Numerical Analysis on Water Hammer Characteristics of

Rocket Propellant Filling Pipeline

Xiang Youhuan, Zhang Ping, Zhang Hui and Bai Fengtian

Technical Department, Taiyuan Satellite Launch Center, Taiyuan, China

Keywords: Propellant Filling System, Water Hammer, Flowmeter, Filling Accuracy.

Abstract: In order to investigate the water hammer problem of the filling pipeline during the rocket propellant filling

process of the spaceflight launch site, the simulation calculation model and the real experimental system is

established. It researches the water hammer characteristics of the filling pipeline, and analyses the law of

pressure change when water hammer occurs. The improved schemes are proposed in this paper, and the

simulation calculation and real experiment are carried through for the proposed schemes. It also carries

through data analysis for the simulation and experimental results. The results show that the proposed

scheme can effectively reduce the water hammer effect of the pipeline during the filling process, improve

the rocket propellant filling accuracy and enhance the security and reliability of the system.

1 INTRODUCTION

The rockets propellant filling system is an important

part of the spaceflight launch site. It’s stability

security and reliability is very important for the

success of the spaceflight tasks. Because of risk and

particularity of the propellant work, safety credibility

and precision is the basic requirement for the filling

system (Xiang, 2014).

The filling pipeline is a kind of key assembly of

the rocket propellant filling system, it can provide

routeway for the propellant transporting from the

storehouse horizontal tank to the rocket tank, and it’s

stability could impact the filling accuracy and the

security and reliability of the system. The water

hammer is a water power phenomena in the pipeline

that the water flow rate changed suddenly, leading to

the pressure rise and fall sharply, caused by some

external reasons, such as the valve suddenly open or

close. In the process of rocket propellant filling in the

spaceflight launch site filling system, it often appears

the case that pressure gauges get full range, and it is

far more than the normal working pressure range. It

is a potential hazard.

The water hammer can damage equipment,

reduce the safety and reliability of the system. It also

can cause violent vibration of pipeline, result in

measurement error for the vortex-shedding flowmeter

(Yang, 2004). That will lead to the filling error of

rocket propellant higher and reduce the real filling

precision. Therefore, it requires analysis and research

on water hammer in the filling system, to put forward

effective improvement measures. It is of great

significance for enhancing the propellant filling

precision and ensuring the complete success of rocket

launch.

At present, there are no special studies on water

hammer effect based on the pipeline of rocket

conventional propellant filling system. However, a

lot of research works have been carried out in the

aspects of water hammer in rocket engine system and

some of the other system.

In literature (Yan, 2012), Yan Zheng studies the

water hammer problem of the spacecraft propulsion

system in the processes of priming and shutdown. On

the basic of the established simulation model of the

spacecraft propulsion system, the simulation research

was conducted and the suppression effect of water

hammer for the orifice and bent duct was analyzed.

The result show that the frequency of water hammer

is lower in the process of priming than that in the

process of shutdown, and the peak pressure of water

hammer in the process of shutdown is higher than

that in the process of priming. Both the bend duct and

the orifice can markedly suppress the pressure in the

process of priming, but the suppression effect of

water hammer is weak in the process of shutdown. In

literature (Lin, 2008), Lin Jing-song researches the

fluid transients of the propellant pipes after the liquid

rocket engine shut down, and carries out numerical

337

Youhuan X., Ping Z., Hui Z. and Fengtian B..

Numerical Analysis on Water Hammer Characteristics of Rocket Propellant Filling Pipeline.

DOI: 10.5220/0005505703370343

In Proceedings of the 5th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2015),

pages 337-343

ISBN: 978-989-758-120-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

simulation of water hammer in shutting liquid rocket

engine based o n the method o f characteristic line.

The correctness of the simulation results was

approved by comparison with the experiment data. It

also calculates and analyzes the relationship between

two locations that were in front of the closing valve

and on the end of the pressure measuring pipe when

the length and diameter of the pressure measuring

pipe were changed. In literature (Nie, 2003), Nie

Wan-sheng researches the pressure and the flow

transients characteristic when the liquid rocket engine

system shut down based on the method of finite

difference characteristic line. The water-hammer

phenomenon is analyzed in literature (Liu, 2010)

based on the method of characteristic line, according

to the actual construction of liquid hydrogen filling

system. It proposes a useful method to reduce the

peak pressure of water-hammer based on the analysis

results, and it provides theory foundation for design

liquid hydrogen loading system. However, it does not

take the influence of pipeline accessories such as

filter and flowmeter into account, so the precision is

not high.

The rest part of this paper is organized as follows:

Section 2 analyzes water hammer phenomena of the

filling system. The mathematics model is established

in section 3. The experimental results are analyzed in

section 4. Finally, section 5 makes the conclusions.

2 ANALYSIS OF FILLING

SYSTEM WATER HAMMER

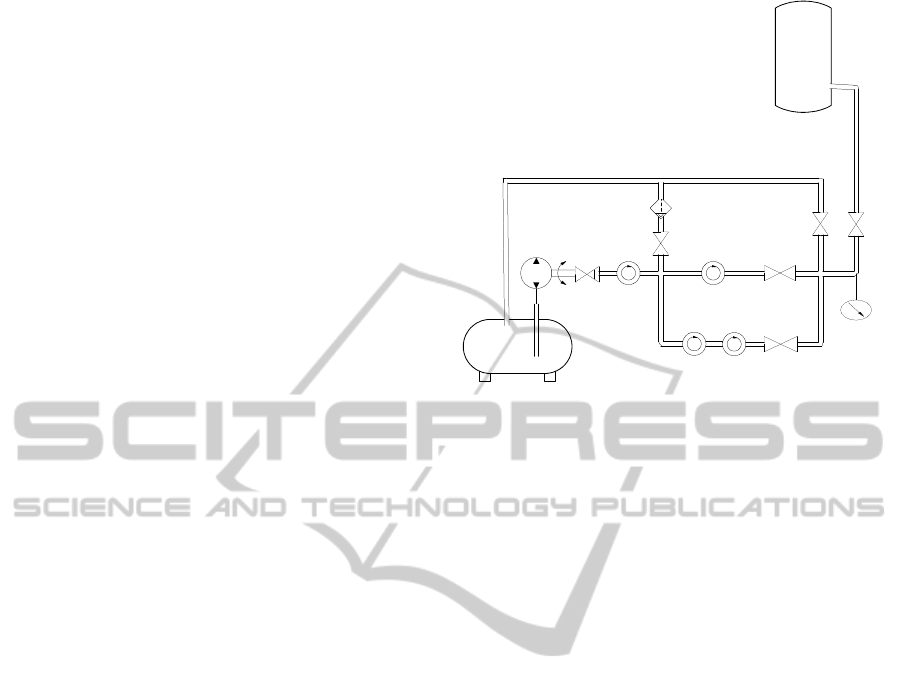

The process diagram of the propellant filling system

is shown in Fig.1. As shown in the Fig, the

equipments such as except the rocket tank are all

located in the pump room of the filling storehouse

and on the same horizontal plane. The rocket tank are

vertically located on the launch pad and on the other

horizontal plane. The height from the 125# valve to

the filling port of the rocket oxidizer tank is 30 meter

or so, and they are connected together through the

filling pipeline. In the process of filling, the state

before interstage conversion is: the frequency of the

pump inverter is 50Hz, the opening of the electric

control valve is 30%, the state of the 134# and 124#

valve is open, and the state of the 125# valve is close.

At the time of interstage conversion, the program

control process is: open the 125# valve, delay 1

second, after that close the 124# and 134# valve. In

the process, the 121# valve has been open, the 122#

valve has been close, the frequency of the pump

inverter has been 50Hz, and the opening of the

electric control valve has been 30%.

Pressure

Gauge

P1

Flowmeter

L1

Pump

Flowmeter

L2

Flowmeter

L3

Flowmeter

L4

125#

124#

Rocket tank

Outlet

134#

Inlet

DT4

121#

122#

Figure 1: Process diagram of the filling system.

From analysis we can know, when open the 125#

valve, the fluid in the vertical pipeline instantly lose

the upward lift force, then it begin to fall under the

action of gravity and achieve maximum quickly. The

instant downward gravity can cause water hammer of

the propellant filling pipeline. When water hammer

occurs, the pipeline nearby 124# valve severe

vibration and engender blare, the valve interface

emits yellow smoke that shows slight leakage occurs

on the interface, and range of the pressure gauge P1

achieves full scale.

From the data recorded in the real filling process,

the pressure of the liquid pipeline is 0.24MPa before

water hammer happening. When water hammer

occurs, the peak pressure of liquid pipeline is more

than 3MPa. It is obvious that great changes have

taken pace for the pressure of liquid pipeline. The

biggest difference is 15 times, and the water hammer

peak pressure is far more than the design pressure. It

can cause the equipment damaged more easily and

increase the probability of the system failure.

3 ESTABLISH MATHEMATICS

MODEL

3.1 Basic Differential Equation of

Water Hammer

The theoretical basic of the basic equation of water

hammer is the law of mechanics and continuous

principle of water flow movement, including motion

equation and continuity equation. It is the basic of the

analysis and calculation of the hydraulic transient,

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

338

containing motion equation and continuity equation

expressed in differential equation. It also reflects

changing rule of water head and flow velocity of

instability flow in the process of hydraulic transient

(Lin, 2007).

The continuous differential equation of water

hammer is as follow:

0sin

2

s

v

g

c

v

s

h

v

t

h

(1)

The motion differential equation of water hammer is

as follow:

0

2

vv

D

f

s

v

v

t

v

s

h

g

(2)

In the above formula, v and h respectively express

the flow velocity and piezometric head when the

water hammer occurred. D, f, g respectively express

the pipe diameter, pipe friction coefficient,

acceleration of gravity. θ is the angle between

pipeline and horizontal plane, c is the water hammer

wave velocity, s is the distance, t is the time.

Because of considering the frictional head loss,

the basic differential equation of water hammer is a

first order quasilinear hyperbolic partial differential

equation, and contains two dependent variables and

two independent variables. It is very difficult to solve

the equations.

3.2 Solve Basic Differential Equation of

Water Hammer by Method of

Characteristic Line

The method of characteristic line firstly changes the

partial differential equation into ordinary differential

equation along the characteristic line, and then

changes into first order finite difference equation for

obtaining the approximate solution. It can solve the

water hammer problem of complicated piping system

and boundary conditions, and the calculation

accuracy is high. (Liu, 2005), (Wu, 2002)

The parameter uses x instead of s in formula 1

and formula 2, and this two formulas are carried

through linear combination with arbitrary unknown

parameters λ1. Then we can get the formula as

follow:

0

2

sin)(

)(

1

1

1

2

1

D

vfv

v

g

v

x

v

t

h

g

c

v

x

v

t

v

L

(3)

According to the algorithms of compound

function, and meet the conditions:

1

2

1

g

v

g

c

v

dt

dx

, we can convert formula

3 into ordinary differential equation with unknown

parameters v and h by selecting two value of λ1. The

formula is as follow:

0

2

sin

11

D

vfv

v

dt

dh

dt

dv

(4)

In the above formula,

c

g

1

, that is, λ1 are two

different real number, and

cv

dt

dx

.

By respectively taking the two values of λ1 into

formula 4, we can get equivalent two ordinary

differential equations. Using C+ and C- respectively

express characteristic line of two directions, the

equations are as follows:

Along C+:

cv

dt

dx

gD

vcfv

v

dt

dv

g

c

dt

dh

0

2

sin

(5)

Along C-:

cv

dt

dx

gD

vcfv

v

dt

dv

g

c

dt

dh

0

2

sin

(6)

In view of C+ characteristic line, we can get the

following formula by adopting the finite difference

form.

0

2

sin

111

11

iii

ipiipi

vv

gD

xf

tv

vv

g

c

hh

(7)

In view of C- characteristic line, we can get the

following formula by adopting the finite difference

form.

0

2

sin

111

11

iii

ipiipi

vv

gD

xf

tv

vv

g

c

hh

(8)

NumericalAnalysisonWaterHammerCharacteristicsofRocketPropellantFillingPipeline

339

The following are the steps that using the

characteristic line to solve the water hammer

problems. The first step: the partial differential

equation that can’t directly to solve should be

changed into a specific form of ordinary differential

equation, namely characteristic line equation. The

second step: carrying through integral calculus for

the ordinary differential equations, getting the

approximate algebraic integral formula, namely

finite difference equation. The third step: according

to the finite difference equation and bound condition

equation of piping system to calculate.

3.3 Establish Calculation Model

The mathematical model of the rocket propellant

filling system is established by the Flowmaste

software, taking the influence of the equipments into

account. The equipments include storehouse

horizontal tank, pump, flowmeter, pipeline, valve,

regulating valve, filter, etc. The equipment

parameters use the data in the actual product manuals.

The physical parameter of fluid N

2

O

4

at the

temperature of 20℃ is: viscosity μ=0.4189×10

-3

Pa·s,

ρ=1.446g/cm

3

, saturation pressure Ps=0.096MPa.

The calculation formula of water hammer wave

velocity is (Xu, 2012):

DEK

K

c

1

. In

the formula, K is the fluid bulk modulus, ρ is the

fluid density, E is the piping materials elastic

modulus, D is the pipe diameter,

is the pipe wall

thickness.

According to the calculation formula of water

hammer wave velocity, the water hammer wave

velocity of oxidant pipeline in the propellant filling

system can be get through calculation, c=850m/s. In

the calculation model, we set pipeline that length

longer than 40m as elastic pipeline, the rest as rigid

pipeline.

On the basis of water hammer wave velocity and

elastic pipeline length, in order to make the time step

to meet the transient stability conditions which is

cx

t

1

, we set the time step of transient

calculation Δt=0.00125s.

4 EXPERIMENTAL RESULT

ANALYSIS

For further analyzing the generating mechanism of

water hammer effect in the filling system and the

pressure change law when water hammer occurs

influenced by the filling control process, and

researching the scheme that can reduce the water

hammer effect in the filling system, the simulation

calculation and real experiment are carried through.

The simulation calculation is carried through

according to the method of mathematics model

mentioned in the above section. The real test scheme

is designed for the real experiment, the state and

parameter is set according to the real filling. We

adopt the pressure acquisition system to capture

water hammer phenomena in the filling system, and

record pressure change law when water hammer

occurs in real time. The position of pressure gauge P1

is shown in Fig.1.

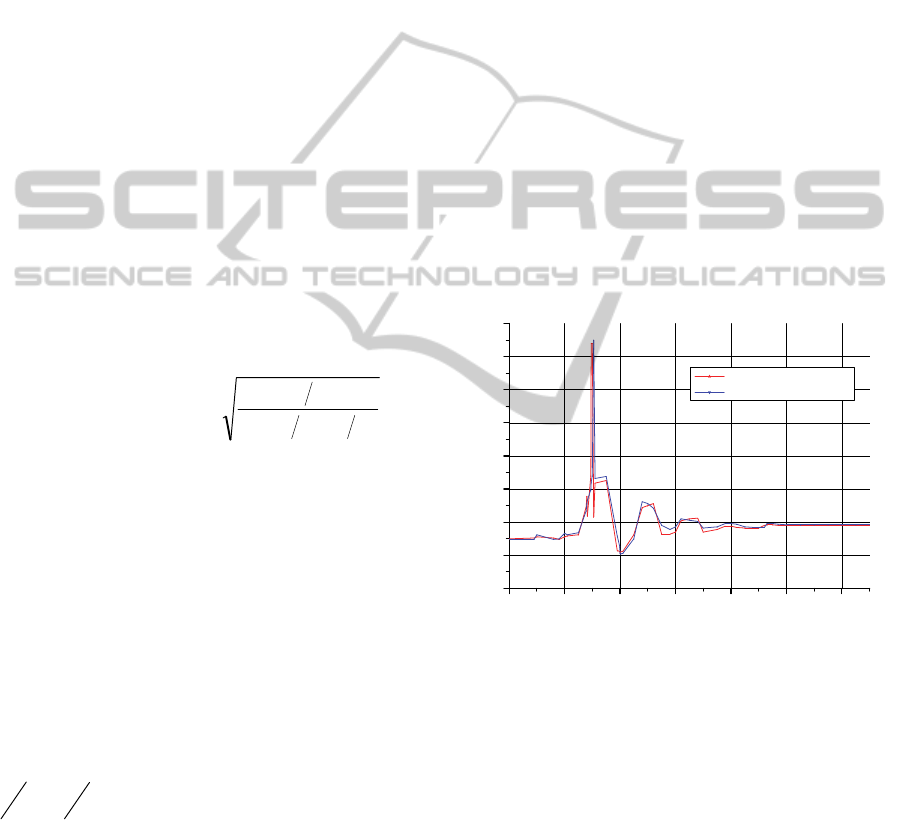

Experiment 1: According to the existing filling

process, when state transition started, the program in

the filling process is: open up 125# valve, delay of 1

second, at the same time close 124# and 134# valve,

the pump speed is 50Hz, the opening of electric

control valve DT4 is 30%. The simulation calculation

results and the real experimental results are shown in

Fig.2.

024681012

-0.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

Pressure (MPa)

Time (s)

real experiment

simulation calculation

Figure 2: Pressure change law when water hammer occurs

in the existing process.

Fig.2 shows the pressure change law when water

hammer occurs in the existing process. The abscissa

expresses the test time, the ordinate expresses the

pressure. The read curve expresses the real

experimental data of pressure, and the blue curve

expresses the simulation calculation data of pressure.

As is shown in the Fig, the pressure is 0.5MPa before

water hammer occurs. When water hammer occurs,

the pressure increases rapidly and the water hammer

peak pressure can achieve 3.25MPa. The pipeline

internal pressure has changed dramatically when

water hammer occurs, and the biggest gap can be up

to 13.5 times.

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

340

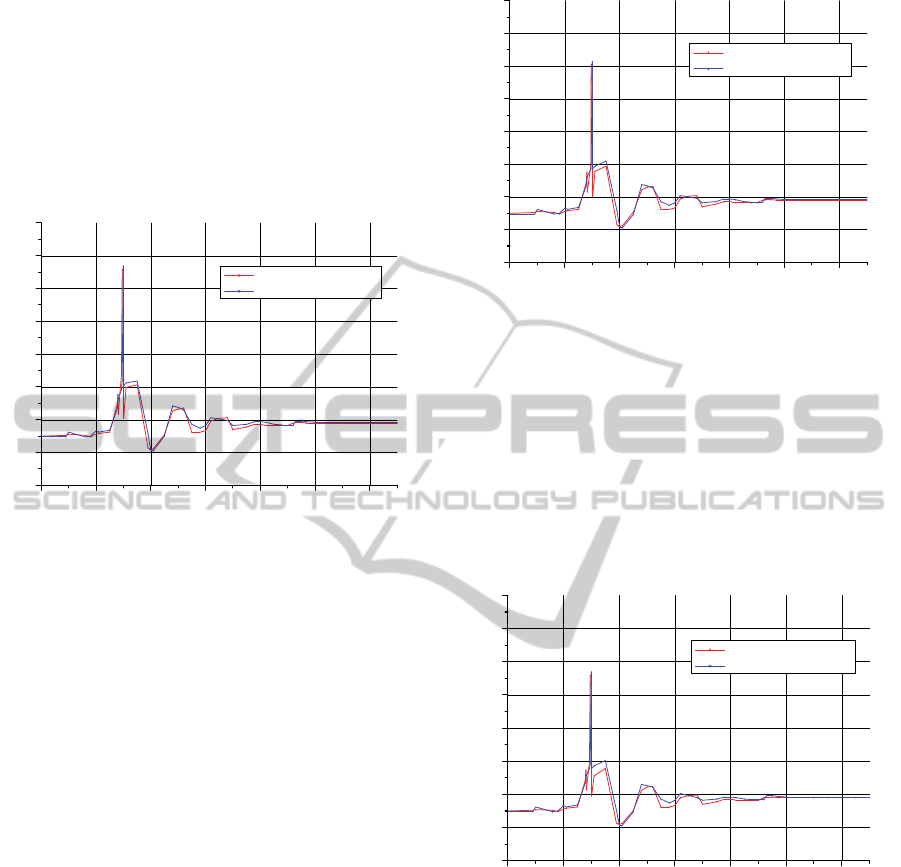

Experiment 2: On the basis of the existing filling

process, we change the closed sequential of the

related valve when water hammer occurs. When state

transition started, the existing program in the filling

process is: at the same time close 124# and 134#

valve. The changed program is: close 124# valve,

delay of 1 second, then close 134# valve. The

simulation calculation results and the real

experimental results are shown in Fig.3.

024681012

-0.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

real experiment

simulation calculation

Pressure (MPa)

Time (s)

Figure 3: Pressure change law when water hammer occurs

after changing the sequential.

The pressure change law when water hammer occurs

after changing the closed sequential of the related

valve is shown in Fig.3. In the Fig, the abscissa

expresses the test time, the ordinate expresses the

pressure. From contrasting Fig.2 and Fig.3, we can

know that it can effectively reduce the water hammer

effect of the filling pipeline by changing the closed

sequential of the related valve. The water hammer

peak pressure reduces from 3.25MPa to 2.85MPa,

and it is reduced by 12.3% compared with the data in

experiment 1.

Experiment 3: On the basis of the existing filling

process and experiment 2, we change the speed of the

filling pump when water hammer occurs. When state

transition started, the existing pump frequency is

50Hz. The changed pump frequency is 40Hz. The

simulation calculation results and the real

experimental results are shown in Fig.4.

Fig.4 shows the pressure change law when water

hammer occurs after changing the pump speed. As is

shown in the Fig, the abscissa expresses the test time,

the ordinate expresses the pressure. From contrasting

Fig.3 and Fig.4, we can know that it can effectively

reduce the water hammer effect of the filling pipeline

by changing the speed of the filling pump. The water

hammer peak pressure reduces from 2.85MPa to

2.57MPa, and it is reduced by 9.8% compared with

the data in experiment 2.

024681012

-0.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

real experiment

simulation calculation

Pressure (MPa)

Time (s)

Figure 4: Pressure change law when water hammer occurs

after changing the pump speed.

Experiment 4: On the basis of experiment 2 and

experiment 3, we change the opening of the electric

control valve DT4 when water hammer occurs. When

state transition started, the existing opening of the

electric control valve is 30%. The changed opening

of the electric control valve is 60%. The simulation

calculation results and the real experimental results

are shown in Fig.5.

024681012

-0.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

real experiment

simulation calculation

Pressure (MPa)

Time (s)

Figure 5: Pressure change law when water hammer occurs

after changing the opening of electric control valve.

The pressure change law when water hammer occurs

after changing the opening of electric control valve

is shown in Fig.5. In the Fig, the abscissa expresses

the test time, the ordinate expresses the pressure.

From contrasting Fig.4 and Fig.5, we can know that it

can effectively reduce the water hammer effect of the

filling pipeline by changing the opening of electric

control valve. The water hammer peak pressure

reduces from 2.57MPa to 2.35MPa, and it is reduced

by 8.6% compared with the data in experiment 3.

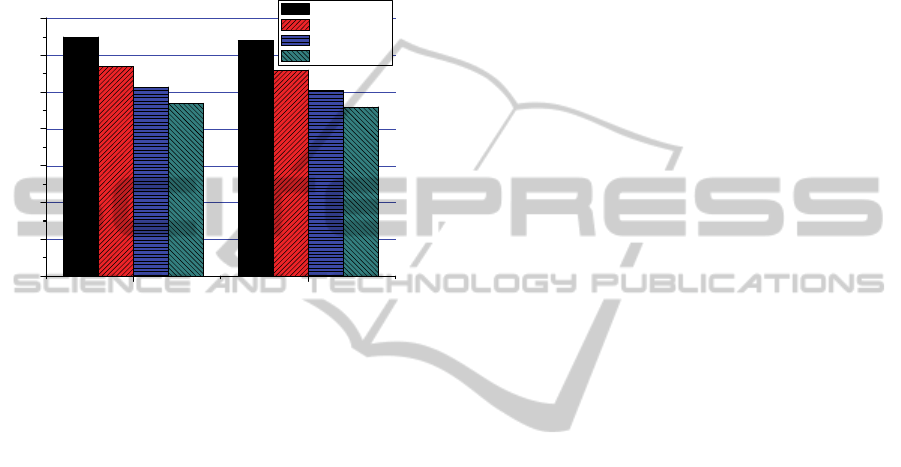

Fig.6 shows the comparison of water hammer

NumericalAnalysisonWaterHammerCharacteristicsofRocketPropellantFillingPipeline

341

peak pressure under different experimental

conditions. As is shown in the Fig, the water hammer

peak pressure in experiment 1 is the highest, and it

reduces in experiment 2, 3 and 4 in turn, the water

hammer peak pressure in experiment 4 is the lowest.

There is no significant different between the

simulation calculation data and real experimental

data under different experiment. The data

consistency is good.

12

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

Real Experiment

Pressure (MPa)

Simulation Calculation

Experiment 1

Experiment 2

Experiment 3

Experiment 4

Figure 6: Comparison of water hammer peak pressure

under different experimental conditions.

As is shown in Fig.6, contrasting experiment 2 and

experiment 1, the water hammer peak pressure

reduces from 3.25MPa to 2.85Mpa, and it is reduced

by 12.3% compared with the data in experiment 1.

Contrasting experiment 3 and experiment 1, the water

hammer peak pressure reduces from 3.25MPa to

2.57Mpa, and it is reduced by 20.9% compared with

the data in experiment 1. Contrasting experiment 4

and experiment 1, the water hammer peak pressure

reduces from 3.25MPa to 2.35Mpa, and it is reduced

by 27.7% compared with the data in experiment 1.

From the experimental results we can know that it

can effectively reduce the water hammer effect of

the filling pipeline by adopting the schemes

proposed in this paper.

Through data analysis for the simulation

calculation data and real experimental data, it

provides theoretical basis and data support for

reducing water hammer effect of the filling system

and optimizing filling process.

5 CONCLUSIONS

The rocket filling system is an important part of the

spaceflight launch site, the filling pipeline is one of

the key components in the filling system. Accurately

grasp it’s work state in the rocket propellant filling

process is very important for the filling accuracy and

the security and reliability of the system.

This paper analyzes the water hammer effect of

the rocket propellant filling pipeline during the

filling process of the spaceflight launch site, and

studies the influence of filling process on water

hammer. It researches the pressure change law of

filling pipeline when water hammer occurs. In order

to reduce the water hammer effect of the filling

pipeline, improved scheme in the aspects of filling

control process is put forward as follows: change the

closed sequential of the related valve, reduce the

speed of the filling pump, and augment the opening

of the electric control valve. Meanwhile, simulation

calculation and real experiment are carried through

in allusion to the proposed scheme, and carries

through data analysis for the simulation and

experimental results. The experimental results show

that the proposed scheme can effectively reduce the

water hammer effect of the pipeline during the filling

process, reduce the error of filling quantity caused by

water hammer, improve the rocket propellant filling

accuracy and enhance the security and reliability of

the system.

The water hammer effect of the rocket propellant

filling pipeline during the filling process is analyzed

in this paper only in the aspects of filling control

process. In order to further eliminate the water

hammer effect, the research direction in the future is

to improve process design for the filling system.

REFERENCES

Xiang Youhuan, Shi Jinfeng, Li Liqun. Accuracy Analysis

on Measuring Model of Rocket Propellant Filling

Based on Weight Measurement[C]. 2014 IEEE

International Conference on Signal Processing

Communications and Computing (ICSPCC 2014).

August 5-8,2014:760-765.

Yang Zhi-qiang, Zhang Hong-jian, Huang Yong-mei.

Research on data value simulation of fluid field

characteristic of vortex flowmeter [J]. Process

Automation Instrumentation. 2004, 25(5):10-13.

Yan Zheng, Peng Xiao-hui, Cheng Yu-qiang, Wu Jian-jun.

Research of water hammer and its suppression

methods for spacecraft propulsion system. Journal of

Aerospace Power. Sep.2012, Vol.27 No.9:2028-2034.

Lin Jingsong, Wang Pingyang, Gao hong. Numerical

Simulation of Water Hammer in Shutting Liquid

Rocket Engine [J]. Aerospace Shanghai. No.3

2008:53-57.

Nie Wansheng, Dai Haide, Xia Peng. Transient

Characteristics during shutdown operation of liquid

feed line for attitude control propulsion system [J].

SIMULTECH2015-5thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

342

Journal of Propulsion Technology. 2003, 24(1):6-8.

Liu Zhaozhi, Ding Pengfei, Tian Qingya. Numerical

Analysis on Water-hammer of Liquid Hydrogen

Loading System [J]. Missiles and Space Vehicles. No.4

2010, Sum No.408:10-12.

Lin Jing-song. Numerical Simulation of Water Hammer in

Shutting Liquid Rocket Engine [D]. Shanghai Jiaotong

University. 2007.

Liu Deyou, Suo Lisheng. Rigid Model of Transient

Analysis for Multiple-characteristic Long Pipeline

with Trapped Air Mass [J]. Journal of Hydrodynamics.

Ser. A, Vol.20, No.1 Jan, 2005:44-49.

Wu yuebin, Gao Jinliang. An Approach to Performance

Assessment for Water Distribution Systems.

Conference on Water Resouces Planning and

Management, Roanoke, VA, 2002.

Xu Feng, Liu Ying-yuan, Chen Hai-feng. Numerical

simulation analysis of water-hammer pressure of

rocket engine. Journal of Rocket Propulsion.

Feb.2012, Vol.38, No.1:72-75.

NumericalAnalysisonWaterHammerCharacteristicsofRocketPropellantFillingPipeline

343