Data Fusion Between a 2D Laser Profile Sensor and a Camera

M. Wagner

1

, P. Heß

1

, S. Reitelsh

¨

ofer

2

and J. Franke

2

1

Nuremberg Campus of Technology, Nuremberg Institute of Technology, F

¨

urther Straße 246c, 90429, Nuremberg, Germany

2

Institute for Factory Automation and Production Systems, Friedrich-Alexander-Universit

¨

at Erlangen-N

¨

urnberg, Germany

Keywords:

3D Reconstruction, Calibration, Color Extension, Sensor Data Fusion, Workpiece Scanning.

Abstract:

This paper describes a color extension of a 2D laser profile sensor by extracting the corresponding color from a

camera image. For these purpose, we developed a routine for an extrinsic calibration between the profile sensor

and the camera. Based on the resulting translation and rotation vectors a belonging pixel can be calculated

for each profile point. Consequently, the color for each profile point can be extracted from the image. This

approach is used to extend the geometric data of a robotic based 3D scanning system by color data.

1 INTRODUCTION

The range of applications for industrial robots ex-

tends. Especially small and medium-sized enterprises

focus on small quantities and consequently a high

flexibility. Thus, workpiece related robot program-

ming is used with increasing frequency for typical

robotic tasks, such as handling, processing or inspec-

tion. In most cases, an already existing CAD-model

is used for this purpose, but for some applications the

scanning of individual workpieces can be necessary.

This is a fast way to get an accurate 3D model of the

real workpiece, especially from unknown objects.

Laser scanners are commonly used for the scan-

ning of workpieces. They are very efficient in extract-

ing geometric information, but one main drawback of

laser sensors is their lack of capability in capturing

textures of objects. Thus, common 2D laser profile

sensors do not have color information implied. In

this paper, we present an extension of a common 2D

laser profile sensor with color information by extract-

ing them from a camera image. One possible way to

fuse the data is to detect the laser profile in the image

and fit it to the measured profile, but the visibility of

the laser depends strongly on the color and the sur-

face of the scanned object. In addition, it means a lot

expenditure to fit the profiles. The selected approach

avoids these disadvantages, by fusing the data of the

two sensors through the transformation between the

base coordinate systems. Thereby, the position of the

profile points in the image can be calculated regard-

less of the visibility of the laser.

To find correspondences between the points of the

profile sensor and the pixels of the camera image the

geometric transformation between the sensor frames

needs to be determined by a calibration. First, an in-

trinsic calibration of the used camera is done for this

purpose. The second calibration step is the extrinsic

calibration between the profile sensor and the camera.

Based on the resulting calibration parameters, a cal-

culation of the corresponding pixels can be realized.

Finally, the color is determined from the image.

The subsequent content of this paper is structured

as follows. The related work in the field of extrin-

sic calibrations between a camera and a laser scanner

is presented in the following section. Furthermore,

the approaches for the sensor calibration and the color

extraction are described in detail. The fourth section

deals with the accuracy investigation of the realized

approach. A short conclusion is at the end of the pa-

per.

2 RELATED WORK

The consideration of the related work is separated

in two sections. Initially, a short summary of 3D

workpieces scanning through industrial robot arms is

given. The state of the art in sensor fusion between

laser scanners and cameras follows afterwards.

2.1 Robot-based Workpiece Scanning

The reconstruction of 3D shapes can be done with

a multitude of sensors and approaches. Thus, many

contact or non-contact sensors, such as radiation-,

159

Wagner M., Heß P., Reitelshöfer S. and Franke J..

Data Fusion Between a 2D Laser Profile Sensor and a Camera.

DOI: 10.5220/0005501601590165

In Proceedings of the 12th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2015), pages 159-165

ISBN: 978-989-758-123-6

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

light- or image-based sensors, are on the market–

either they are three-dimensional sensors or they are

one- or two-dimensional sensors moved by hand or by

machine. One flexible machine for doing this motion

is an industrial robot arm. By linking the measure-

ment points with the robot positions, 3D point data

can be derived.

For robotic based workpiece scanning non-contact

sensors are mainly used. Due to the requirement for

a high accuracy and a close range triangulation-based

sensors are preferred. Thus, 2D laser profile sensors

are frequently used for scanning workpieces by mov-

ing the sensor by a robot arm (Larsson and Kjellan-

der, 2006; Borangiu and Dumitrache, 2010; Li et al.,

2011; Shen and Zhu, 2012). These scanning sys-

tems for example are used for a reverse engineering

process, as shown in (Larsson and Kjellander, 2006).

A workpiece scanning for subsequent processing has

been pursued in (Borangiu and Dumitrache, 2010).

Most of the approaches use an additional rotation ta-

ble on which the workpiece is placed to improve the

reachability. In our approach, the system is extended

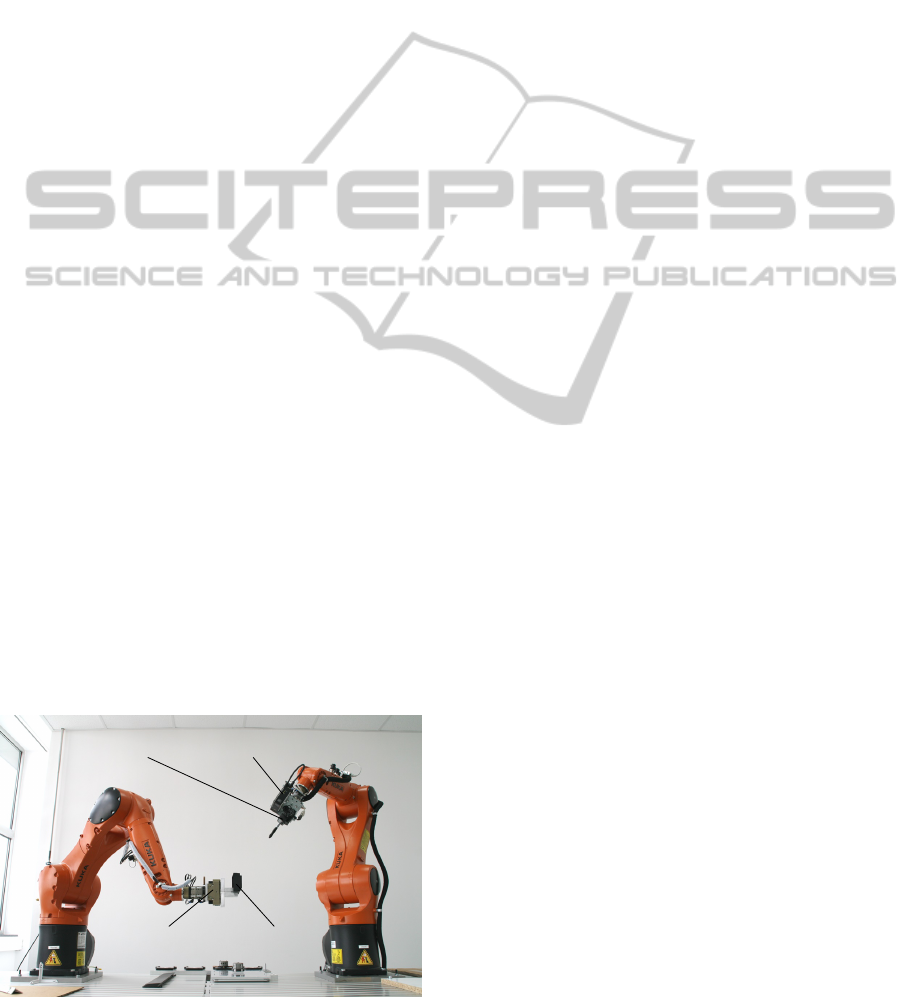

by moving the workpiece with a second robot arm (cf.

Figure 1) to improve the reachability furthermore and

to include the robot-related workpiece position in the

scans for following processing steps.

The realized scans with all of these robotic-based

systems include only the geometric information, what

is sufficient for many applications. No color informa-

tion is included, but for example for object recogni-

tion or realistic model building it can be necessary.

Therefore, they need to be obtained by additional sen-

sors.

2.2 Sensor Fusion

Not for every application a perfect individual sensor

is available. Thus, multiple sensors need to be used

frequently to achieve all of the necessary data. To

combine the data of multiple sensors an extrinsic cal-

Camera Scanner

Gripper Workpiece

Figure 1: Robot set-up for workpiece scanning.

ibration between the sensor coordinate systems must

be done first. Therefore, related reference points visi-

ble in all of the data sets need to be obtained.

Many approaches for the fusion of a camera and a

2D or 3D laser scanner have been realized in the past.

The main application is navigation for mobile robots

(Zhang and Pless, 2004; Mei and Rives, 2006; Scara-

muzza et al., 2007; G. Li et al., 2009; Nunez et al.,

2009) or vehicles (Garcia-Alegre et al., 2011; Osgood

and Huang, 2013). Object recognition–also for mo-

bile robots (Klimentjew et al., 2010) or vehicles (Mo-

hottala et al., 2009)–is a frequent application, too. In

addition, other applications, for example model build-

ing or medical applications, are considered (Cobzas

et al., 2002).

Some of the realized extrinsic calibration methods

use manually selected reference points, as shown in

(Cobzas et al., 2002) or in (Scaramuzza et al., 2007).

More intuitive approaches use calibration objects for

an automatic reference point detection. Approaches

with known and with unknown objects are realized.

Most of them use a calibration plane to detect refer-

ences. Thus, for example in (Zhang and Pless, 2004)

and in (Mohottala et al., 2009) a checkerboard in dif-

ferent poses has been used. The approach realized in

(G. Li et al., 2009) uses the edges of a plane and in

(Nunez et al., 2009) only the corners of a rectangu-

lar object, such as a pattern, are used. Another way

is the use of patterns with geometrical extensions, as

shown in (Klimentjew et al., 2010). In this approach,

a typically checkered pattern is extended with a 3D

structure to get reference points in both data sets. The

corners or walls of a room can be used as well (Mei

and Rives, 2006). Some approaches use specific sin-

gle objects as reference points. Thus, in (Osgood and

Huang, 2013) small white discs are placed in the laser

plane and detected through the reflection in the cam-

era image, for example. In (Navarrete et al., 2013)

small catadioptrics are used and the laser intensity in-

formation is converted to a 2D image which is fused

with the camera image.

To the best of our knowledge, no approach for a

color extension of a short ranged 2D laser profile sen-

sor has been realized, yet.

3 APPROACH

The color extension of the robotic-based 3D scanning

system is based on the data fusion between the geo-

metric position data from the profile sensor and the

belonging color data from the camera image. This

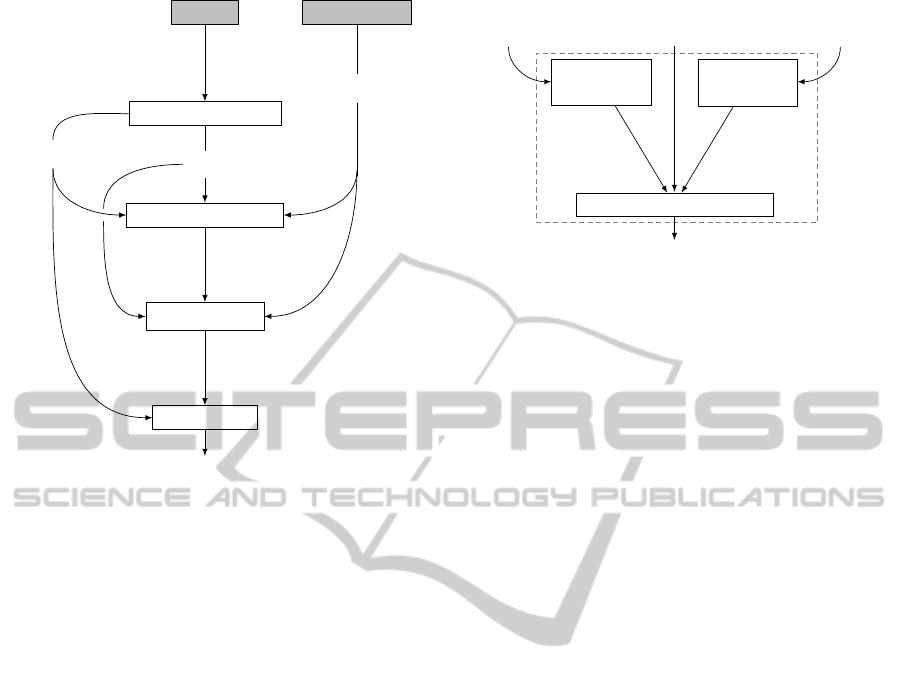

process is done in four main steps (cf. Figure 2).

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

160

Camera

Profile sensor

Intrinsic calibration

Extrinsic calibration

Calculat pixels

Extract color

Color values

Rectified image

Profile points

A, k

Raw image

r, t

Pixels

Figure 2: Color extension routine.

First, the used sensors need to be calibrated intrin-

sic to ensure the accuracy of the measurements. The

used profile sensor is already calibrated by the manu-

facturer. Thus, only the camera needs to be calibrated

intrinsic to achieve a rectified image. The resulting

intrinsic camera parameters and the rectified image is

used for the following extrinsic calibration between

the camera and the profile sensor by getting matched

image and profile points. The extrinsic calibration

results the transformation between the two sensors.

With the intrinsic and the extrinsic parameters a be-

longing pixel can be calculated for each profile point.

In the last step, for each profile point a color is ex-

tracted from the rectified image.

The main steps of the color extension routine are

described in the following subsections in detail.

3.1 Intrinsic Calibration

Before the fusion of the two sensors data, each of

the sensors need to be calibrated intrinsic. As al-

ready mentioned before, the used 2D laser profile sen-

sor is already calibrated intrinsic by the manufacturer.

Therefore, this step does not need to be considered.

However, this does not apply for the camera.

As already shown by (Tan et al., 1995), classic

camera calibration methods use complicated calibra-

tion objects, with known 3D coordinates. Newer cali-

bration methods either seek calibration cues from the

scene or only require simple calibration objects. A

common method is the calibration by a planar pat-

Rectified

images

Profile

points

A, k

r, t

Image

processing

Profile

processing

Transformation calculation

Image

reference

points

Profile

reference

points

Figure 3: Extrinsic calibration routine.

tern published in (Zhang, 2000). By moving either

the camera or the pattern and detecting the pattern in

the image in multiple poses, the intrinsic parameters

can be calculated. They consist of the intrinsic matrix

A =

f

x

γ c

x

0 f

y

c

y

0 0 1

and the distortion vector k = (k

1

k

2

p

1

p

2

)

T

. We use

this approach with a typical 9 × 6 chessboard. The

implementation is based on the open source library

OpenCV.

3.2 Extrinsic Calibration

The realized extrinsic calibration routine is shown in

Figure 3. Before calculating the transformation be-

tween the sensors, each sensor data is processed to

achieve the reference points. Afterwards, the trans-

lation vector t = (t

x

t

y

t

z

)

T

and the rotation vector

r = (θ

x

θ

y

θ

z

)

T

are calculated from the reference

points and the intrinsic camera parameters.

In our approach, any planar calibration object fit-

ting in the measurement range of the profile sensor is

usable. The exact color and size of the object is not

important. As reference points the corner points of

the profile and the end points of the laser line inside

of the image are detected.

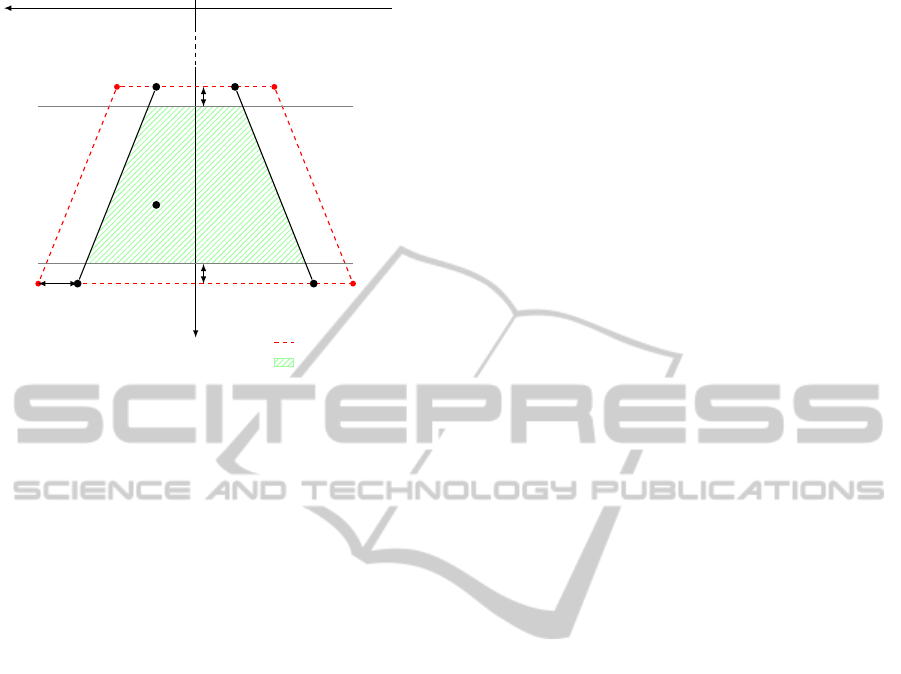

3.2.1 Profile Processing

Starting from the fact that only the calibration ob-

ject is in the range of the profile sensor, we achieve

the profile reference points by taking the two profile

points with the smallest and the largest x-value.

To make sure that all reference points are mea-

sured correctly, the trapezium shaped measuring

range is limited as follows (cf. Figure 4). First, the

values are limited to a z-range, that is a little bit (e.g.

DataFusionBetweena2DLaserProfileSensorandaCamera

161

x

z

P

P

min

P

N

min

P

P

max

P

N

max

z

min

z

max

P

n

Sensor range

Measurement range

∆z

∆z

∆x

Figure 4: Range limitation for the profile sensor.

five times the z-resolution) smaller than the z-range of

the sensor, to ensure that no reference points close to

the boundary of the sensor-range are taken. Thus, the

z-range borders are shifted about ∆z and only points

inside of these borders are used furthermore. In the

next step, the x-value of the reference points is con-

trolled by calculating the two scalar products:

d

P

= (P

P

max

− P

P

min

) ·(P

n

− P

P

max

) (1)

d

N

= (P

N

min

− P

N

max

) · (P

n

− P

N

min

) (2)

Thereby, the sensor range is reduced on both sides

about ∆x. If d

P

> 0 and d

N

> 0, the reference point

P

n

is inside of the limited range and can be used for

calibration. A calibration object close to or even out-

side of the profile sensor measurement range results

negative values. Thus, these points are not saved for

calibration.

3.2.2 Image Processing

The laser appears in a visible line on the calibration

object. The visibility of the laser depends on the mate-

rial and the surface of the scanned object as well as the

viewing angle. Therefore, we reduce the camera im-

age to a binary image with values that are in range of

a color spectrum matching to the laser line color. The

spectrum is selected individually by choosing ranges

either for the HSV (hue-saturation-value) or the RGB

(Red-Green-Blue) parameters. Furthermore, an ero-

sion and a dilation is done on the binary image to

clearly stand out the laser line. In the next step, a line

fitting procedure using least squares method is done,

resulting the linear equation. The two end points of

the line are achieved by determining the bounding box

and calculating the points of intersection between the

box and the linear equation.

To ensure that all image reference points are col-

lected correctly, the image frame is also reduced by a

small stripe. Thus, only points inside of the reduced

frame are accepted. If the calibration object is posi-

tioned close or even outside of the image frame, no

reference points are saved.

3.2.3 Transformation Calculation

The transformation between the profile sensor and

the camera consists of translations in the three di-

mensions and rotations around the three axis, repre-

sented by a translation vector t and a rotation vec-

tor r. The calculation of the transformation between

the two sensor coordinate systems is done by an it-

erative method based on Levenberg-Marquardt opti-

mization. This method has already successfully been

used in several previous approaches for sensor fusion

(Cobzas et al., 2002; Zhang and Pless, 2004; Scara-

muzza et al., 2007; Mohottala et al., 2009). In order

to solve the established equation systems N ≥ 3 refer-

ence points are necessary. Since we have two points

per measurement, at least two measurements are re-

quired. From the N corresponding reference points in

the profile P

Re f

n

and in the image I

Re f

n

as well as the

intrinsic camera parameters A and k (cf. Section 3.1)

the translation t and the rotation r finally result.

3.3 Pixel Calculation

Both used sensors only offer two-dimensional infor-

mation. Thus, the profile points P

n

= (p

x

0 p

z

)

T

and

the image points I

n

= (i

x

i

y

0)

T

contain only two vari-

ables. The relationship between the data points can be

described by the following equation:

I

n

(i

x

, i

y

) = R · P

n

(p

x

, p

z

) + t (3)

Using this geometric relation, a belonging pixel

for every profile point could be calculated. The ro-

tation matrix R can be derived from rotation r de-

termined through the extrinsic calibration (cf. Sec-

tion 3.2) as well as the translation t. The resulting

pixel corresponds the projection of the profile point

onto the image plane.

3.4 Color Extraction

Several approaches are possible for the extraction of

the color values from the camera image. The most

obvious one is the extraction directly from the calcu-

lated pixels. However, with visible laser sensors the

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

162

object is discolored by the laser in these areas. Thus,

the laser needs to be turned of temporary, for exam-

ple through pulsation. But this takes time, which is

disadvantageous especially in a full 3D scan. This

drawback can be avoided by coloring the entire point

cloud after the scan. Therefore, multiple images could

be necessary to color all sides of the point cloud. But

in this case, the color information is not already us-

able during the individual profile shots. Our third ap-

proach avoids both disadvantages by approximately

determining the color values from neighboring pix-

els. For this purpose, for each profile point two neigh-

bor points N

n

= (p

x

± δ p

z

)

T

with a distance δ in y-

direction are used to calculate the corresponding pix-

els by:

I

n

(i

x

, i

y

) = R · N

n

(p

x

, ±δ, p

z

) + t (4)

The offset must be chosen large enough that the

laser is not hit anymore. The corresponding color

value is then averaged from the color values of the two

nearby pixels. Thus, the color values can be quickly

obtained on-the-fly, with the disadvantage of an inac-

curacy.

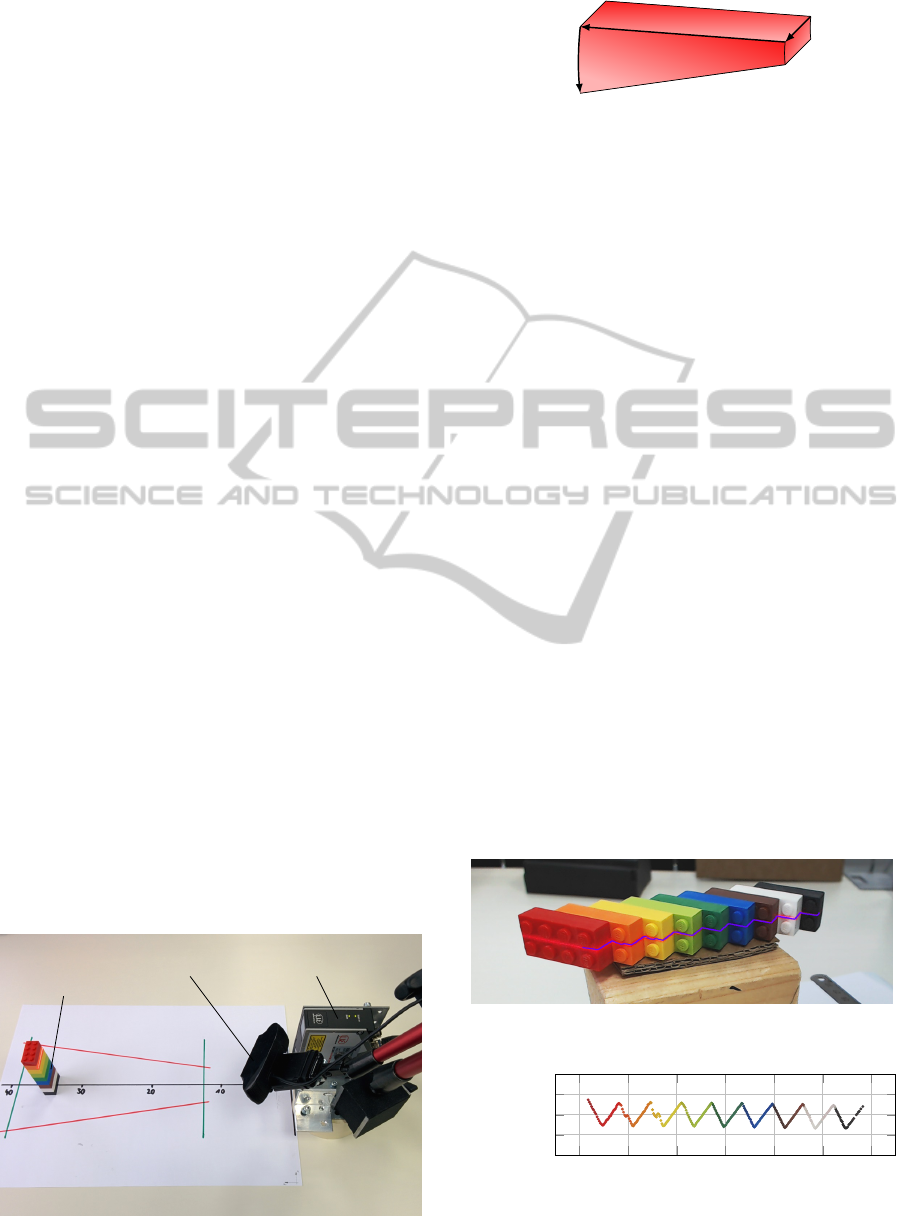

4 EXPERIMENTS AND RESULTS

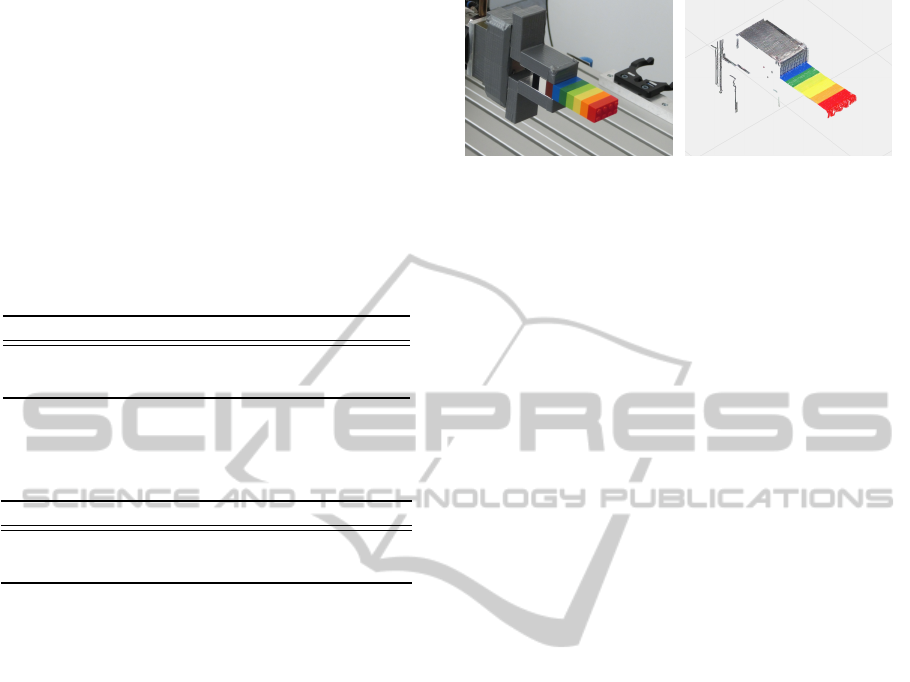

As mentioned in Section 3.2, any planar calibra-

tion object fitting in the measurement range of the

profile sensor is usable for our approach. As ex-

ample we use Lego bricks with different colors

in order to investigate the influence of the color

(cf. Figure 5). The used camera is a Logitech

920c with a resolution of 1920 × 1080 and a frame

rate of 30 fps. The used laser profile sensor is

a Micro-Epsilon scanCONTROL 2600-100 with a

range from 125.0 mm to 390.0 mm in z-direction.

The x-range of the sensor is between ±28.5 mm and

ScannerCamera

Calibration

object

Figure 5: Experimental set-up for sensor fusion.

H

S

V

Figure 6: Exemplar color spectrum (H : 339

◦

− 351

◦

,

S : 29.8 − 87.2 %, V : 98.0 − 100.0 %) for line detection.

±71.0 mm. Inside of this range the sensor is mea-

suring 640 points per profile with a z-resolution of

12 µm. Through the adjustable shutter time the sen-

sor can be set well to different surfaces.

For the individual color of the calibration object

a specific color spectrum is selected through a color

dialog or through a pipette, by clicking on to image

pixels. Thus, one of the lightest pixels and one of the

darkest pixels of the laser line is selected to achieve a

good spectrum. An example spectrum is depicted in

Figure 6.

To illustrate the correctness of the calibration,

stepped Lego bricks with different colors along the

profile are used, as shown in Figure 7. The profile

point based calculated pixels are colored purple in-

side of this image. It becomes apparent, that the cal-

culated points are close to the actual laser line. Based

on the calculated pixels the color information is ex-

tracted from the camera image and the corresponding

color profile is visualized in Figure 8, showing the

color changes at step transitions.

In order to make a concrete statement about the ac-

curacy of the calibration, the belonging pixel for each

profile reference point and furthermore the distance

between the pixel and the corresponding end of the

detected line is calculated. From the sum of the dis-

tances of all used reference points the average pixel

error is calculated.

Twenty calibrations with two experimental set-ups

Figure 7: Multi-color example for color extraction.

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

−60

−40 −20 0 20 40

60

250

255

260

265

270

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

x (mm)

z (mm)

Figure 8: Resluting colored profile for Multi-color example.

DataFusionBetweena2DLaserProfileSensorandaCamera

163

have been performed. The first set-up is shown in Fig-

ure 5 and in the second set-up the camera is mounted

as close as possible to the profile sensor. Thereby, ei-

ther two, five or ten object positions scattered inside

of the reference areas were used. However, an in-

creased number of reference points has no significant

influence on the results. Thus, a number of N = 4 ref-

erence points is sufficient. The resulting mean values

and the standard deviation values for each parameter

are shown in Table 1 and 2.

Table 1: Parameter estimation for first experimental

set-up.

t (mm) σ (mm) r (deg) σ (deg) Error (pixel) σ (pixel)

72.3995 0.8716 34.4061 0.1101

80.1886 0.3726 -22.9854 0.2741 0.9349 0.1891

20.5744 0.4808 -3.4034 0.1325

Table 2: Parameter estimation for second experimen-

tal set-up.

t (mm) σ (mm) r (deg) σ (deg) Error (pixel) σ (pixel)

1.9726 0.0445 -9.2074 0.0310

-32.7163 0.1503 -5.9926 0.0370 0.8696 0.0721

-18.5722 0.3498 -89.2548 0.0621

The realized approach achieves stable solutions

and consequently a good repeatability. The validation

shows low standard deviation values for the transfor-

mations (σ < 1mm, σ < 0.3

◦

). A good absolute accu-

racy is also achieved with average pixel errors below

the resolution of the camera (1 pixel). This error oc-

curs partially by rounding errors that can hardly be

avoided.

The calibrated sensors are used for workpiece

scanning with two robot arms (cf. Section 2.1). Fig-

ure 9 shows a partial reconstruction of some Lego

bricks held up by a gripper. Due to the contained color

information, it can be clearly distinguished between

the individual bricks and the gripper.

5 CONCLUSIONS

In this paper, a color extension for a 2D laser profile

sensor by getting the color information from a cam-

era is presented. For this purpose, a sensor fusion be-

tween the two sensors has been realized. Therefore,

a flexible calibration routine has been created. Indefi-

nite planar calibration objects are usable with this ap-

proach regardless of their color. The accuracy of the

approach is confirmed through experiments. A pixel

error close to the resolution of the camera has been

achieved.

(a) Scene (b) Point cloud

Figure 9: Example for a colored reconstruction.

So far, the coloring needs approximately 4 ms per

profile point. Future work will be focused on the time

optimization of the process. In addition, an improve-

ment of the reference point distribution, by splitting

the profile sensor measurement range in sections and

a partial restriction on one reference point per section,

is prospected.

REFERENCES

Borangiu, T. and Dumitrache, A. (2010). Robot arms with

3d vision capabilities. In Advances in Robot Manipu-

lator, Vukovar, Croatia. InTech.

Cobzas, D., Zhang, H., and Jagersand, M. (2002). A

comparative analysis of geometric and image-based

volumetric and intensity data registration algorithms.

In Proceedings of the International Conference on

Robotics and Automation, volume 3, Washington, DC,

USA. IEEE.

G. Li, L. D., Pan, L., and Henghai, F. (2009). The cali-

bration algorithm of a 3d color measurement system

based on the line feature.

Garcia-Alegre, M. C., Martin, D., Guinea, D. M., and

Guinea, D. (2011). Real-time fusion of visual images

and laser data images for safe navigation in outdoor

environments. In Sensor Fusion - Foundation and Ap-

plications, Vukovar, Croatia. InTech.

Klimentjew, D., Hendrich, N., and Zhang, J. (2010). Multi

sensor fusion of camera and 3d laser range finder for

object recognition. In Proceedings of the Conference

on Multisensor Fusion and Integration for Intelligent

Systems, Salt Lake City, UT, USA. IEEE.

Larsson, S. and Kjellander, J. (2006). Motion control and

data capturing for laser scanning with an industrial

robot. In Robotics and Autonomous Systems, vol-

ume 54, Amsterdam, Netherlands. Elsevier B.V.

Li, J., Chen, M., Jin, X., Xuebi, C., Yu, D., Z.Dai, Ou, Z.,

and Tang, Q. (2011). Calibration of a multiple axes 3-

d laser scanning system consisting of robot, portable

laser scanner and turntable. In Optik - International

Journal for Light and Electron Optics, volume 122,

Amsterdam, Netherlands. Elsevier B.V.

Mei, C. and Rives, P. (2006). Calibration between a cen-

tral catadioptric camera and a laser range finder for

robotic applications. In Proceedings of the Interna-

tional Conference on Robotics and Automation, Or-

lando, FL, USA. IEEE.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

164

Mohottala, S., Ono, S., M.Kagesawa, and Ikeuchi, K.

(2009). Fusion of a camera and a laser range sensor for

vehicle recognition. In Proceedings of the Computer

Society Conference on Computer Vision and Pattern

Recognition Workshops, Miami, FL, USA. IEEE.

Navarrete, J., Viejo, D., and Cazorla, M. (2013). Portable

3d laser-camera calibration system with color fusion

for slam. volume 3, Taipei, Taiwan. AUSMT.

Nunez, P., Drews, P., Rocha, R., and Dias, J. (2009). Data

fusion calibration for a 3d laser range finder and a

camera using inertial data. In Proceedings of the 4th

European Conference on Mobile Robots, Barcelona,

Spain. IEEE.

Osgood, T. J. and Huang, Y. (2013). Calibration of laser

scanner and camera fusion system for intelligent vehi-

cles using neldermead optimization. volume 24. IOP

Publishing Ltd.

Scaramuzza, D., Harati, A., and Siegwart, R. (2007). Ex-

trinsic self calibration of a camera and a 3d laser range

finder from natural scenes. In Proceedings of the In-

ternational Conference on Intelligent Robots and Sys-

tems, San Diego, CA, USA. IEEE.

Shen, C. and Zhu, S. (2012). A robotic system for sur-

face measurement via 3d laser scanner. In Proceed-

ings of the 2nd International Conference on Computer

Application and System Modeling, volume 21, Paris,

France. Atlantis Press.

Tan, T. N., Sullivan, G. D., and Baker, K. D. (1995). Recov-

ery of intrinsic and extrinsic camera parameters us-

ing perspective views of rectangles. In Proceedings of

the 1995 British Conference on Machine Vision (Vol.

1), BMVC ’95, pages 177–186, Surrey, UK. BMVA

Press.

Zhang, Q. and Pless, R. (2004). Extrinsic calibration of a

camera and laser range finder (improves camera cal-

ibration). In Proceedings of the International Con-

ference on Intelligent Robots and Systems, volume 3,

Sendai, Japan. IEEE.

Zhang, Z. (2000). A flexible new technique for camera cal-

ibration. IEEE Transactions on Pattern Analysis and

Machine Intelligence, 22(11):1330–1334.

DataFusionBetweena2DLaserProfileSensorandaCamera

165