelengths. Moreover several new applications for holograms on a

modified PTR glass were tested: such as holographic marks in telescopic systems and complex linked

holograms. Due to high transparency in visible range, PTR glass now can be applied for creating

holographic marks in telescopic systems. Studies show transparency of 92% with Fresnel losses. Also it is

found that spectral selectivity is maintained for such holograms, thus it is opening a new way of optical

solutions in telescopic systems. As it was measured, spectral selectivity of recorded hologram corresponds

to 400mkm efficient thickness according to calculations. Though, it needs further studies to increase the

effective thickness of such holograms as well as investigations of different Bragg angles at recording step.

Complex (linked) holography is another way of multiplexing inside a bulk glass. It leads to combination of

reflecting and transmitting Bragg gratings as a unite element with proper functions. This, for instance, can

provide positive feedback for complexes of laser diode crystals on a small size site. Simultaneously, such

element can combine emission from all emitting surfaces in one beam. This study may lead to creation of

high power coherent diode laser sources at small size site with ultra-narrow emitting bandwidth and high

quality spatial beam characteristics.

1 INTRODUCTION

Not as long ago as a holographic medium was

mostly used thin mediums, efficient thickness of

hologram for those was below 1mm. Such

restrictions had place due to low homogeneity as

well as incapability of achieving thick

photosensitive layers. For complex elements with

high spatial and wavelength selectivity, it is

necessary to record holograms at high deep. It’s

necessary, first of all, because selectivity of Bragg

grating depends from efficient thickness of

hologram and this dependence is linear. For

instance, selectivity of grating with 500mkm

thickness is twice lower than such for 1000mkm

one. Due to this fact, such material as a photo-

thermo-refractive (PTR) glass, which allows

recording of holograms with high efficient thickness,

keep getting more and more popular as a material for

amplitude-phase hologram and diffraction elements

creation (

Adibi, Buse, and Psaltis, 2001). PTR glass is

manufactured by several companies: Corning(USA),

Optigrate(USA), PD-LD(USA) and University

ITMO(Russia). On the basis of commercially

produced (classical) PTR glass a variety of

holographic diffractive optical elements can be

produced: spectral and spatial selectors, narrow-

filters intracavity Bragg mirrors, Bragg chirped

gratings for compression of light pulses, combiners

for powerful laser beams, etc. (Efimov et al, 1999).

78

Ivanov S., Nikonorov N. and Ignatiev A..

Latest Achievements in Chemical Composition Optimization of Photo-Thermo-Refractive Glass and Its Applications.

DOI: 10.5220/0005334400780084

In Proceedings of the 3rd International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2015), pages 78-84

ISBN: 978-989-758-092-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

2 RECORDING PROCESS

PTR glass is a multicomponent material which

includes such components as glass formers and

modifiers Na

2

O, A1

2

O

3

and ZnO as well as different

dopants. Ce

3+

is a donor of photoelectrons which

defines the photosensitivity of material. Ions of Sb

5+

and Sn

4+

,

at first, act as photoelectron acceptors and

trap photoelectrons from cerium, at second, act as

donors of electron for silver ions, during the process

of thermal treatment. Silver ions are responsible for

formation of colloidal particles, which are becoming

a core for the crystalline phase growth. Halides and

bromides are crystalized on the silver cores, during

the process of thermal treatment, which leads to

refractive index change.

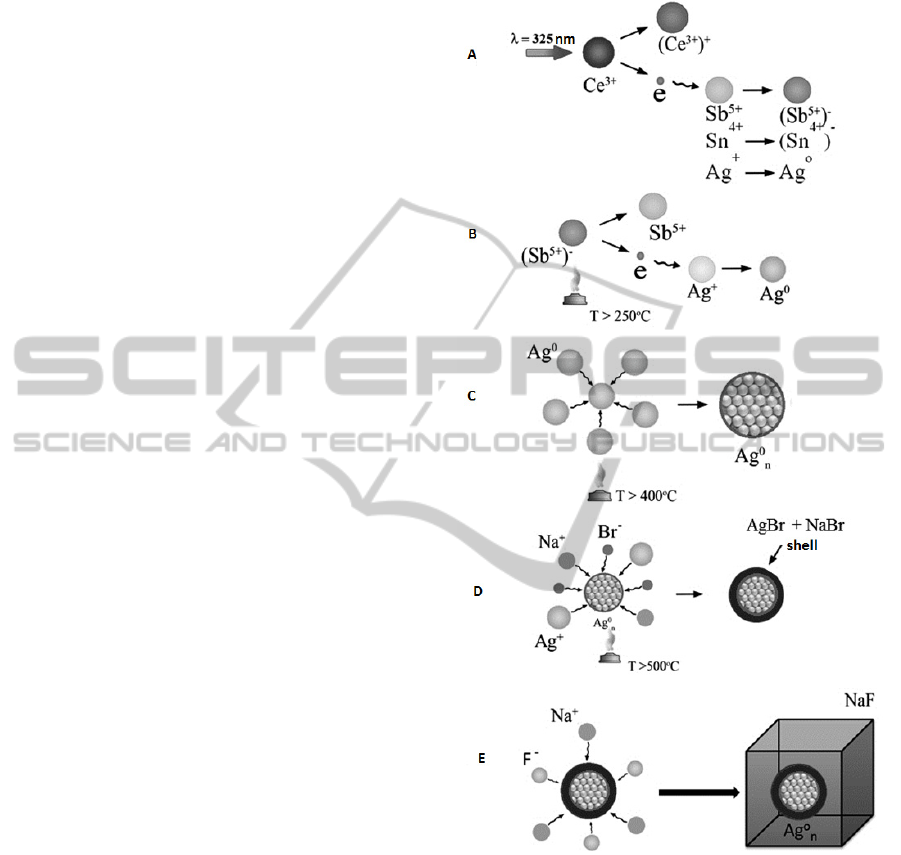

The hologram recording process is divided on two

steps. First is UV expose at 325nm wavelength,

which is close to absorption band of Ce

3+

(λ max ≈

310 nm). During the expose cerium gives away

electron with oxidation (figure 1a) according to

following reaction:

Ce

3+

+ hν → e

-

+ [Ce

3+

]

+

Approximately 20% of photoelectrons gained at

photo ionization process are trapped by ions of

silver, which create molecular clusters (Ag

2

+

,

Ag

3

2+

et al.) rest of them are accepted by ions of tin

and antimony (figure 1b):

e

-

+ Sb

5+

→ [Sb

5+

]

–

e

-

+ Sn

4+

→ [Sn

4+

]

–

Subsequent thermal treatment at temperatures

around 300

о

С leads to discharge of tin and antimony

and formation of molecular clusters and colloidal

particles of silver Ag

o

n (figure 1c):

[Sb

5+

]

-

→ [Sb

5+

]

-

+ e

-

[Sn

4+

]

-

→ [Sn

4+

]

-

+ e

-

nAg

+

+ ne

–

→ nAg

o

Further temperature increase leads to the shell

growth on the colloidal particle of silver (figure 1.d).

And finally crystalline phase NaF grows on the shell

(Pierson and Stookey, 1999) (figure 1.e).

The UV dose defines concentration of colloidal

particles and thus concentration of microcrystals.

Then temperature and duration of thermal treatment

defines the size of microcrystals and their volume

fraction. As a result, difference in refractive index,

between exposed and unexposed parts of glass,

appears. In exposed part refractive index is defined

by refractive index of crystalline phase and its

volume fraction as well as refractive index of

residual glass phase from which fluorite and sodium

are crystallized. In unexposed part refractive index

doesn’t change compare to virgin glass (Pierson and

Stookey, 1999). Summary, the refractive index

change in PTR glass depends from UV exposure

dose and temperature and time of thermal treatment

and known to reach values of n = 510

-4

. With

Figure 1 photo-thermo-inducted crystallization of PT

R

glass:

A) Cerium photoionization and accept of electrons by

Sb and Sn ions;

B) Discharge electrons by Sn and Sb and accept with

Ag ions with formation of neutral silver;

C) Colloidal particles formation at heating up to 400 ºС;

D) Shell growth (Ag,Na)Br on colloidal particle o

f

silver T>500ºС;

E) Growth of microcrystals NaF T>500 ºС.

LatestAchievementsinChemicalCompositionOptimizationofPhoto-Thermo-RefractiveGlassandItsApplications

79

high efficient thickness of holograms, such value is

enough for achieving 99% diffraction efficiency. In

addition, lifetime of such elements is nearly

unlimited due to high stability of NaF crystals.

Holograms recorded in PTR glass are high resistant

to mechanical and chemical treatment almost like

BK7 glass. Optical breakdown for PTR glass is

1kJ/cm

2

at = 1.06μm. Optical and spectral

characteristics of holograms are stable with heating

up to 450 ºС.

An important advantage of PTR glass as a

material for hologram recording is its high

homogeneity (refractive index fluctuations in the

order of 10

-5

) and reproducible characteristics of the

glass. PTR glass, like BK7 optical glass, allows

traditional methods of machining - grinding and

polishing, as well as a variety of forming techniques

(e.g., sagging and aspheric surfaces creation). It is

worth noting that the glass itself is flexible material

and allows various ways for composition

modification, for example, it can be doped with rare

earth ions, or it can be ion exchanged for waveguide

structures creation or material strength increase.

Production of PTR glass can be carried out both in

the laboratory (600 g) and industrial (300 kg) scales

using simple and non-toxic technology. Wherein the

chemical reagents required for the synthesis of glass

are commercially available and inexpensive.

To date, the properties of PTR glass still are

actively studied and improved. One of the important

aspects is the study of influence of different

modifications of the chemical composition on the

holographic properties of the glass.

3 CHEMICAL COMPOSITION

IMPROVEMENTS

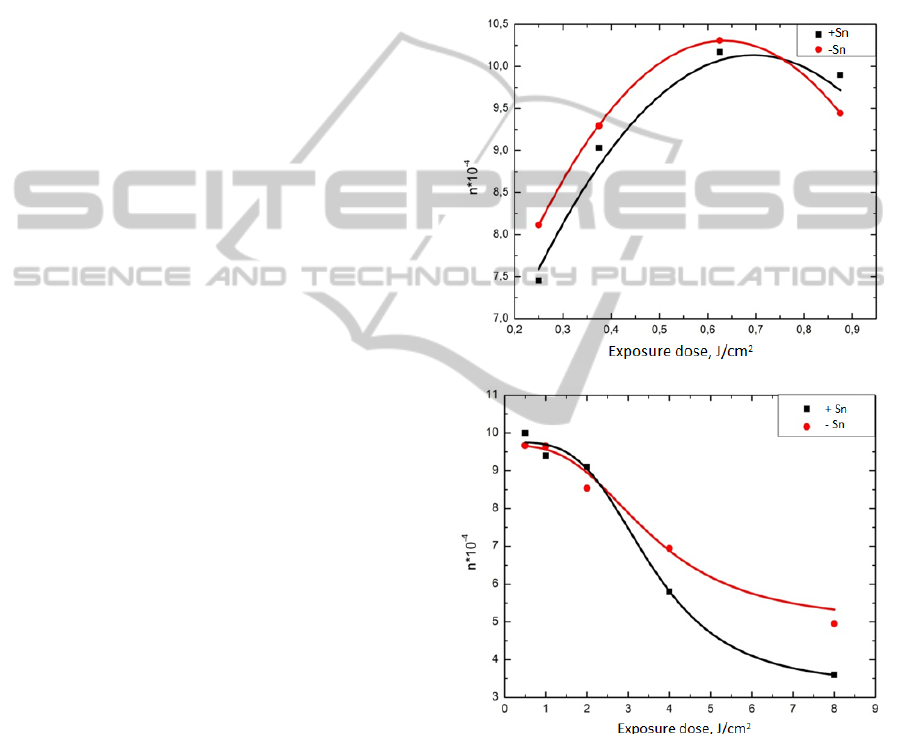

A study of tin influence on holographic

characteristics was held. It was found that the

addition of Tin in the glass composition adversely

affects characteristics of the recorded diffraction

elements. In the course of this work, was compared

several key parameters of holographic gratings for

different glass compositions. These parameters were

efficient thickness of the hologram, and refractive

index modulation amplitude (RIMA). RIMA is a

quantity equal value to half of the refractive index

change resulting from the process of photo-thermo-

inducted (PTI) crystallization. During the hologram

recording process in the glass sinusoidal distribution

of the refractive index is formed. While the two

amplitudes of the distribution fall within the

dynamic range of refractive index change

(corresponds to refractive index change caused by

PTI crystallization process). Thus, by measuring the

RIMA at the optimum recording conditions, it is

possible to obtain data on the maximum dynamic

range of the refractive index change. A study, based

on a comparison of the RIMA for the glass

composition with different tin concentration, showed

that the presence of tin does not affect the dynamic

range of the refractive index change (figure 2a).

a

b

Figure 2: amplitude of the refractive indexmodulation with

respect to exposure dose in optimal exposure range (a) and

over-exposure range (b).

RIMA curves for the investigated glass were almost

identical. The difference in the maximum value of

the refractive index change is actually missing.

Further studies revealed that in range of over-

exposure (figure 2.b), beyond the optimal dose of

UV irradiation, the fall of the RIMA is different. We

suppose that it’s connected with scattering

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

80

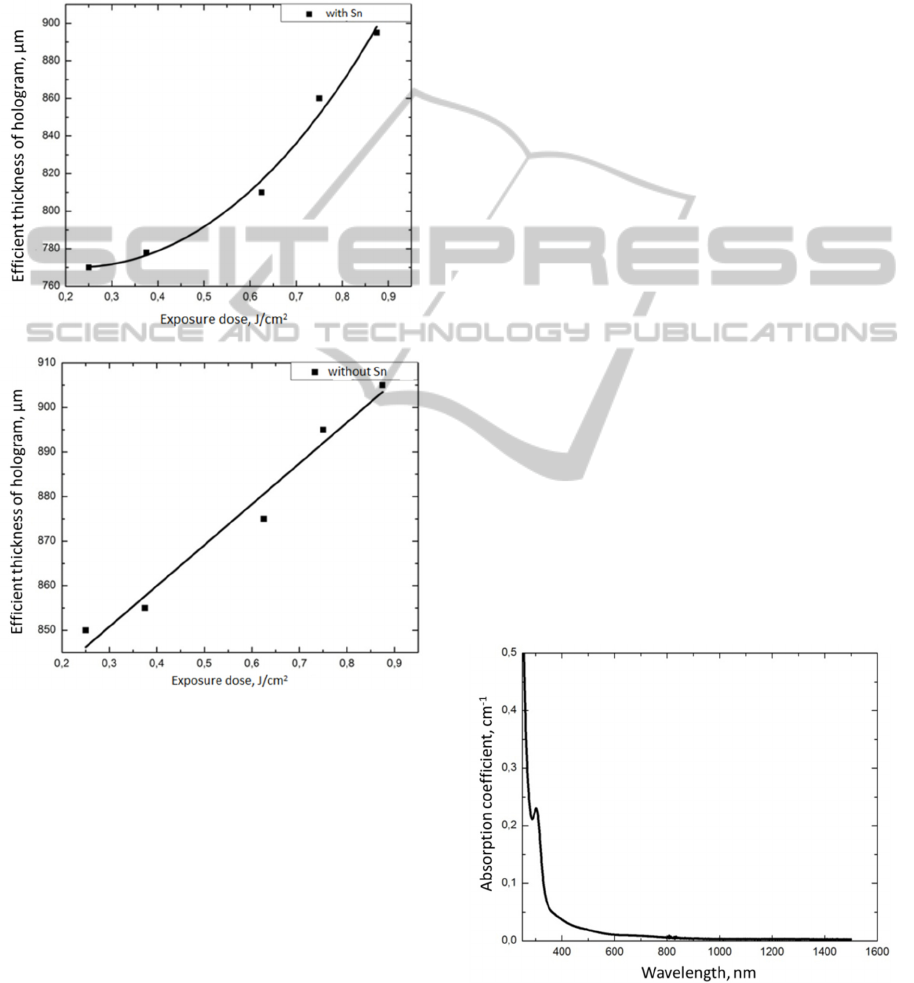

difference at the recording step. This assumption

was confirmed by comparison of efficient thickness

of obtained holographic gratings. Gratings, recorded

in the glass containing tin, had a smaller efficient

thickness compare to the gratings in the glass

without tin, at the same doses of UV irradiation and

thermal treatment regime.

a

b

Figure 3: efficient thickness with respect to exposure dose

sample with tin (a) and without (b).

Moreover, the efficient thickness dependence of

exposure for the composition containing tin differs

from linear (figure 3 a), whereas for glass without

tin dependence is strictly linear (figure 3 b).

Exclusion of tin from composition of the modified

PTR glass, allows reducing of stray formation of

silver clusters in the unexposed areas of interference

pattern, i.e. reducing scattering of recorded

holograms, as well as adjusting growth kinetics of

silver particles in the irradiated areas.

Further study of chemical composition allowed

complex optimization of components, with main

goal to decrease optical losses in visible spectral

range caused by absorption band of colloidal silver

(

Ivanov et al, 2014)

. Concentration optimization

undergone following elements: halides (fluorides

and bromides), responsible for the growth of

microcrystalline shell and crystalline phase;

Antimony ions, which play a key role in the

acceptance and donation of the photoelectrons

received upon irradiation of cerium and subsequent

thermal treatment of PTR glass; also was lowered

the concentration of impurities capable of

photoelectrons capture. In work, mainly was

compared RIMA and induced losses spectra in the

visible range. As well as comparison between the

value of the optimal exposure for the classic and

improved glass was made. During the work, we also

had to upgrade the regime of thermal treatment,

because the new glass composition reveals its

potential in other regime than classic PTR glass

composition. As a result was improved a number of

parameters exceeding commercially produced

material. First of all, problem with absorption in

visible spectral range was solved, resulting in great

reduction of induced optical losses caused by

colloidal silver. The new composition of PTR glass

after the FTI crystallization process shows no

absorption band of the colloidal particles in the

optical losses spectra of PTR glass with recorded

hologram (figure 4).

The absence of the absorption band in visible

spectral range allows production of pure phase

volume holographic gratings, which positively

affects the characteristics of the following elements,

and as a consequence the quality of the diffracted

beam.

Figure 4: Absorption coefficient spectra of modified PTR

glass with recorded hologram.

LatestAchievementsinChemicalCompositionOptimizationofPhoto-Thermo-RefractiveGlassandItsApplications

81

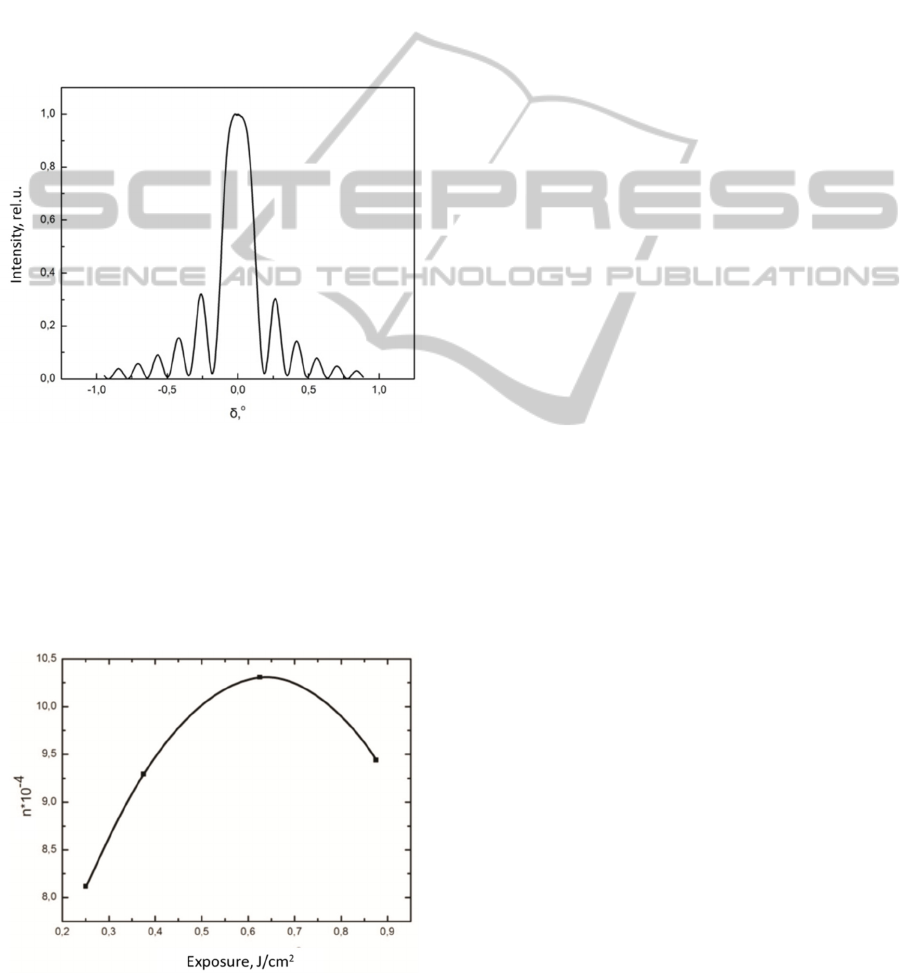

Thus, the absence of the induced losses in the visible

spectrum allows usage of the elements on this

material in schemes with high requirements for

transmission in optical channel. Because holograms

are purely phase, i.e. they lack the contribution of

the amplitude component; contours of angular and

spectral selectivity have good quality and symmetry

(figure 5) that positively affects the optical quality of

the beam in diffracted order. In addition, chemical

composition optimization increased RIMA up to n

1

= 10.210

−4

which means that refractive index

dynamic range of the new PTR glass has value of

2×10

-3

.

Figure 5: Contour of angular selectivity of hologram

recorded on modified PTR glass.

Optimization of antimony concentration led to shift

of optimal exposition towards shorter times (figure

6), i.e. for modified PTR glass maximum RIMA is

achieved with 4 times lesser recording times than

that for a commercially produced material and lays

in range of 0.5J/cm

2

.

Figure 6: amplitude of the refractive indexmodulation with

respect to exposure dose.

This is beneficial for the quality of obtained

diffractive elements, because the process of

hologram recording is very sensitive to air

turbulence and vibrations of the optical scheme, high

recording times are extremely undesirable and lead

to decrease of contrast in the interference pattern.

Synthesis of modified PTR glass from high purity

reagents allowed to lower impurities concentration

(mainly iron oxide), which are responsible for

capturing and irretrievable loss of photoelectrons,

required during PTI crystallization process. Also,

it’s improved the transmission of the virgin glass in

the UV optical range.

4 NEW APPLICATION

All the above optimizations led to the new field of

application for PTR glass as a holographic medium

for holographic marks for telescoping systems

(

Ivanov et al, 2014)

. Since transmission of glass,

containing hologram, is above 90% without AR

coating, it can took its place in problems with strict

requirements to transmission in observation channel

such as collimator sight. Application of PTR glass

can solve problem of mark image stabilization,

which is necessary due to the instability of laser

diode source used in such scopes. To date this

problem is solved by addition in optical scheme

achromatizing diffraction elements such as

additional thin gratings, complex two cavity mirrors

or compound objectives. Wavelength shift, caused

by laser diode temperature changes, can be nullified

by spectral selectivity of thick hologram recorded on

PTR glass. While the central wavelength of laser

diode shifts, recorded hologram continues to

reconstruct image of mark on proper angle – thus

maintaining the position of mark in target plane.

And redistribution of energy in diode output spectra

leads to insignificant lowering of intensity of the

mark which can be easily leveled by diode power

output adjustment. Since the diffraction efficiency of

holograms on PTR glass can achieve values of 99%,

intensity required for mark observation is pretty low.

Important to note that current materials used for

mark recording are vulnerable to external impact

such as moisture and mechanical damage, that leads

to need in additional cover for holograms. With

application of PTR glass, since it is high resistant to

external impacts, there is no need in additional

protection of observation channel.

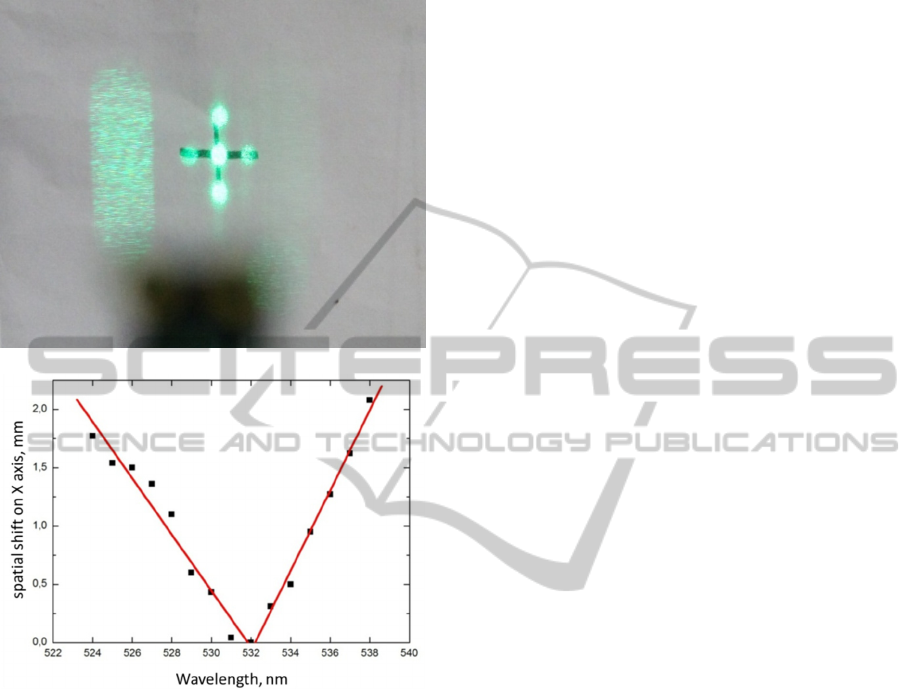

In pictures below are photo of reconstructed

image of mark (figure 7 a) and spatial shift of central

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

82

dot in the mark image with respect to wavelength

change (figure 7 b).

a

b

Figure 7: photo of reconstructed image of mark in target

plane at 180 cm (a) and spatial shift of central dot in the

mark image with respect to wavelength (b).

Due to the complexity of measuring spectral

selectivity of image hologram, in the experiment

was measured spatial shift of central dot in the mark

image. From that spatial shift spectral selectivity of

recorded hologram was calculated. Spectral

selectivity matches theoretical predictions and

corresponds to 400μm efficient thickness of

recorded hologram. Such a low thickness is a result

of huge losses of intensity during recording process,

what means that expose times should be readjusted

to achieve desirable spectral selectivity and spatial

stability of mark image.

5 COMPLEX MULTIPLEXATION

Another promising application of holograms on PTR

glass is complex (linked) multiplexation, which

means recording multiply gratings in a single

volume, where each grating corresponds to Bragg

conditions inside the medium for another grating.

Reciprocal gratings combination within the medium

can be various, and they can perform their functions

simultaneously. For instance, it is possible to create

a combination of reflective and transmitting

hologram for spatial and spectral filtering at the

same time; that can be used to create arrays from

emitting diode elements at the small size site.

Complex element in such application will provide

positive feedback for each emitting area, stabilizing

the emission wavelength and adjusting the spatial

characteristics of the beam. In one optical path

inside the element radiation is directed onto a

reflective grating, which has high spectral

selectivity. Reflective hologram is responsible for

the spectral stabilization. Reflected radiation is

directed back into the crystal along the same path.

Another path within the complex element is for

output. Transmitting grating provides radiation

output at the appropriate angle for all emitting areas.

Presence of multiple transmitting gratings allows

correction of the spatial characteristics of the beam

emerging from the system. It is noteworthy that in

this implementation is possible to create a single

cavity for a large number of emitting semiconductor

crystals, this leads to the creation of a coherent high

power source of radiation with extremely narrow

bandwidth. Due to the large dynamic range of the

refractive index change in PTR glass, it is possible

to record a plurality of holographic elements in one

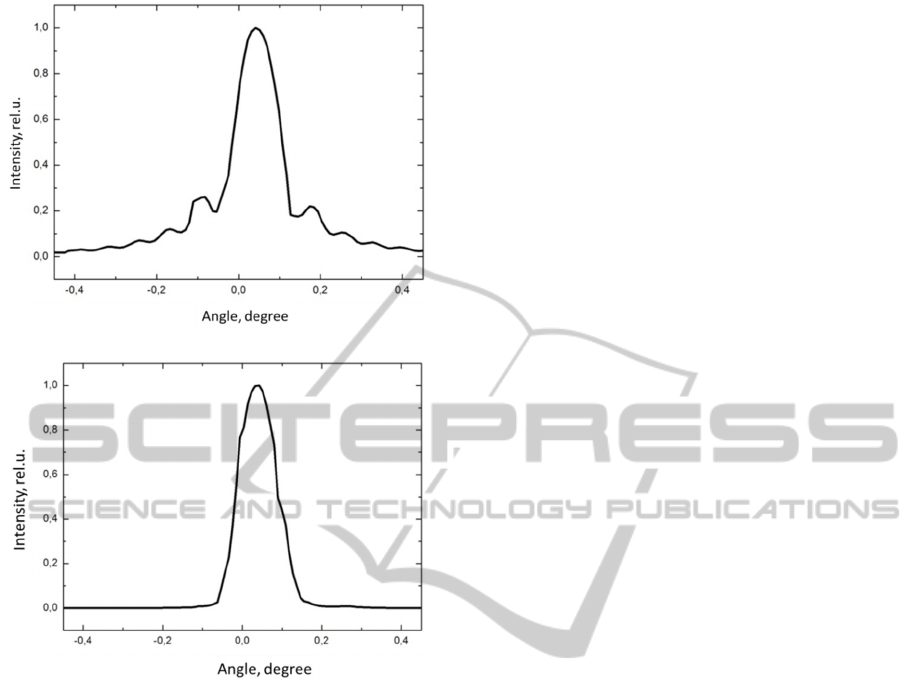

volume. In pictures below are shown spatial

contours of single hologram and complex hologram

(figure 8). Gratings period and their spatial

orientation within the medium are selected following

next conditions: first diffraction order from first

grating meets Bragg condition in the medium for the

second grating.

6 CONCLUSIONS

These studies, aimed at material characteristics

improvement led to: refractive index dynamic range

increase; optimal exposure lowering; scattering

during recording process and after thermal treatment

reduction; and allowed to get rid of the absorption

band of the colloidal particles in the visible spectral

LatestAchievementsinChemicalCompositionOptimizationofPhoto-Thermo-RefractiveGlassandItsApplications

83

a

b

Figure 8: angular selectivity contours of usual (a) and

complex linked hologram (b).

range. All of the above makes it possible to extend

the application area of this material, including such

as: recording of holographic marks for telescopic

systems; complex elements for semiconductor laser

diodes creation and powerful coherent radiation

sources based on them; usage the elements on PTR

glass as intracavity selectors and filters for pulse

Raman lasers.

In summary, PTR glass and optical elements

based on it has the following advantages: high

refractive index dynamic range (Δn ≈ 2×10

-3

); High

diffraction efficiency (up to 99%); large efficient

thickness of the hologram (above few mm), which

allows you to create narrow spectral (Δλ ≈ 0,05nm)

and spatial (0.2degree) filters; unlimited lifetime of

hologram (up to ten years), high thermal (up to 450 °

C), mechanical and chemical resistance. Optical

breakdown threshold of the hologram on the PTR

glass close to the breakdown threshold of

commercial optical glass BK7 (1 kJ/cm2 under

pulsed irradiation at λ= 1.06μm).

This work was financially supported by Russian

Scientific Foundation (Agreement # 14-23-00136).

REFERENCES

Adibi, Buse K., and Psaltis D. (2001) ‘System measure for

persistence in holographic recording and application to

singly-doped and doubly-doped lithium niobate’,

Applied Optics Vol.40, p.5175 -5182.

Efimov O. M., Glebov L. B., Glebova L. N., Richardson

K. A. and Smirnov V. I. (1999) ‘High Efficiency Bragg

gratings in Photothermal Refractive glass’, Applied

Optics vol.38, p. 619-627.

Pierson J. E. and Stookey S. D. (1999) Method for making

photosensitive colored glasses. Patent USA. №

4057408. 1977.

Pierson J. E. and Stookey S. D. (1999) Photosensitive

colored glasses. Patent USA. № 4017318. 1977.

Ivanov S. A., Ignatiev A. I, Nkonorov N. V., Aseev V. A.

(2014) ‘Holographic characteristics of a modified

photo-thermo-refractive glass’, Journal of Optical

Technology Vol. 81, Issue 6, pp. 356-360.

Ivanov S. A., Angervaks A. E., Shcheulin A. S. (2014)

‘Application of photo-thermo-refractive glass as a

holographic medium for holographic collimator gun

sights’, SPIE Photonics Europe - Conference

Proceedings, Belgium, Vol. 9131. pp. 91311B.

Ivanov S. A., Angervaks A. E., Shcheulin A. S., Ignatiev

A. I., Nikonorov N. V. (2014) ‘Recording holographic

marks for telescoping systems in photo-thermo-

refractive glass’, Optics and Spectroscopy No. 6, pp.

971-9.

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

84