Enhanced Stability and Re-usability of the Optical Sensor for pH

Monitoring Using a Layer-by-layer Deposition Technique

Nahid Raoufi

1,2

, Frederic Surre

2

, Muttukrishnan Rajarajan

2

, Tong Sun

2

and Kenneth T. V. Grattan

2,3

1

Engineering Department, Islamic Azad University – South Tehran Branch, Tehran, Iran

2

School of Engineering and Mathematical Sciences, City University London, London, EC1V 0HB, U.K.

3

City Graduate School, City University London, London, EC1V 0HB, U.K.

Keywords: Stabilization, Stable, Layer-by-layer, Sensor, pH Optical Sensor, Re-usability.

Abstract: Stable and reliable pH optical sensor is important for many industrial applications. The layer-by-layer

deposition technique is a simple and versatile method used to deposit a sensitive thin film on such an optical

fibre-based device but creating a coating which can often be destroyed in use in highly acid or alkali solutions.

It is thus important to create stable and durable sensors for operation under these extreme environments. The

main aim of this study has been to prepare a number of such sensors and compare the performance of three

different stabilization approaches used for the development of an effective wavelength-dependent pH-

sensitive optical sensor. Techniques such as employing heat treatment, the deposition of two layers of a

PAH/SiO

2

thin film and the deposition of two layers APTMS/SiO

2

as topping layers have been studied to

determine the optimum approach to creating a desirable sensor – one yielding the same value of peak

wavelength for a measurement of a known value of pH and to do so repeatedly. An improvement in

performance and in shelf-life, stability and re-usability of the sensor has been achieved by the addition of two

bilayers of APTMS/SiO

2

in the work carried out and the results of the investigation undertaken are reported.

1 INTRODUCTION

Nowadays, the detection of a range of chemical and

biochemical substances, as well as the measurement

of a variety of system operating parameters play an

important role in many situations. pH is one of the

most common analytical measurements needed in

both industrial processing and in laboratory research,

in which reliable real time sensor data, such as can be

obtained from an optical sensor system due to its light

weight and non-electrical mode of operation is

needed. In order to achieve optical recognition of

these parameters using optical fibre-based devices,

active indicators such as sensitive films must be

immobilized on the distal ends of suitable optical

fibres. The layer-by-layer technique is one of the

deposition methods widely used to coat such thin

films on to optical substrates and optical fibres. The

layer-by-layer (LbL) technique is used to build up a

sufficient thickness of such material on the fibre and

is based on the electrostatic attraction between

oppositely charged molecules to create the layers and

thereby increase the overall coating thickness

(Decher et al., 1992). The principal advantage of the

use of this technique is the ability to create stable

deposited thin films with well-organized structure

and controlled nanometer thicknesses on substrates of

various shapes and sizes (Decher and Schlenoff,

2002, Ai et al., 2003, Johnston et al., 2006,

Cassagneau et al., 1998, Dubas et al., 2006).

Generally, the thin films created by using the LbL

technique are stable (de Villiers et al., 2011, Decher

and Schlenoff, 2002), and it is difficult to remove

them from a solid substrate. There are two main

methods to remove LbL deposited films, should this

be needed. First, a solution of high pH can be used

which will attack the first polycation layer and

destroy the ionic bonds that stabilize the films. A

second method is to expose the LbL multilayers to a

solution with very high ionic strength. For practical

applications, especially those needing continuous

monitoring, it is critical to have a pH probe that can

give consistent results and survive for as long as

possible. However, the destruction of the layers limits

the life of the probe and does not make it as suitable

for continuous monitoring. A variety of techniques

has been proposed to improve the stability of the film

and to avoid progressive destruction of the coating.

Ionic strength, pH, concentration of the polyion

solutions and the presence of a copolymer such as salt

156

Raoufi N., Surre F., Rajarajan M., Sun T. and Grattan K..

Enhanced Stability and Re-usability of the Optical Sensor for pH Monitoring Using a Layer-by-layer Deposition Technique.

DOI: 10.5220/0005432401560167

In Proceedings of the 3rd International Conference on Photonics, Optics and Laser Technology (OSENS-2015), pages 156-167

ISBN: 978-989-758-092-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

affect the LbL assembly, the film thickness and its

stability (Ai et al., 2003, Decher and Schlenoff,

2002). Heat treatment is also an important process

which has been discussed in many works in the

literature (Sharma et al., 2001, Singh et al., 2008,

Decher et al., 1994) to achieve a higher stability of the

thin films and avoid problems with the destruction of

the films when they are immersed in buffer solutions

of different values of pH (Villar et al., 2005, Villar et

al., 2008). However this sort of treatment affects the

sensor performance and decreases its sensitivity

(Villar et al., 2008), as well as allowing for a

degradation of the indicator dyes used which happens

at high temperatures.

The stability of thin films thus generated does

depend on the interaction between the layers, such as

through the formation and destruction of hydrogen

bonds. Hence, the stabilization of the LbL-assembled

films via polyamide bond formation was a further

method reported in the literature (Ichinose et al.,

1999, Yamada et al., 1981, Li et al., 2005). The amine

coupling reaction can easily allow a cross-linkage of

an amino group to a cationic polyelectrolytes and a

carboxyl group on anionic polyelectrolytes via amide

bond formation. There is a further report in the

literature (Saeki et al., 2013) which focused on the

film stability under chlorine treatment as a means to

improve the stability of the LbL-assembled

nanofilteration membranes in combined high ionic

strength conditions and under chlorine treatment. In

another approach, the stabilizing of the thin film is

achieved by forming siloxane bonds owing to a silane

coupling reaction between oppositely charged

polyelectrolytes which leads to the crosslinking

between the silane groups (Sen et al., 1992, Saeki et

al., 2013). Egawa et al. demonstrated (Egawa et al.,

2007) crosslinking between the sulfonate group in

the polyanion and the diazonium ion in polycation

due to exposure to UV light. The pH sensor reported

in their work could be used to measure solutions of

high pH.

An alternative approach is to build up several capping

layers using different materials such as nanoparticles

to enhance the film stability. Prakash et al. (Prakash

et al., 2013) discussed applying nanoparticles to

achieve an adequate sensitivity and stability with the

modification of the sensors (or biosensors) with

nanomaterials such as gold and/or silver

nanoparticles (Su and Li, 2008, Dubas et al., 2006),

carbon nanomaterials (Llobet, 2013) and silica

nanoparticles (Wang et al., 2013) and these have

shown considerable promise. Putzbach et al. reported

that the immobilization of enzymes improves stability

of the biosensor discussed (Putzbach and Ronkainen,

2013).

The application of silica nanoparticles (SiO

2

) has

drawn considerable attention for surface

modification, due to its uses as an enhancer for the

sensitivity, selectivity and strength of the thin films as

well as a its use as a pH indicator in many research

situations and in industry (Liu and Cui, 2007,

Nallathambi et al., 2011, Potapov et al., 2011, Lee and

Cui, 2012, Rahman and Padavettan, 2012). The work

presented in this paper thus takes advantage of this

and compares and contrasts three different

stabilization approaches with the aim of creating a

stable pH sensor which is re-usable and stable under

storage. In the course of the investigation and

optimization of the sensor system developed, aspects

of the fabrication process such as heat treatment, the

deposition of two layers of PAH/SiO

2

as thin film

‘topping’ layers and the deposition of two layers of

APTMS/SiO

2

as similar ‘topping’ layers have been

investigated and the resulting sensors characterized to

determine the best approach to creating a sensor

which is stable and reliable in operation: thus giving

the same calibration, in terms of the value of the peak

wavelength for a particular value of pH, and doing so

in a reproducible way. Further aspects which relate to

improved sensor performance, such as longer shelf-

life, better stability and sensor re-usability after

cleaning for a sensor prepared using the LbL

technique in this work are considered and reported,

showing the value of the approach taken in this

research.

2 MATERIALS AND METHODS

2.1 Chemicals

In order to create an effective optical pH sensor,

brilliant yellow (BY) was selected as the pH indicator

to be used, as discussed in prior work by the authors

(Raoufi et al., 2012b). This indicator dye was chosen

for its wavelength variation and ease of use and it was

cross-linked to poly(allylamine hydrochloride)

[PAH] with an average molecular weight (MW)

~15000, supplied by Sigma-Aldrich. PAH is a

positively charged molecule and was used as a

polycation. 3-Aminopropyl-trimethoxy silane

(APTMS) (99%) as a silane coupling agent and SM-

30 containing 30 wt% SiO

2

nanoparticles in H

2

O as a

strength enhancer were used as supplied by Sigma-

Aldrich. The structures of these molecules are shown

schematically in Figure 1.

EnhancedStabilityandRe-usabilityoftheOpticalSensorforpHMonitoringUsingaLayer-by-layerDepositionTechnique

157

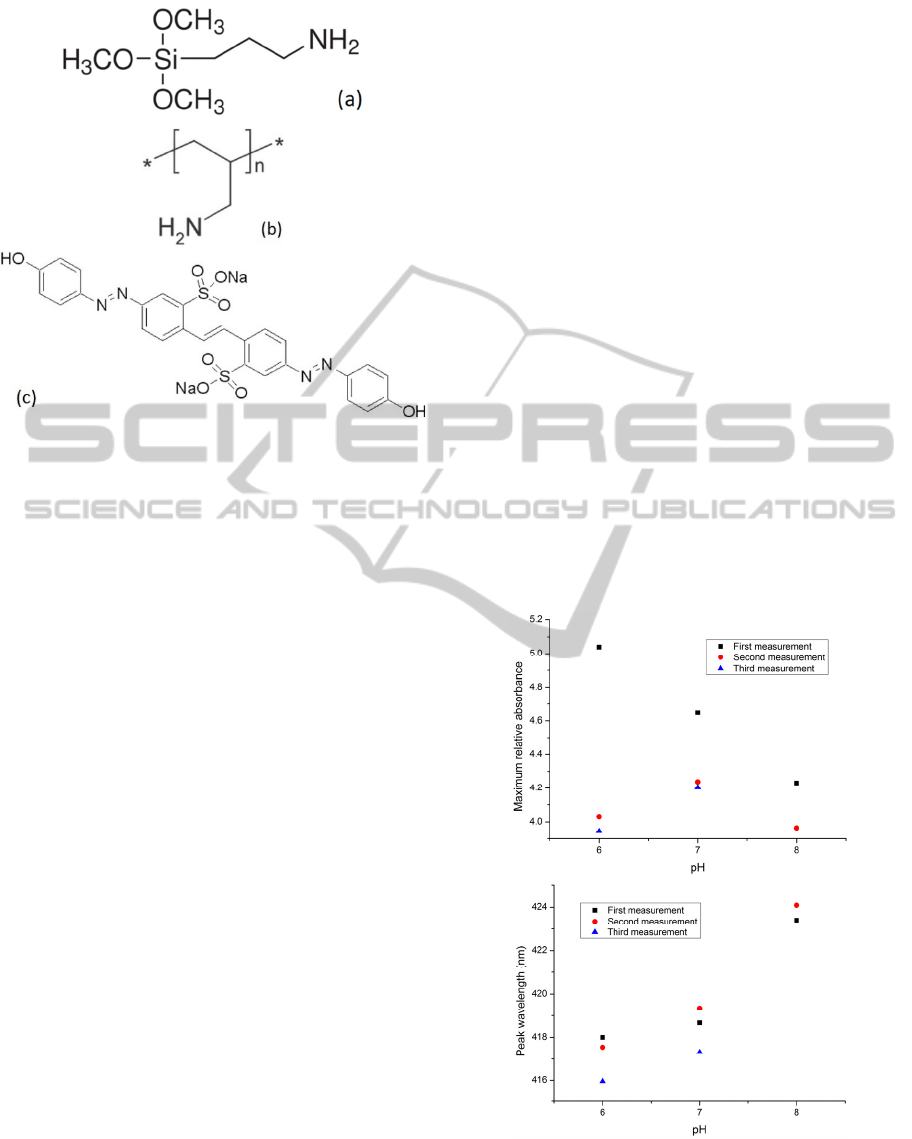

Figure 1: Chemical structure of (a) APTMS, (b) Poly

(allylamine) hydrochloride [PAH] and (c) brilliant yellow.

2.2 Procedures

The multilayer coating which was deposited by using

a self-assembly, Layer-by-Layer (LbL) technique

was carried out using a glass microscope slides of

dimensions 76×26 mm, with thickness of 1.0 mm.

The glass slide used was treated with Piranha solution

(30:70 (v/v) mixture of hydrogen peroxide (H

2

O

2

)

(30%) and concentrated sulfuric acid (H

2

SO

4

)) for 60

minutes to produce the negatively charged surface

and was then rinsed with distilled water, followed by

drying with compressed nitrogen. The glass slide was

then ready to be coated with positively charged

molecules. The Layer-by-Layer technique is based

on the successive deposition of oppositely charged

molecules onto a solid surface. In this technique, the

functionalized surface of a glass slide dipped into

PAH solution for 5 minutes to create a polycation

layer. The glass slide was then dipped into distilled

water for 5 minutes to wash off the un-bonded

molecules. This glass slide was then dipped in BY

solution for 5 minutes to construct the polyanion layer

above the PAH layer. To wash away the un-bonded

molecules, the glass slide was then immersed in fresh

distilled water for 5 minutes. This operation was then

repeated six times to build up six bilayers of

(PAH/BY) and thus increase the thickness of the thin

film deposited on the glass slide, which then was

ready to be used as the active element in the sensor

system, tested by being used for measurement of the

pH of a buffer solution. The performance of the

sensor prepared was examined through the

measurement and the evaluation of the change in the

peak wavelength of the absorption when the sensor

was evaluated by being dipped into buffer solutions

of different and varying pH. The process was carried

out by dipping the sensor slide into the pH solution

for a few minutes, following which the absorbed light

versus wavelengths is measured by use of the Perkin

Elmer spectrophotometer. The glass slide was then

taken out of the solution and was immersed in

another, fresh buffer solution (of different and known

pH), this being following by a measurement of the

absorbance spectra. The measurement was carried out

several times, using fresh buffer solutions increasing

from pH 6 to 9, and then decreasing from pH 9 to 6,

this being repeated typically two or three times for a

number of such samples. The maximum value of the

absorbance was normalized by dividing by the

minimum value and th results were plotted as a graph

of relative absorbance versus pH. For consistency, the

preparation conditions and the concentration of the

polyion solutions used were the same in all these

experiments. However, it was found that to achieve a

sensor performance that is consistent and shows the

same values of peak wavelength for an identical pH,

especially after -three times of use, further operations

on the design and construction of the sensor are

needed and this is discussed in the following work.

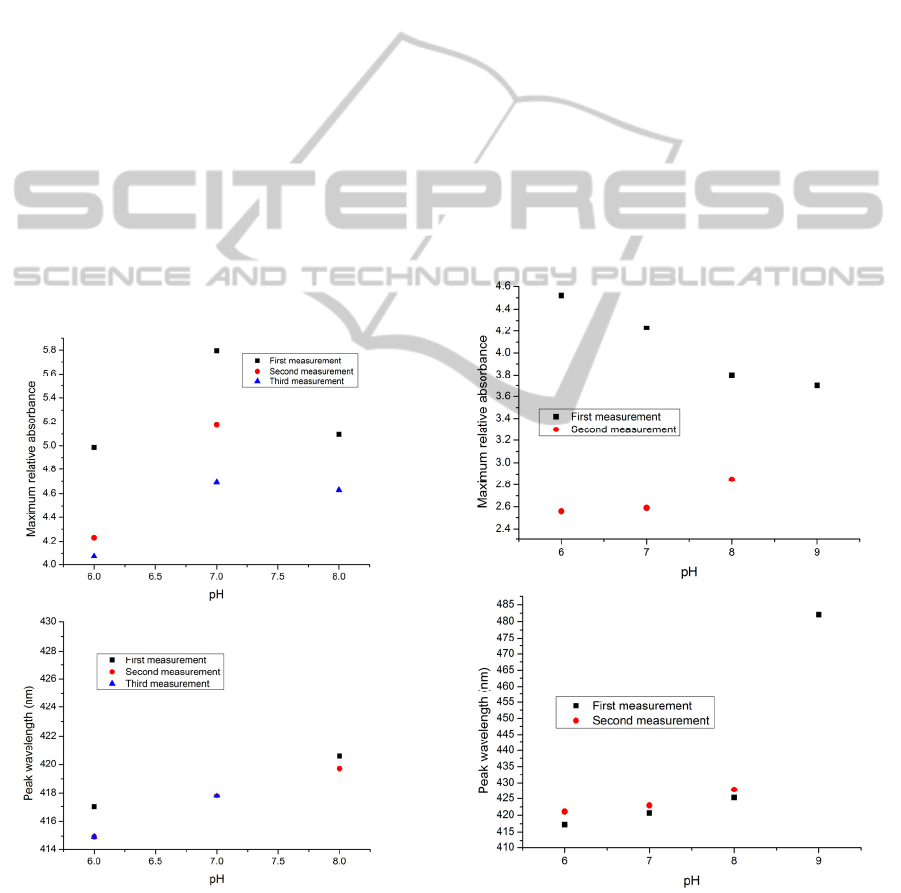

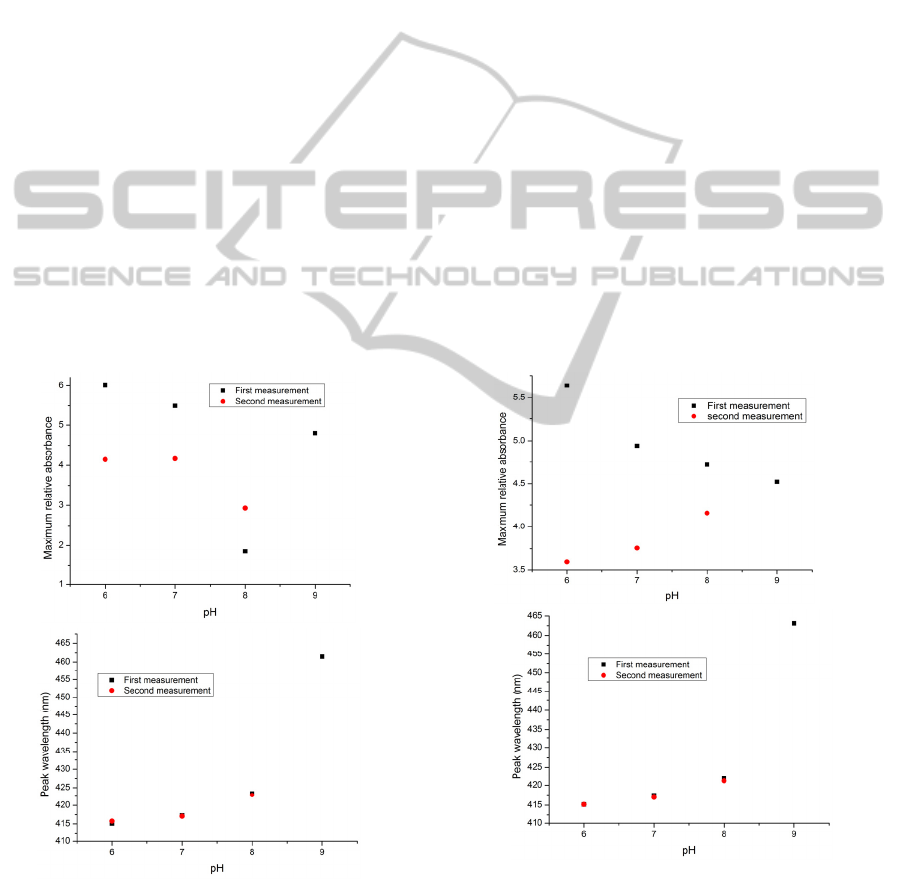

Figure 2: The maximum value of the relative absorbance

(up) and the peak wavelength (down) versus pH for the

consecutive measurements of the pH solutions for

(PAH/BY)

8

on the glass slide. No heat treatment or drying

was used in the process (The sample is designated GS01).

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

158

2.3 Experiments

Following the approach in previous research reported

by (Raoufi et al., 2012b, Raoufi et al., 2013), a glass

slide was prepared on which was deposited alternate

layers of brilliant yellow (BY) (as a pH indicator) and

poly (allylamine hydrochloride) [PAH] (as a cross-

linker of the layers of brilliant yellow), using layer-

by-layer coating technique. To determine the stability

of thin film, initially neither heat treatment or drying

was used in the process of coating of glass slide with

a total of 8 bilayers of (PAH/BY); this configuration

is denoted by (PAH/BY)

8

, where the subscript

indicates the number of bilayers, in this case 8. As

high pH can discharge the first polyion layer and

destroy the ionic bonds that stabilize the films, to

prevent this action solutions with a pH in the range

from 6 to 8 (over the neutral pH range) only were

examined. The results of several (three) successive

measurements using this sensor approach are shown

in Figure 2. However, it can be seen that the stability

of the bilayer system thus prepared could be enhanced

and this was achieved by further operations including

heat treatment or applying a capping layer. In order to

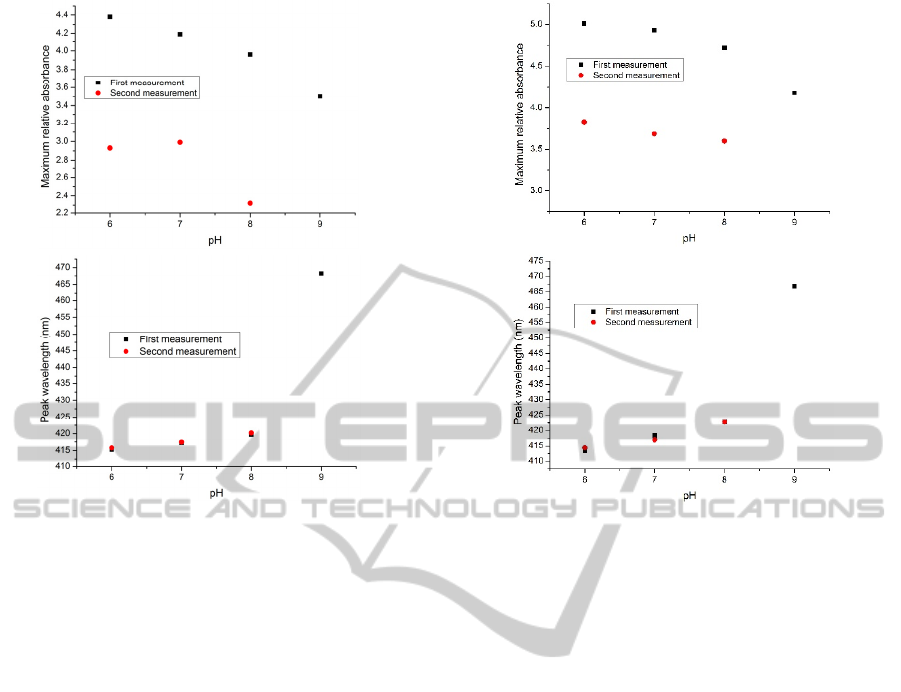

Figure 3: The maximum value of the relative absorbance

(up) and the peak wavelength (down) versus pH for the

consecutive measurements of the pH solutions for

(PAH/BY)

16

on the glass slide. The sample was cured at

120°C for 4 hours (The sample is designated GS02).

determine the most efficient method, a number of

different methods were considered and applied

including a) heat treatment b) covering the layers with

PAH and silica nanoparticles and c) coating the layers

with APTMS and silica nanoparticles as discussed

below.

2.3.1 Heat Treatment

In order to make a stable thin film, two glass slides

coated as indicated with (PAH/BY)

16

and (PAH/BY)

6

and cured in 120°C for 4 hours were examined.

The glass slide coated with (PAH/BY)

16

was

investigated using buffer solutions with pH varying

from 6 to 8 and then back from 8 to 6, while the other

slide was tested in a similar way with buffer solutions

ranging from 6 to 9. The maximum value of the

relative absorbance and the peak wavelength versus

pH for the consecutive measurements of the pH of the

solutions investigated for these two samples are

shown in Figure 3 and Figure 4.

Figure 4: The maximum value of the relative absorbance

(up) and the peak wavelength (down) versus pH for the

consecutive measurements of the pH solutions for

(PAH/BY)

6

on the glass slide. The sample was cured at

120°C for 4 hours (The sample is designated GS03).

EnhancedStabilityandRe-usabilityoftheOpticalSensorforpHMonitoringUsingaLayer-by-layerDepositionTechnique

159

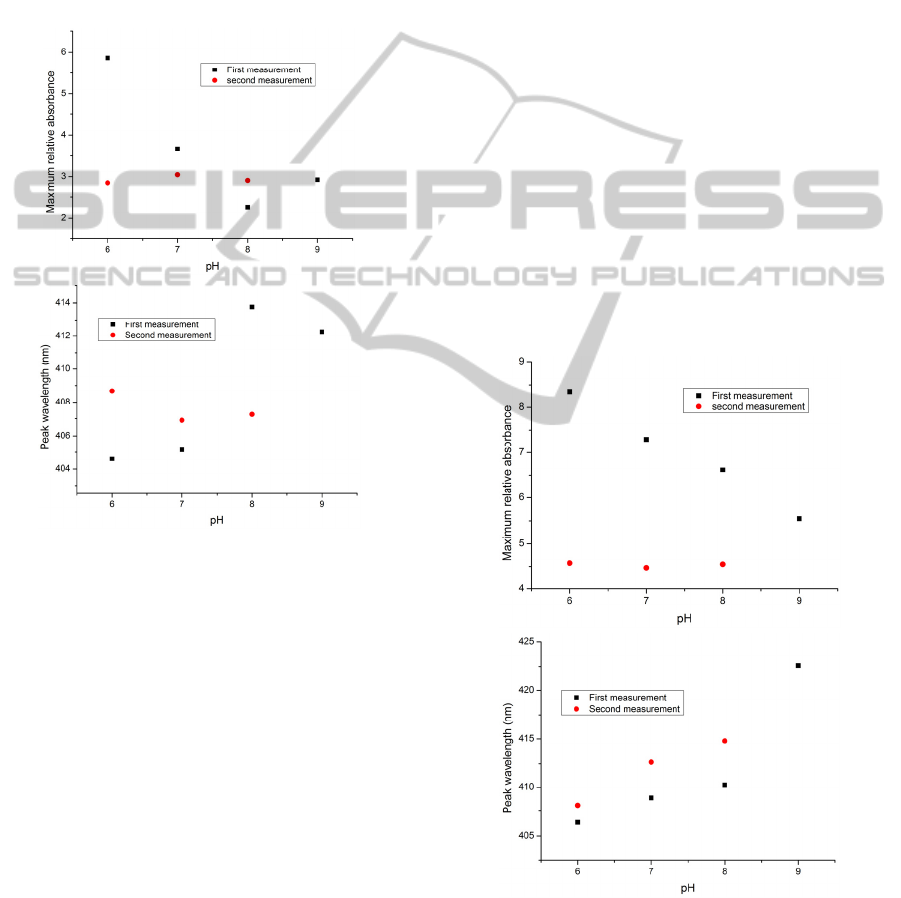

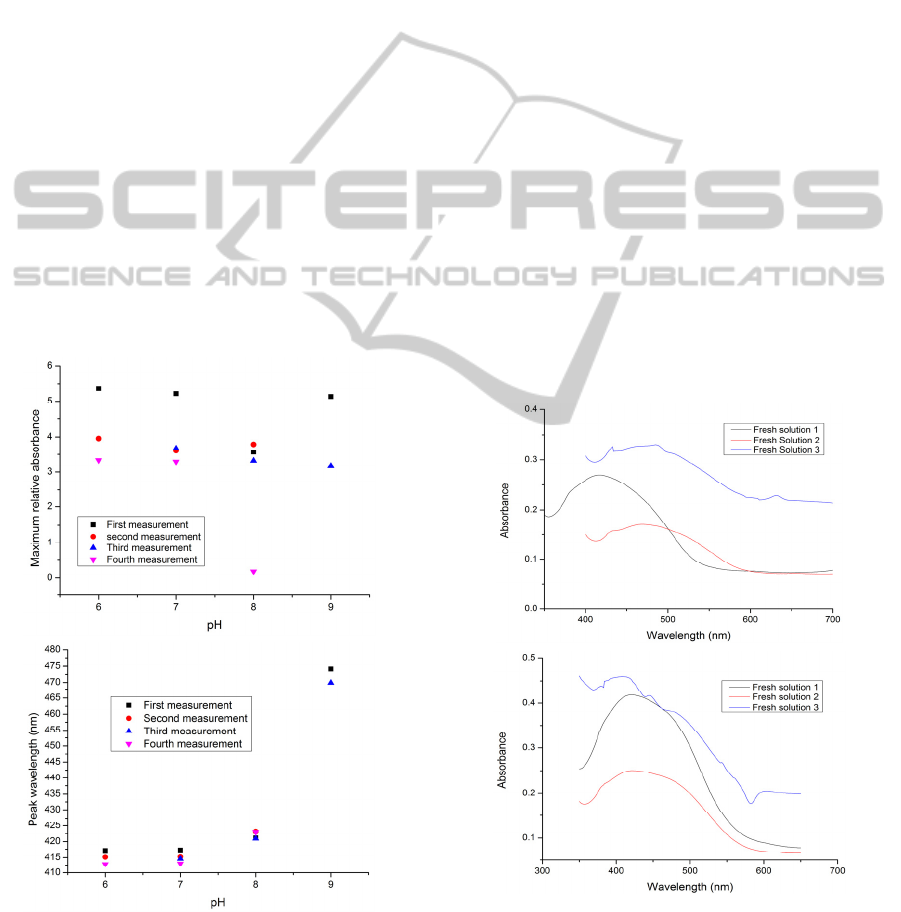

Figure 5: The maximum value of the relative absorbance

(up) and the peak wavelength (down) versus pH for the

consecutive measurements of the pH solutions for

(PAH/BY)

6

(PAH/SiO

2

)

2

on the glass slide (The sample

designated as GS04).

2.3.2 Using PAH and Silica Nanoparticle

Coatings

The use of silica nanoparticles covering the indicator

multilayers is designed to enhance the strength of the

film. Therefore, a series of experiments was carried

out and discussed below in which layers of silica

nanoparticles were built up on a glass slide already

coated with 6 bilayers of (PAH/BY), i.e (PAH/BY)

6

.

Different methods of curing were examined to find

out the most appropriate way to develop the most

stable coating. The silica solution used (SiO

2

) was

prepared at 1 wt.% (1.7mM) concentration. As the

SiO

2

solution is strongly alkaline (with pH 10.5), it

causes the destruction of the BY layers; hence the pH

of the SiO

2

solution was adjusted to pH 7 by adding

some drops of HCl to the solution before the

deposition of the layers was commenced. The glass

slide thus prepared with (PAH/BY)

6

was then

functionalized by using two bilayers of (PAH/SiO

2

)

followed by curing at 120°C for four hours (this

sample being designated GS04). The results of the

measurements taken using this sensor sample, over

the range from pH 6 to pH 9 and from 9 back to 6, is

shown in Figure 5. In a further experiment, the

temperature used for the annealing of the thin film

coating and comprising the following combination –

Figure 6: The maximum value of the relative absorbance

(up) and the peak wavelength (down) versus pH for the

consecutive measurements of the pH solutions for

(PAH/BY)

6

(PAH/SiO

2

)

2

on the glass slide. The sample was

cured at 130°C for 7 hours (The sample designated as

GS05).

(PAH/BY)

6

(PAH/SiO

2

)

2

was heat treated for a

longer period, of to 7 hours, at 130°C (the sample

being designated GS05) was and exposed to the

buffer solutions. Experiment has shown that higher

temperatures cannot be applied successfully because

of the degradation caused to the BY material.

In the next experiment, UV irradiation was utilized to

provide energy to cause the layers to form a stronger

bond, in addition to the electrostatic attraction

present. The silica nanoparticle coating is a

photosensitive material and the ionic bonds between

SiO

2

and PAH may be converted to covalent bonds

by use of this UV irradiation. To do so, the sample

was exposed to the UV light (irradiation intensity:

1112 mWcm

-2

at 365 nm) for 20 minutes, after

annealing at 130°C for 7 hours and then the sensor

was exposed to the different pH buffer solutions. The

results of the spectra recorded for this sample

(designated GS06) are shown in Figure 7. The silica

nanoparticles act as polyanions in the same way as the

BY material. It can be speculated that if the silica

molecules are located amongst the molecules of

brilliant yellow (BY), then the formation of the

molecular bonds between the silica and the PAH

molecules would create a bilayer which would

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

160

surround the BY molecules in each layer. Therefore,

a further set of experiments was carried out in which

a silica nanoparticle solution was added to a BY

solution (1.7 mM SiO

2

: 0.25 mM BY) and the pH of

the solution was adjusted to pH 6. Having coated the

glass slide sensor in this way to create

(PAH/(BY+SiO

2

))

6

, then annealing at 120°C for 4

hours, the deposited glass slide (designated GS07)

was examined under various buffer solutions of

different values of pH. The results of this test and

thus the recorded spectra are shown in Figure 8.

Figure 7: The maximum value of the relative absorbance

(up) and the peak wavelength (down) versus pH for the

consecutive measurements of the pH solutions for

(PAH/BY)

6

(PAH/SiO

2

)

2

on the glass slide. The sample was

cured at 130°C for 7 hours and exposed to UV light for 20

minutes (The sample designated as GS06).

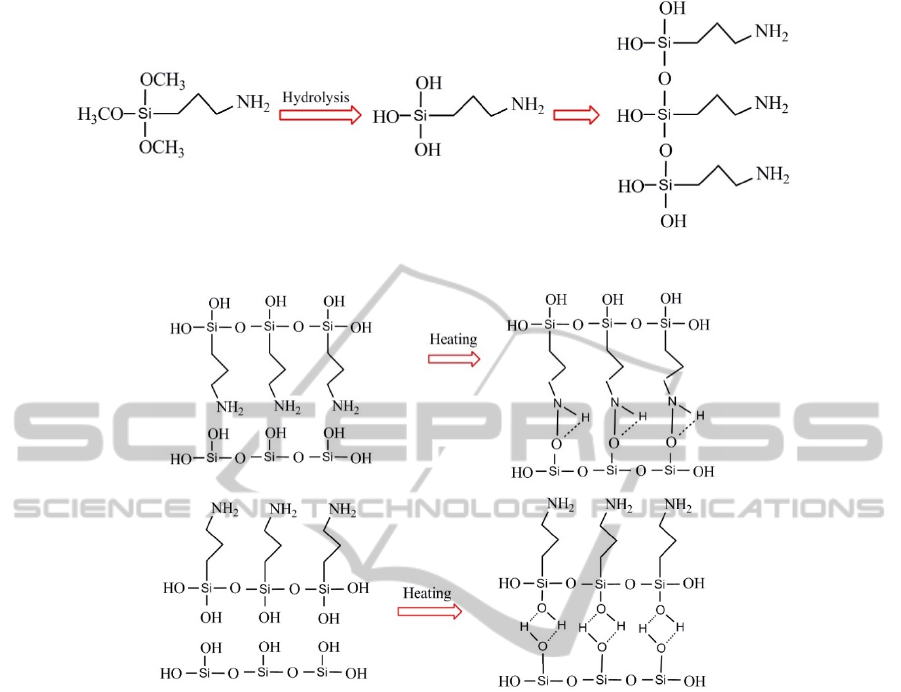

2.3.3 Use of APTMS and Silica

Nanoparticles

Further experimentation was carried out by replacing

the polycation; PAH; with 3-Aminopropyl-

trimethoxysilane (APTMS) in the capping layers.

APTMS is known as a silane coupling agent in which

a water based solution is polymerized after

hydrolysis, as shown schematically in Figure 9. The

surface of the SiO2 nanoparticle thin film contains

hydroxyl groups in the form of SiOH. These groups

may donate or accept a proton from the solution,

leaving a negativelycharged or a positively charged

surface group respectively (Liu and Cui, 2007).

Therefore, there are two possibilities that the

molecules of APTMS bond to the silica nanoparticles;

the molecule constitutes of an amine group as a

positive charge supplier and hydroxyl groups as

negative charges supplier which bond to silicon, as

shown in Figure 10. In the experiment, the solution

of 1 wt.% APTMS in H

2

O (1.4 mM) used was

strongly alkaline (with pH 10.8) and should thus be

adjusted to the neutral pH (~pH 6) that is best suited

for use as polyelectrolyte in the LbL technique which

is possible by adding several drops of HCl to both

solutions of the polycation and polyanion.

Two glass slide sensor samples coated with

(PAH/BY)

6

(APTMS/SiO

2

)

2

were prepared; one of

them was examined the same day of preparation (the

sample designated GS08) and the second (the sample

designated GS09) was evaluated a week later. The

results of the tests carried out are shown in Figure 11

and Figure 12 respectively.

To investigate the effect of the use of APTMS alone,

a thin film comprising 6 bilayers of (PAH/BY),

dipped in APTMS solution for 30 minutes, followed

by dipping in distilled water for 5 minutes, then cured

at 120°C for 4 hours was examined. The results of

this experiment is shown in Figure 13.

Figure 8: The maximum value of the relative absorbance

(up) and the peak wavelength (down) versus pH for the

consecutive measurements of the pH solutions for

(PAH/(BY+SiO

2

))

6

on the glass slide. The sample was

cured at 120°C for 4 hours (sample designated GS07).

EnhancedStabilityandRe-usabilityoftheOpticalSensorforpHMonitoringUsingaLayer-by-layerDepositionTechnique

161

Figure 9: APTMS is polymerized in aqueous solution after hydrolysis.

Figure 10: Two possibilities reaction between molecules of APTMS and silica nanoparticles.

2.3.4 Re-usability and Aging

To investigate the effect on sensor stability of the

storage of the glass slides, different coated glass

slides of different types were examined. Thus in this

investigation, initially the glass slide with a coating

was dipped into a fresh buffer solution with constant

pH for 60 minutes and after this time the absorbance

spectra was recorded as a reference. After that the

glass slide was removed from that solution and then

was immersed into another solution (with the same

pH) for a further 60 minutes and a second absorbance

spectra was recorded. This operation was repeated a

third time. Several different slides with different films

were recorded: the stability and thus the re-usability

of the multilayer thin film slides using two different

samples with different structures, these being

(PAH/BY)

6

and (PAH/BY)

6

(APTMS/SiO

2

)

2

were

examined at two different values of pH; pH 6 and 8,

separately. The results of this test are shown in Figure

14 and Figure 15 and the positive results obtained

imply the stability of these two sensor samples under

exposure to these solutions for the times indicated.

3 RESULTS AND DISCUSSION

In the layer-by-layer coating technique, the stability

of the layers is seen to depend on type and

concentration of the salt, the strength of ions and

polyelectrolytes, the polymer molecular weight, the

pH of the solutions and the thermal energy. In order

to form a stable multilayer thin film, a minimum

charge density in each layer is needed which depends

on the salt concentration and the salt type; this was

investigated (Raoufi et al., 2012a) by the authors

previously and also it was shown that to rely very

strongly on the chemical identity of the charged units

involved in forming the thin film (Bertrand et al.,

2000). Stronger ion pairing will also yield more stable

multilayers (Decher and Schlenoff, 2002) and

moreover, high molecular weight polymers promote

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

162

the stability of the layers (Shimazaki et al., 2001,

Tang et al., 2002, Kotov et al., 1998). High and low

pH solutions can potentially discharge the ions and

destroy the layers, while heat treatment causes a

chemical reaction between the molecules of two

adjacent layers and makes the bonds stronger and

creates a more stable multilayer film, as can be seen

in the first three experiments discussed (shown in

Figure 2, Figure 3 and Figure 4). As the figures show,

in this series of experiments there is a continuous

decrease in the maximum absorbance for each pH

buffer solution for two successive measurements

while the values of the peak wavelength show a

significant change from the first to the second

measurement for the sample without heat treatment,

and this represents an increase in stability of the thin

film because of the thermal effect. In the sample

designated GS03 and examined in solutions ranging

from pH 6 to pH 9, a dramatic decline in the

maximum absorbance was seen, compared to other

samples examined over the range from pH 6 to pH 8.

The reduction in absorbance is a clear proof that

leaching of the indicator is occurring and the decrease

of the thickness of the thin film. In particular, in the

case where a pH 9 solution is used, which causes

greater destruction of the layers, a noticeable decrease

Figure 11: The maximum value of the relative absorbance

(up) and the peak wavelength (down) versus pH for the

consecutive measurements of the pH solutions for

(PAH/BY)

6

(APTMS/SiO

2

)

2

on the glass slide. The sample

was cured at 120°C for 4 hours (The sample designated

GS08).

takes place in the absorbance from the first to the

second measurement. In addition to the absorbance,

in all the samples studied the wavelength has not

stayed stable during consecutive measurements and a

small change of around 0 to 2 nm in the peak

wavelength was observed; although with increasing

the number of bilayers the amount of this change is

reduced. Covering the sensitive thin film with a

couple of layers of silica nanoparticles leads to a

coating which creates such a stable film that the

wavelength continues to remain constant for a certain

known pH, while the absorbance decreases

irregularly during the two cycles of measurement, as

shown in Figure 5. Referring to Figure 6, the duration

and the temperature of thermal treatment used did not

have any significant effect on the stability of the film

as the values of the peak wavelengths for the first and

the second measurements for both samples used,

designated GS04 and GS05, were roughly the same.

However, exposing the samples to UV light did not

modify the molecular bonds. As Figure 7 shows there

is not a regular change in the peak wavelength but a

drastic decline is seen in both the absorbance and the

peak wavelength values compared to previous

experiments and also a dramatic absorbance

reduction was observed in the first measurement.

Figure 12: The maximum value of the relative absorbance

(up) and the peak wavelength (down) versus pH for the

consecutive measurements of the pH solutions for

(PAH/BY)

6

(APTMS/SiO

2

)

2

on the glass slide. The sample

was cured at 120°C for 4 hours and examined after a week

(The sample designated GS09).

EnhancedStabilityandRe-usabilityoftheOpticalSensorforpHMonitoringUsingaLayer-by-layerDepositionTechnique

163

This means that by applying UV irritation, an increase

in the strength of the inter-molecular bonds occurs

temporarily.

However, these inter-molecular forces are loss after a

few times of dipping the sensor slide into the buffer

solutions. As a result, the molecules of BY start to

leach out from the sensitive thin film and this causes

a steep decrease in absorbance and a very undesirable

situation for a sensor system.

Adding silica nanoparticles to BY solutions shifts the

absorbance spectra to the lower peak wavelength

values, as shown in Figure 8. It can be seen in this

figure that the absorbance has increased significantly

compared to that of the other samples; however, the

values of both the absorbance and the peak

wavelength in the second measurement become close

to the values seen from the previous tests. Looking

more closely, it can be said that the higher values of

maximum absorbance in the first measurement imply

a larger number of molecules of brilliant yellow in the

deposited layers. In other words, the SiO

2

-PAH

bilayers can protect the BY from significant damage,

but not for a long time.

When the PAH was replaced by APTMS in the

capping layers, the results showed that the peak

Figure 13: The maximum value of the relative absorbance

(up) and the peak wavelength (down) versus pH for the

consecutive measurements of the pH solutions for

(PAH/BY)

6

APTMS on the glass slide. The sample was

cured at 120°C for 4 hours (The sample designated GS10).

wavelength for each pH solution used demonstrated

almost same values as shown in Figure 12. Table

1compares the peak wavelengths of three slides

(designated GS04, GS08 and GS09) for two

successive measurements over the range from pH 6 to

pH 9 and then from 9 to 6. It is noticeable that the

APTMS does not cause any significant changes to the

peak wavelengths, compared to the use of PAH and

the three tests carried out exhibited the same peak

wavelengths, in spite of the difference in the peak

intensity. The most striking result of this series of

experiments is the remarkable reduction of the

degradation of the probes and thus the improvement

that would be seen to their shelf-life, as well as their

re-usability, which are key considerations for the use

of this type of coating in an industrial sensor system.

Figure 13 shows that when the sensitive film is coated

with a layer of APTMS, the peak wavelength for each

pH value changes during successive measurements

and also there is not a regular shift with different

times of measurements. This therefore implies that

the stability of the measured wavelength cannot be

maintained because of the polycation properties.

Moreover, the influence of SiO

2

is more effective in

creating a stable sensor than does the polycation.

However, the cross-comparison of the two sensor

samples (designated as GS03 (without APTMS) and

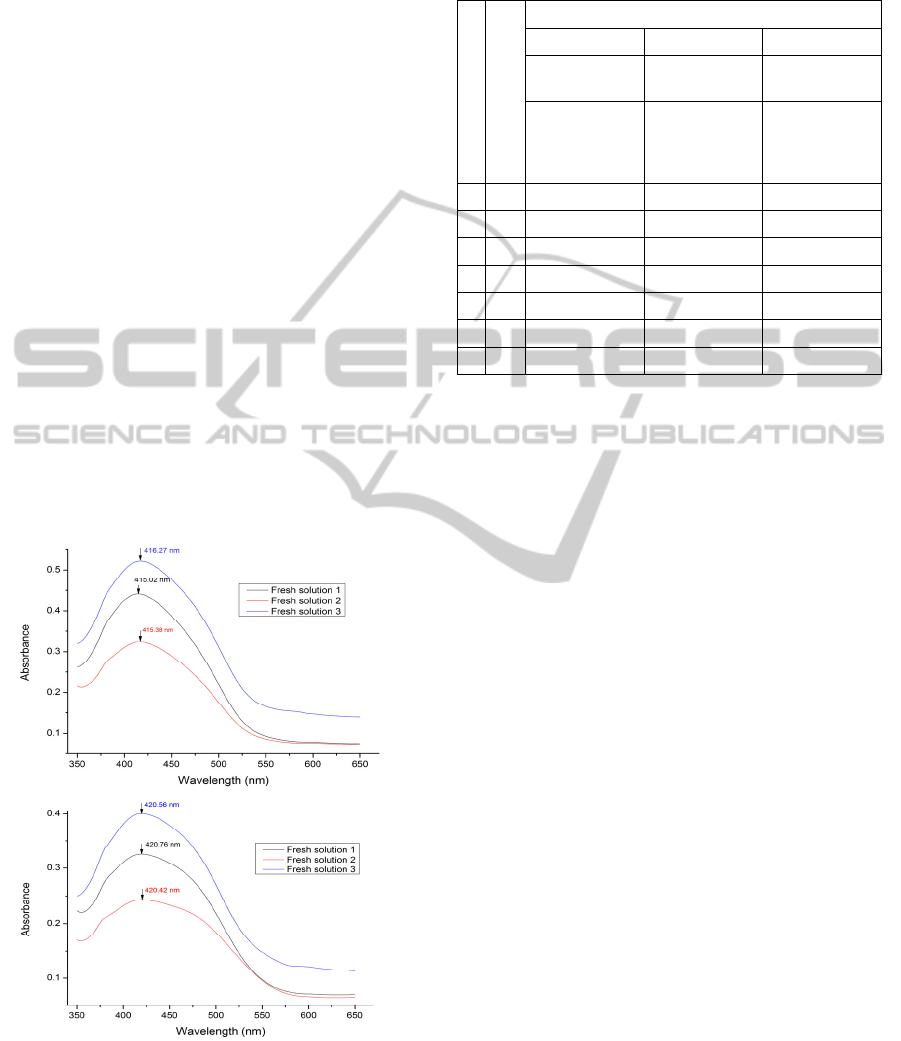

Figure 14: The spectra for the coated glass slides with

(PAH/BY)

6

dipped into the fresh buffer solution for three

times and each time for 60 minutes. Up: pH 6 (The sample

designated GS11), Down: pH 8 (The sample is designated

GS12). The samples were cured at 120°C for 4 hours.

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

164

GS10 (with a layer of APTMS)) and shown in Figure

4 and Figure 13 confirms that the effect of APTMS

on stability cannot be ignored. Indeed, as Table 1

shows, there is no significant difference in the

stability observed between the situations where two

capping layers of (PAH/SiO

2

) and (APTMS/SiO

2

) are

applied. This may arise because of the similarity

between the functional groups (amine groups) in both

the PAH and the APTMS and thus the same

interaction occurring between the polyanion and the

polycation species.

In addition, a comparison of the last two columns of

Table 1 shows that storing the samples for a week has

had a negligible effect on the peak wavelength values.

Applying these capping layers not only improved the

sensor shelf-life but also enhances the re-usability of

the sensor, as can be seen when sensors designated

GS11 and GS12 are compared to GS13 and GS14, as

illustrated in Figure 14 and Figure 15, respectively.

Figure 14 shows a result which implies that destroying

the deposited layers after 60 minutes exposure to the

buffer solution results in the peak wavelength staying

constant for those samples covered with two layers of

APTMS/SiO

2

, even after immersion on two separate

occasions in the buffer solutions, for periods of 60

minutes in each case.

Figure 15: The spectra for the coated glass slides with

(PAH/BY)

6

(APTMS/SiO

2

)

2

dipped into the fresh buffer

solution for three times and each time for 60 minutes. Up:

pH 6 (The sample is designated GS13), Down: pH 8 (The

sample is designated GS14). The samples were cured at

120°C for 4 hours.

Table 1: The peak wavelength for two times consecutive

measurements for the glass slides, designated GS04, GS08

and GS09 in pH solutions from 6 to 9 and then from 9 to 6.

p

H

Measurement

Peak wavelength (nm)

GS04 GS08 GS09

(PAH/BY)

6

(PA

H/SiO

2

)

2

(PAH/BY)

6

(AP

TMS/SiO

2

)

2

(PAH/BY)

6

(AP

TMS/SiO

2

)

2

Error (%)

Error (%)

Error (%)

6

1

S

t

415.26 - 415.10 - 415.18 -

7

1

S

t

417.24 - 417.26 - 417.36 -

8

1

S

t

423.19 - 423.4 - 421.92 -

9

1

S

t

468.25 - 461.5 - 463.12 -

8

2

nd

423.09 -0.02 422.9 -0.1 421.17 -0.2

7

2

nd

417.45 0.05 417.06 -0.08 417.06 -0.07

6

2

nd

415.75 0.1 415.75 0.1 415.18 0

4 CONCLUSIONS

In this study, the stability and the deterioration of

wavelength-dependent optical sensor devices to pH

changes using techniques to build up a series of

nanolayer coatings was investigated and the results

reported.

The stability of the pH sensors thus fabricated was

studied using different pH buffer solutions. A variety

of techniques was proposed and investigated to

improve the stability of the film and to avoid

progressive destruction of the indicator layer. One

technique explored extensively was to build up

capping bilayers using different materials i.e. silica

nanoparticles as the polyanion and PAH or APTMS

as the polycation. Another approach investigated was

to apply thermal treatment after the layer building

process and an alternative method considered was

applying UV light irradiation.

The results of the experiments carried out,

including covering the sensitive thin film with two

layers of (APTMS/silica) nanoparticles was shown to

improve the stability of the sensor (indicated by the

stability of the peak wavelength) and also to enhances

the stability and potential shelf life of the sample,

when the nanolayers are deposited on the glass slide

substrates. The most striking result is that the peak

wavelength continues to remain constant for a

particular pH while the layers were affected during

repeated measurements over three cycles.

The durability of the sensors thus created makes

the probe a suitable wavelength-dependent

EnhancedStabilityandRe-usabilityoftheOpticalSensorforpHMonitoringUsingaLayer-by-layerDepositionTechnique

165

measurement device which is well suited to use as a

high resolution pH sensor. To do so, the layers

described can be coated directly on optical fibres of

various diameters or coated glass substrates can be

attached to the distal end of the fibre probes created.

In that way compact optical fibre sensors can be

created for a range of applications and as the work has

shown, stored for some time before use.

ACKNOWLEDGMENTS

This work was supported by Islamic Azad University-

South Tehran Branch and City University London.

REFERENCES

Ai, J., Jones, S. A. and Lvov, Y. M. 2003. Biomedical

Applications of Electrostatic Layer-By-Layer Nano-

Assembly of Polymers, Enzymes, and Nanoparticles.

Cell Biochemistry and Biophysics, 39, 23-43.

Bertrand, P., Jonas, A., Laschewsky, A. and Legras, R.

2000. Ultrathin Polymer Coatings by Complexation of

Polyelectrolytes at Interfaces: Suitable Materials,

Structure and Properties. Macromolecular Rapid

Communications, 21, 319-348.

Cassagneau, T., Mallouk, T. E. and Fendler, J. H. 1998.

Layer-by-layer Assembly of Thin Film Zener Diodes

from Conducting Polymers and Cdse Nanoparticles.

Journal Of The American Chemical Society, 120, 7848-

7859.

De Villiers, M. M., Otto, D. P., Strydom, S. J. and Lvov, Y.

M. 2011. Introduction to Nanocoatings Produced by

Layer-by-layer (Lbl) Self-Assembly. Advanced Drug

Delivery Reviews, 63, 701-715.

Decher, G., Hong, J. D. and Schmitt, J. 1992. Buildup Of

Ultra Thin Multi Layer Films By A Self Assembly

Process: Ii. Consecutively Alternating Adsorption Of

Anionic And Cationic Poly Electrolytes On Charged

Surfaces. Thin Solid Films, 831, 210-211.

Decher, G., Lvov, Y. and Schmitt, J. 1994. Proof Of

Multilayer Structural Organization In Self-Assembled

Polycation-Polyanion Molecular Films. Thin Solid

Films, 244, 772-777.

Decher, G. and Schlenoff, J. B. 2002. Multilayer Thin

Films, Wiley-Vch Verlag Gmbh and Co.

Dubas, S. T., Kumlangdudsana, P. and Potiyaraj, P. 2006.

Layer-by-layer Deposition of Antimicrobial Silver

Nanoparticles on Textile Fibers. Colloids and Surfaces

A: Physicochemical and Engineering Aspects, 289,

105-109.

Egawa, Y., Hayashida, R. and Anzai, J.-I. 2007. Covalently

Cross-Linked Multilayer Thin Films Composed of

Diazoresin And Brilliant Yellow for an Optical Ph

Sensor Polymer, 48, 1455-1458.

Ichinose, I., Muzuki, S., Ohno, S., Shiraishi, H. and

Kunitake, T. 1999. Preparation of Cross-Linked

Ultrathin Films Based on Layer-by-layer Assembly of

Polymers. Polymer Journal, 31, 1065-1070.

Johnston, A. P. R., Cortez, C., Angelatos, A. S. and Caruso,

F. 2006. Layer-By-Layer Engineered Capsules and

Their Applications. Current Opinion In Colloid and

Interface Science, 11, 203-209.

Kotov, N. A., Magonov, S. and Tropsha, E. 1998. Layer-

By-Layer Self-Assembly of Alumosilicate−

Polyelectrolyte Composites: Mechanism of

Deposition, Crack Resistance, and Perspectives for

Novel Membrane Materials. Chemistry of Materials,

10, 886-895.

Lee, D. and Cui, T. 2012 A Role of Silica Nanoparticles In

Layer-by-layer Self-Assembled Carbon Nanotube and

In2o3 Nanoparticle Thin-Film Ph Sensors: Tunable

Sensitivity And Linearity. Sensors and Actuators A:

Physical, 188, 203-211.

Li, Q., Quinn, J. F. and Caruso, F. 2005. Nanoporous

Polymer Thin Films Via Polyelectrolyte Templating.

Advanced Materials, 17, 2058-2062.

Liu, Y. and Cui, T. 2007. Ion-Sensitive Field-Effect

Transistor Based Ph Sensors Using Nano Self-

Assembled Polyelectrolyte/Nanoparticle Multilayer

Films. Sensors And Actuators B 123, 148-152.

Llobet, E. 2013. Gas Sensors Using Carbon Nanomaterials:

A Review. Sensors And Actuators B 179, 32- 45.

Nallathambi, G., Ramachandran, T., Rajendran, V. and

Palanivelu, R. 2011. Effect of Silica Nanoparticles and

Btca on Physical Properties of Cotton Fabrics.

Materials Research, 14, 552-559.

Potapov, V. V., Shitikov, E. S., Trutnev, N. S., Gorbach, V.

A. and Portnyagin, N. N. 2011. Influence of Silica

Nanoparticles on the Strength Characteristics of

Cement Samples. Glass Physics And Chemistry, 37, 98-

105.

Prakash, S., Chakrabarty, T., Singh, A. K. and Shahi, V. K.

2013. Polymer Thin Films Embedded With Metal

Nanoparticles For Electrochemical Biosensors

Applications. Biosensors And Bioelectronics, 41, 43-

53.

Putzbach, W. and Ronkainen, N. 2013. Immobilization

Techniques In The Fabrication Of Nanomaterial-Based

Electrochemical Biosensors: A Review. Sensors, 13,

4811-4840.

Rahman, I. A. and Padavettan, V. 2012. Synthesis of Silica

Nanoparticles by Sol-Gel: Size-Dependent Properties,

Surface Modification, and Applications In Silica-

Polymer Nanocomposites—A Review. Journal of

Nanomaterials, 2012, 1-15.

Raoufi, N., Surre, F., Rajarajan, M., Sun, T. and Grattan, K.

2013. Fibre Optic Ph Sensor Using Optimized Layer-

By-Layer Coating Approach Sensors Journal, Ieee In

Press.

Raoufi, N., Surre, F., Sun, T., Grattan, K. T. V. and

Rajarajan, M. Improvement of Optical Properties of Ph-

Sensitive Nanolayers Coating Deposited Using Layer-

by-layer Technique. Sensors, 2012 Ieee, 28-31 Oct.

2012 2012a. 1-4.

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

166

Raoufi, N., Surre, F., Sun, T., Rajarajan, M. and Grattan, K.

T. V. 2012b. Wavelength Dependent Ph Optical Sensor

Using The Layer-By-Layer Technique. Sensors And

Actuators B: Chemical, 169, 374-381.

Saeki, D., Imanishi, M., Ohmukai, Y., Maruyama, T. and

Matsuyama, H. 2013. Stabilization Of Layer-By-Layer

Assembled Nanofiltration Membranes By Crosslinking

Via Amide Bond Formation And Siloxane Bond

Formation. Journal Of Membrane Science, 447, 128-

133.

Sen, A. K., Mukherjee, B., Bhattacharyya, A. S., De, P. P.

and Bhowmick, A. K. 1992. Kinetics Of Silane

Grafting And Moisture Crosslinking Of Polyethylene

And Ethylene Propylene Rubber. Journal of Applied

Polymer Science, 44, 1153-1164.

Sharma, R. K., Chan, P. C. H., Tang, Z., Yan, G., Hsing, I.

M. and Sin, J. K. O. 2001. Sensitive, Selective And

Stable Tin Dioxide Thin-Films For Carbon Monoxide

And Hydrogen Sensing In Integrated Gas Sensor Array

Applications. Sensors And Actuators B: Chemical, 72,

160-166.

Shimazaki, Y., Nakamura, R., Ito, S. and Yamamoto, M.

2001. Molecular Weight Dependence of Alternate

Adsorption Through Charge-Transfer Interaction.

Langmuir, 17, 953-956.

Singh, R., Goel, T. C. and Chandra, S. 2008. Rf Magnetron

Sputtered La3+-Modified Pzt Thin Films: Perovskite

Phase Stabilization And Properties. Materials

Chemistry And Physics, 110, 120-127.

Su, Y.-L. and Li, C. 2008. Stable Multilayer Thin Films

Composed Of Gold Nanoparticles And Lysozyme.

Applied Surface Science, 254, 2003-2008.

Tang, Z., Wang, Y. and Kotov, N. A. 2002. Semiconductor

Nanoparticles On Solid Substrates: Film Structure,

Intermolecular Interactions, And Polyelectrolyte

Effects. Langmuir, 18, 7035-7040.

Villar, I. D., Matias, I. R. and Arregui, F. J. 2008. Fiber-

Optic Chemical Nanosensors By Electrostatic

Molecular Self-Assembly. Current Analytical

Chemistry, 4, 341-355.

Villar, I. D., Matías, I. R., Arregui, F. J. and Claus, R. O.

2005. Esa-Based In Fiber Nanocavity For Hydrogen

Peroxide Detection. Ieee Transactions On

Nanotechnology, 4, 187-193.

Wang, D., Shakeel, H., Lovette, J., Rice, G. W., Heflin, J.

R. and Agah, M. 2013. Highly Stable Surface

Functionalization Of Microgas Chromatography

Columns Using Layer-By-Layer Self-Assembly Of

Silica Nanoparticles. Analytical Chemistry, 85, 8135-

8141.

Yamada, H., Imoto, T., Fujita, K., Okazaki, K. and

Motomura, M. 1981. Selective Modification Of

Aspartic Acid-101 In Lysozyme By Carbodiimide

Reaction. Biochemistry, 20, 4836-4842.

EnhancedStabilityandRe-usabilityoftheOpticalSensorforpHMonitoringUsingaLayer-by-layerDepositionTechnique

167